Patents

Literature

36results about How to "Eliminates the hassle of manual cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

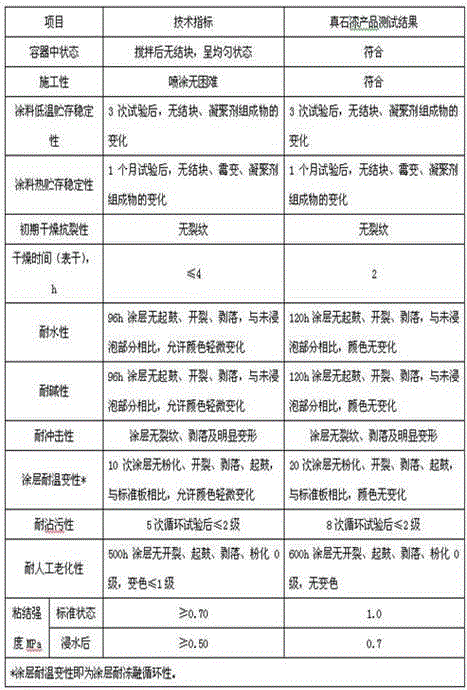

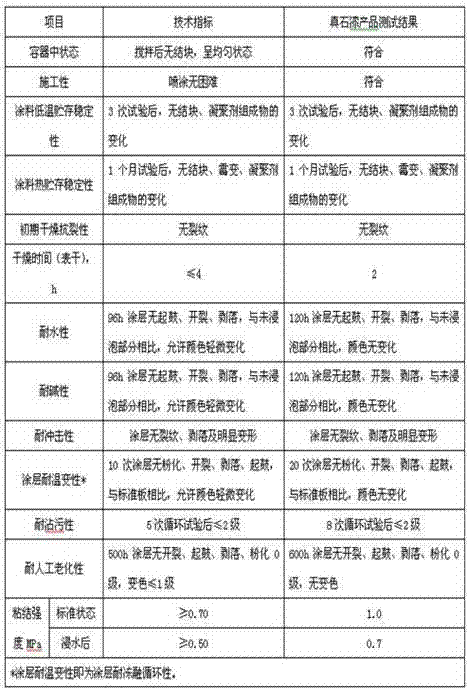

Real stone paint and preparation method thereof

The invention discloses a real stone paint and a preparation method thereof. The real stone paint is prepared from the following raw materials in parts by weight: 80.0-120.0 parts of water, 3.0-17.0 parts of ethylene glycol, 1.0-10.0 parts of a dispersant, 0.2-1.0 part of a wetting agent, 0.2-4.0 parts of cellulose, 0.2-4.0 parts of a PH modifier, 10.0-40.0 parts of silica sol, 30.0-50.0 parts of elastic emulsion, 20.0-90.0 parts of styrene-acrylic emulsion, 40.0-60.0 parts of 20-40mesh natural colored fine sand, 160.0-240.0 parts of 40-80mesh natural colored medium sand, 400.0-480.0 parts of 80-120mesh natural colored coarse sand, 50.0-70.0 parts of color sheets of the real stone paint, 1.0-10.0 parts of coalescing agent, 0.2-4.0 parts of defoamer and 0.2-4.0 parts of a corrosion remover. By adopting the preparation method of the real stone paint, the elastic emulsion and the styrene-acrylic emulsion are matched; the film has the hardness of a surface film and the advantage of interior flexibility of a coating, can resist external damage, can cope with flaws caused by similar wall cracking and substrate construction defects, and is especially applicable to an area with a large temperature difference between day and night.

Owner:西北永新涂料有限公司

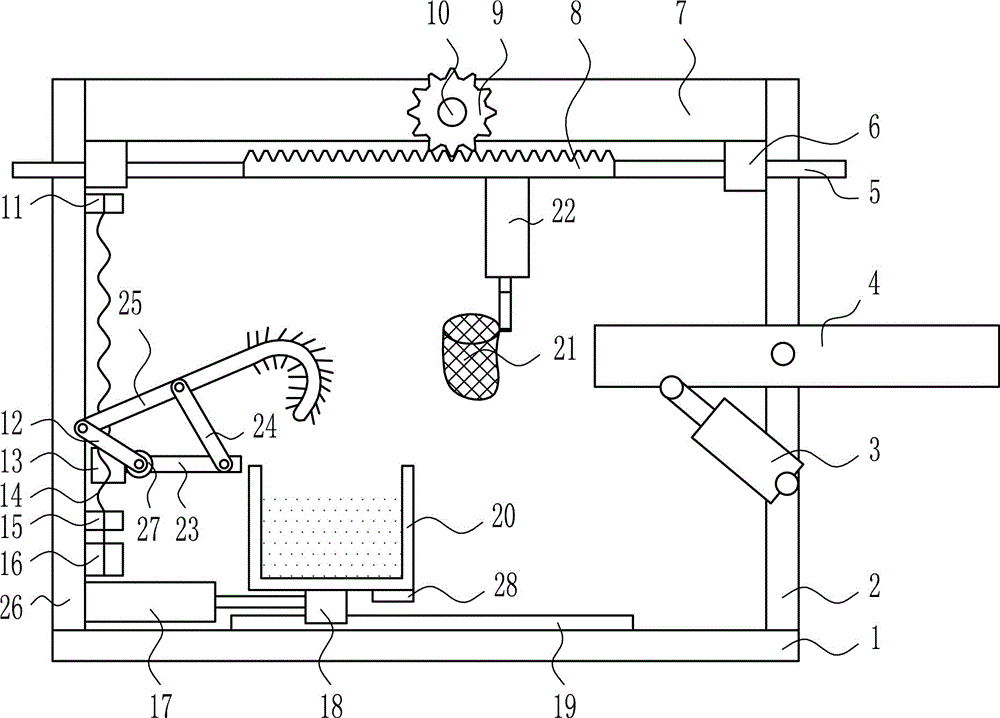

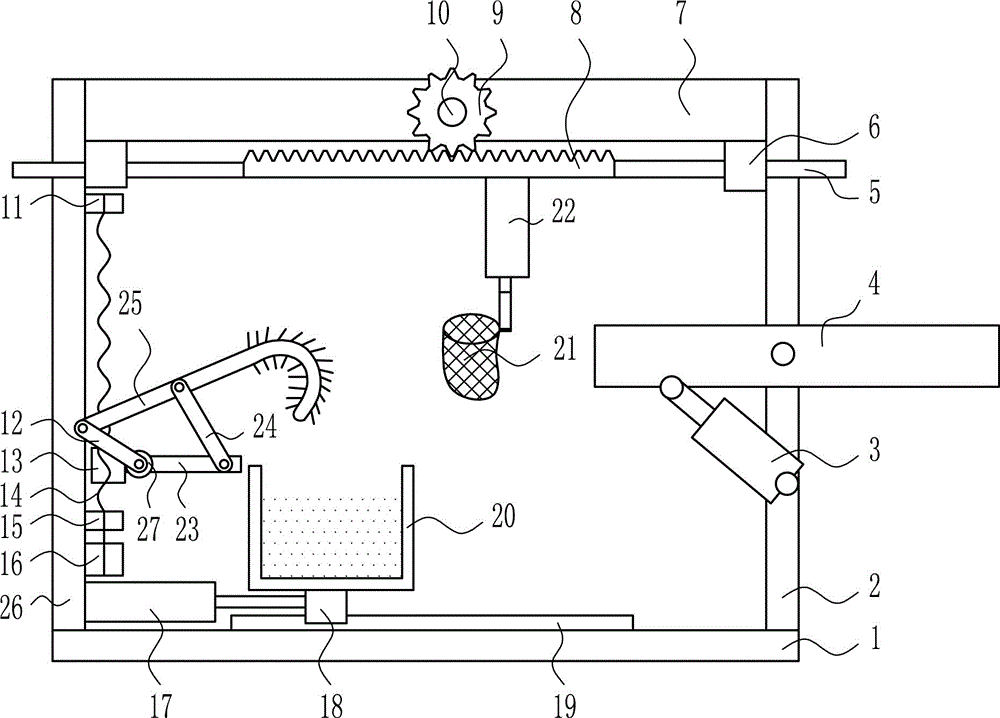

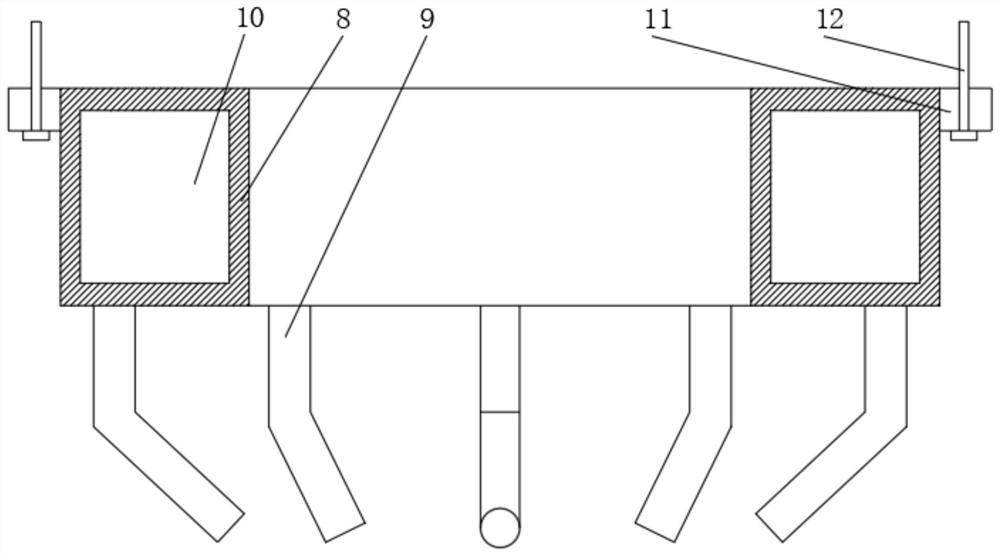

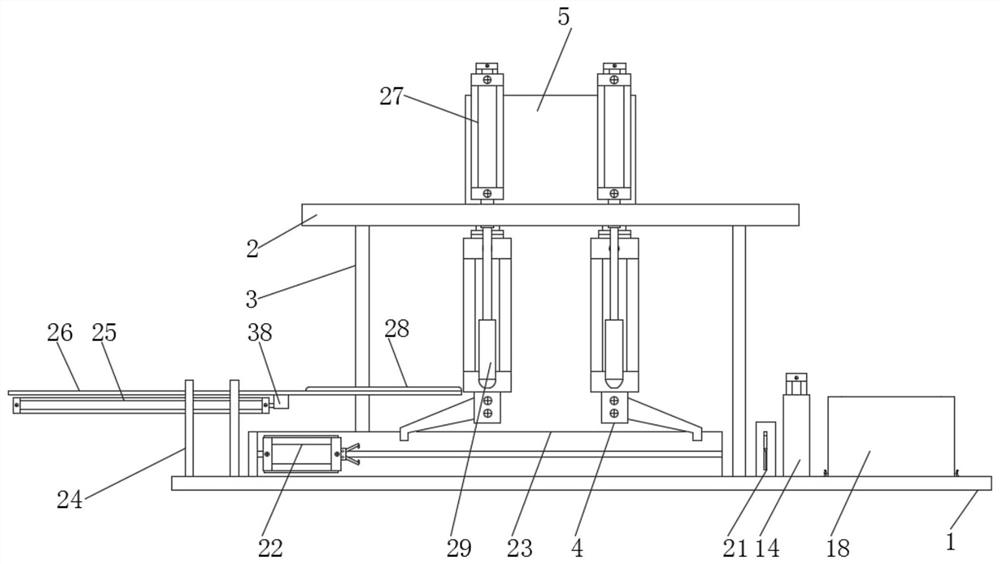

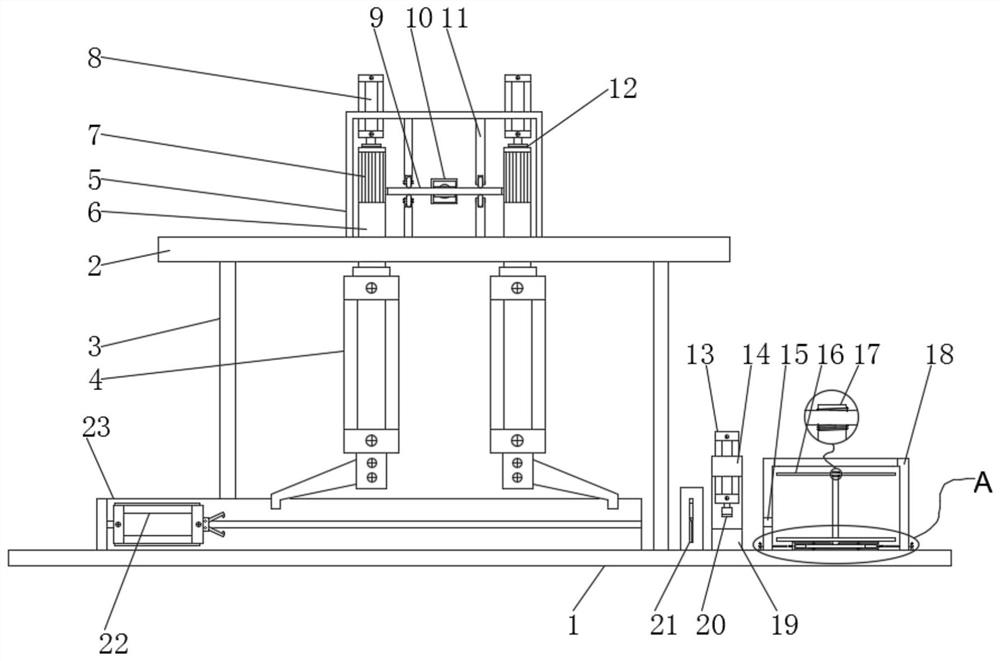

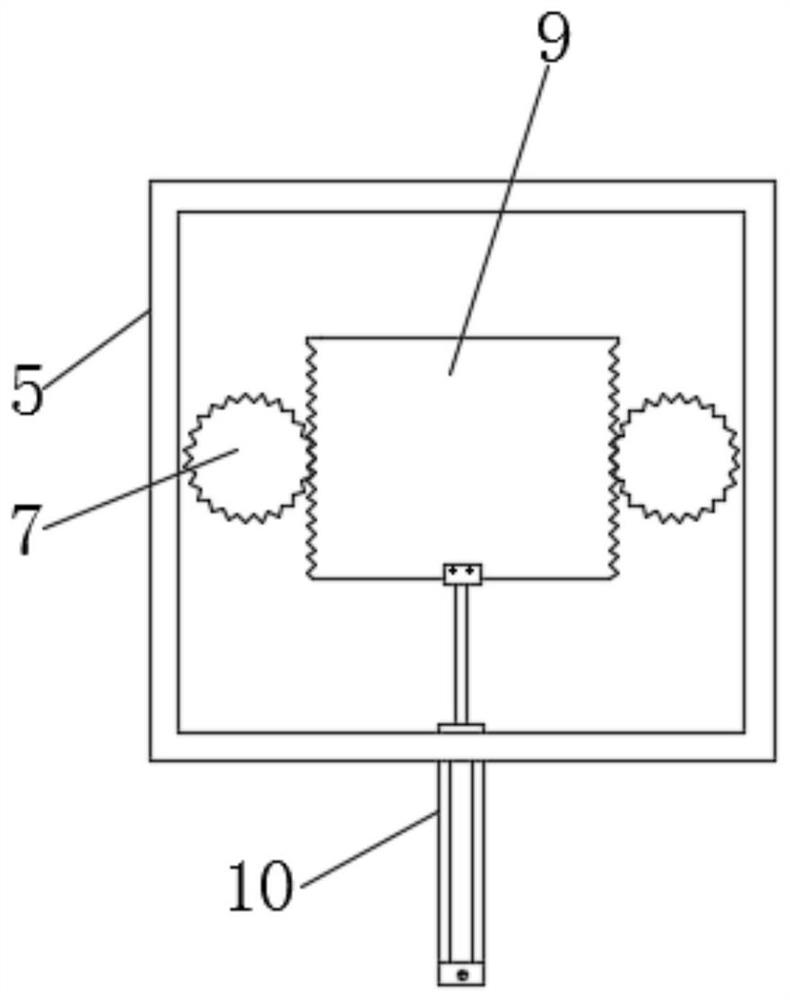

Basketball cleaning device for sports

InactiveCN106238354AImprove toughness and strengthNot easy to rustCleaning using toolsCleaning using liquidsEngineeringMaterial resources

The invention relates to a cleaning device, in particular to a basketball cleaning device for sports. The basketball cleaning device for sports saves time and labor, is high in cleaning efficiency and is complete in cleaning. The basketball cleaning device for sports comprises a bottom plate, a right bracket, a first electric pushing rod, a transport unit, a movable rod, a slide sleeve, a top plate, a rack, a gear, a first motor, an upper bearing base, a first connecting rod, a nut, a lead screw, a lower bearing base, a second motor, an air cylinder, a slide block, a slide rail, a cleaning frame, a catching net, a second electric pushing rod, a fixed plate, a second connecting rod, a cleaning brush, a transfer plate, a left bracket and a third motor. The basketball cleaning device for sports achieves the effects of saving time and force, being high in cleaning efficiency and complete in cleaning, avoids a lot of trouble in manual cleaning, and achieves the best cleaning effect with shortest time, so that manpower and material resources are saved.

Owner:叶明

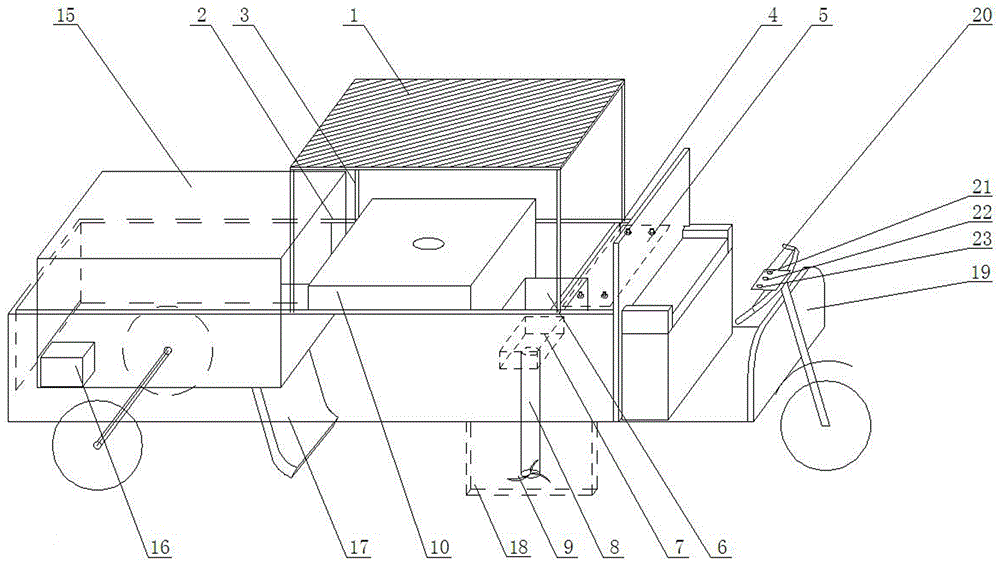

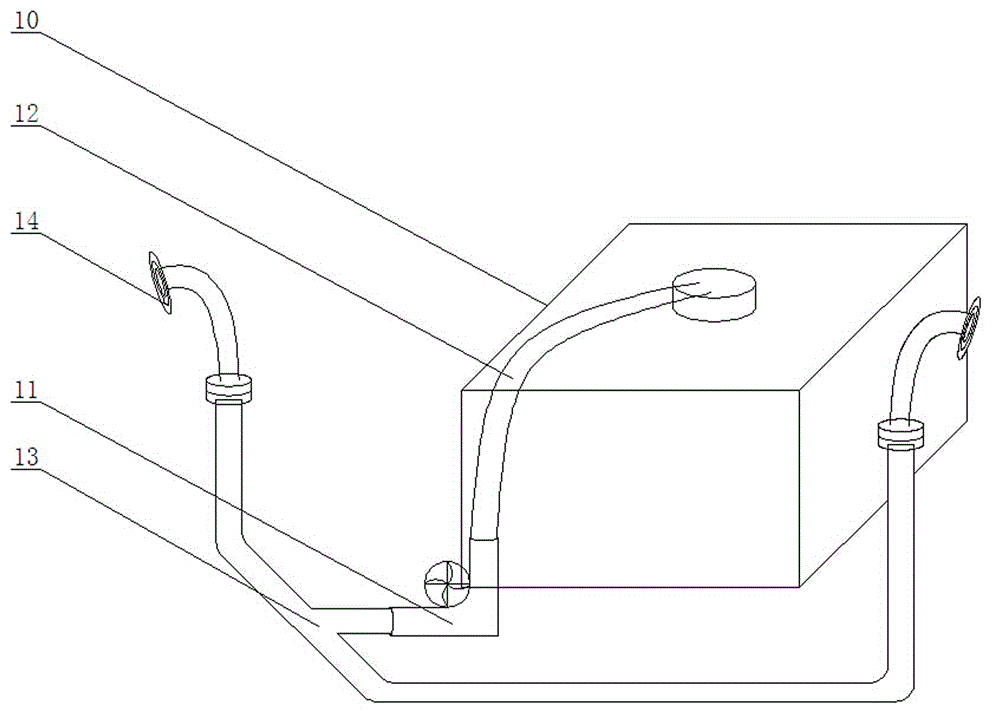

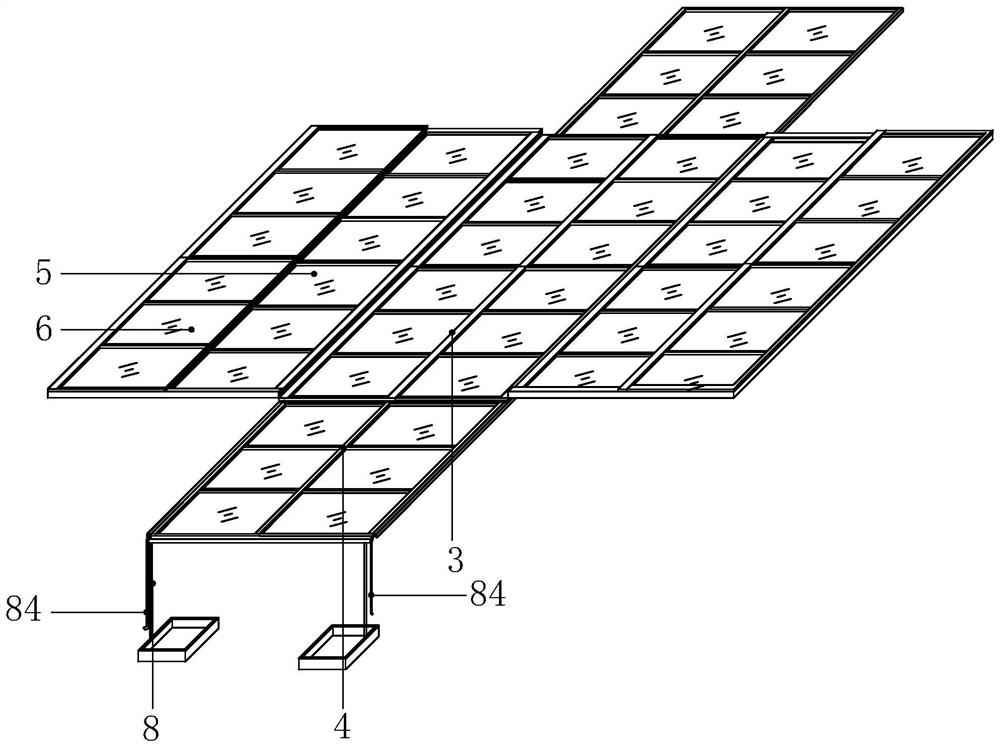

Solar watering and weeding multi-purpose vehicle

InactiveCN106304942AEffective Green WateringWon't hurtMowersWatering devicesGarden plantsEngineering

