A high-definition printing machine for small-capacity injection ampoules in pharmaceutical factories

A technology for ampoules and printing machines, which is applied to printing machines, rotary printing machines, printing, etc. It can solve the problems of inability to adjust between lines, half-cut characters, and easy distortion of printed characters, so as to achieve fast and convenient exchange of fonts and production High efficiency and uniform ink application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

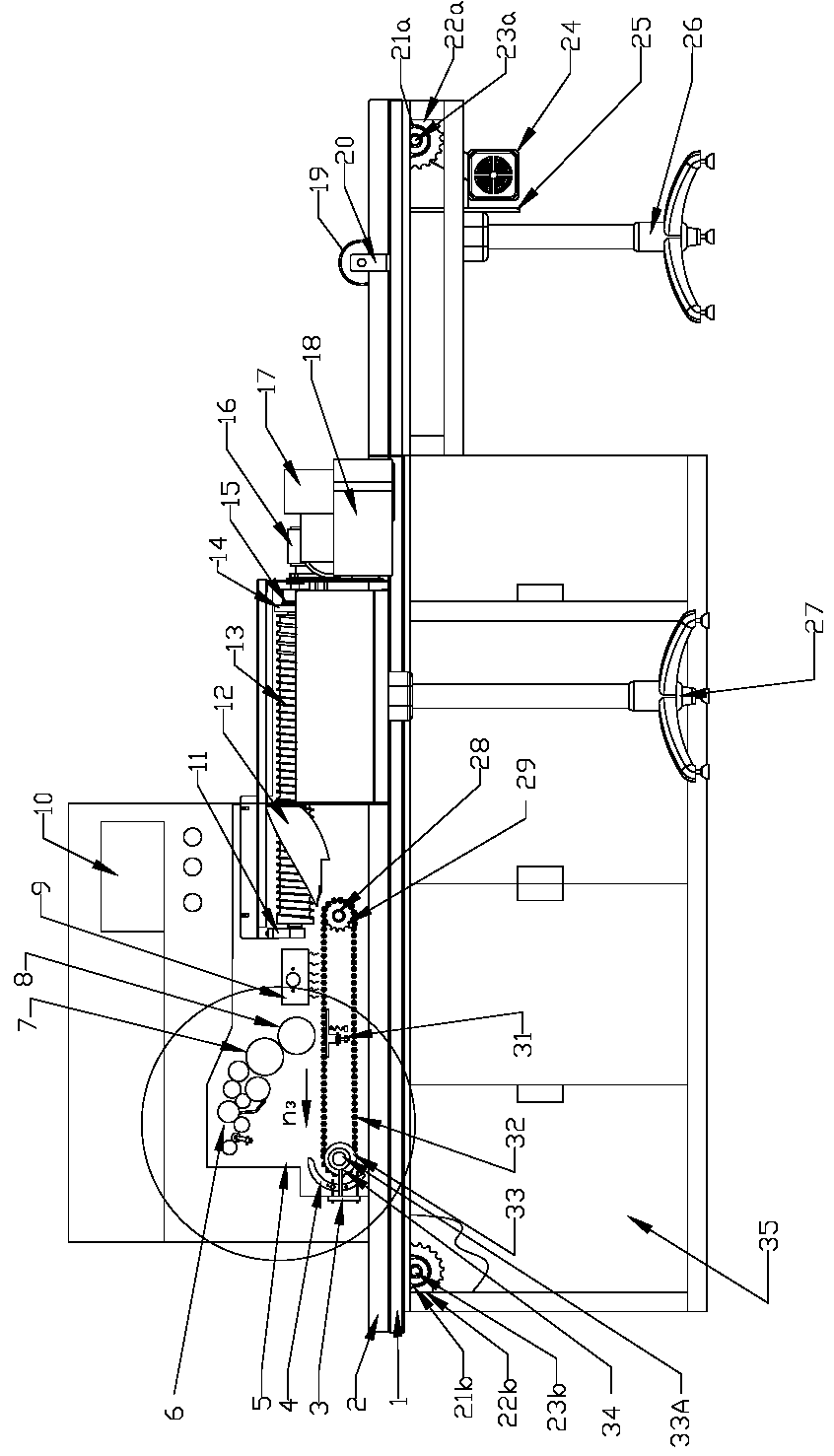

