Capsicum frutescens pickled pepper quantitative bagging machine

A technology for quantifying millet peppers and peppers, which is applied in the directions of packaging, transportation and packaging, and types of packaging items, and can solve problems such as low production efficiency and affecting food hygiene and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

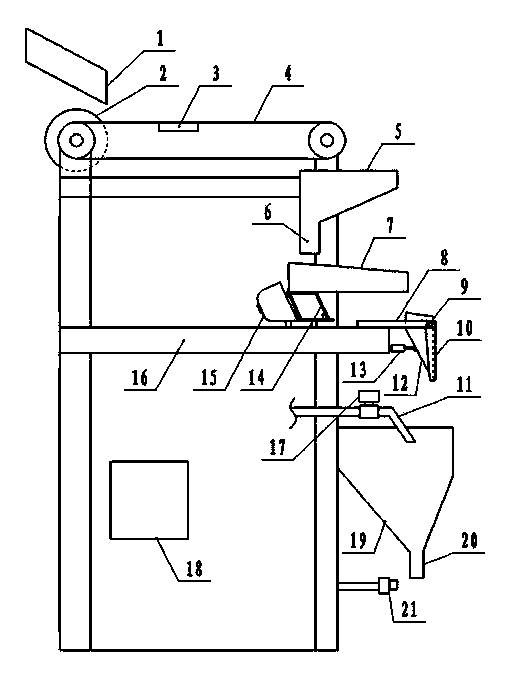

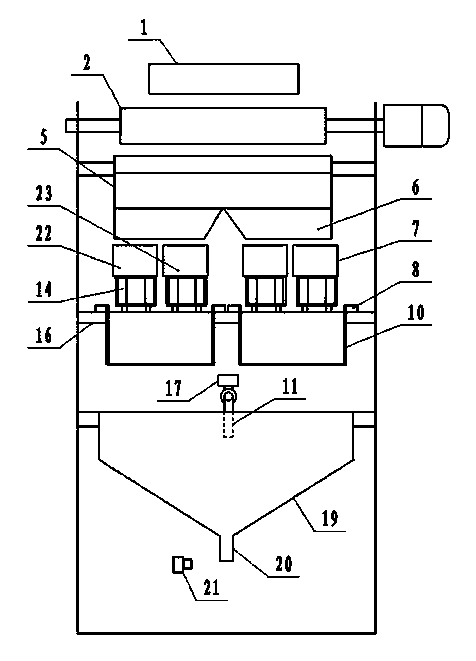

[0007] Example: such as figure 1 with figure 2 Shown, a kind of millet hot pepper quantitative bagging machine, the input port 1 of millet spicy raw material is installed on the top of this machine, and the speed-regulating conveyor belt 4 is installed below the input port 1, and a rotating roller of the speed-regulating conveyor belt 4 The upper part is connected with the speed regulating motor 2, a weight sensor 3 is installed under the belt of the speed regulating conveyor belt 4, and a distribution bin 5 is installed under the front end of the speed regulation conveyor belt 4, and the lower end of the distribution bin 5 has two discharge ports 6, Two vibrating conveying plates 7 are respectively installed below the two outlets 6, one of the two vibrating conveying plates 7 is the main conveying plate 22, the other is a fine-tuning conveying plate 23, and a vibrating frame 14 is installed at the bottom of the vibrating conveying plate , the vibrating frame 14 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com