The invention discloses a solar watering and weeding multi-purpose vehicle which comprises a vehicle body, a solar panel, a storage battery, a water tank, a water pump, a rotating nozzle, a weeding chamber, an electromotor, a rotating shaft, a grass cutter, a grass sucking chamber and a grass sucking pump, wherein the solar panel is connected with the storage battery; the storage battery is positioned inside an isolation zone; the weeding chamber is arranged behind the isolation strip; the electromotor is arranged inside the weeding chamber; the electromotor is connected with the rotating shaft; the rotating shaft is connected with the grass cutter; the water tank is arranged behind the weeding chamber; one end of the water pump is connected with the water tank through a water tube; the other end of the water pump is connected with the nozzle; the grass sucking chamber is arranged behind the water tank; the grass sucking pump is arranged inside the grass sucking chamber; the grass sucking pump is connected with a grass sucking hole. By adopting the solar watering and weeding multi-purpose vehicle, green belts can be greened and watered effectively, plants are not damaged, and meanwhile the rotating nozzle can be rotated, so that gardening plants and the green belts can be watered in all directions, and the working efficiency is high; due to arrangement of the grass cutter, lawns can be cleaned and tidied in time, and meanwhile the cut grass can be collected into the grass sucking chamber through the grass sucking pump, so that the trouble that grass needs to be manually cleaned after being cut is avoided, and the solar watering and weeding multi-purpose vehicle is energy-saving and environmental-friendly, simple to operate and applicable to gardening operators.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