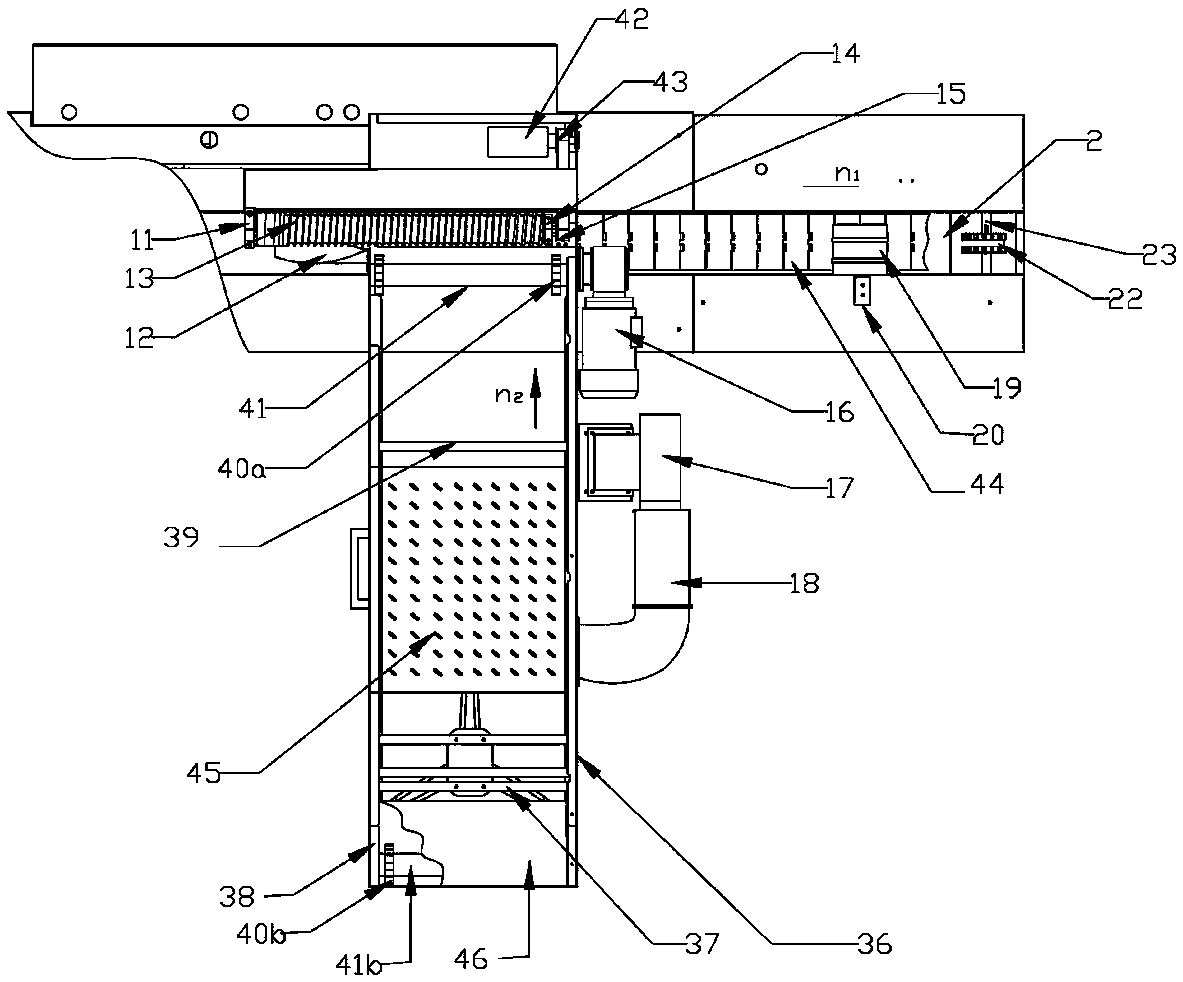

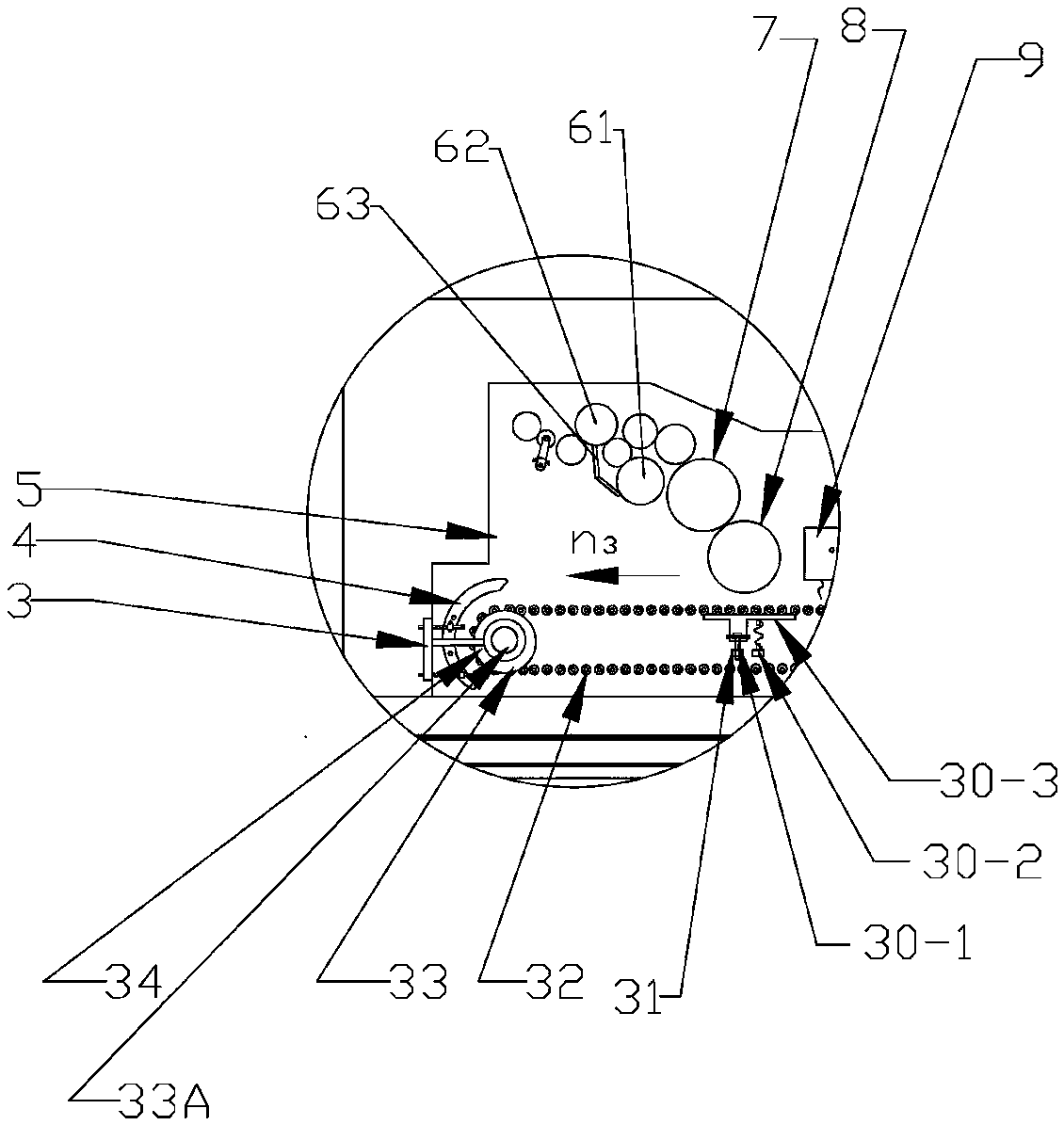

[0026] Such as Figure 1-8 As shown, a high-definition printing machine for small-capacity injection ampoule bottles in a pharmaceutical factory includes a frame, an ampoule bottle printing device arranged on the frame, a flat feeding device for ampoule bottles, and a box holder conveying device.

[0027] The ampoule bottle printing device includes a printer wallboard 5, a glass ink transmission mechanism 6, a plate roller 7, a blanket roller 8, a dryer 9, a printer chain drive shaft 23, a printer chain drive wheel 22, and an anti-broken bottle device Setting, bracket picking arm 31, printing machine chain 32, printing machine chain driven wheel 33, fastening sleeve 34, support 3, crescent-shaped guide plate 4. There are two printer wallboards 5, and they are vertically parallel to each other and fixedly installed on the frame 2 upper ends, which are the carriers supported by the above-mentioned parts. The glass ink transfer mechanism 6 is arranged on the upper side between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com