Ball point pen

A technology for ballpoint pens and ballpoint pen tips, applied to ballpoint pens, printing, writing utensils, etc., can solve the problems of pen tip shaking, reduce writing feeling, pen tip swing, etc., and achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

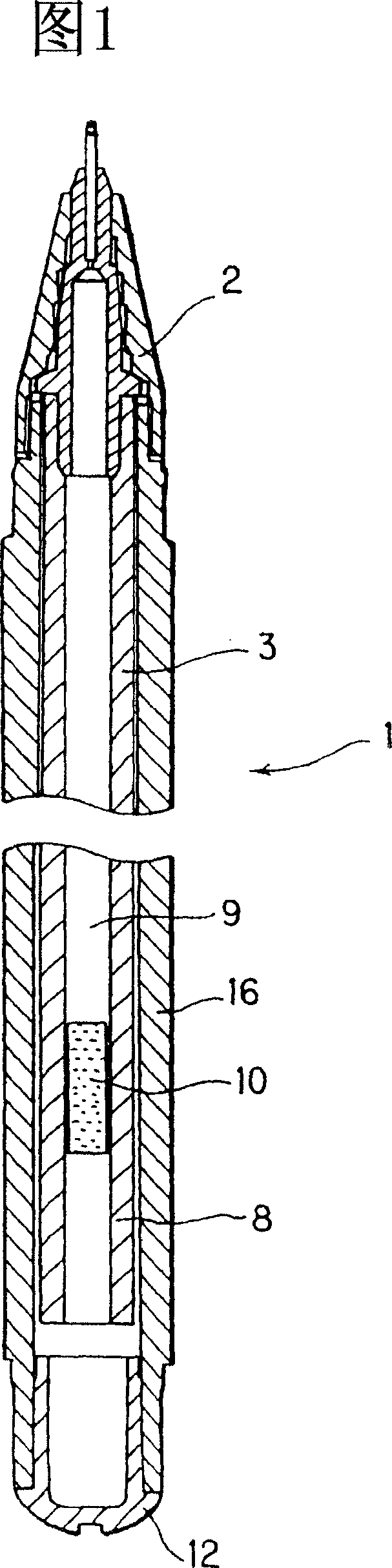

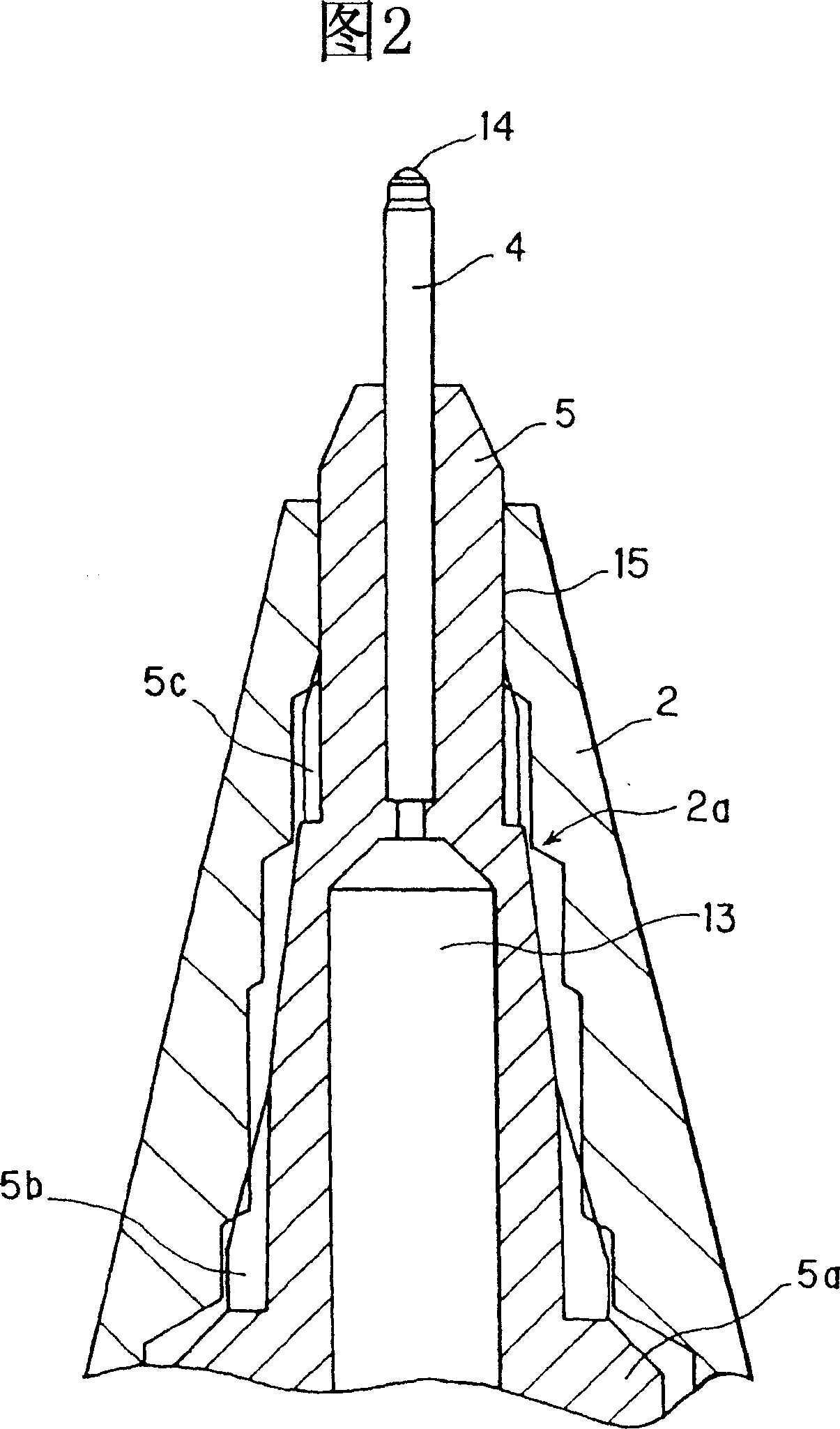

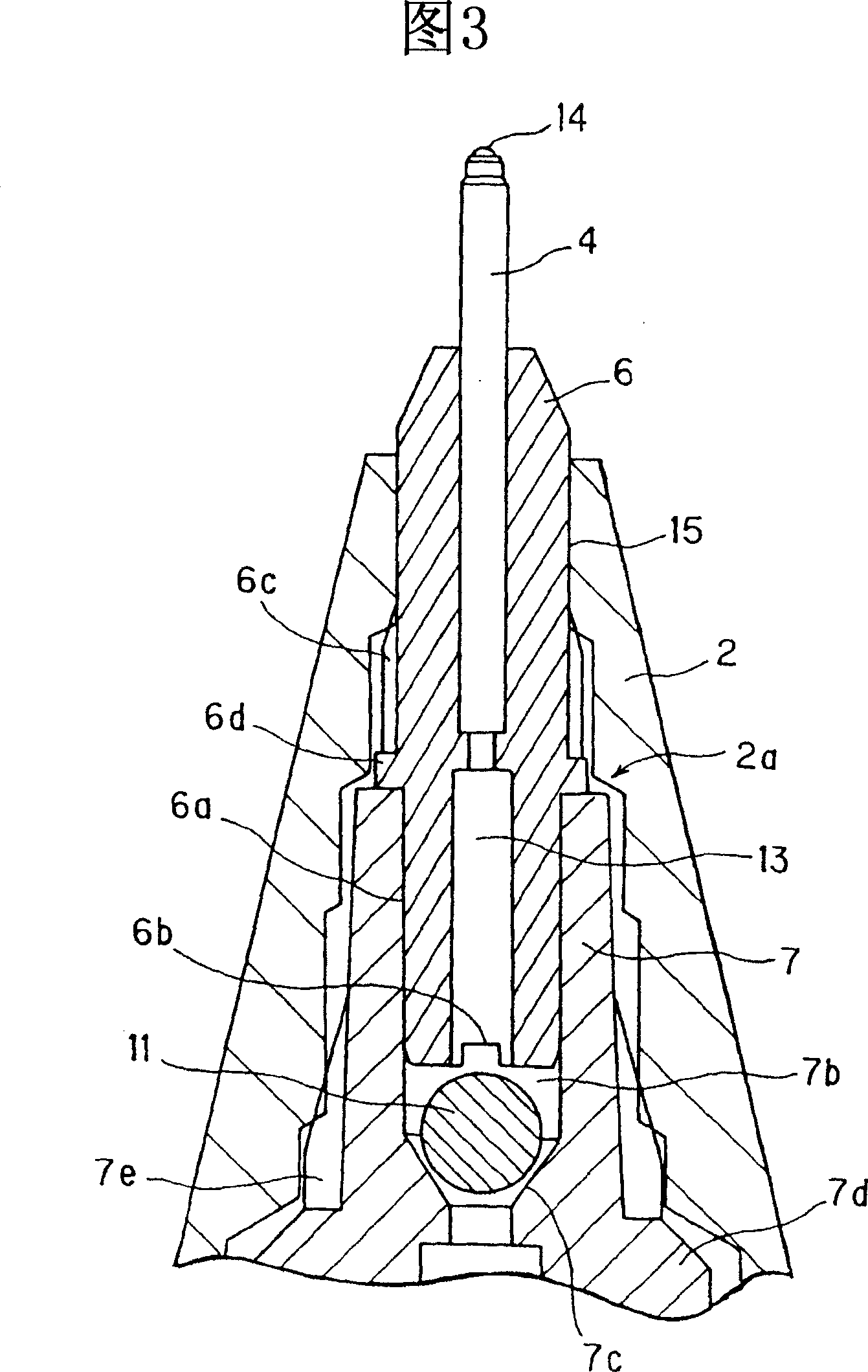

[0020] Embodiments of the invention are shown in FIGS. 1 , 2 , 3 and 4 .

[0021] With reference to Fig. 1 at first, ball-point pen of the present invention comprises the outer tube 16 that its front and rear end openings have rod-like cylindrical shape, the mouthpiece 2 that thread is assembled on the front end of outer tube 16 and the ball-point pen refill that is contained in outer tube 16 the inside 3. In this embodiment, the barrel shown at 1 consists of a mouthpiece 2 and an outer sleeve 16 . Here, the mouthpiece 2 does not have to be formed as a separate component, but can be formed integrally with the outer sleeve 16 .

[0022] The pen holder 1 has a ventilation hole or a ventilation slot, which is formed by drilling a ventilation hole through the pen holder 1 to the inside at a suitable position or by forming a groove at the threaded portion on which the mouthpiece 2 is fixed. . A ventilation hole communicating with the interior of the barrel may also be formed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com