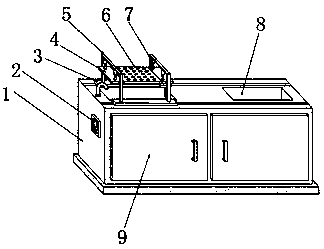

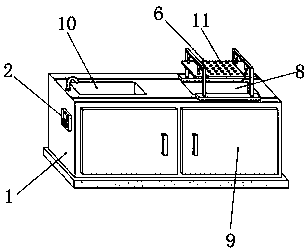

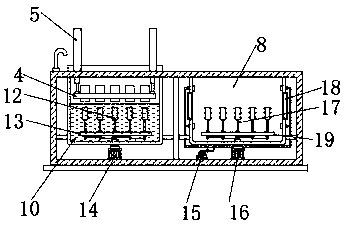

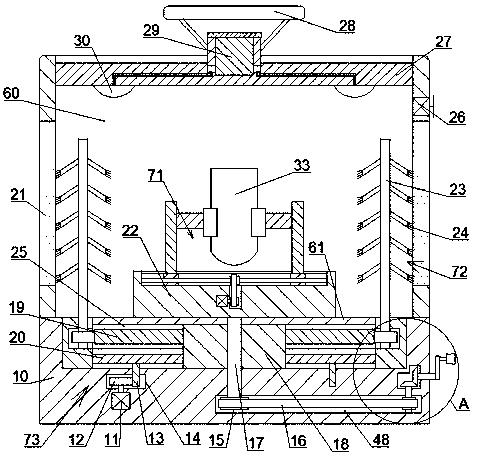

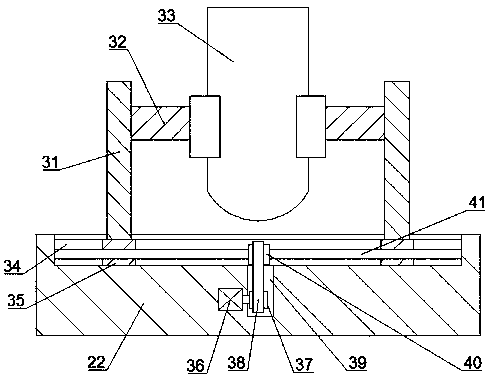

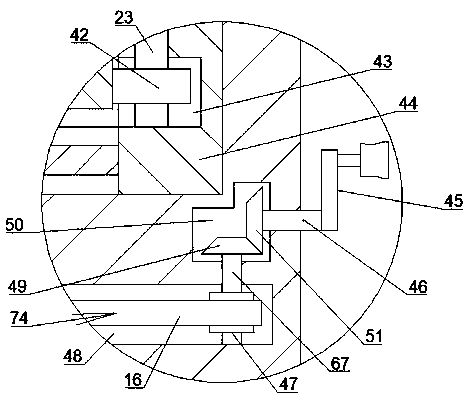

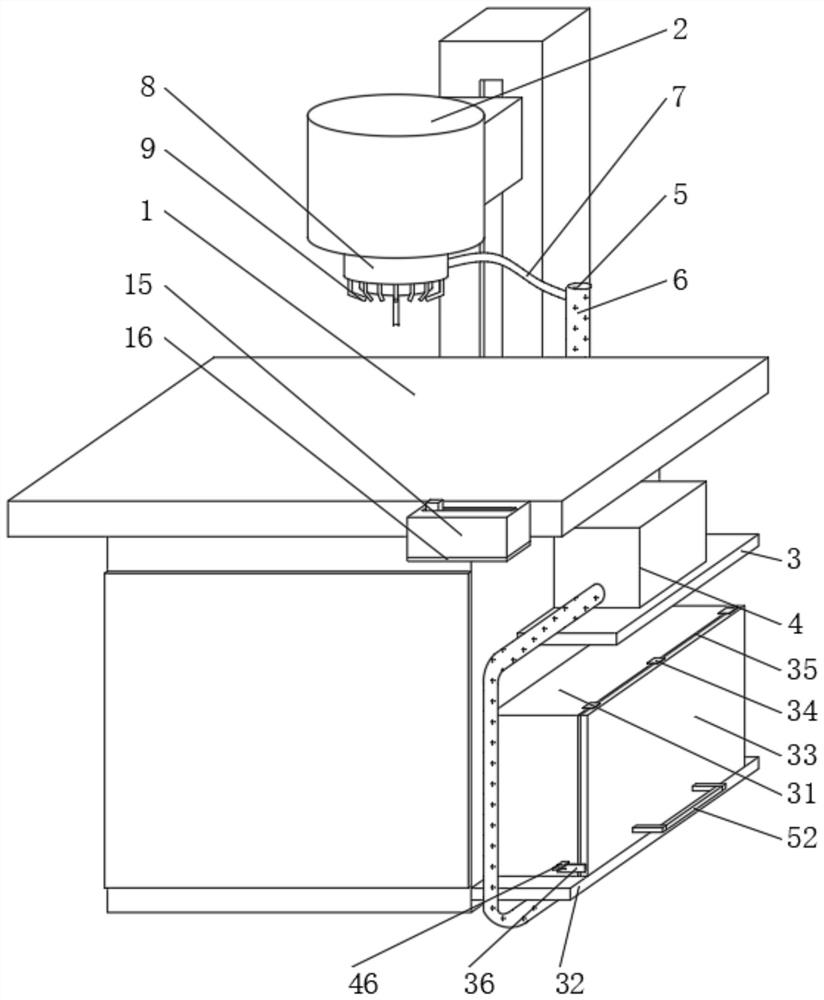

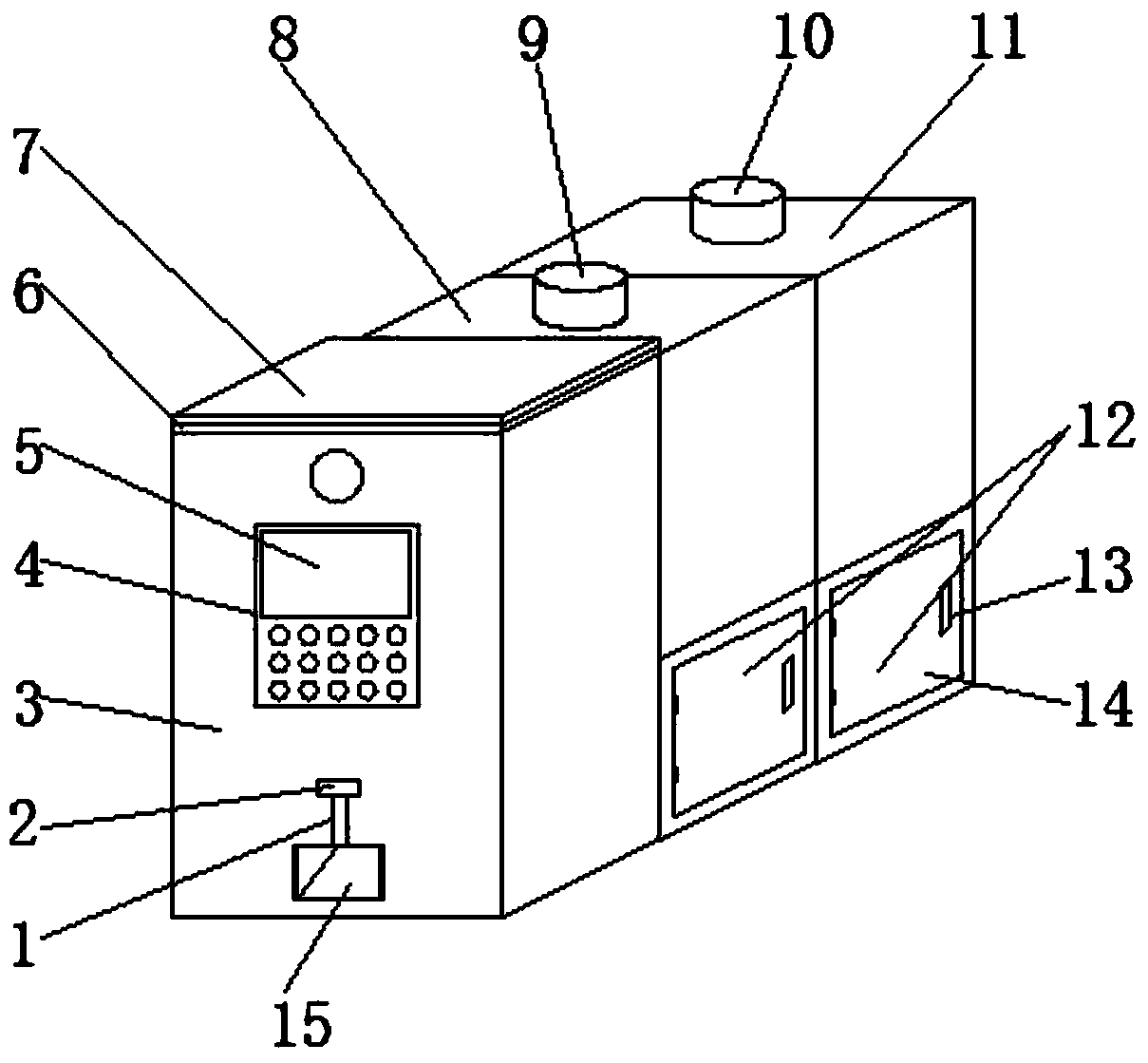

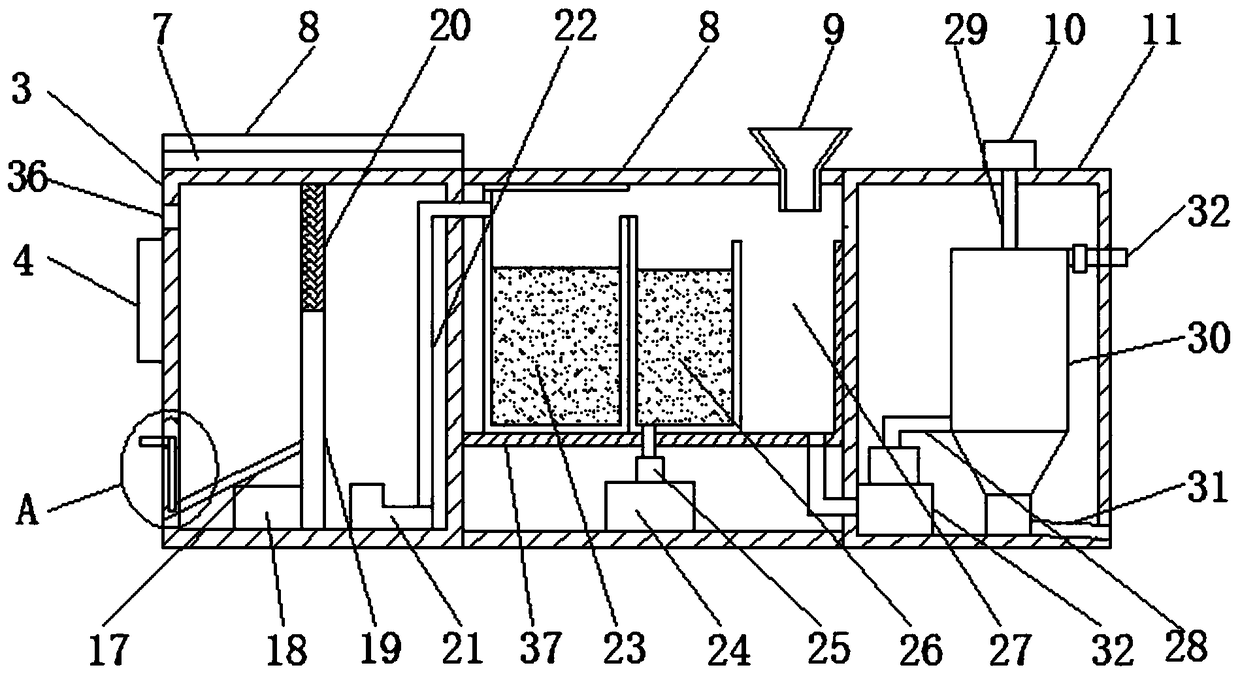

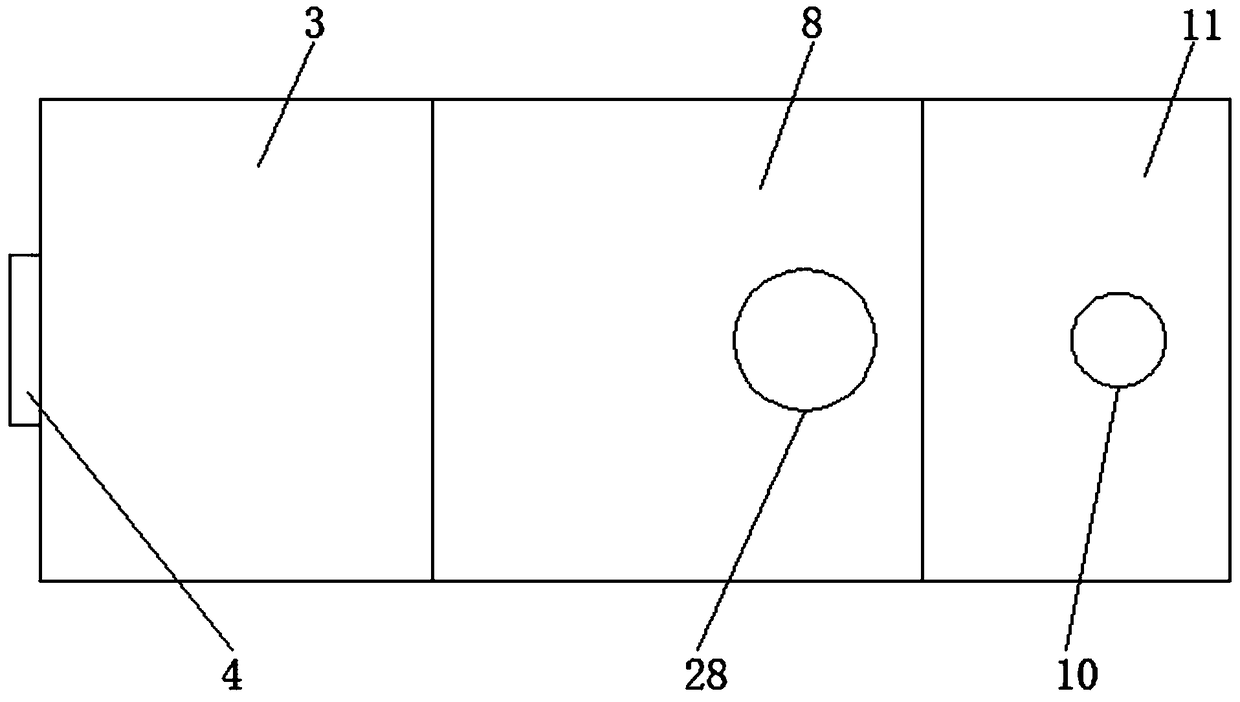

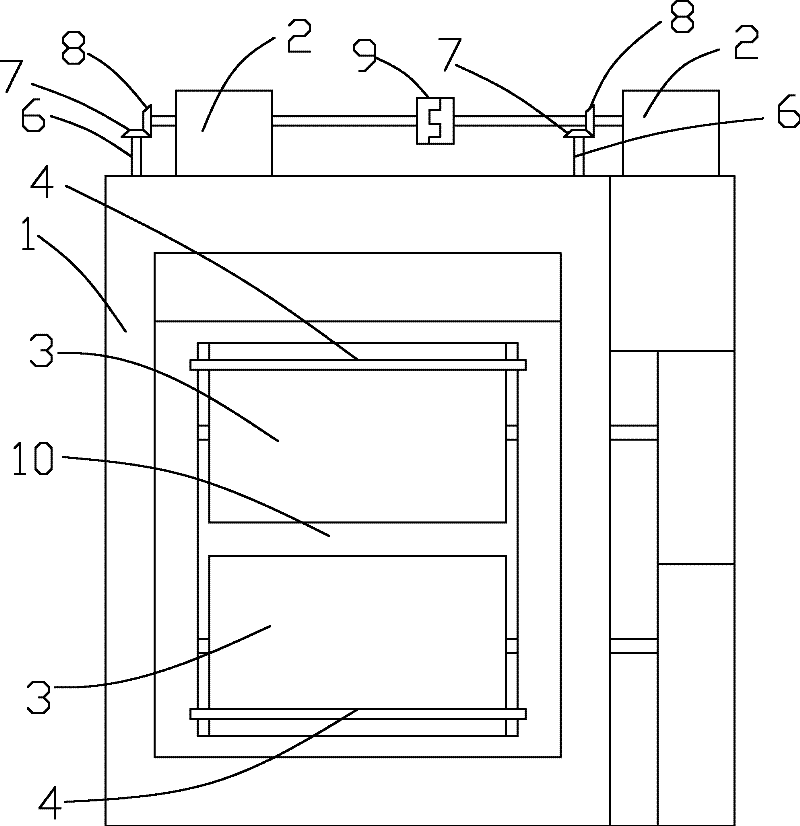

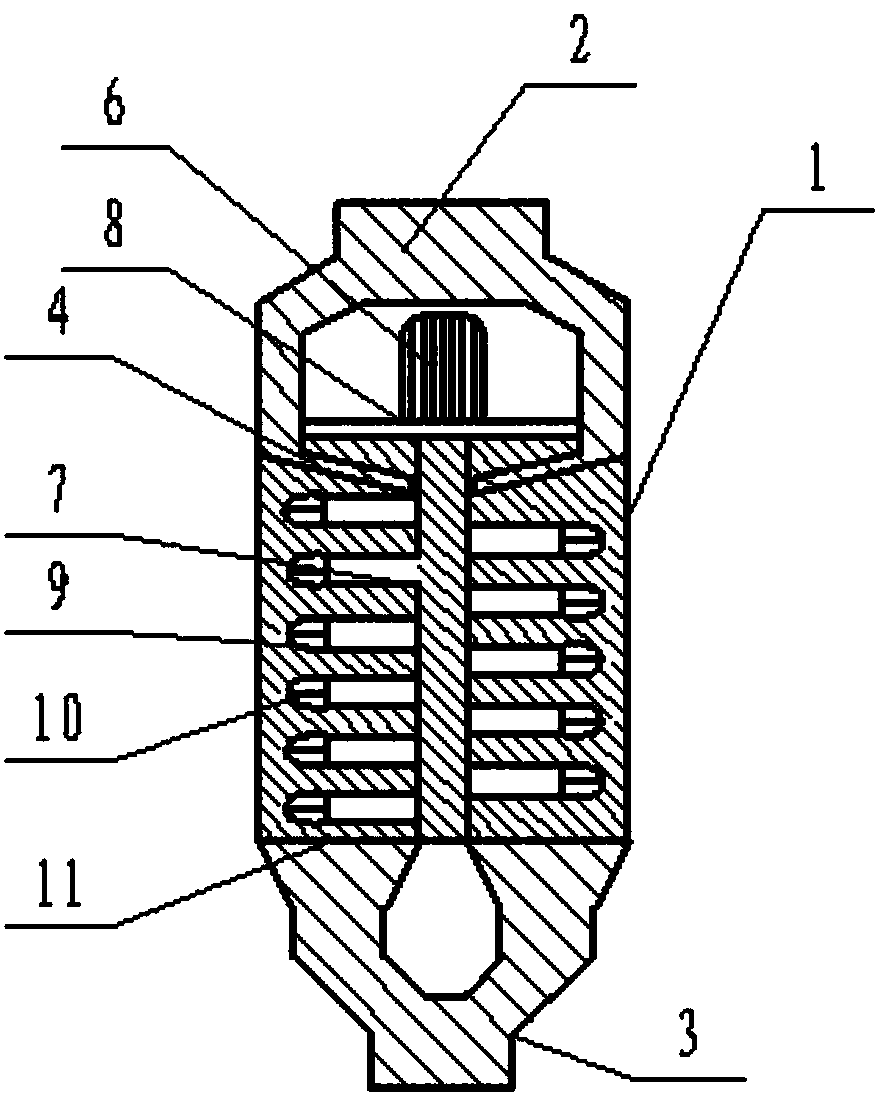

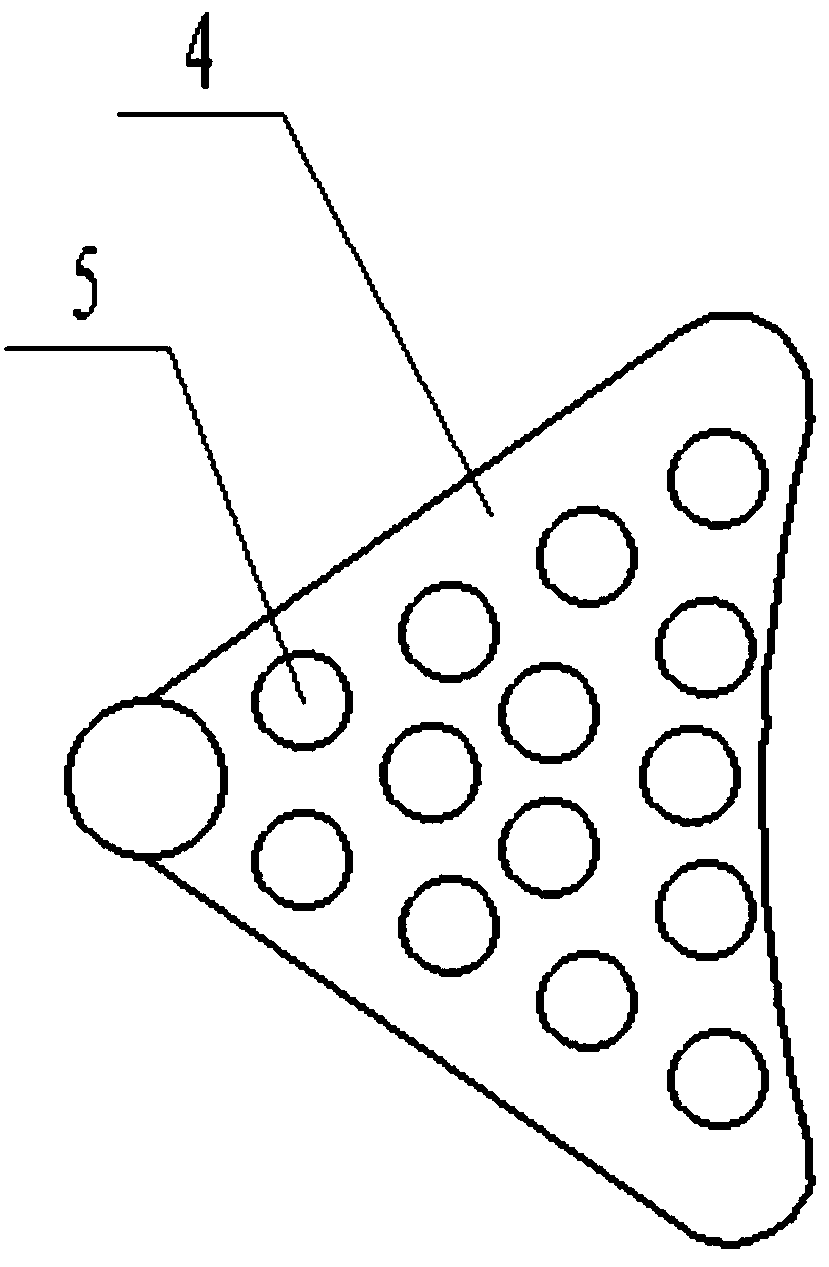

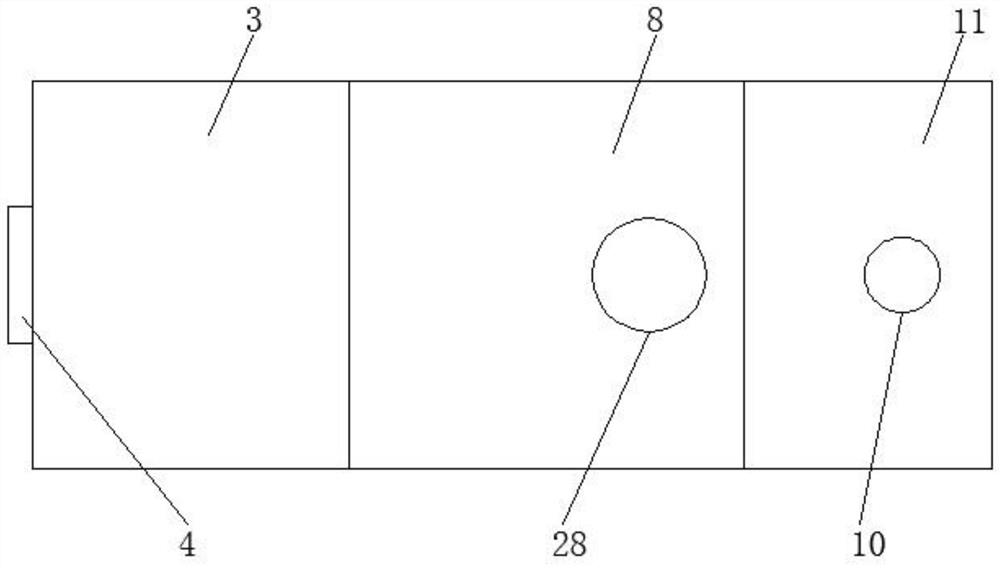

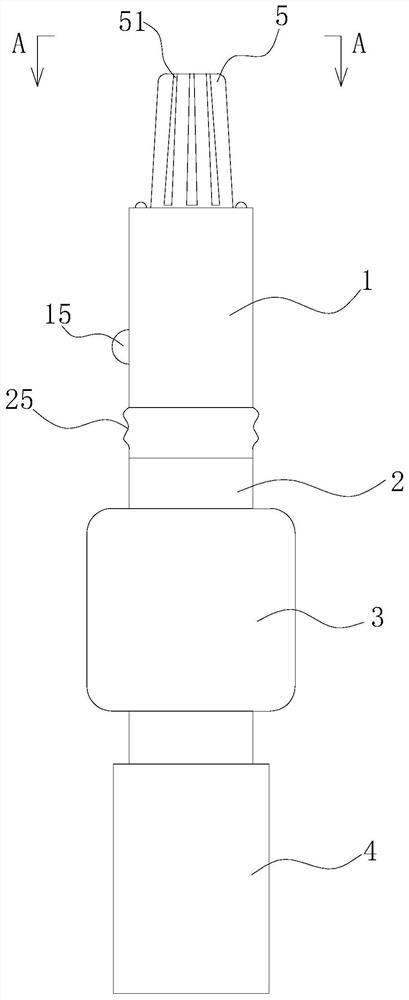

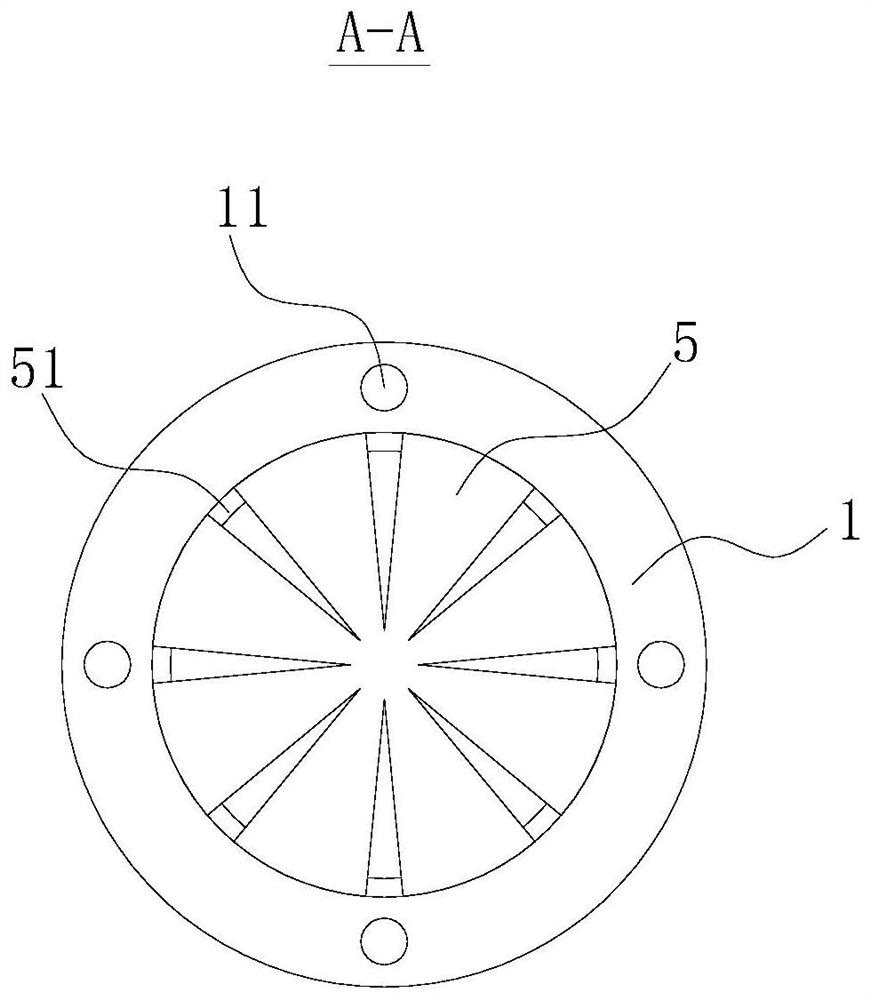

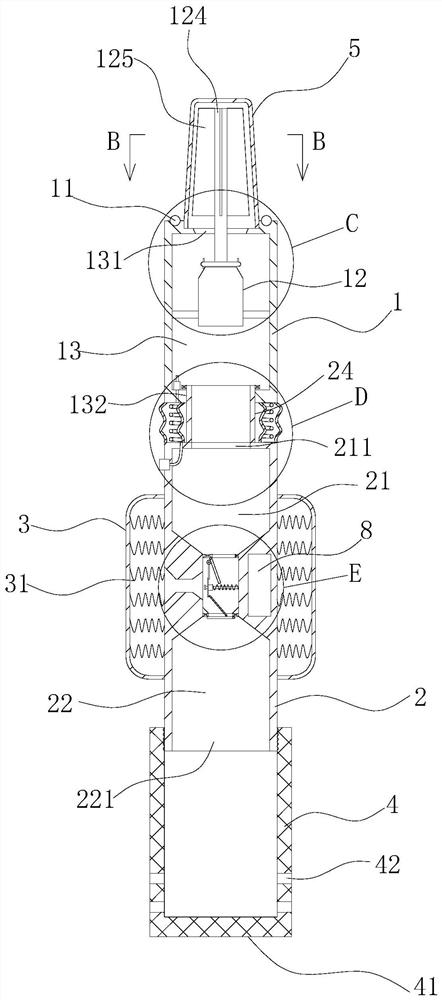

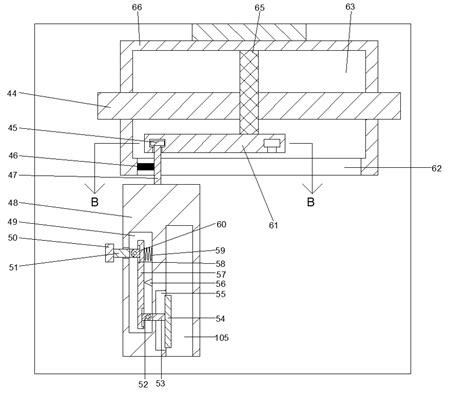

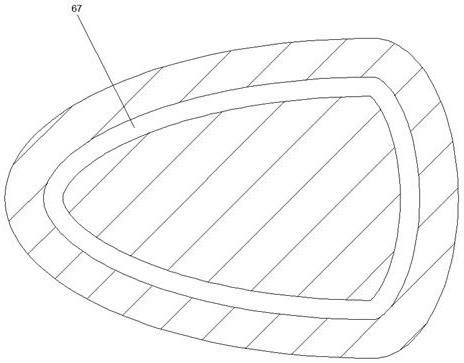

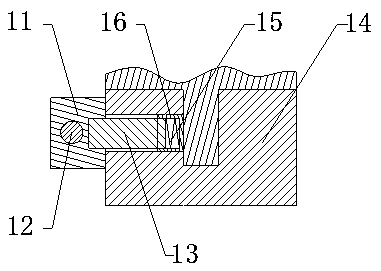

Cleaning device for chemical experiment teaching aid

InactiveCN108580485AEasy to removeEliminates the hassle of manual cleaningHollow article cleaningDrying gas arrangementsEngineeringControl switch

The invention discloses a cleaning device for a chemical experiment teaching aid. The cleaning device comprises a box. The side face of the box is fixedly provided with a control switch. A first sliding base is fixedly arranged at the upper end of the box, and the position, located on the inner side of the first sliding base, of the upper surface of the box is provided with a disinfection tank. Through a test tube plate and a cleaning tank, the trouble of manual test tube cleaning is saved, operation is convenient, cleaning is more thorough, and the cleaning time is saved for experimenters; the disinfection tank is utilized for conducting air drying and disinfection on cleaned test tubes, test tube cleaning, air drying and disinfection integration is achieved, the sanitation quality of thetest tubes is improved, and reusing is convenient; and through bolts and a second sliding base, the test tube plate can be conveniently detached after the test tubes are cleaned and disinfected, theexperimenters conveniently store the test tube plate and the test tubes, and the test tubes can be protected and prevented from being damaged. According to the design, the structure is simple, the function is practical, and cleaning is more rapid and thorough.

Owner:胡耀丹

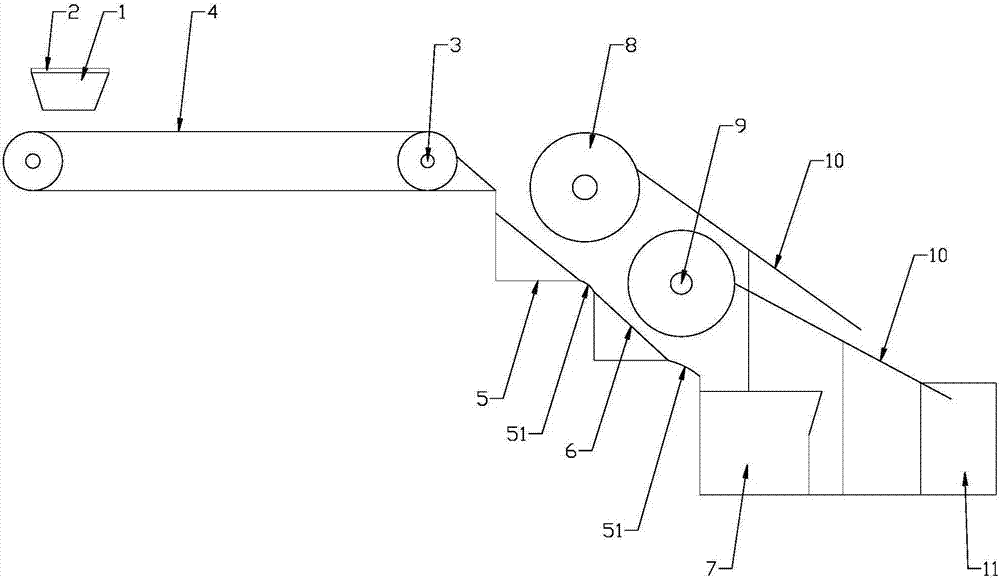

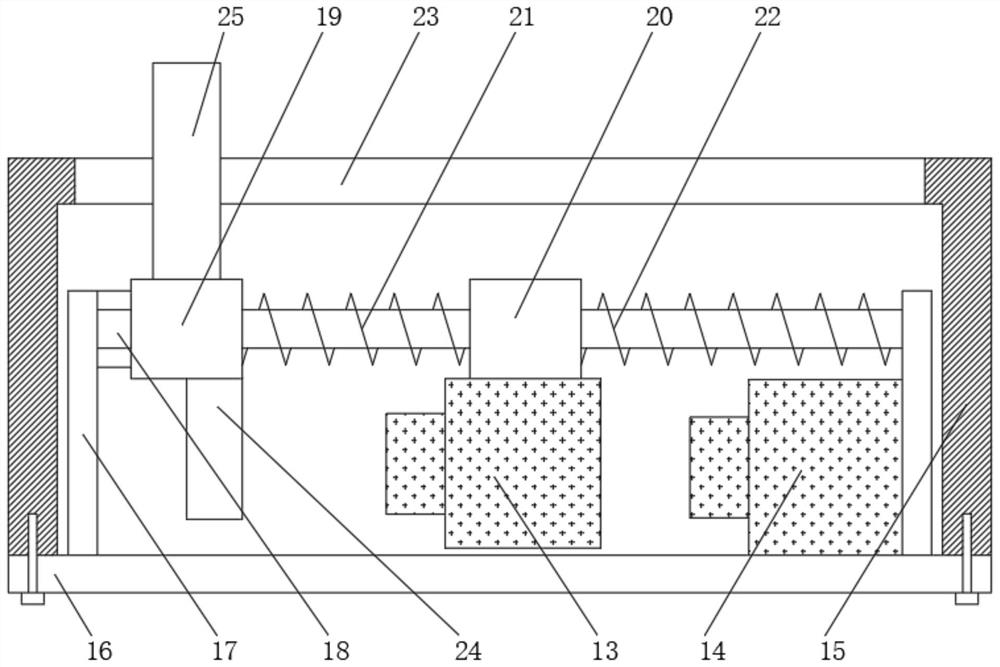

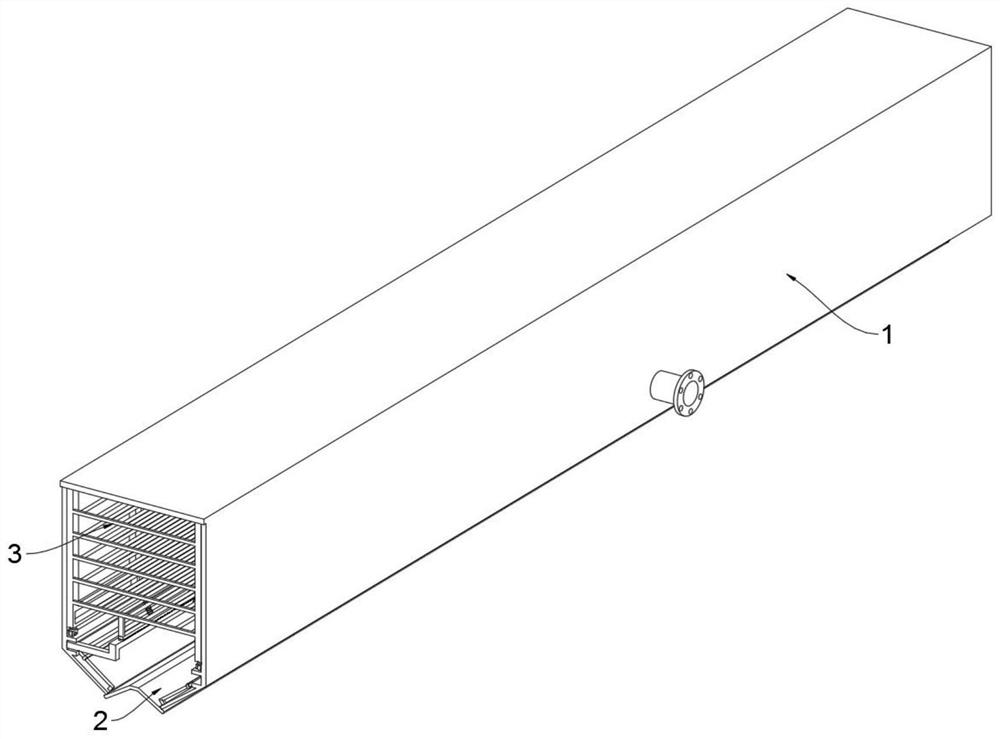

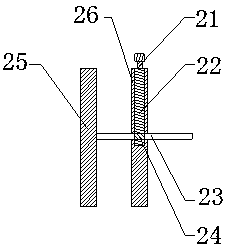

Foundry sand processing system

InactiveCN107344226AEfficient removalEliminates the hassle of manual cleaningMould handling/dressing devicesFoundrySlag

The invention relates to sand processing equipment, in particular to a foundry sand processing system. The foundry sand processing system comprises a filtering mechanism, a horizontal conveying mechanism, an inclined conveying mechanism, a magnet ring set, a sand storage box and a waste slag box; the filtering mechanism comprises a sand hopper and a filtering plate detachably connected with a sand inlet of the sand hopper; the horizontal conveying mechanism comprises a rotary shaft and a conveying belt driven by the rotary shaft; the inclined conveying mechanism comprises step platforms and inclined plates arranged on the step platforms correspondingly; a sand inlet of the sand storage box is lower than the sand outlet end of the inclined conveying mechanism; the magnet ring set is arranged on one side of the inclined conveying mechanism, is attached to the inclined plates, and comprises magnet rings, driving shafts for driving the magnet rings to rotate, and scraper blades for removing scrap iron on the magnet rings, the scraper blades are obliquely arranged, the scraping ends of the scraper blades abut against the magnet rings, and the discharging ends of the scraper blades stretches into the waste slag box. According to the foundry sand processing system adopting the technical scheme, the scrap iron in foundry sand can be effectively removed, troubles caused by manual cleaning are avoided, and the safety of the next procedure is ensured.

Owner:CHENGDU XINGYU PRECISION CASTING

Spinning dust collection device

InactiveCN108442024AGood dust removal effectAvoid secondary dustCombination devicesUsing liquid separation agentEngineeringCam

The invention discloses a spinning dust collection device. The spinning dust collection device comprises a first dust collection pipe, a second dust collection pipe and a dust collection box, whereina motor and a water tank are fixed in the dust collection box, an adsorption cylinder is connected on an output shaft of the motor, a sponge block is fixedly connected in the adsorption cylinder, a wastewater pool is arranged at the lower portion of the adsorption cylinder and is communicated with the second dust collection pipe, a water absorption pipe is communicated on the side wall, close to the motor, of the water tank, a water spraying pipe is communicated to one end, close to the water tank, of the water absorption pipe, the communication portion between the water tank and the water absorption pipe and the communication portion between the water absorption pipe and the water spraying pipe are each provided with a one-way valve, a piston is slidingly connected in the water absorptionpipe, a piston rod is connected on the piston, the part, located in the water absorption pipe, of the piston rod is sleeved with a tension spring, a cam is connected on the output shaft of the motor,the piston rod abuts against the cam, and a first negative-pressure draught fan is fixed at the end of the second dust collection pipe. By means of the spinning dust collection device in the technical scheme, the problems that the dust collecting device needs to be manually cleaned, and the dust collecting and cleaning effect is poor are solved.

