Hairbrush and manufacturing process thereof

A brush and the technology of its production method, applied in the direction of nib, printing, writing utensils, etc., can solve the problems of hand feeling inferior to animal hair, poor elasticity of nylon hair, poor water retention rate, etc., and achieve good market prospects, strong ink storage capacity, and comfortable writing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

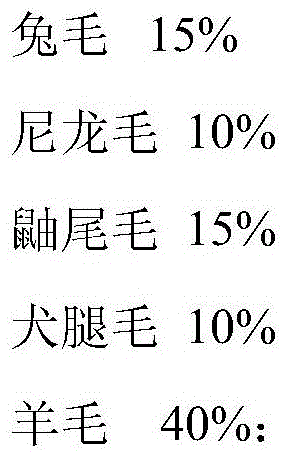

[0031] A kind of writing brush, the pen core of described writing brush nib is made up of the raw material of following percentage by weight:

[0032] Refill:

[0033]

[0034]

[0035] The outer side of the nib is made of goat hair, with a thickness of 1mm on one side;

[0036] The preparation method of described nylon wool is:

[0037] (1) Preparation of modified nylon 6 silk: 683 parts of nylon, 2.6 parts of tourmaline powder, 1 part of sericite powder, 0.5 part of talc powder, 0.8 part of nano-montmorillonite powder, 0.5 part of magnesium oxide, and 0.3 part of chitosan (the molecular weight of described chitosan is 2500-3200); Add in the high-speed mixer, obtain the modified nylon 6 mixture after high-speed dispersion: the mixture melt processing becomes the modified nylon 6 filament that diameter D is 0.10mm;

[0038] The particle size of the tourmaline powder is 8nm; the particle size of the sericite powder is 10nm, the particle size of the talc powder is 18nm, ...

Embodiment 2

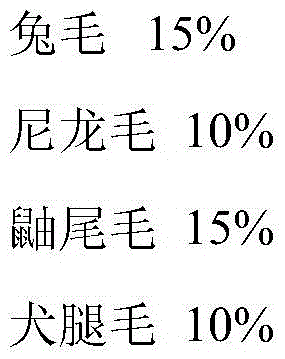

[0049] A kind of writing brush, the pen core of described writing brush nib is made up of the raw material of following percentage by weight:

[0050] Refill:

[0051]

[0052] The outside of the nib is covered with goat hair, with a thickness of 1-1.2mm on one side;

[0053] The preparation method of described nylon wool is:

[0054] (1) Preparation of modified nylon 6 silk: 685 parts of nylon, 2.8 parts of tourmaline powder, 1 part of sericite powder, 0.5 part of talcum powder, 0.8 part of nano-montmorillonite powder, 0.5 part of magnesium oxide, and 0.3 part of chitosan (the molecular weight of described chitosan is 2500-3200) adds in the high-speed mixer, obtains the modified nylon 6 mixture after high-speed dispersion: the mixture melt processing becomes the modified nylon 6 filament that diameter D is 0.10mm;

[0055] (2) Preparation of nylon wool by swelling and abrasion method: the modified nylon 6 wire with a diameter D of 0.10 mm is cut into a length of 65 mm, w...

Embodiment 3

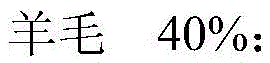

[0066] A kind of writing brush, the pen core of described writing brush nib is made up of the raw material of following percentage by weight:

[0067] Refill:

[0068]

[0069] The outside of the nib is covered with goat hair, with a thickness of 1-1.2mm on one side;

[0070] The preparation method of described nylon wool is:

[0071] (1) Preparation of modified nylon 6 silk: 683 parts of nylon, 2.5 parts of tourmaline powder, 1 part of sericite powder, 0.5 part of talc powder, 0.8 part of nano-montmorillonite powder, 0.5 part of magnesium oxide, and 0.3 part of chitosan (the molecular weight of described chitosan is 2500-3200) adds in the high-speed mixer, obtains the modified nylon 6 mixture after high-speed dispersion: the mixture melt processing becomes the modified nylon 6 filament that diameter D is 0.10mm;

[0072] The particle size of the tourmaline powder is 7nm; the particle size of the sericite powder is 13nm, the particle size of the talc powder is 21nm, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com