Production process for peacock writing brush

A production process, peacock technology, applied in the field of peacock brush production technology, can solve the problems of complex production process, achieve the effect of good wrapping performance, reasonable proportion, and reduce damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

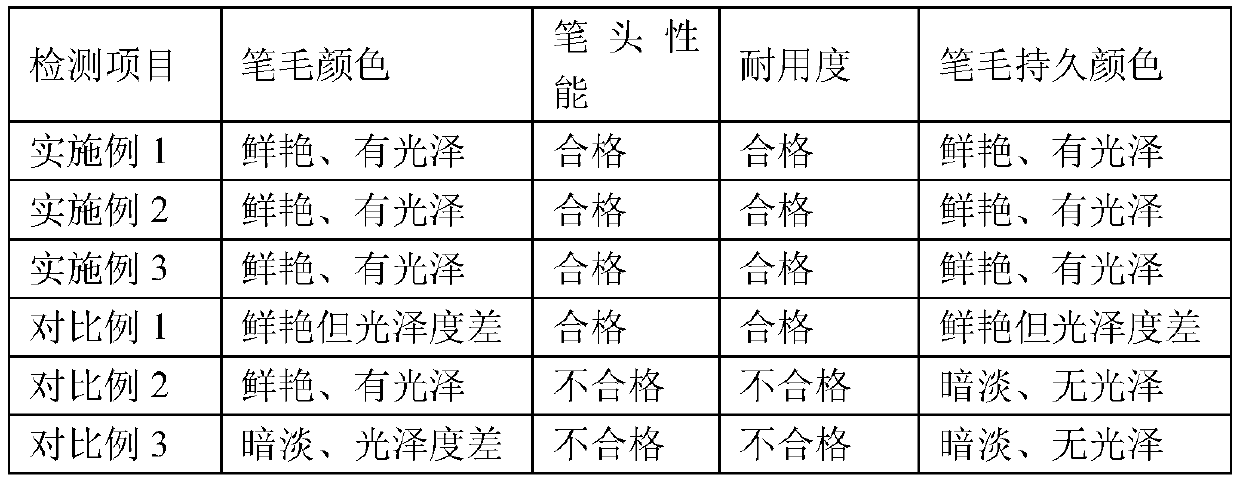

Examples

Embodiment 1

[0021] A kind of manufacture craft of peacock writing brush, comprises the following steps:

[0022] A material selection: select peacock hair with uniform thickness, wash and dry it and apply glycerin on its surface; the thickness of glycerin application should not be less than 1mm;

[0023] B pretreatment: after tidying up the peacock hair, spread plant ash on it, then spread waste newspaper on it, iron it back and forth with an electric iron at 75°C for 25 minutes, take it out after cooling; soak the taken out peacock hair in a special treatment solution for 12 hours hours, take it out, wash and dry it, and trim it to a suitable length;

[0024] C-made nib: The brush hair of the nib is composed of wool, nylon hair and peacock hair; the wool and nylon hair are mixed and placed on the inside of the nib, and the peacock hair is placed on the outside of the nib, tied into the nib, and the nib is shaped to achieve the shape , evenly arranged;

[0025] D installed nib: install ...

Embodiment 2

[0032] A kind of manufacture craft of peacock writing brush, comprises the following steps:

[0033] A material selection: select peacock hair with uniform thickness, wash and dry it and apply glycerin on its surface; the thickness of glycerin application should not be less than 1mm;

[0034] B pretreatment: after tidying up the peacock hair, spread plant ash on it, and then spread waste newspaper on it, iron it back and forth with an electric iron at 80°C for 20 minutes, wait for it to cool down and take it out; soak the taken out peacock hair in a special treatment solution for 16 hours hours, take it out, wash and dry it, and trim it to a suitable length;

[0035] C-made nib: The brush hair of the nib is composed of wool, nylon hair and peacock hair; the wool and nylon hair are mixed and placed on the inside of the nib, and the peacock hair is placed on the outside of the nib, tied into the nib, and the nib is shaped to achieve the shape , evenly arranged;

[0036] D inst...

Embodiment 3

[0043] A kind of manufacture craft of peacock writing brush, comprises the following steps:

[0044] A material selection: select peacock hair with uniform thickness, wash and dry it and apply glycerin on its surface; the thickness of glycerin application should not be less than 1mm;

[0045] B pretreatment: after tidying up the peacock hair, spread plant ash on it, and then spread waste newspaper on it, iron it back and forth with an electric iron at 60°C for 30 minutes, take it out after cooling; soak the taken out peacock hair in a special treatment solution for 13 hours hours, take it out, wash and dry it, and trim it to a suitable length;

[0046] C-made nib: The brush hair of the nib is composed of wool, nylon hair and peacock hair; the wool and nylon hair are mixed and placed on the inside of the nib, and the peacock hair is placed on the outside of the nib, tied into the nib, and the nib is shaped to achieve the shape , evenly arranged;

[0047] D installed nib: inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com