Owner:NINGBO WENZE TEXTILE CO LTD

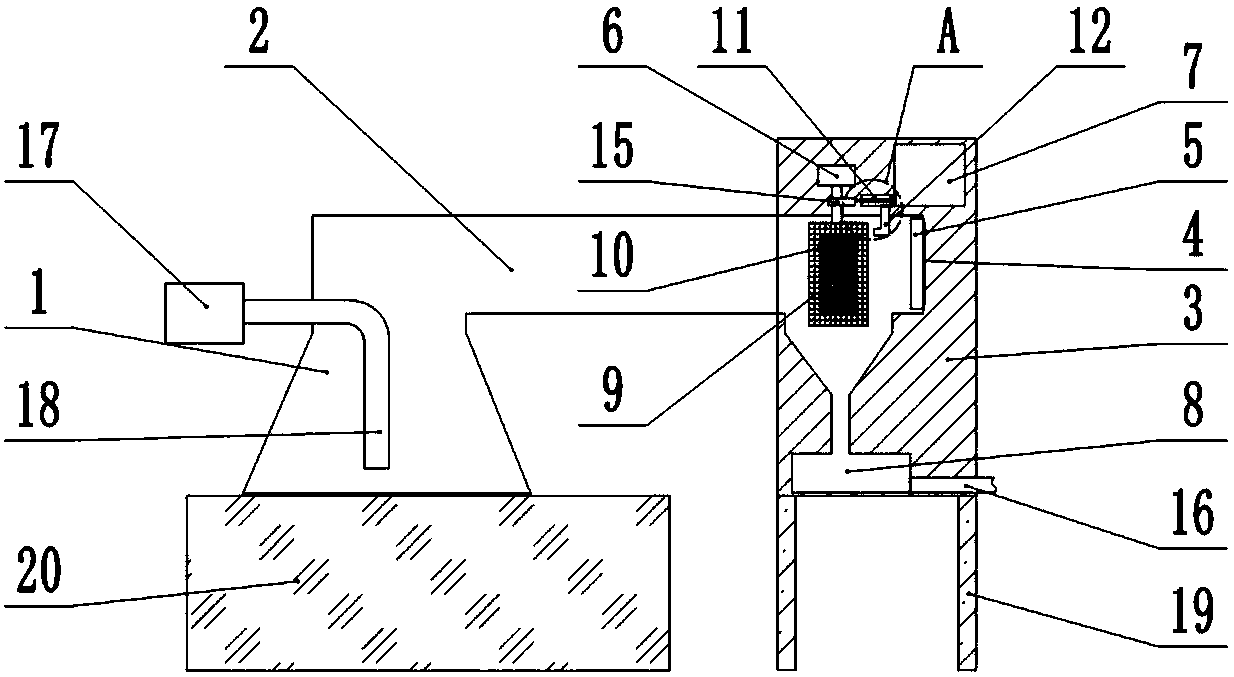

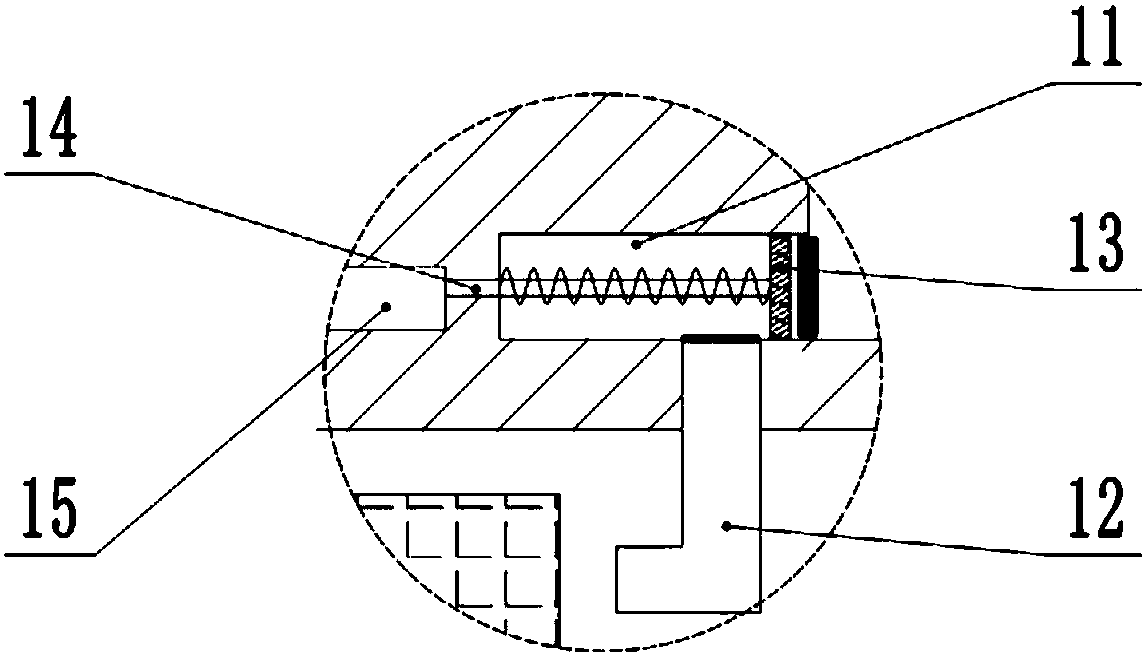

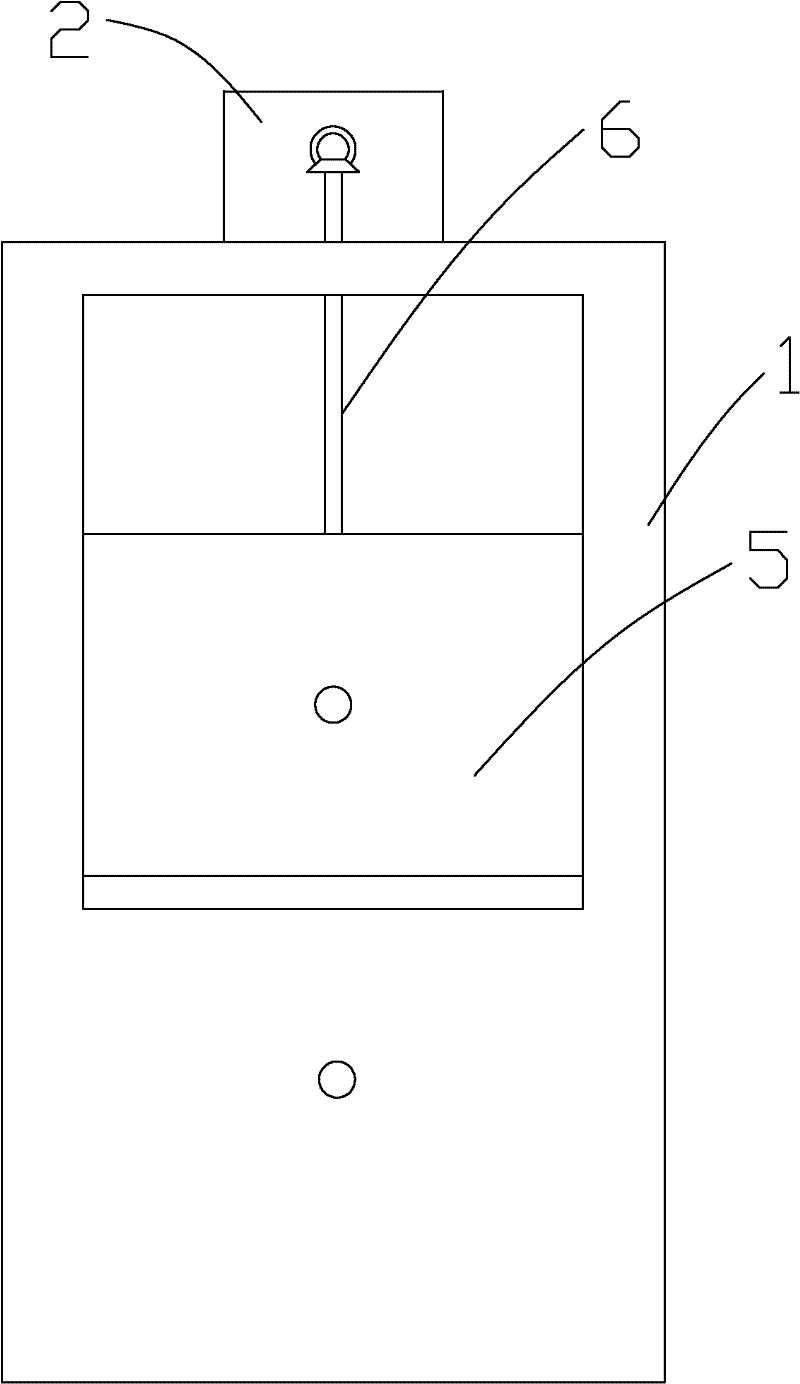

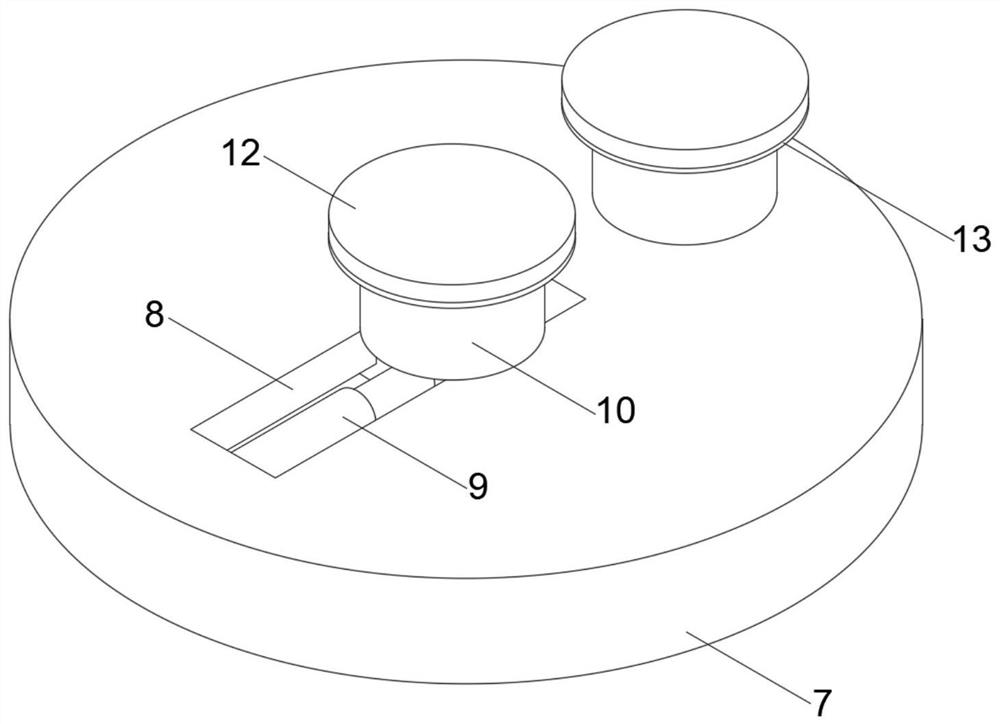

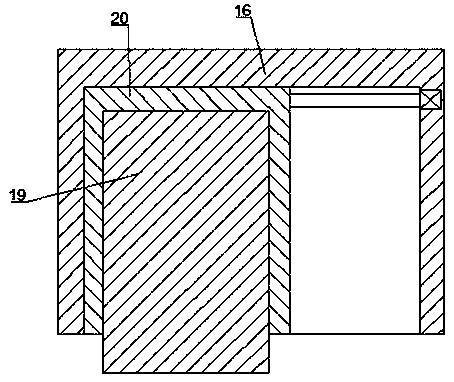

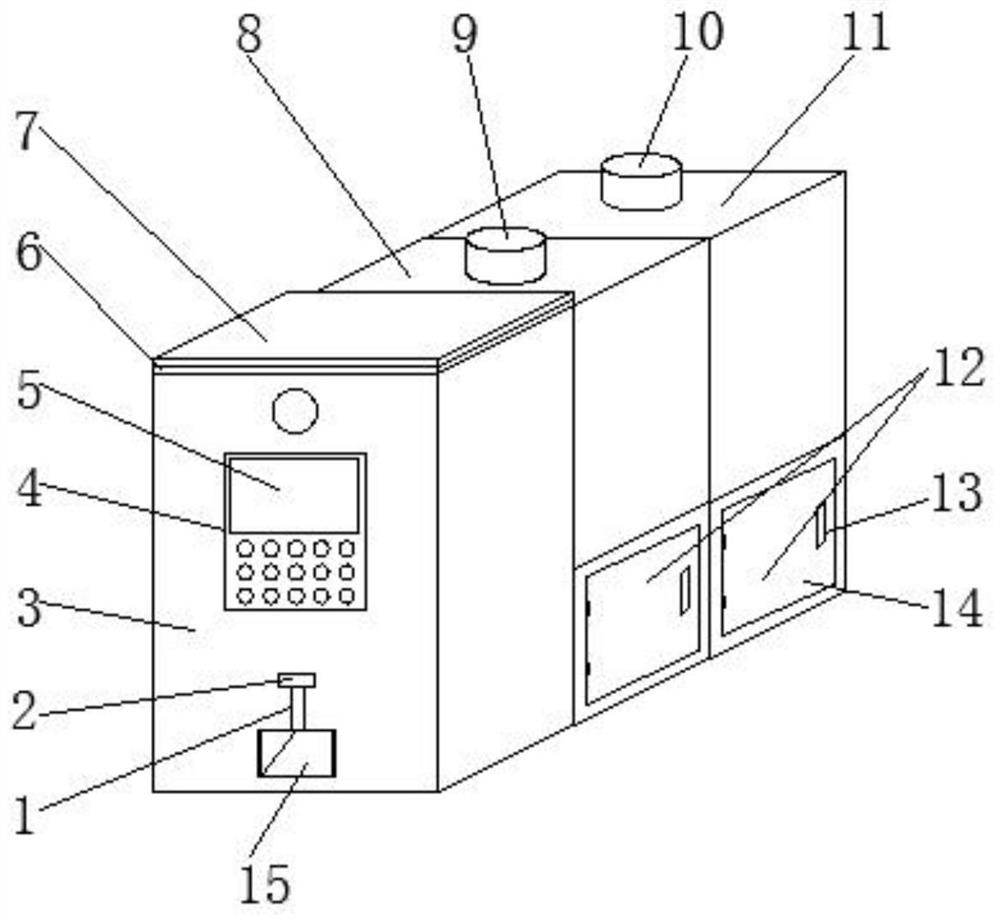

Animal embryo refrigeration cabinet having convenience in observation

InactiveCN110122475AEasy to observeEliminates the hassle of manual cleaningDead animal preservationEmbryoEngineering

The invention discloses an animal embryo refrigeration cabinet having convenience in observation. The refrigerated cabinet comprises a base, wherein a cylindrical cavity is formed in the top end faceof the base; a fixing column is fixedly arranged on the bottom wall of the cylindrical cavity; a top plate is fixedly arranged at the top ends of the fixing columns; a cylindrical box body is fixedlyarranged at the top end of the base; the middle part of the cylindrical box body is designed to be transparent; a storage cavity is formed in the cylindrical box body; a display stand is arranged in the storage cavity; the display stand is fixed at the top end of the top plate; and a clamping mechanism capable of fixing a culture dish is arranged on the display platform. According to the refrigerated cabinet, the interior of the storage cavity can be automatically cleaned through the power mechanism and the cleaning mechanism after use, and the trouble of manual cleaning is omitted. The display stand can be rotated by manually shaking the rocking rod, so that the condition in the culture dish can be observed in all directions.

Owner:JINYUN XUANYA ELECTRONICS TECH CO LTD

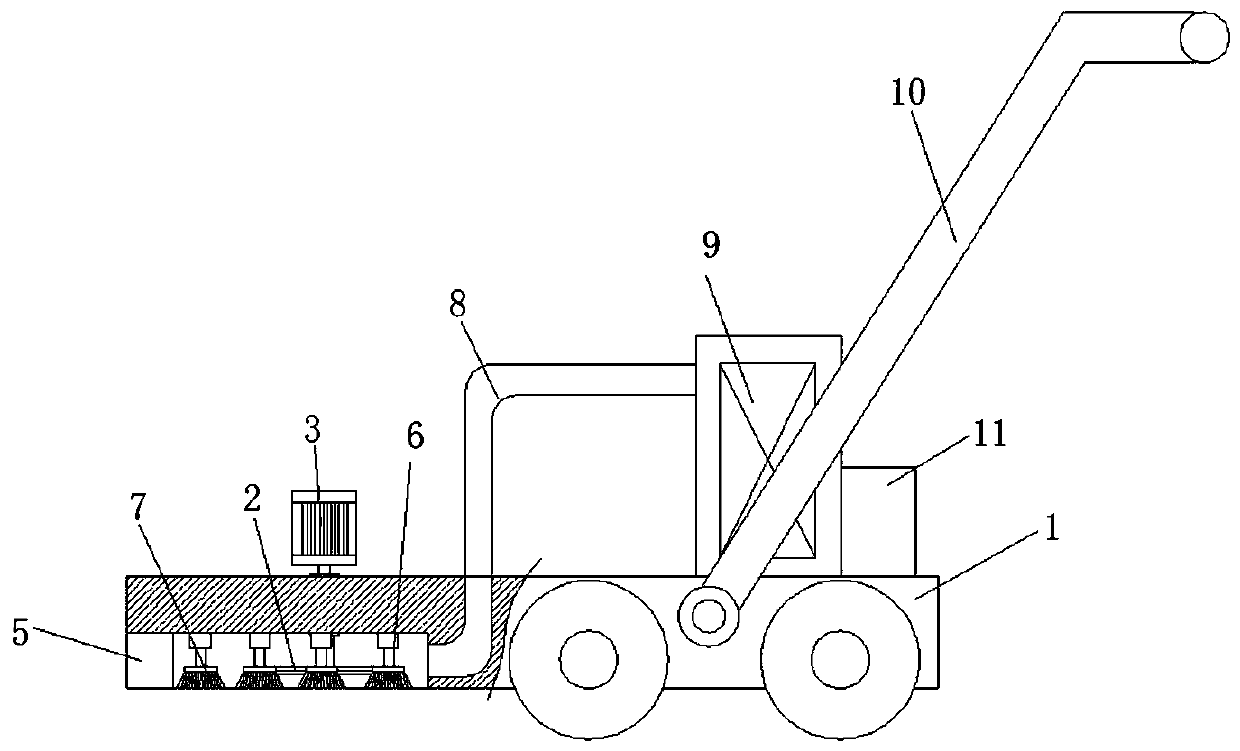

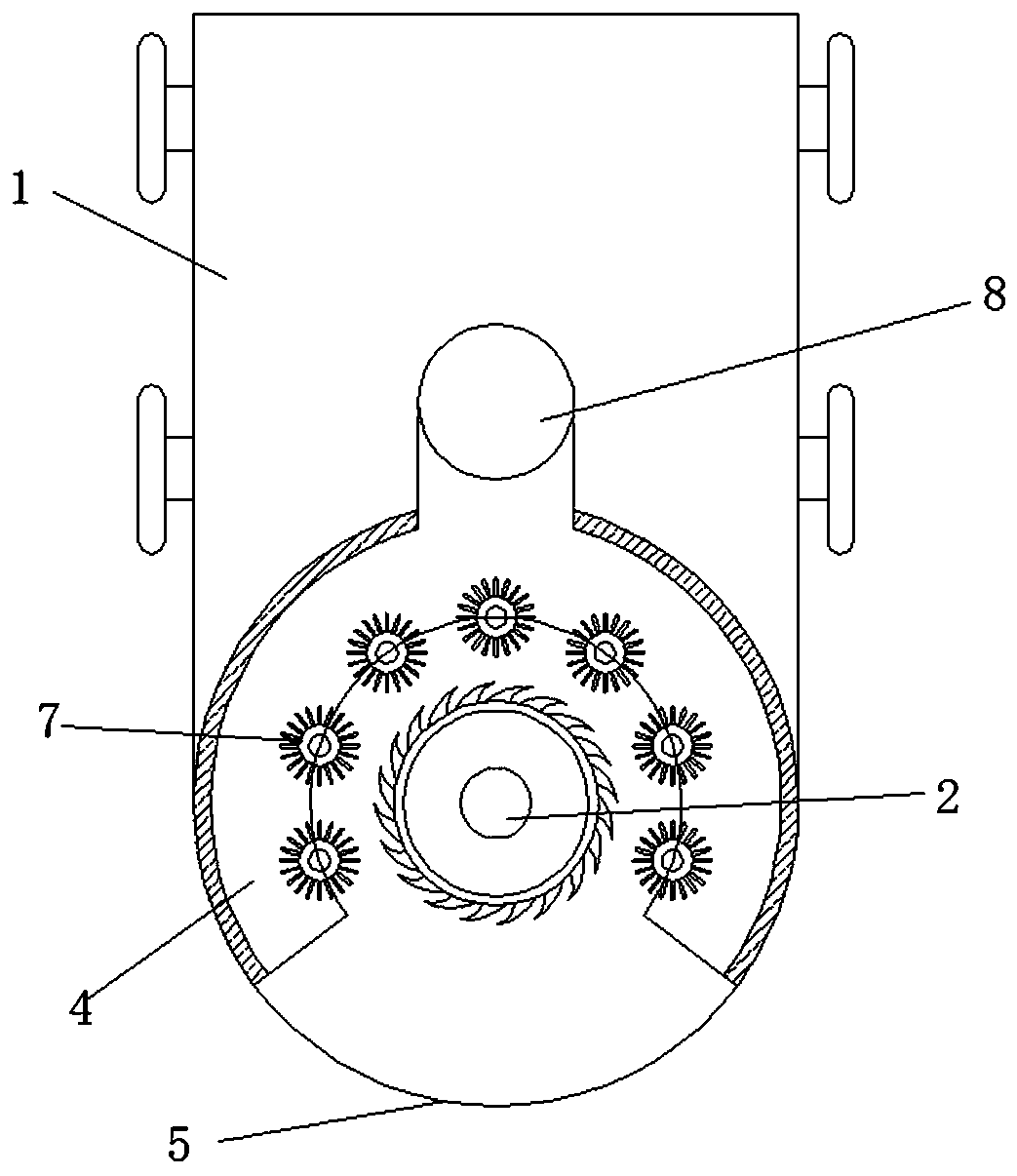

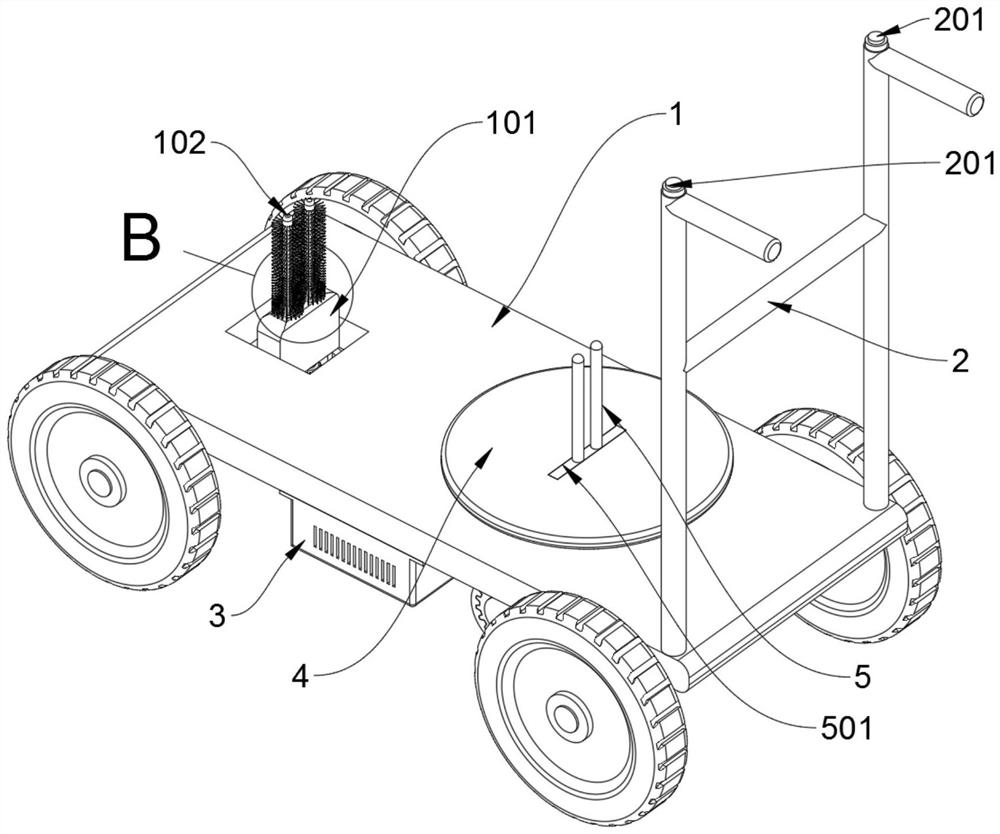

Convenient weeding device for garden

InactiveCN109804773AImprove convenienceEliminates the hassle of manual cleaningMowersDrive motorEngineering

The invention discloses a convenient weeding device for a garden. The convenient weeding device comprises a moving base, a circular cutting groove is formed in the bottom of one end of the moving base, and a mowing cutter plate is installed at the center of the circular cutting groove through a bearing. A drive motor is mounted on the moving base, and an output shaft of the drive motor is fixedlyconnected with the mowing cutter plate. An annular grass receiving cavity is formed in the outer side of the circular cutting groove, an opening is formed in the inner annular side, close to the mowing cutter plate, of the annular grass receiving cavity, rotating shafts are mounted at equal intervals at the opening along the circumference, circular cleaning brushes are rotatably connected to the ends, close to the ground, of the rotating shafts, and a grass inlet opening is formed in one end of the annular grass receiving cavity. According to the convenient weeding device, a cutting cutter plate cuts weeds, the circular cleaning brushes are matched with an air suction device to draw the weeds into a storage box, so that after the weeds are cut, the cut weed blades can be cleaned, the trouble of manual cleaning in the later stage is eliminated, and the convenience of weeding is improved.

