High-intensity inorganic-salt wine bucket and production method thereof

An inorganic salt, high-strength technology, applied in the field of wine barrels, can solve the problems of low strength of metal wine barrels, single color of wine barrels, and leakage of wine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The invention provides a method for preparing a high-strength inorganic salt wine barrel, the method comprising: mixing water, embryo raw materials, colorants, forming agents, clarifiers, alumina and bentonite to prepare a mixed material; Under the condition of stirring, the mixed material is heated to obtain a molten slurry; finally, the molten slurry is pressed into a model to make the high-strength inorganic salt wine barrel; in parts by weight, relative to 100 parts of raw materials for embryos , the consumption of described water is 60-80 parts, the consumption of pigment is 5-20 parts, the consumption of forming agent is 5-10 parts, the consumption of clarifying agent is 2-8 parts, the consumption of aluminum oxide is 2-10 parts parts, the consumption of bentonite is 5-15 parts.

[0010] In the above preparation method, the specific types of raw materials for embryos can be selected in a wide range, but considering the convenience of material extraction, preferabl...

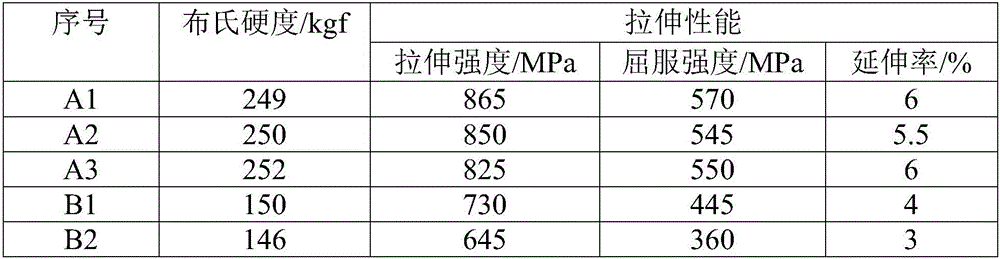

Embodiment 1

[0020] In parts by weight, 62 parts of water, 100 parts of feldspar powder, 7 parts of chrome yellow, 6 parts of silicon dioxide, 3 parts of antimony oxide, 3 parts of aluminum oxide and 7 parts of bentonite with a particle size of 64 μm were added to the reaction vessel at 350 rpm Stir and mix at a certain speed to obtain a mixed material. Then, under the above-mentioned stirring conditions, heat at 720° C. for 75 minutes to prepare a molten slurry. Finally, the magma is pressed into a mold to make the high-strength inorganic salt wine barrel A1.

Embodiment 2

[0022] In parts by weight, 76 parts of water, 100 parts of quartz powder, 18 parts of iron blue, 8 parts of boron oxide, 7 parts of sodium nitrate, 8 parts of aluminum oxide and 12 parts of bentonite with a particle size of 95 μm were added to the reaction vessel. Stir and mix at a rotating speed to obtain a mixed material. Then, under the above-mentioned stirring conditions, heat at 950° C. for 45 minutes to prepare a molten slurry. Finally, the molten slurry is pressed into a mold to make the high-strength inorganic salt wine barrel A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com