Owner:西安思途米环保科技有限公司

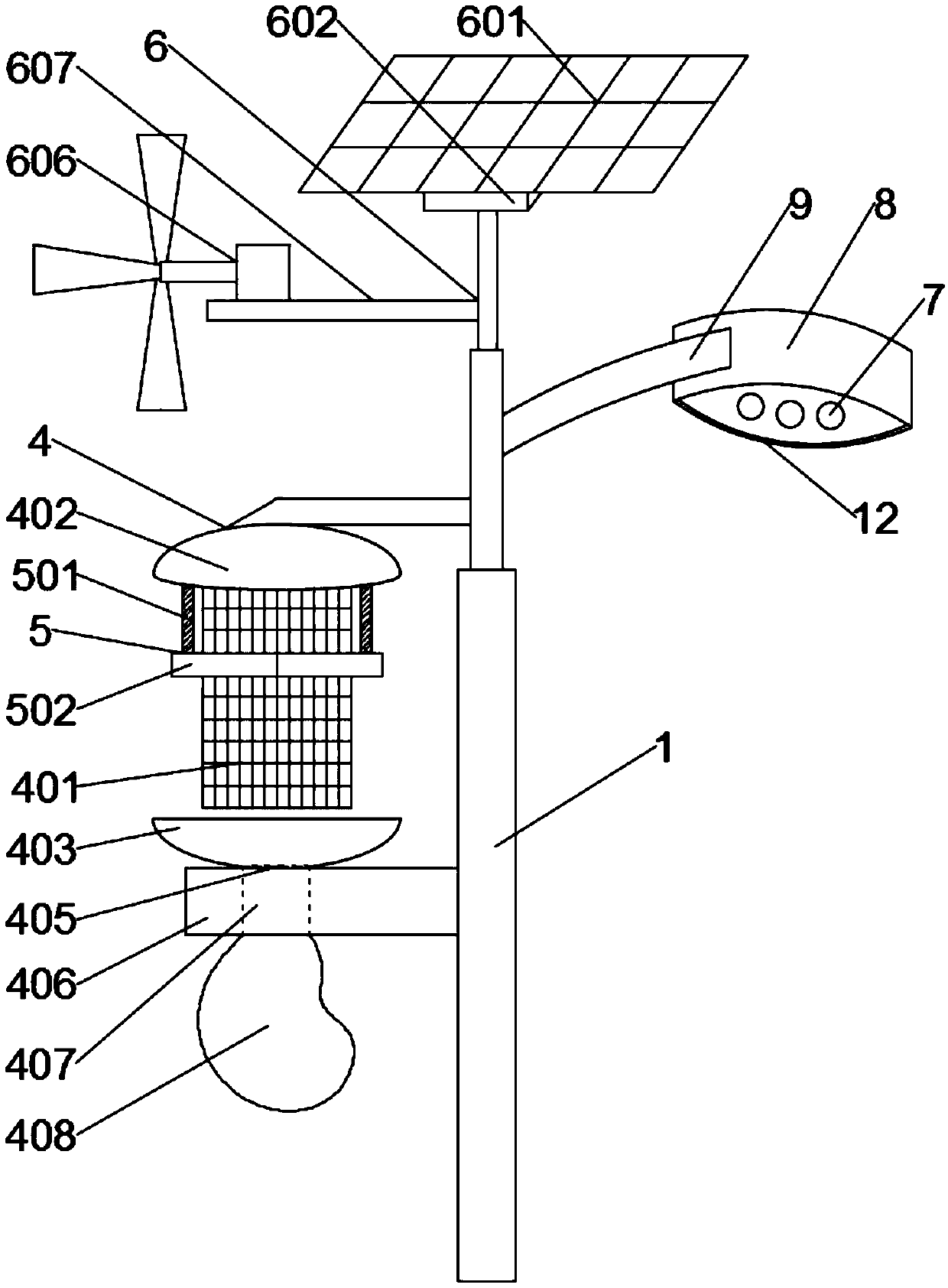

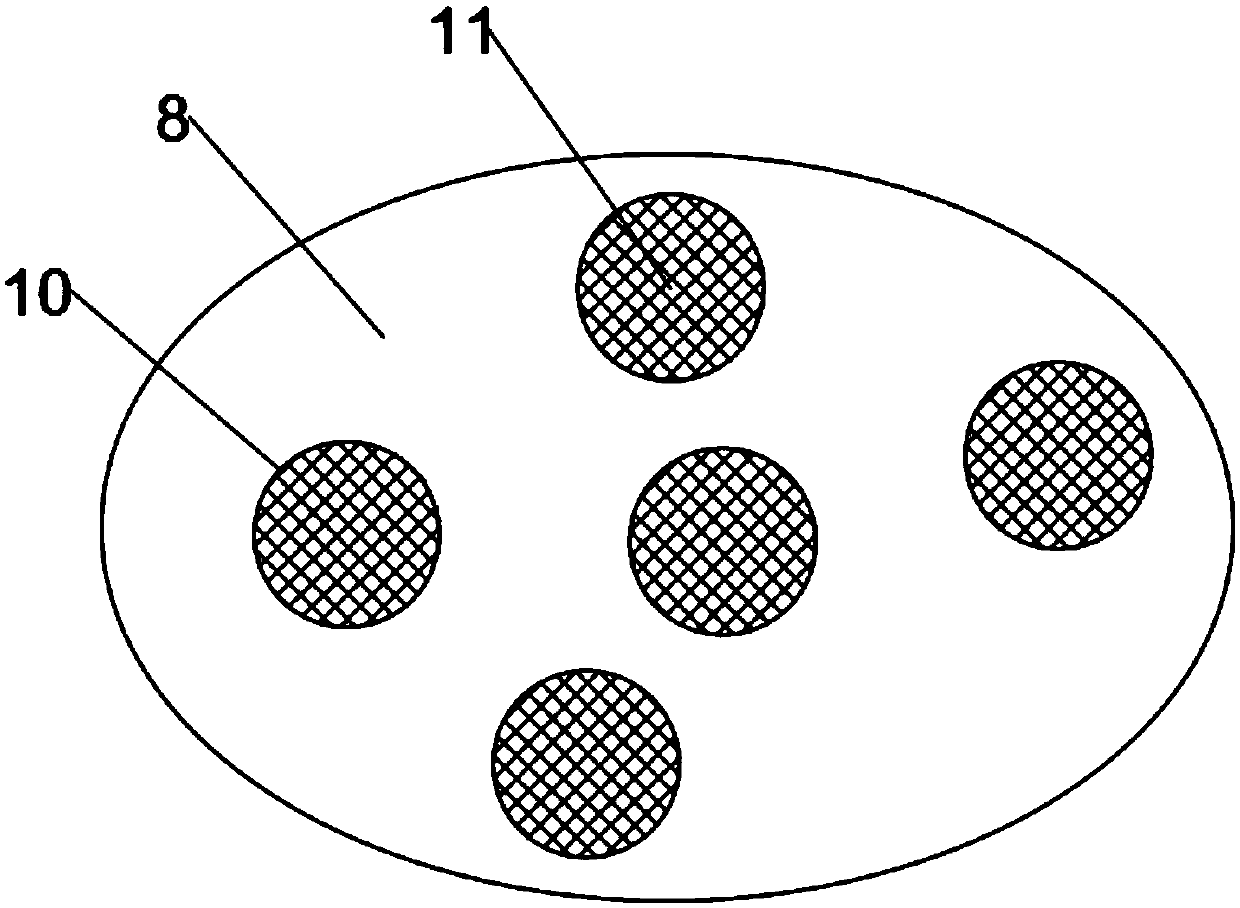

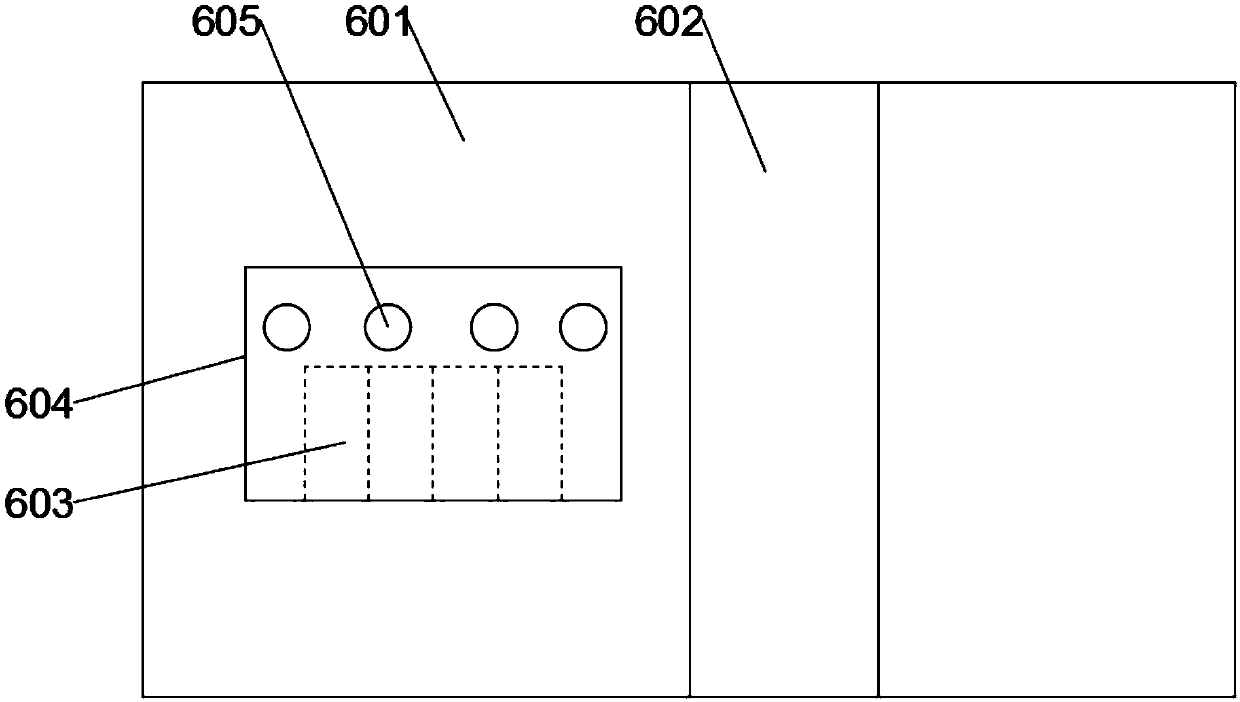

Multifunctional insecticidal lamp

PendingCN109601499AAvoid lostGuaranteed insecticidal efficacyBatteries circuit arrangementsLighting elementsControl systemComputer module

The invention discloses a multifunctional insecticidal lamp which comprises a support frame with a hollow structure, a master control system based on an AT89S52 chip and an alarm module in control connection with the master control system, wherein an all-around insecticidal device is arranged on the support frame; an automatic cleaning component in control connection with the master control systemis further mounted on the all-around insecticidal device; the multifunctional insecticidal lamp further comprises an energy combination power generating device based on solar energy and wind energy;the energy combination power generating device is used for supplying power to the master control system and the all-around insecticidal device and can make full use of the solar energy and the wind energy to generate more electric energy; electric energy demands of the multifunctional insecticidal lamp in a working process are satisfied; a timely alarm function when a hazardous condition appears is achieved; at the same time, automatic cleaning treatment operation of the surface of an insecticidal grid can be achieved; an insecticidal effect of the insecticidal grid is guaranteed; the influence of dead insects accumulated on the surface of the insecticidal grid on insecticidal performance of the insecticidal grid is effectively avoided; a trouble of manual cleaning is removed; and the insecticidal efficiency of the multifunctional insecticidal lamp is improved.

Owner:HUNAN UNIV OF SCI & ENG

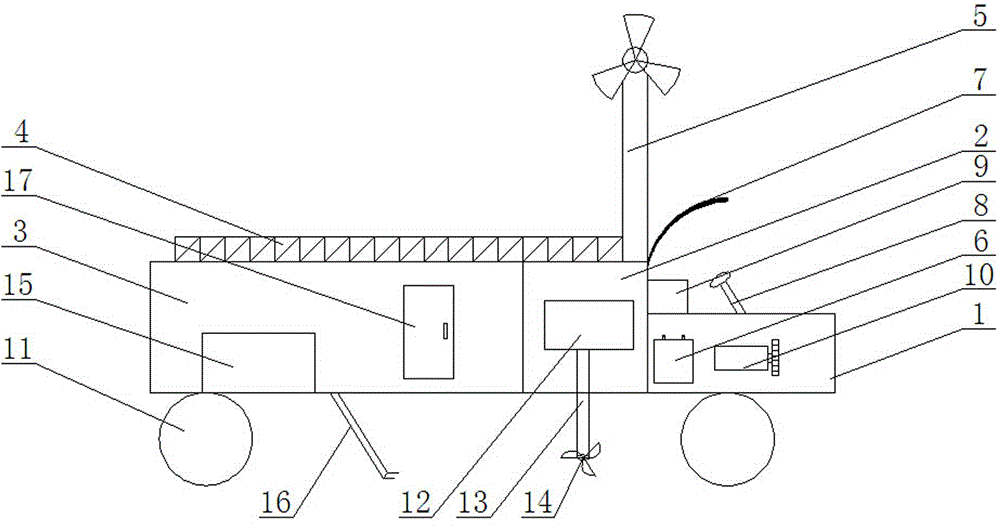

Wind-solar complementary weeding vehicle

The invention discloses a wind-solar complementary weeding vehicle which comprises a vehicle head, a grass cutting chamber, a grass collecting chamber, a storage battery, a solar panel and a small-size wind power generator, wherein the vehicle head is connected with the grass cutting chamber; the grass cutting chamber is connected with the grass collecting chamber; the solar panel is arranged at the tops of the grass cutting chamber and the grass collecting chamber; the small-size wind power generator is arranged above the solar panel; the solar panel and the small-size wind power generator are connected with the storage battery inside the vehicle head. The wind-solar complementary weeding vehicle has the advantages that a solar resource and a wind resource can be adopted as power sources according to different weather conditions and areas, lawns can be cleaned, and meanwhile cut grass can be collected into the grass collecting chamber through a grass sucking pump, so that the trouble that grass needs to be manually cleaned after being cut is avoided, and the wind-solar complementary weeding vehicle is energy-saving and environmental-friendly, simple to operate and applicable to gardening operators.

Owner:HARBIN HONGWANZHI SCI & TECH DEV

Aluminum alloy plate machining equipment and using method thereof

InactiveCN111940775AFall off quicklyAchieve coolingMaintainance and safety accessoriesBoring/drilling machinesElectric machineryEngineering

The invention discloses aluminum alloy plate machining equipment and a using method thereof, and belongs to the technical field of aluminum alloy plate machining. The aluminum alloy plate machining equipment comprises a drilling machine body, a driving motor and a second switch, wherein the driving motor and the second switch are arranged on the drilling machine body, a first supporting plate is fixedly installed on the side face of the drilling machine body, and an air blower is fixedly installed at the top of the first supporting plate; and a plastic pipe is fixedly installed at an air outlet of the air blower, one end of the plastic pipe communicates with a hose, an annular piece is arranged at the bottom of the driving motor, a plurality of air nozzles are fixedly connected to the lower surface of the annular piece, and an annular protrusion is arranged at the top of the outer side face of the annular piece. According to the aluminum alloy plate machining equipment, the air bloweris arranged, the air generated by the air blower is sprayed to a drill bit of the drilling machine body through the air nozzles, so that sweeps wound on the drill bit of the drilling machine body canquickly fall off under the action of airflow, the trouble of manual cleaning is avoided, the actual operation and maintenance cost is reduced, and the drill bit and the workpiece are cooled.

Owner:马鞍山思哲知识产权服务有限公司

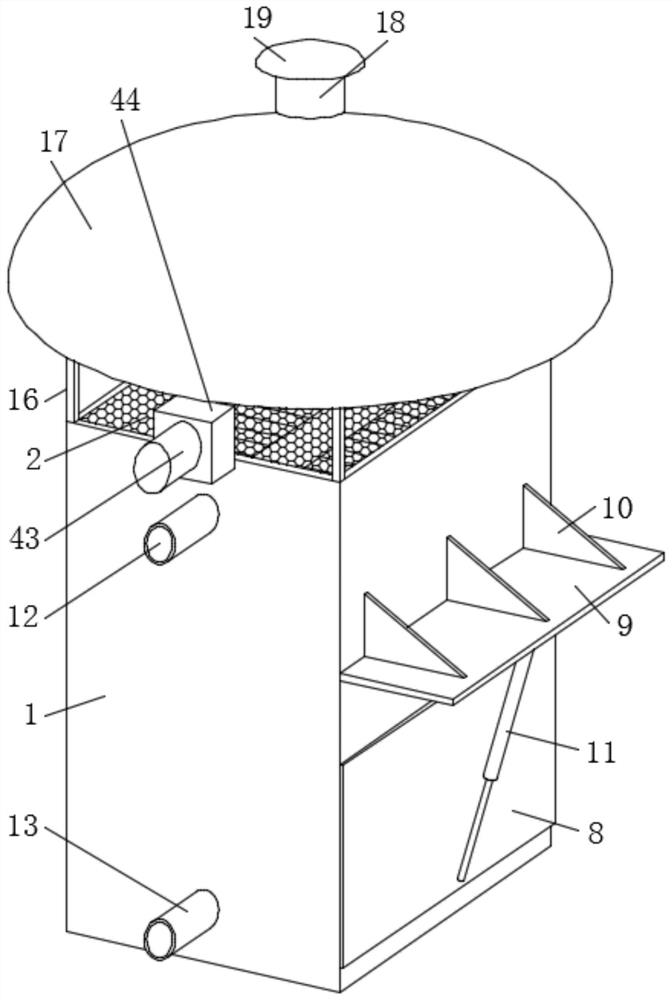

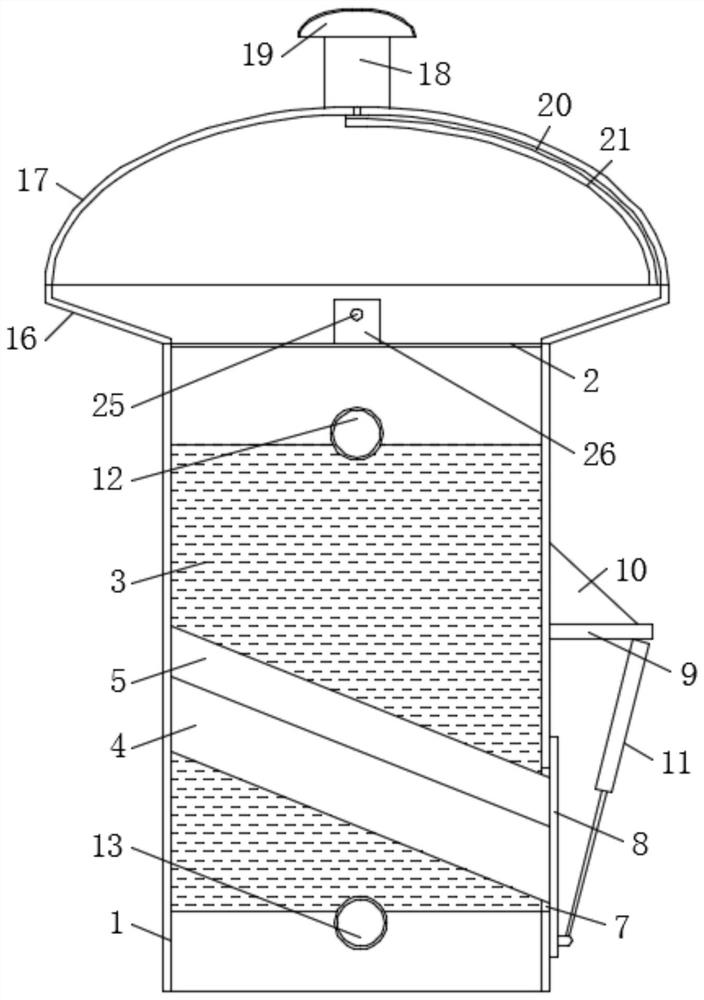

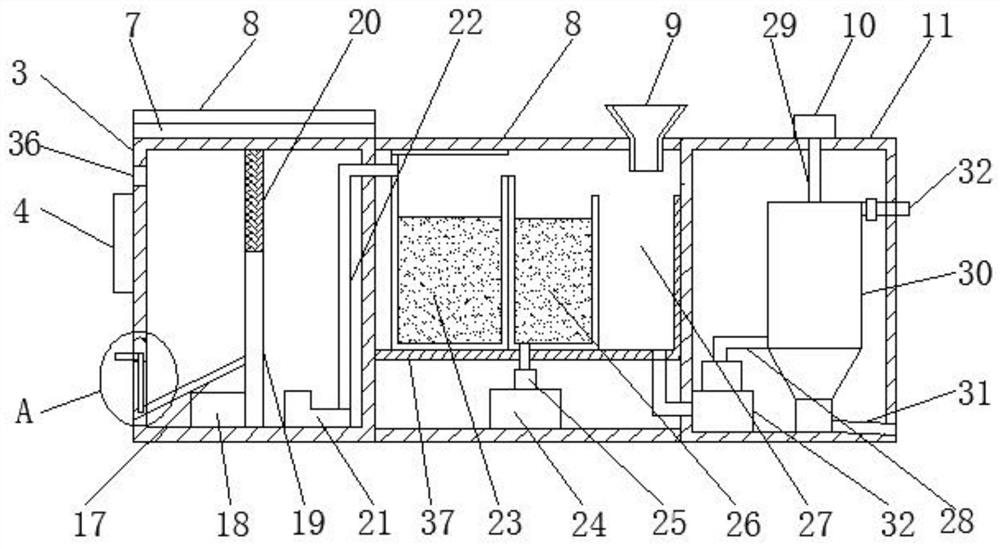

River sewage treatment device

ActiveCN109081516AEasy to operateEasy to useTreatment involving filtrationTreatment with aerobic and anaerobic processesSewage treatmentUltimate tensile strength

The invention discloses a river sewage treatment device, comprising a drive box, a purifying box and a filter box. The purifying box is arranged on one side of the drive box, the filter box is fixedlyarranged on one side of the purifying box, a backwashing pipe is arranged on the top of a filter barrel, a pure water outlet pipe is arranged on the top of the one side wall of the filter barrel, anda first-stage filter layer, a second-stage filter layer and a third-stage filter layer are arranged inside the filter barrel from top to bottom sequentially; dregs, remained at the bottoms of the first-stage filter layer, the second-stage filter layer and the third-stage filter layer, and cannot enter the filter layers upwards due to different bore diameters; a tap water pipe is connected with the joint of a water pipe, tap water flows into the filter barrel from the backwashing pipe, and the dregs between the filter layers are flushed away, and then discharged from the backwashing pipe at the bottom of the filter barrel, thus, manual work in cleaning is omitted, filtering without toxin or harm is carried out based on physical principle, sewage treatment efficiency of the device is improved, and labor intensity of workers is reduced.

Owner:缙云县智禾环保科技有限公司

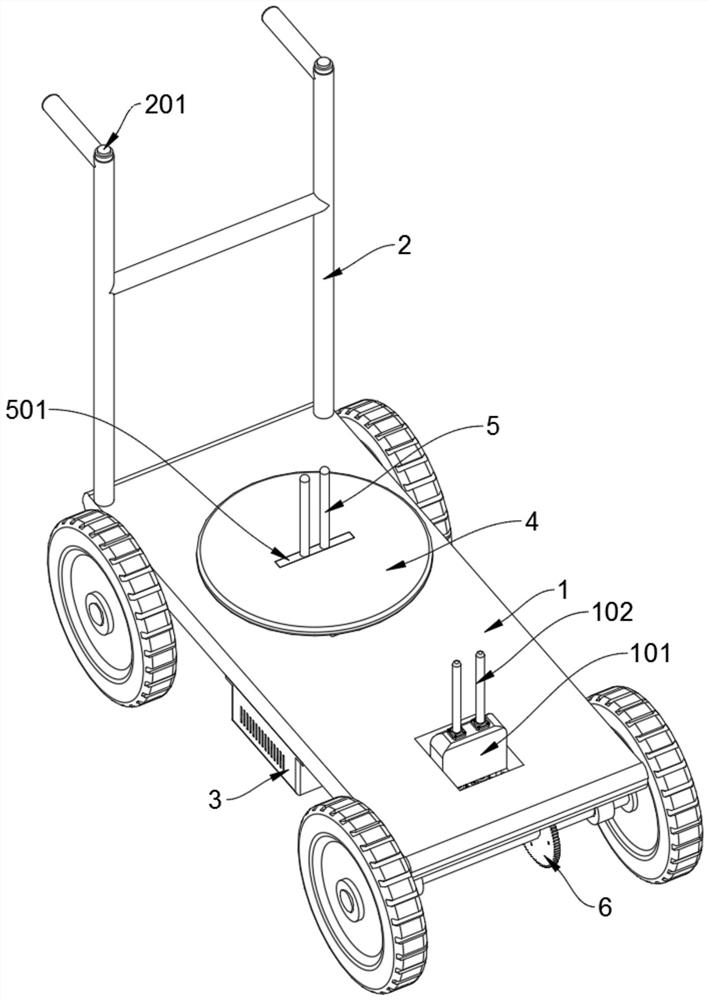

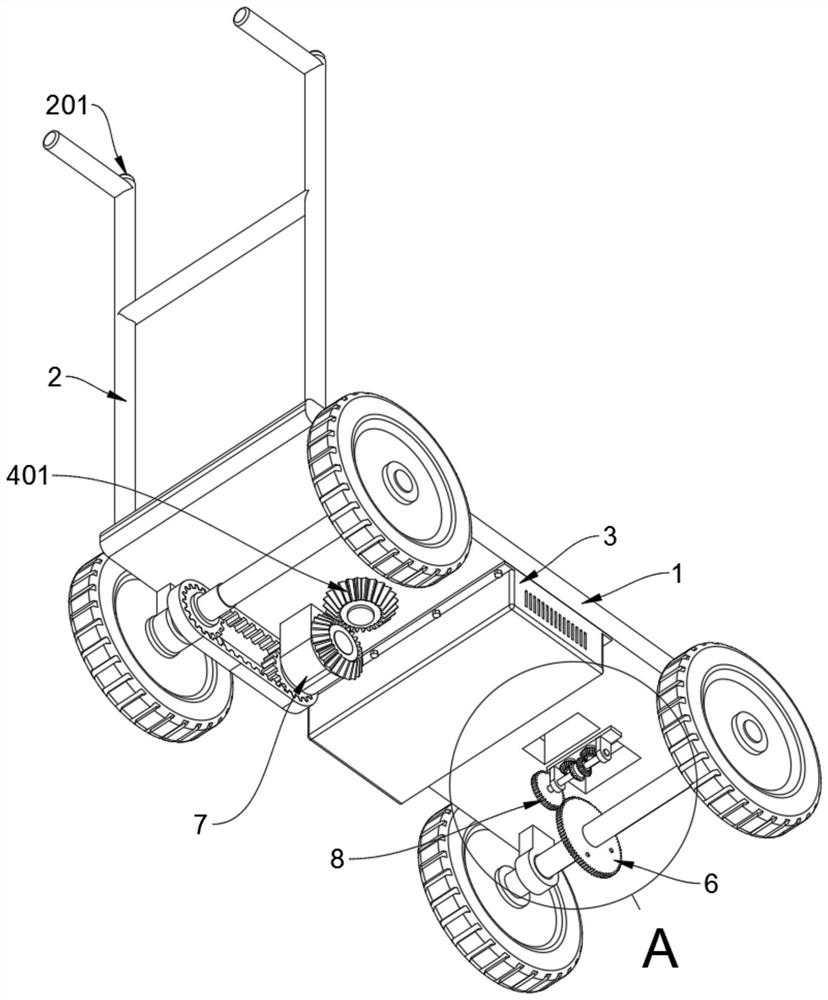

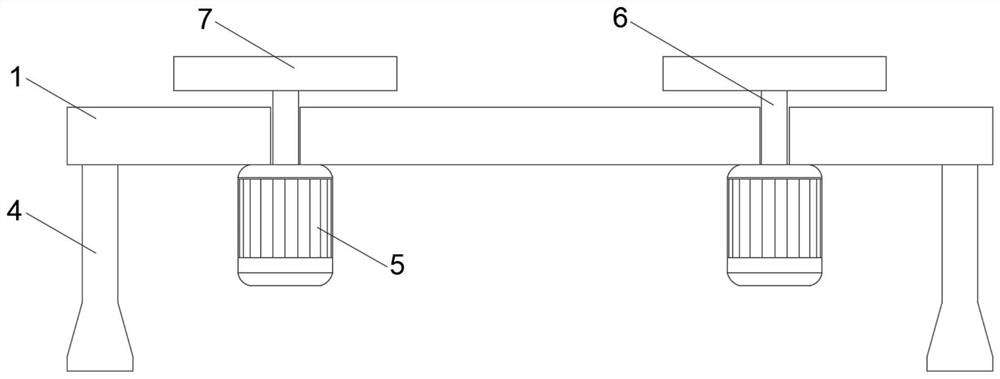

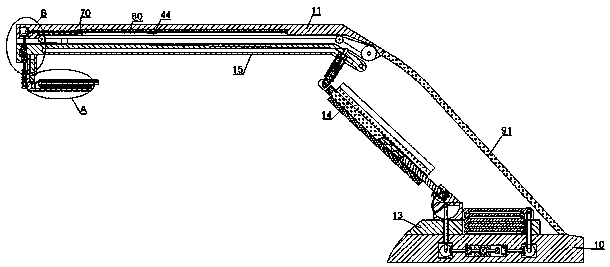

Rubber hose portable laying and collecting coiled pipe device based on garden irrigation

InactiveCN111634759AReduce dosageEliminates the hassle of manual cleaningWatering devicesCleaning using toolsElectric machineryContactor

The invention discloses a rubber hose portable laying and collecting pipe coiling device based on garden irrigation. The device comprises a chassis, positioning clamping rods, a rotating shaft gear and a positioning insertion frame, wherein the chassis comprises a vertical support mounting block and two vertical support rotating shafts; four wheels are rotationally mounted at the bottom of the chassis through a front wheel shaft and a rear wheel shaft, a square groove is formed in the middle of the front half section of the chassis in a penetrating manner, and the vertical support mounting block is fixedly welded in the square groove; and a pushing frame is welded to the top end of the rear side of the chassis in a supporting mode, pressing switches are fixedly mounted at the top ends of aleft vertical support rod and a right vertical support rod of the pushing frame, and the two pressing switches are electrically connected with two contactors inside a control electric box and used for controlling starting and stopping of a motor. According to the portable rubber hose laying and collecting pipe coiling device based on garden irrigation, vertical support brush wires at the bottomsof the two vertical support rotating shafts can rotate to wipe soil falling on the top surface of the vertical support mounting block, so that the plug accumulation of the soil at the top end of the vertical support mounting block is avoided, and then the problem that a rubber hose cannot pass smoothly is solved.

Owner:林景生

Rolling machine

InactiveCN102671935AEliminates the hassle of manual cleaningImprove rolling efficiencyRolling equipment maintainenceMetal rolling arrangementsStructural engineeringMachine

The invention discloses a rolling machine, comprising a machine base and a pair of rollers which are arranged on the machine base in parallel up and down and are rotated oppositely, wherein the axial leads of the rollers are arranged horizontally; a rolling channel is formed between a pair of the rollers; the machine base is provided with blades respectively above and below the rolling channel; the cutting edge of each blade is extended along an axial direction of a roller and is clung on the surface of the circumferential direction of a corresponding roller; and therefore, when the rollers are rotated in a rolling procedure, metal filing attached on the rollers are wiped or cleaned by cutting edges of the blades simultaneously so as to avoid trouble of manual cleaning; simultaneously, rolling efficiency is increased.

Owner:苏州中信科技股份有限公司

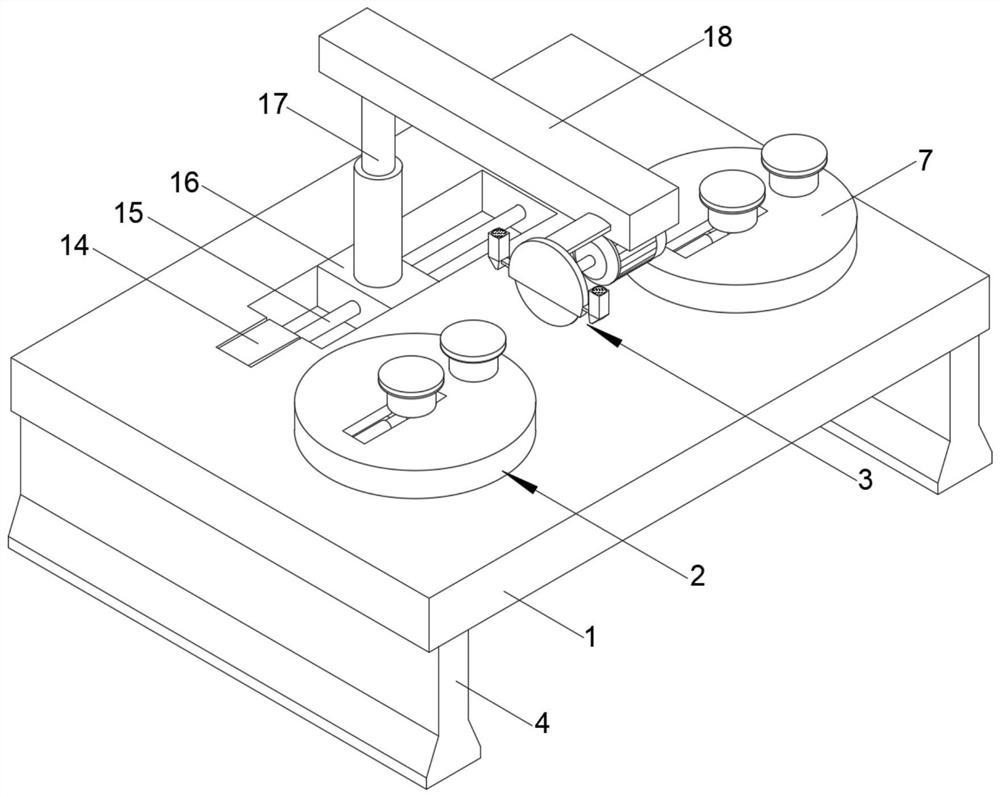

Rapid twisting and cutting equipment for building steel bars

InactiveCN111745088AEasy to operateEliminates the hassle of manual cleaningCleaning using gasesDrive shaftArchitectural engineering

The invention discloses rapid twisting and cutting equipment for building steel bars. The rapid twisting and cutting equipment for the building steel bars includes a supporting plate, two groups of horizontally maintained twisting mechanisms, a cutting mechanism and two groups of supporting feet welded to two sides of the bottom wall of the supporting plate. Each group of twisting mechanisms is composed of first motors welded to the bottom wall of the supporting plate, first transmission shafts penetrating through the supporting plate and coaxially fixedly connected with crankshafts of the first motors and rotating discs welded and fixed to the top ends of the first transmission shafts, a group of accommodating grooves accommodating lead screws and the moving blocks are formed in the top wall of the supporting plate, and the lead screws penetrate through the moving blocks in the horizontal direction. According to the rapid twisting and cutting equipment for the building steel bars, therotating discs, an adjustment groove, an electric push rod and two groups of positioning blocks are arranged, so that the electric push rod is expanded and contracted to drive one group of positioning blocks to move to adjust the distance between the two groups of positioning blocks, the twisting mechanisms can fix the steel bars of different thicknesses, and the two groups of positioning blocksare used for enabling the twisting mechanisms to keep stable when the twisting mechanism fix the steel bars of different thicknesses.

Owner:伍周睿

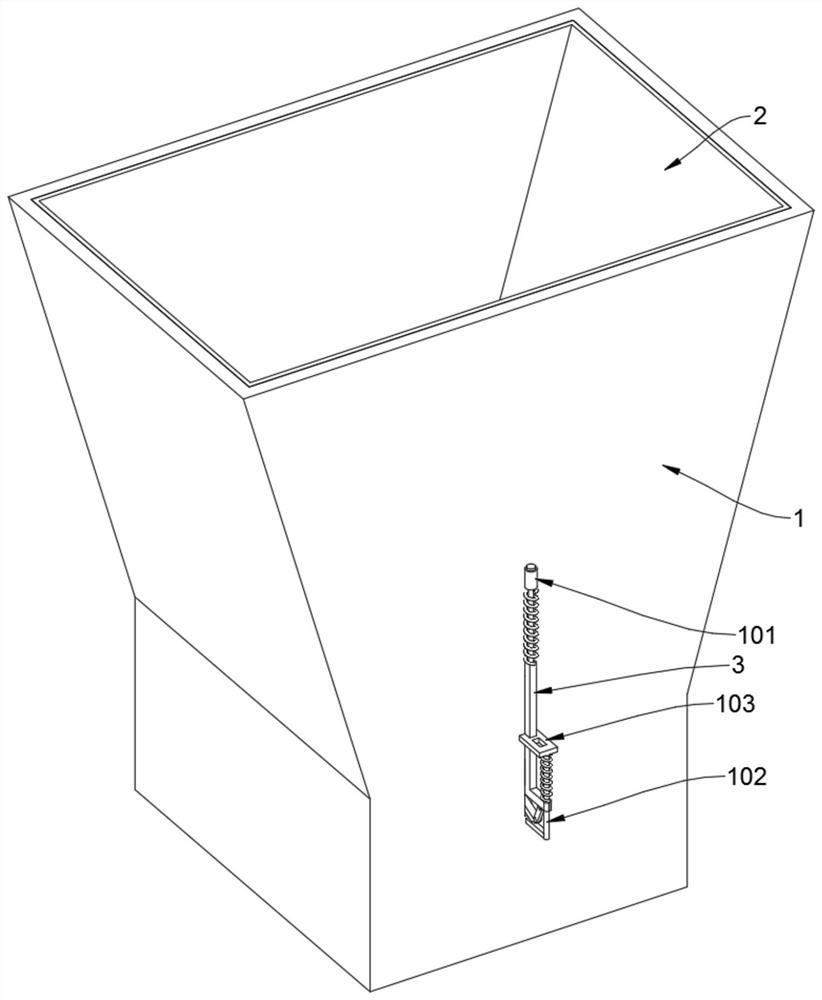

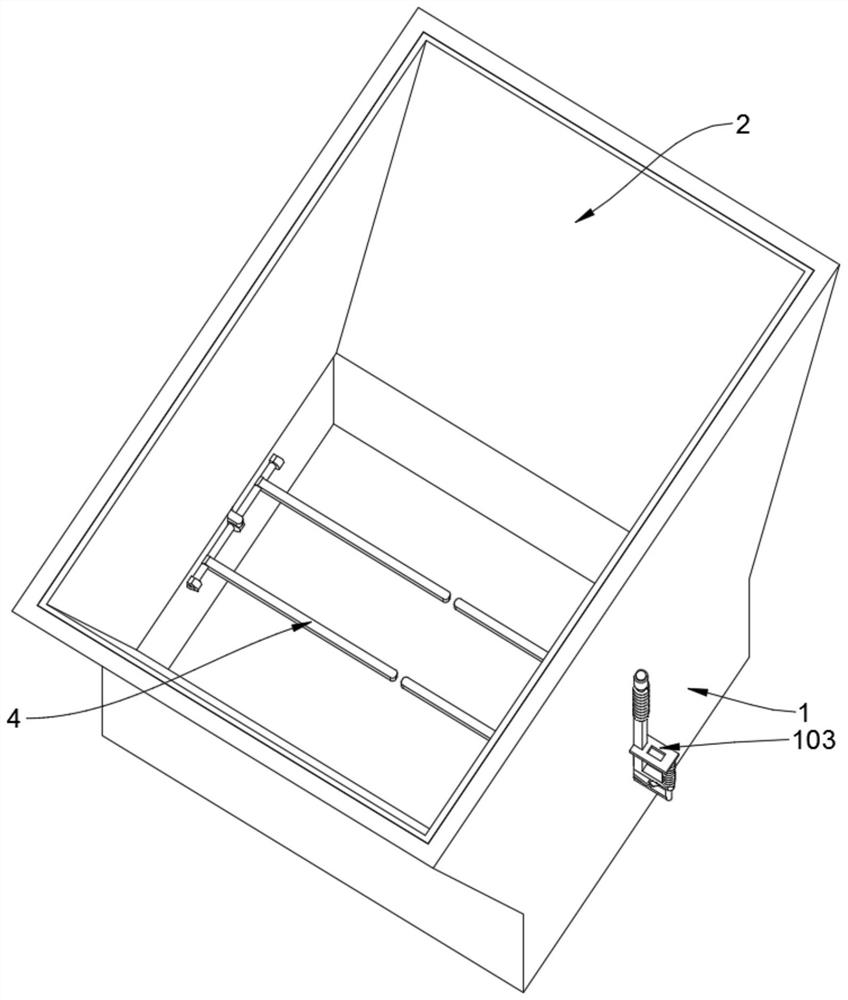

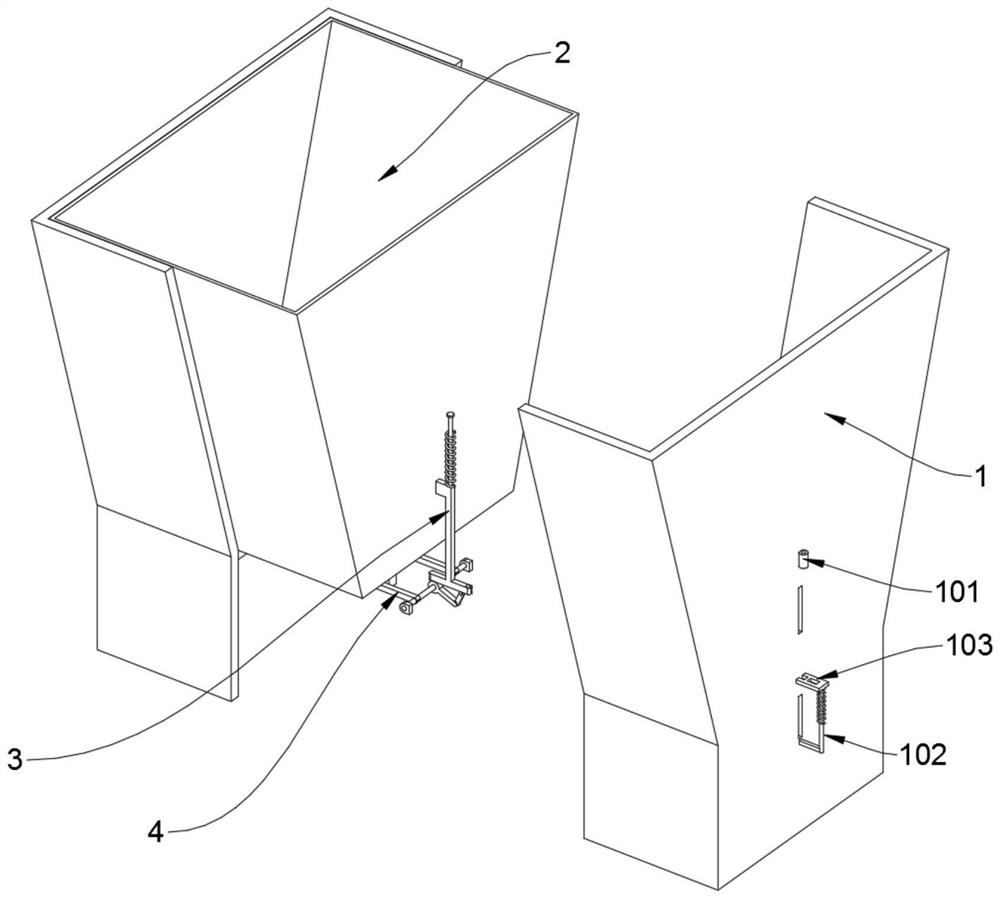

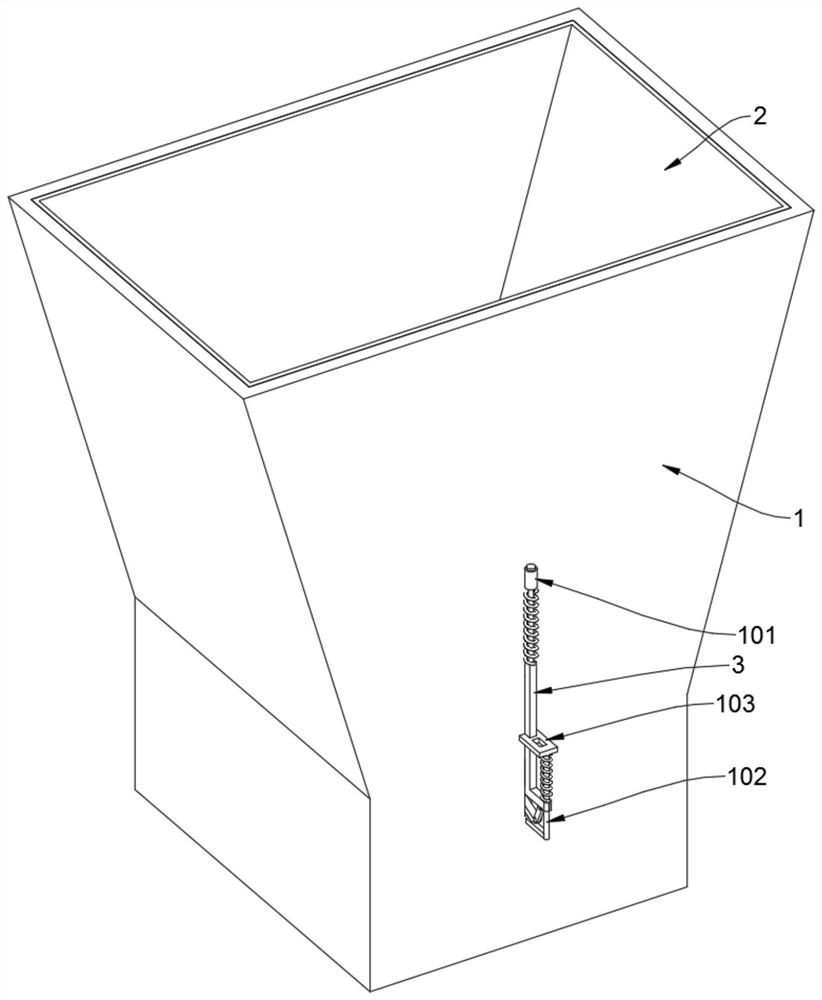

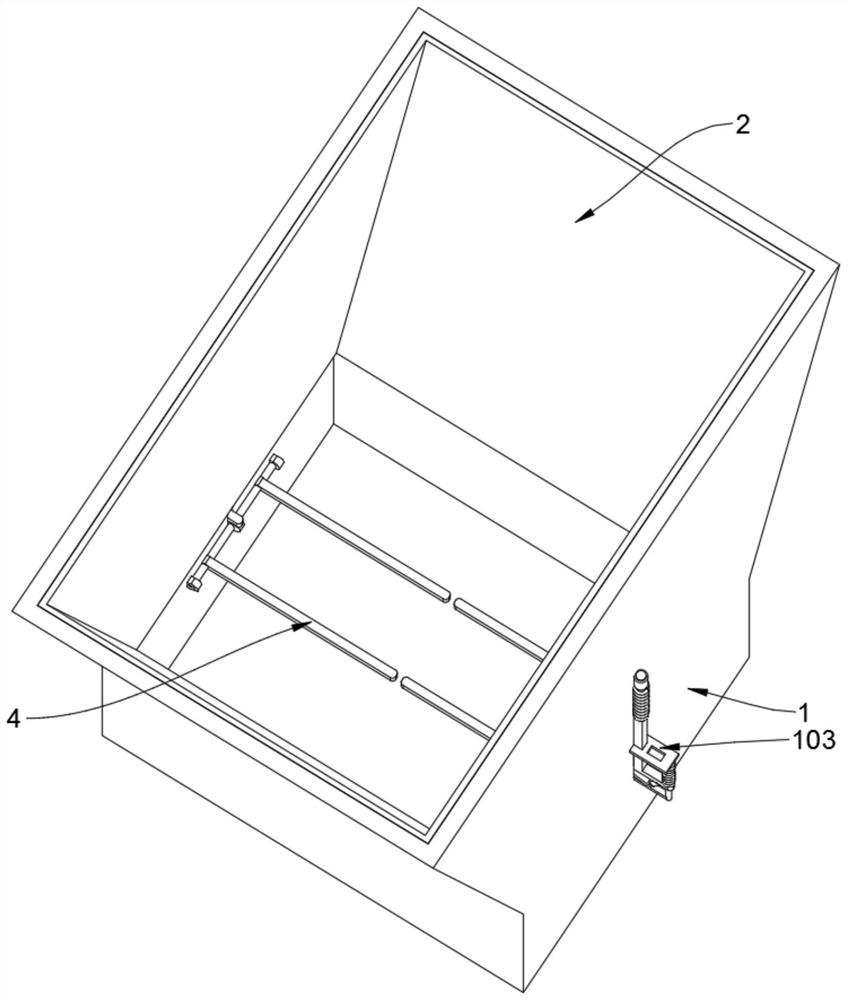

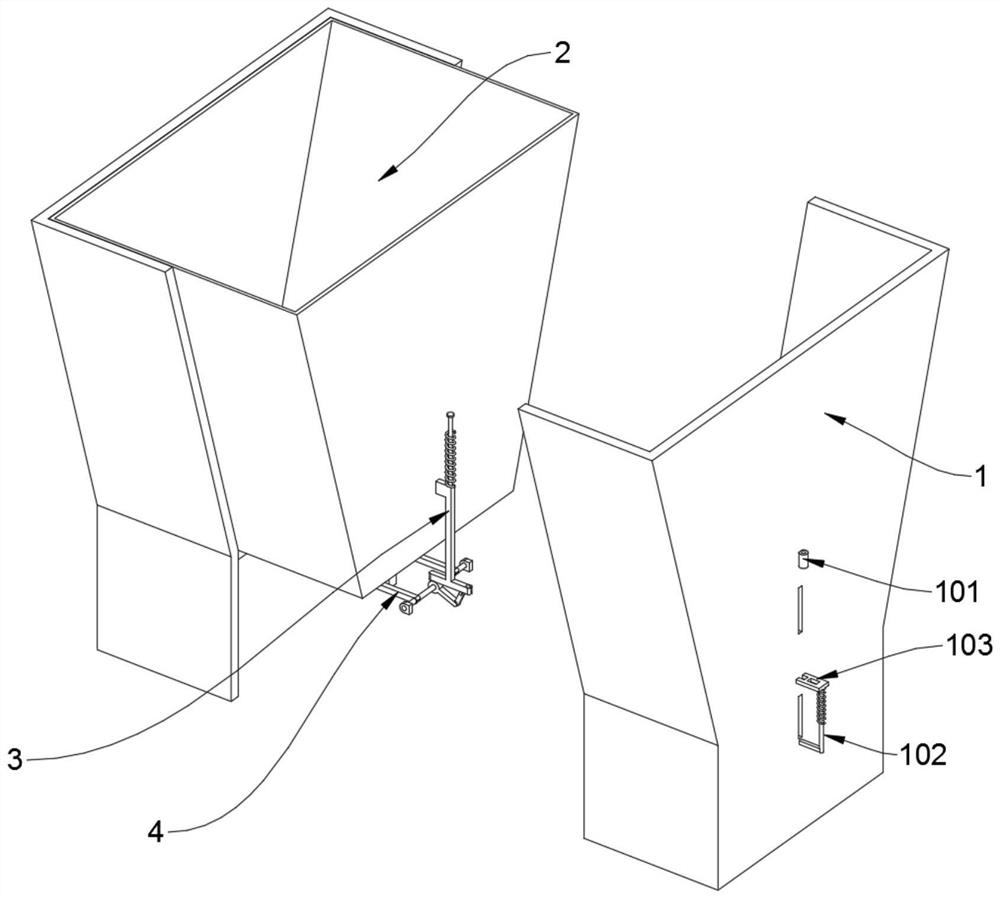

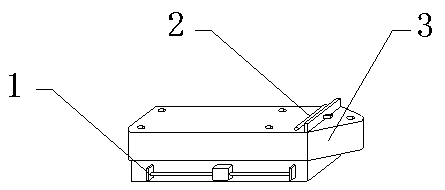

Feed hopper structure capable of avoiding dust accumulation for mining machinery

ActiveCN112896826AGood for vibration removalThoroughly shake outLarge containersGrain treatmentsDust controlStructural engineering

The invention discloses a feed hopper structure capable of avoiding dust accumulation for mining machinery, and relates to the technical field of feed hoppers of mining machinery. The problems that when dust on the inner wall of an existing feed hopper is removed, regular shutdown needs to be performed, production time is occupied, manual cleaning is performed, and cleaning operation is tedious, strenuous and inconvenient are solved. The feed hopper structure capable of avoiding dust accumulation for mining machinery comprises a feed hopper, the feed hopper comprises a positioning sleeve, a vertical supporting positioning shaft and a rectangular positioning block, the whole feed hopper is of a rectangular structure, and the bottom of the feed hopper is communicated with a square discharging barrel in a welded mode; a trapezoidal lining is installed in the feed hopper in a sliding mode, and the trapezoidal lining abuts against the inner wall of the feed hopper in a sealed mode; and two positioning sleeves are symmetrically welded to the middle positions of the left side wall and the right side wall of the feed hopper. According to the feed hopper structure, through power transmission of two stress frames, the trapezoidal lining can be driven to slide up and down by utilizing impact force generated when ores fall off to be discharged, so that a dust removal motor is not required to be additionally arranged for the trapezoidal lining.

Owner:湖北工建绿色材料投资有限公司 +1

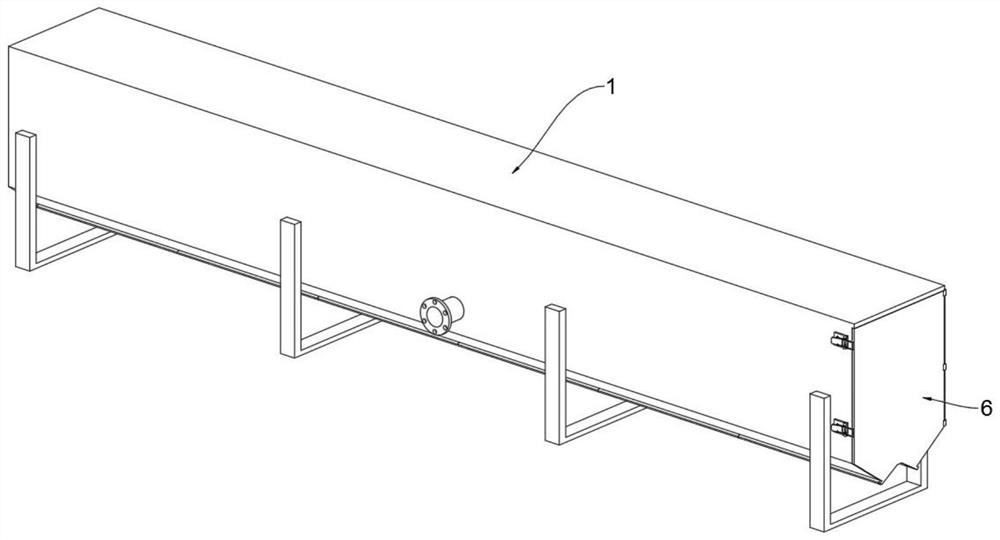

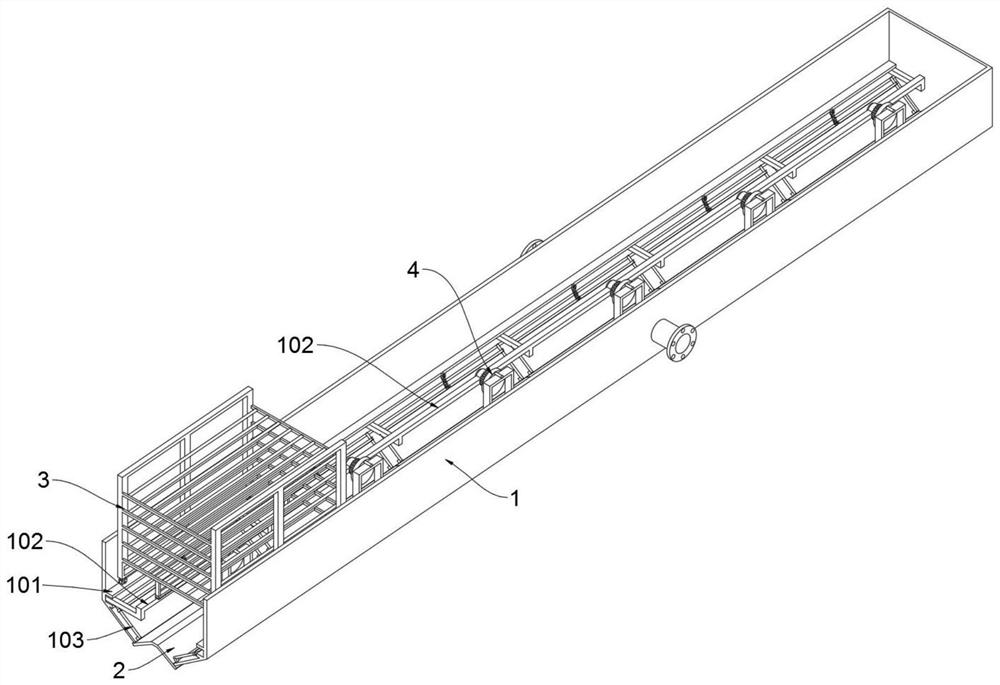

Edible fungus bag sterilization device

ActiveCN111919670AEasy to cleanReduce wasted timeCultivating equipmentsMushroom cultivationProcess engineeringMechanical engineering

The invention discloses an edible fungus bag sterilization device, relates to the technical field of fungus bag sterilization equipment, and solves the problems that existing sterilization devices need to manually brush and clean leaked disintegrating slag on a bottom plate of a sterilization container, the number of manual participation steps is large, operation and use are tedious and inconvenient, and the labor intensity of workers is high. The edible fungus bag sterilization device comprises a sterilization box, the sterilization box comprises a supporting strip plate, a middle supportingrod and an inclined positioning shaft, the sterilization box is of a long-strip-shaped rectangular structure as a whole, the bottom of the sterilization box is obliquely gathered towards the inner side, and a box door covers an opening in the front end of the sterilization box in a rotating mode; and six V-shaped sealing baffles are arranged on a water leakage opening between two inclined bottom plates at the bottom of the sterilization box in a blocking and covering mode. The V-shaped sealing baffles can be in impact contact with the bottom plates of the sterilization box in the up-and-down reciprocating sliding process, so that shred residues and dust accumulated on the V-shaped sealing baffles can be vibrated to fall off, and the cleaning effect of the V-shaped sealing baffles is better.

Owner:东平亿顺菌业科技有限公司

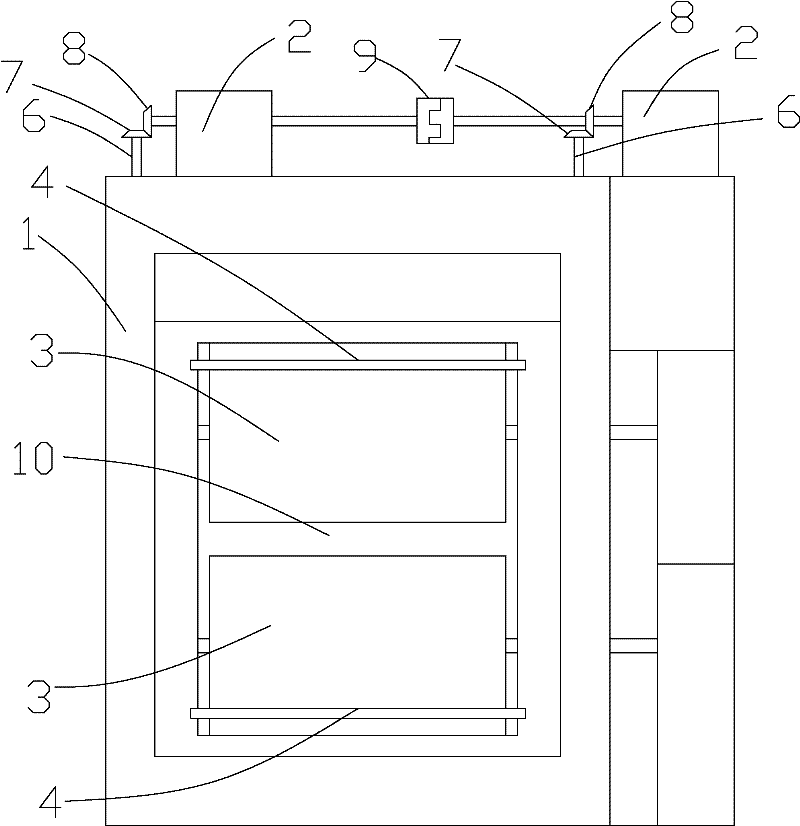

Vehicle-mounted multifunctional display screen based on data transmission

InactiveCN111422144AEliminates the hassle of manual cleaningSimple structurePhotovoltaic supportsBatteries circuit arrangementsIn vehicleEngineering

The invention discloses a vehicle-mounted multifunctional display screen based on data transmission. The display screen includes a base and a top plate, wherein the top plate is located on the upper left side of the base; obliquely designed light-transmitting glass is mounted between the base and the top plate; the inclination degree of the light-transmitting glass is kept consistent with that ofa front windshield of the automobile so that the top plate and the base can be conveniently mounted in the automobile; two guide rails which are symmetrical front and back are fixedly arranged on thebottom surface of the top plate; guide sliding grooves are formed in the guide rails. The display screen can slide from the front row to the rear row, a charging panel can be inserted into a chargingblock to be charged, meanwhile, a solar panel can be unfolded to generate power through solar energy when no person is in the vehicle, clean energy is used, the environment is protected, the display screen can be automatically cleaned at regular time through a brush, and the trouble of manual cleaning is omitted.

Owner:王柳兵

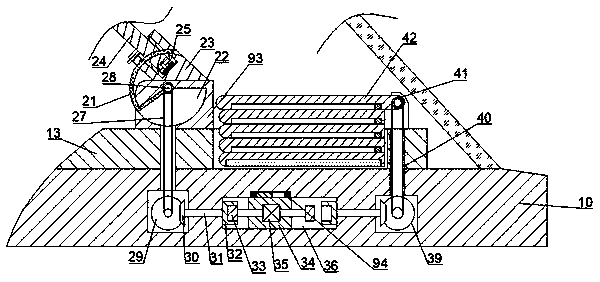

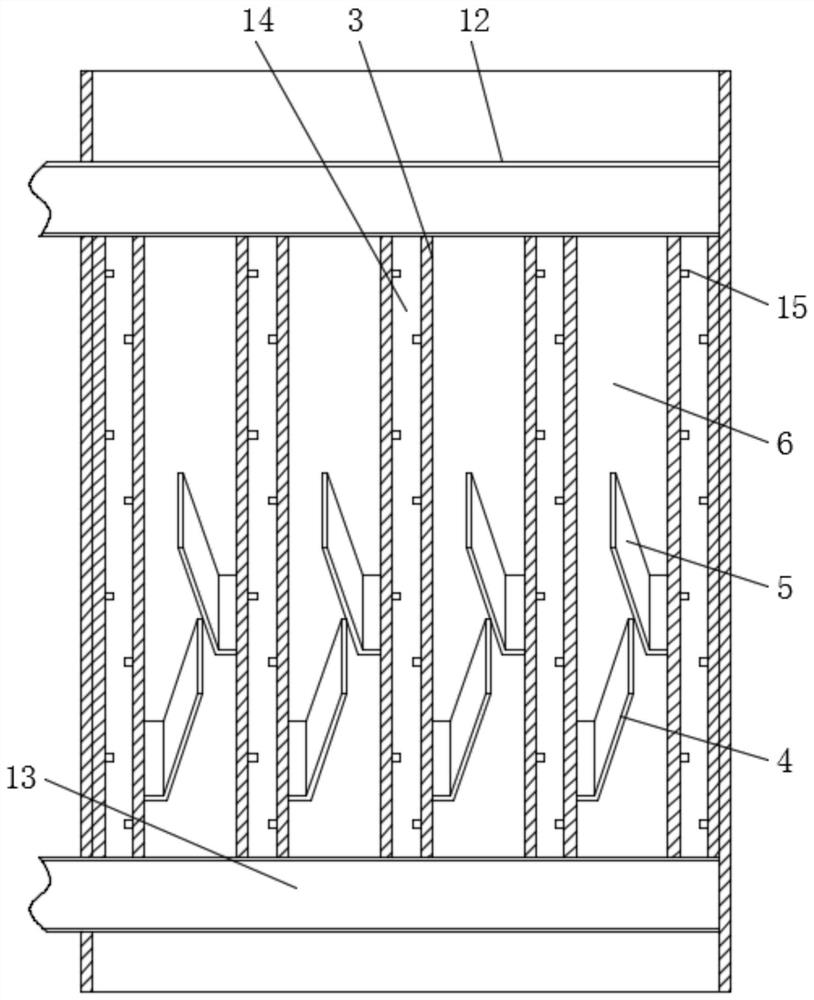

Pulverized coal and coal cinder cleaning device for coal feeding port of coking furnace, and using method thereof

ActiveCN113477007AImplement clean collectionSimple structureCombination devicesDispersed particle filtrationThermodynamicsDust control

The invention discloses a pulverized coal and coal cinder cleaning device for a coal feeding port of a coking furnace, and a using method thereof, and belongs to the technical field of coking furnaces. The pulverized coal and coal cinder cleaning device comprises a square cylinder, a dust removal net is fixedly mounted at the top of the square cylinder, a plurality of first fixing plates are fixedly mounted in the square cylinder, and a first material receiving inclined plate and a second material receiving inclined plate are fixed to the two opposite side faces of every two adjacent first fixing plates correspondingly. The dust removal net, the first material receiving inclined plate and the second material receiving inclined plate are arranged, and the maximum distance between the first material receiving inclined plate and first fixing plates and the maximum distance between the second material receiving inclined plate and the first fixing plates are controlled to be larger than half of the distance between every two adjacent first fixing plates. Therefore, pulverized coal cinder entering the tops of the first material receiving inclined plate and the second material receiving inclined plate along with hot air can completely fall onto the first material receiving inclined plate and the second material receiving inclined plate, cleaning and collecting of the pulverized coal cinder are achieved through the simple structure, the structure is simple, the use and maintenance cost is low, and practicability is high.

Owner:安徽紫朔环境工程技术有限公司

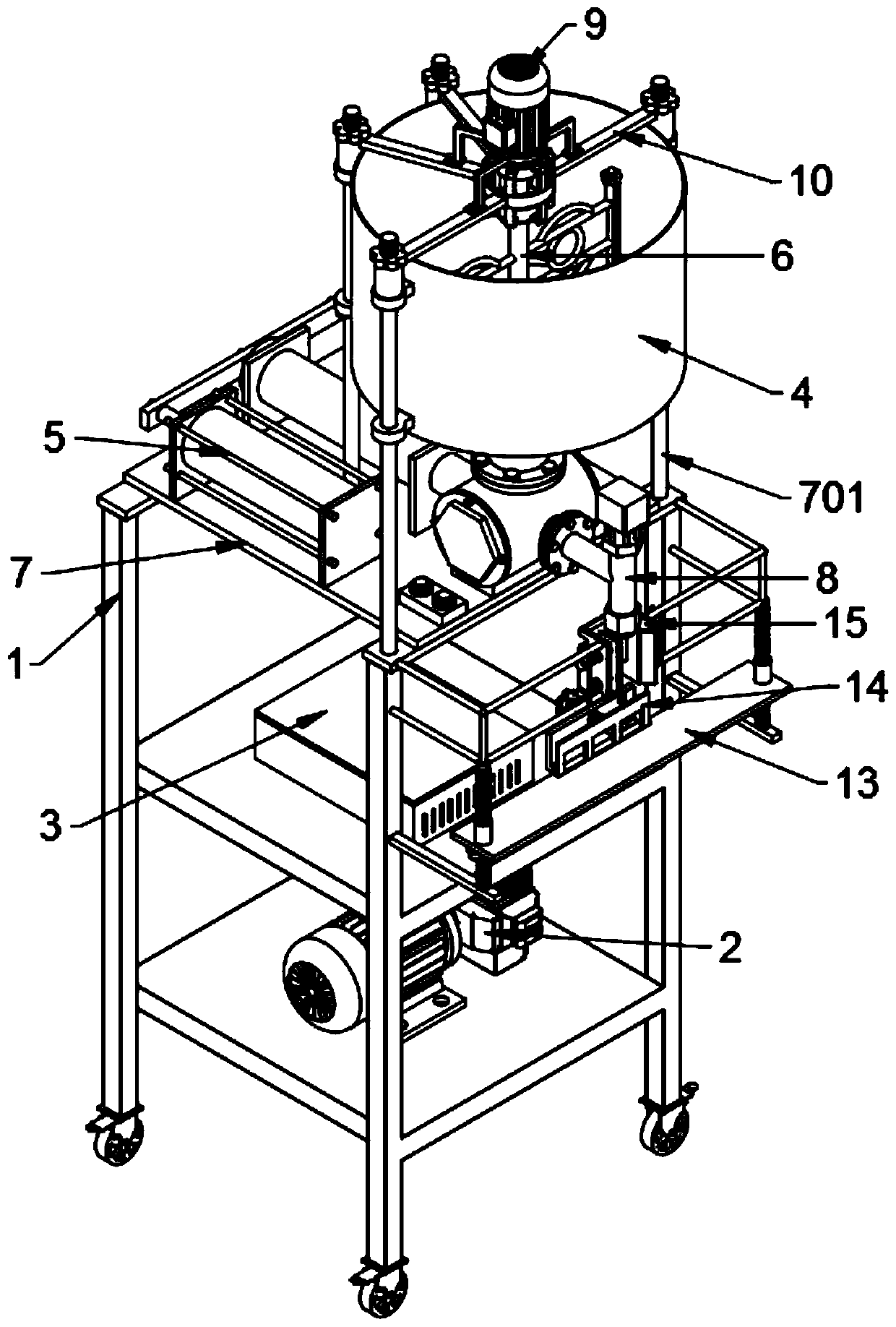

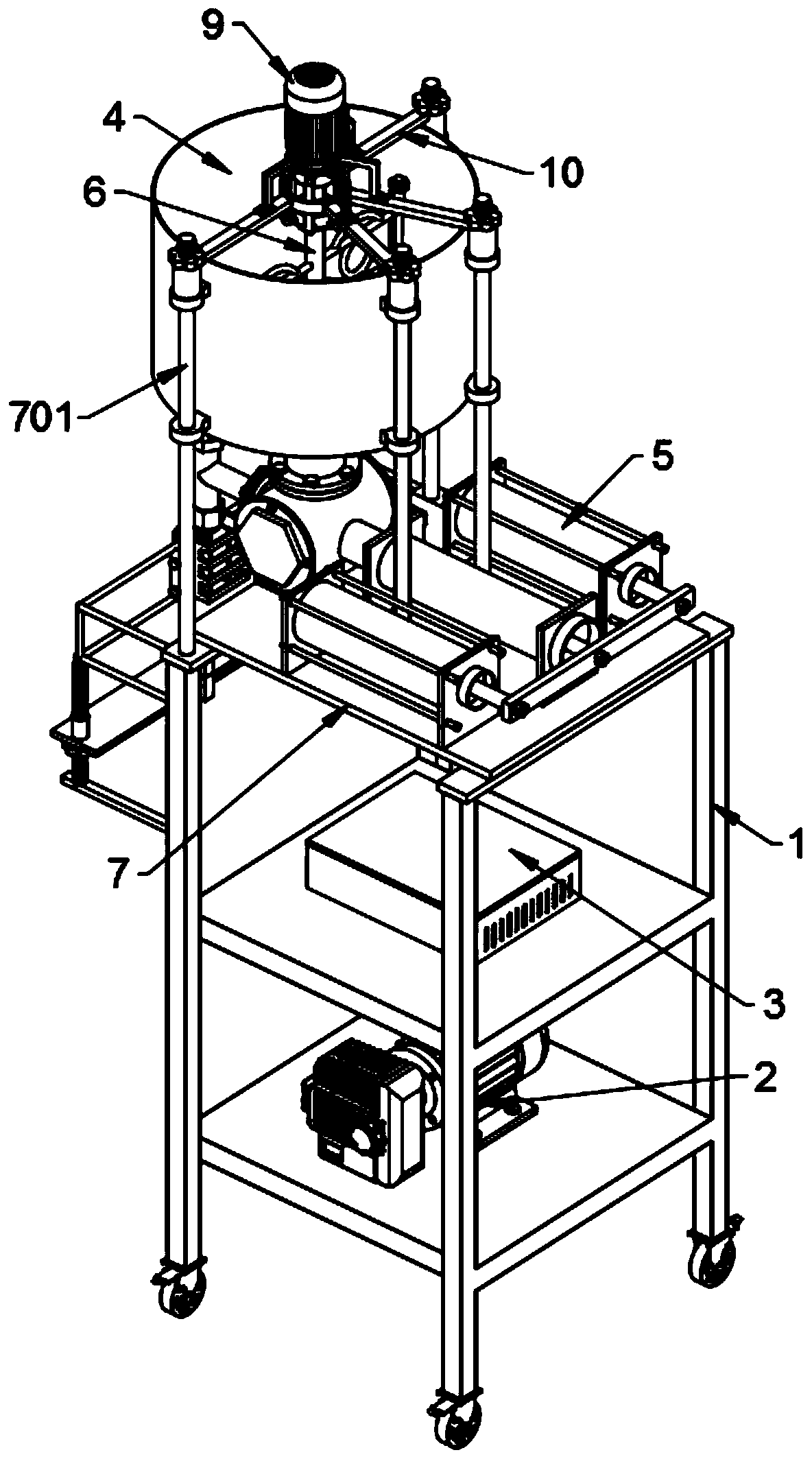

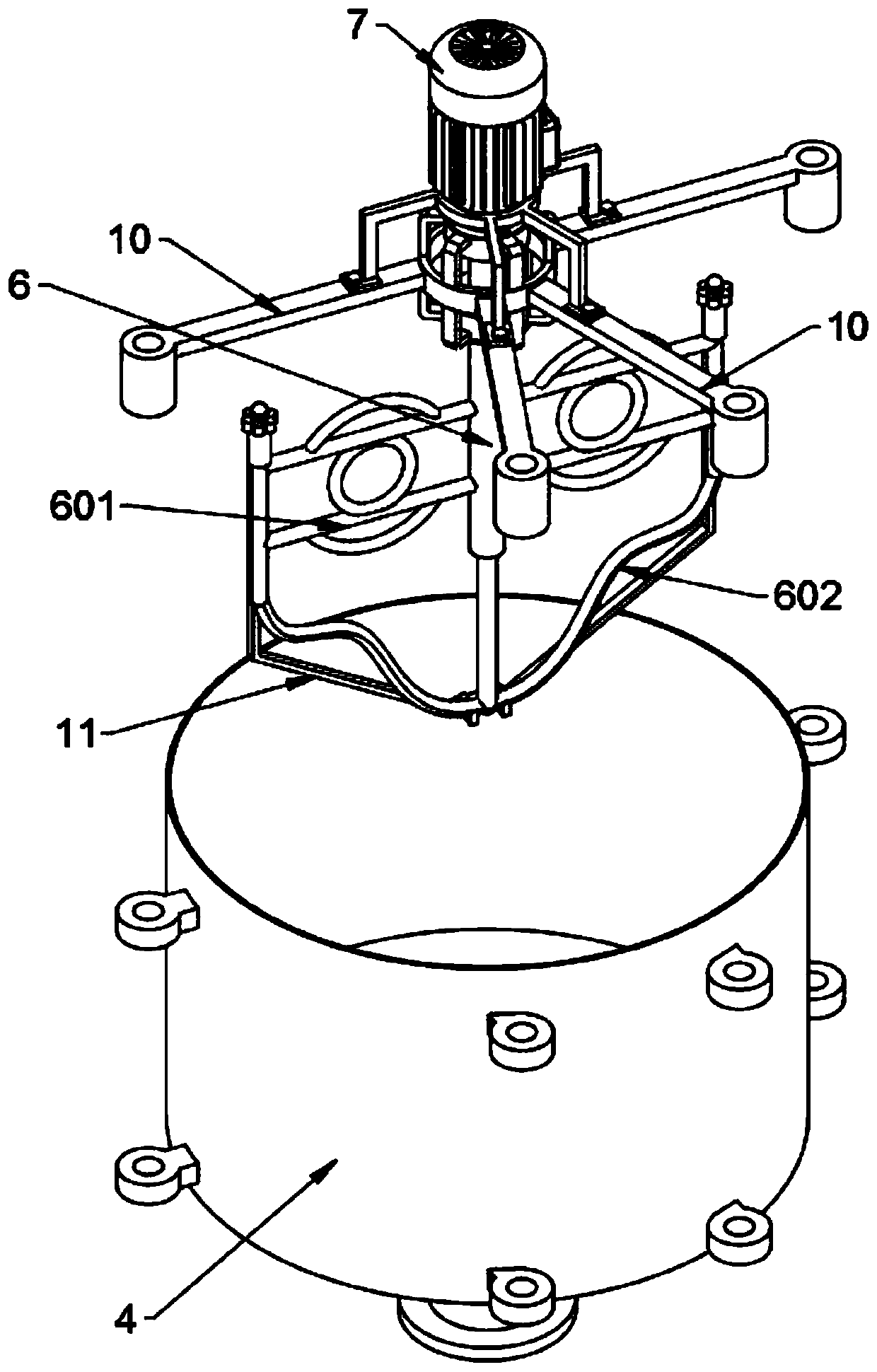

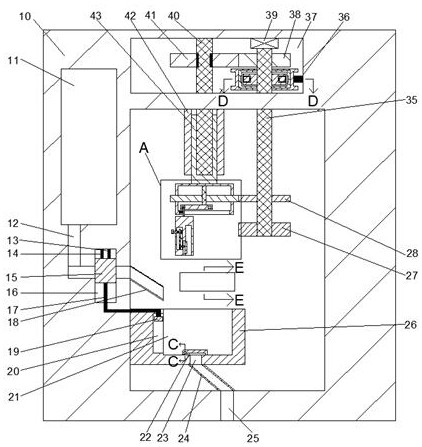

Powder stirring device with higher stirring uniformity

InactiveCN109420449AStir wellGuaranteed clean flowRotary stirring mixersTransportation and packagingEngineeringDuring feed

The invention discloses a powder stirring device with higher stirring uniformity. The powder stirring device is characterized by comprising a stirring device body, a feeding inlet, a discharging outlet, inclined plates, round holes, a motor, a rotating shaft, a brush, stirring rods, stirring cages and a feed-blocking value, wherein the top part of the stirring device body is provided with the feeding inlet; the bottom part of the stirring device body is provided with the discharging outlet; the middle position of the interior of the stirring device body is provided with the rotating shaft; thetop part of the rotating shaft is provided with the brush; the part, located at the exterior of the stirring device body, of the rotating shaft is connected with the motor; the stirring rods with a number of N which is no less than 10 are arranged at two sides of the rotating shaft in an intersected manner; the top part of each stirring rod is provided with a stirring cage; and the position of the discharging outlet is provided with the feed-blocking valve. The powder stirring device provided by the invention has the following advantages: powder is uniformly scattered in the stirring device body during feeding; the stirring effect of the powder is more uniform; the trouble of manual cleaning is avoided; no waste of resources is caused; complete discharging of the powder in the stirring device body can be guaranteed; and no influence on stirring for the next time is caused by residues.

Owner:TIANJIN SHENGXINLONG POWDER PAINT

A river sewage treatment device

ActiveCN109081516BEasy to operateEasy to useTreatment involving filtrationTreatment with aerobic and anaerobic processesTap waterSewage

The invention discloses a river sewage treatment device, which comprises three parts: a drive box, a purification box and a filter box. One side of the drive box is provided with a purification box. The top of the bucket is provided with a backwash pipe, and the top of the side wall on one side of the filter bucket is provided with a clean water outlet pipe. The inside of the filter bucket is provided with a first-stage filter layer, a second-stage filter layer, and a third-stage filter layer from bottom to top. layer, the first filter layer, the second filter layer and the bottom of the third filter layer will have sundries. Due to the difference in pore size, the sundries cannot pass through the filter layer upwards. The washing pipe enters the filter barrel, washes away the sundries between the filter layers, and discharges them from the backwash sewage pipe at the bottom of the filter barrel, eliminating the trouble of manual cleaning, filtering according to physical principles, non-toxic and harmless, and improving the sewage of the equipment Improve processing efficiency and reduce labor intensity of workers.

Owner:缙云县智禾环保科技有限公司

Medical vibrissa removing device

PendingCN113910309AImprove removal efficiencyGuaranteed to workMetal working apparatusEngineeringMechanical engineering

The invention provides a medical vibrissa removing device, and belongs to the technical field of medical equipment. The device comprises a first rod body, a protective cover, a mounting box, a first motor, a second rod body, a suction mechanism and a collection mechanism, a first cavity is formed in the first rod body, the protective cover is arranged on the upper end face of the first rod body, a plurality of through groove holes are formed in the side wall of the protective cover, the mounting box is fixedly arranged in the first cavity, and a first rotating shaft is rotationally arranged on the mounting box; and the upper end of the first rotating shaft extends into the protective cover, a plurality of first blades are arranged at the end of the first rotating shaft in the circumferential direction, the second rod body is coaxially arranged below the first rod body, a second cavity, a channel cavity and a third cavity are sequentially formed in the second rod body from top to bottom, and the suction mechanism is coaxially arranged in the channel cavity. The suction mechanism can suck vibrissae in the first cavity, and the collection mechanism can collect vibrissae in the third cavity. The device can quickly suck away trimmed vibrissa in a nasal cavity, and the vibrissa is prevented from entering a respiratory tract to cause discomfort.

Owner:义乌市中心医院

Liquid leakage prevention type filling device for facial cleanser production

ActiveCN109720615AEasy to wipe cleanEliminates the hassle of manual cleaningLiquid materialCleansers skinEngineering

The invention provides a liquid leakage prevention type filling device for facial cleanser production. The device comprises a pushing-against frame, a positioning frame, a clamping plate and a slidingrod; supporting positions of four motor supporting plates correspond to four supporting shafts, stirring motors are supported and locked on the four motor supporting plates, tail ends of two inclinedstirring rods are each welded with a positioning inserting rod in a supporting manner, when a brush frame is inserted and fixed to two stirring frames by a locking sleeve, two positioning inserting rods are rightly inserted in two inserting holes in a bottom connecting plate of the brush frame, the tail ends of the four motor supporting plates are correspondingly and downwards welded with four supporting shafts in an inserting and sleeving manner and are locked and positioned through four plum blossom nuts. Through the brush frame, through combined inserting mounting use of the brush frame, amaterial tank can be conveniently subjected to wiping cleaning, and manual cleaning troublesome can be avoided.

Owner:浙江海狮医疗技术集团股份有限公司

Brush cleaning and drying equipment

The invention discloses a brush cleaning and drying equipment, comprising a casing, a transmission cavity is arranged on the upper side of the casing, a transmission mechanism is arranged in the transmission cavity, a working cavity is arranged on the lower side of the transmission cavity, and the A cleaning mechanism is arranged in the working chamber, a drying mechanism for wiping the brush after cleaning is arranged in the working chamber, a water exchange mechanism for replacing water is arranged in the working chamber, and a water changing mechanism is arranged in the working chamber. The clamping mechanism for clamping the brush has a simple structure and convenient operation. When the invention is in use, after the brush that needs to be cleaned is put into the designated place, the machine can clean the brush, which saves the need for manual work. The trouble of cleaning makes the user more labor-saving, and it is also faster and more convenient, and the water will be changed and rewashed during the cleaning process, which also makes the machine cleaning cleaner and closer to hand washing. After the cleaning is completed, the machine will automatically It is wiped dry with a paper towel to reduce the manual workload.

Owner:湖州天祺自动化科技有限公司

Mask welding equipment

InactiveCN112721178AStable travelStable steering angleFilament handlingSevering textilesSteering angleGear wheel

The invention discloses mask welding equipment. The mask welding equipment comprises an operation plate and a top plate, wherein the top plate is fixedly mounted above the operation plate through stand columns, a top box is fixedly mounted on the top face of the top plate, a fifth air cylinder is fixedly mounted in front of the front vertical face of the top box, a piston rod of the fifth air cylinder penetrates through the top plate to be connected to a welding head, a first air cylinder is fixedly connected to the top face of the top box in a penetrating mode, a gear column is rotatably connected to the bottom face of the piston rod of the first air cylinder through a first axial rotating base, a connecting shaft is fixedly connected to the bottom face of the gear column, penetrates through the top plate and is slidably connected to the top plate. The mask welding equipment has the beneficial effects that steering of the first finger air cylinder is completed through the second air cylinder, the structure is simple and stable, repairing and maintaining are convenient, the production cost is lower, meanwhile, the stroke of the second air cylinder is stable, the steering angle of the first finger air cylinder is stabler, in addition, the second air cylinder responds rapidly, therefore the rotating speed of the first finger air cylinder is increased, and furthermore, the production efficiency is improved.

Owner:江西企事通医疗器械有限公司

Real stone paint and preparation method thereof

The invention discloses a real stone paint and a preparation method thereof. The real stone paint is prepared from the following raw materials in parts by weight: 80.0-120.0 parts of water, 3.0-17.0 parts of ethylene glycol, 1.0-10.0 parts of a dispersant, 0.2-1.0 part of a wetting agent, 0.2-4.0 parts of cellulose, 0.2-4.0 parts of a PH modifier, 10.0-40.0 parts of silica sol, 30.0-50.0 parts of elastic emulsion, 20.0-90.0 parts of styrene-acrylic emulsion, 40.0-60.0 parts of 20-40mesh natural colored fine sand, 160.0-240.0 parts of 40-80mesh natural colored medium sand, 400.0-480.0 parts of 80-120mesh natural colored coarse sand, 50.0-70.0 parts of color sheets of the real stone paint, 1.0-10.0 parts of coalescing agent, 0.2-4.0 parts of defoamer and 0.2-4.0 parts of a corrosion remover. By adopting the preparation method of the real stone paint, the elastic emulsion and the styrene-acrylic emulsion are matched; the film has the hardness of a surface film and the advantage of interior flexibility of a coating, can resist external damage, can cope with flaws caused by similar wall cracking and substrate construction defects, and is especially applicable to an area with a large temperature difference between day and night.

Owner:西北永新涂料有限公司

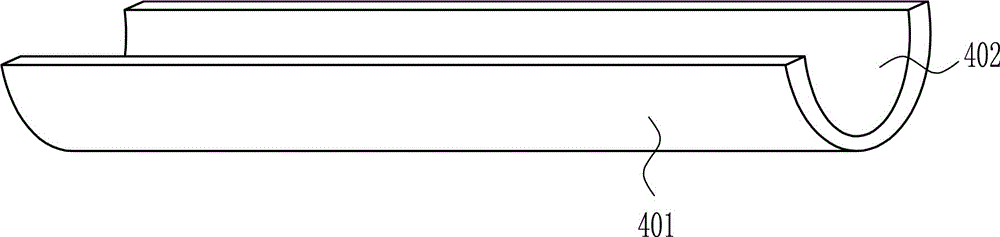

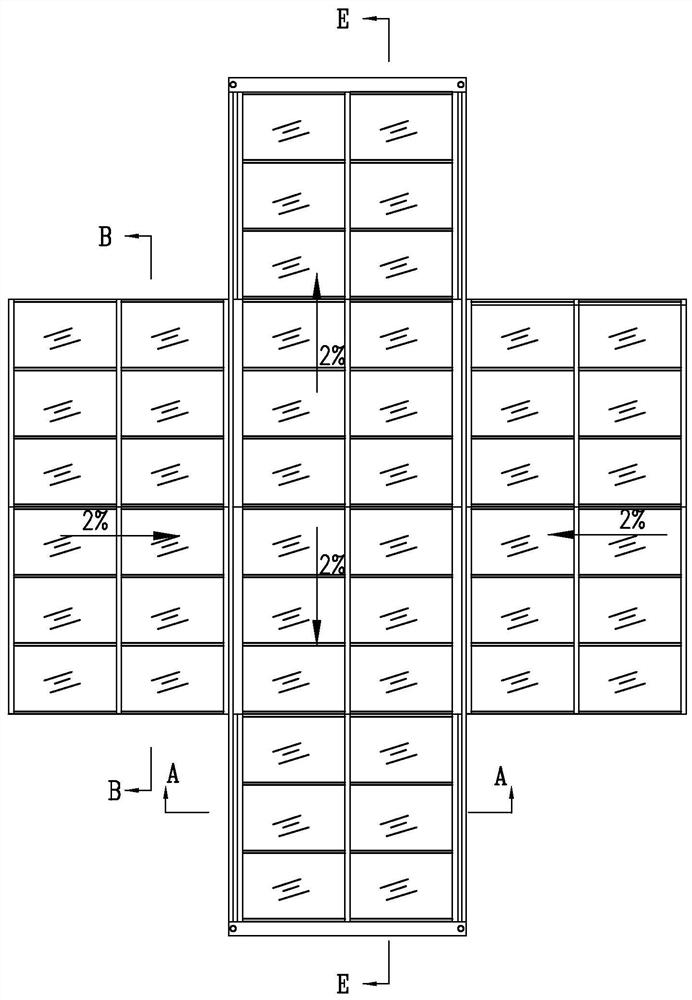

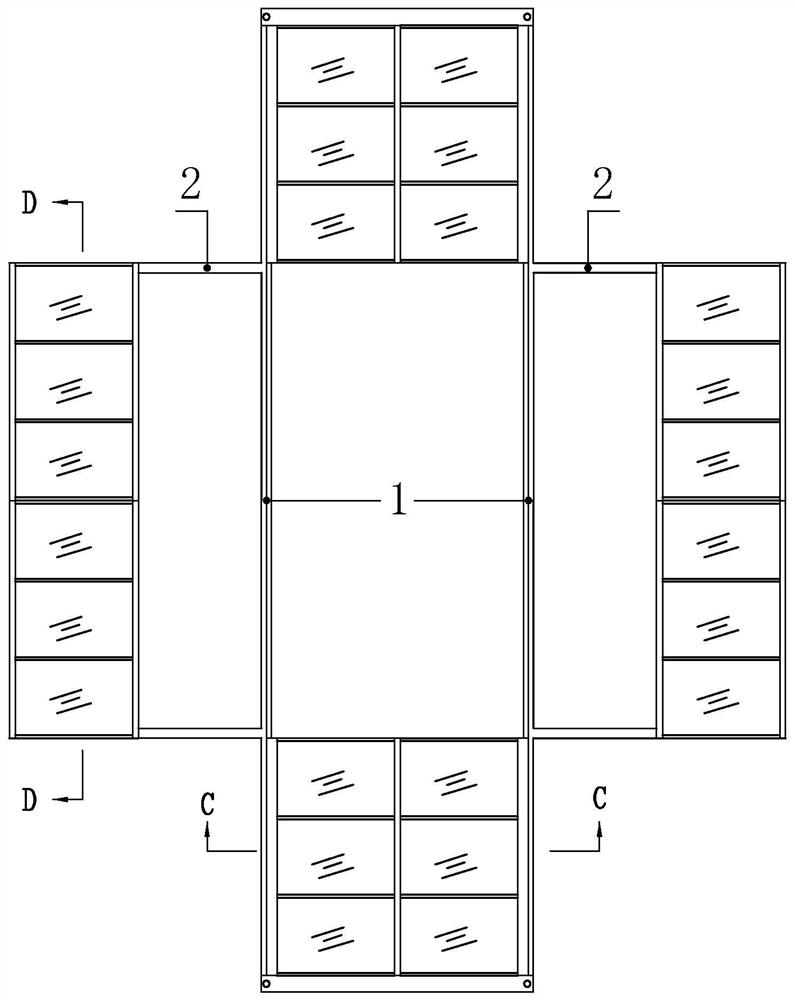

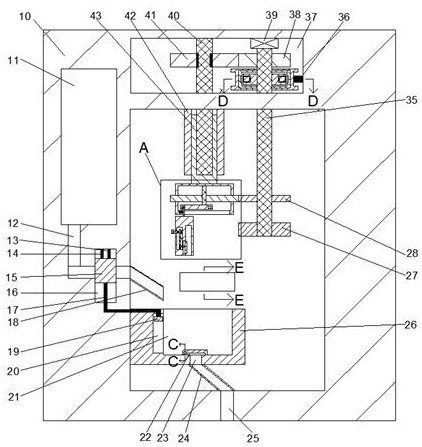

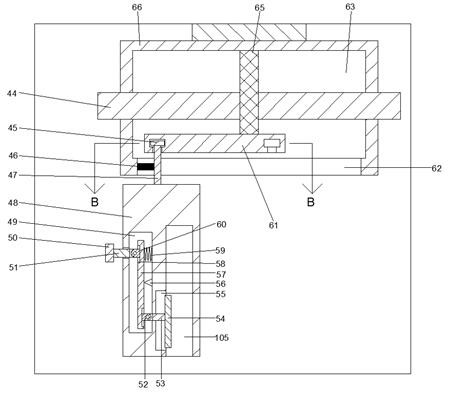

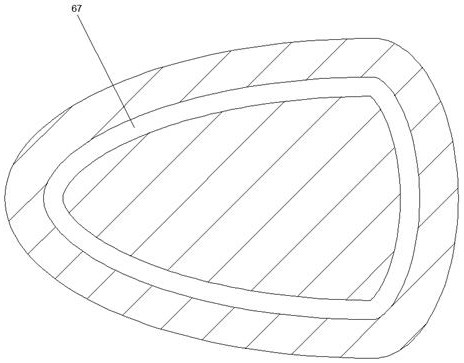

A micro-climate intelligent adjustment system for courtyard public courtyards

ActiveCN111456493BDoes not affect outdoor activitiesRealize self-cleaningBuilding roofsRoof drainageSnow removalStructural engineering

The invention relates to a micro-climate intelligent adjustment system of a courtyard public courtyard, which relates to the technical field of courtyard buildings. The invention solves the problem that ventilation cannot be realized in the existing enclosed ceiling for the public courtyard of a compound courtyard, and relying on manual snow removal has the problems of low snow removal efficiency, time-consuming and laborious work, and potential safety hazards. The ceilings in the middle of the two courtyards of the present invention are arranged opposite to each other along the length direction of the public courtyard of the courtyard. When the ceiling in the middle of the courtyard is in a ventilated state, the movable module in the middle of the courtyard slides outward to the upper part of the fixed module in the middle of the courtyard, and the ceilings in the two courtyards are arranged symmetrically. On both sides of the ceiling in the middle of the two courtyards, when the ceiling at the edge of the courtyard is in a ventilated state, the movable module at the edge of the courtyard slides outward to the lower part of the fixed module at the edge of the courtyard, the movable module in the middle of the courtyard, the fixed module in the middle of the courtyard, and the fixed module at the edge of the courtyard Both the movable module and the fixed module at the edge of the courtyard are equipped with snow removal devices. The invention is used to realize the intelligent regulation of the microclimate in the public courtyard of the courtyard.

Owner:HARBIN UNIV OF SCI & TECH

Writing brush cleaning and drying equipment

The invention discloses writing brush cleaning and drying equipment. The writing brush cleaning and drying equipment comprises a machine shell, a transmission cavity is formed in the upper side of themachine shell, a transmission mechanism is arranged in the transmission cavity, a working cavity is formed in the lower side of the transmission cavity, a cleaning mechanism is arranged in the working cavity, a drying mechanism for wiping a cleaned writing brush is arranged in the working cavity, a water replacing mechanism used for replacing water is arranged in the working cavity, and a clamping mechanism for clamping the writing brush is arranged in the working cavity. The writing brush cleaning and drying equipment is simple in structure and convenient to operate, when the writing brush cleaning and drying equipment is used, after the writing brush needing to be cleaned after being used is put into a designated place, the writing brush can be cleaned by the machine, and therefore, thetrouble of manual cleaning is omitted, a user can save more labor and wash more quickly and conveniently, water can be changed for rewashing in the cleaning process, the machine can clean the writingbrush more cleanly and is closer to hand washing, the machine can automatically wipe the writing brush dry with paper towels after cleaning is completed, and the workload of manual labor is reduced.

Owner:湖州天祺自动化科技有限公司

A feed hopper structure for mining machinery to avoid dust accumulation

ActiveCN112896826BGood for vibration removalThoroughly shake outLarge containersGrain treatmentsMining engineeringDust control

The invention discloses a feeding hopper structure for mining machinery that avoids dust accumulation, relates to the technical field of feeding hoppers for mining machinery, and solves the problem that the existing feeding hopper needs to be shut down periodically to clean the dust on the inner wall. Manual cleaning takes up production time, and the cleaning operation is cumbersome, laborious and inconvenient. A feeding hopper structure for mining machinery that avoids dust accumulation, including a feeding hopper, the feeding hopper includes a positioning sleeve, a vertical support positioning shaft and a rectangular positioning block, the entire feeding hopper has a rectangular structure, and its bottom is welded There is a square lower barrel connected, and a trapezoidal lining is slidingly installed inside the feeding hopper, and the trapezoidal lining is sealed against the inner wall of the feeding hopper; the middle position of the left and right side walls of the feeding hopper is symmetrical There are two positioning sleeves for welding. In the present invention, through the power transmission of the two stress frames, the trapezoidal lining can be driven to slide up and down by the impact force when the ore is dropped and unloaded, which saves an additional dust removal motor for the trapezoidal lining.

Owner:湖北工建绿色材料投资有限公司 +1

Automobile engine mounting bracket

ActiveCN109986942AEasy to installEasy to disassembleVehicle cleaningJet propulsion mountingElectric machineryEngineering

The invention provides an automobile engine mounting bracket which comprises a connecting block, a lead screw, a connecting rod, a base, a spring, a guide tube, a miniature motor, a rotating shaft, arack, a circular gear, a cleaning rod and a supporting plate. The connecting block is mounted on the lead screw; the connecting rod is arranged at the rear end of the connecting block, the spring is mounted at the rear end of the connecting rod and is placed at the rear end in the guide tube, and the connecting rod is placed on the guide tube. The automobile engine mounting bracket is convenient to disassemble, the miniature motor is mounted on the rear side of the supporting plate, the rack is arranged on the supporting plate, the circular gear is arranged at the lower end of the rack, a rotating shaft is arranged on the circular gear, the miniature motor is arranged at the rear end of the rotating shaft, a cleaning rod is arranged at the left end of the rack, and the cleaning rod is mounted on the left side of the supporting plate. The automobile engine mounting bracket is convenient to clean, convenient to use and operate, good in stability, high in reliability, convenient to disassemble and convenient to clean.

Owner:CHONGQING YONGCHUAN DISTRICT BANGWEI MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com