Liquid leakage prevention type filling device for facial cleanser production

A filling equipment and anti-leakage liquid technology, applied in packaging, liquid materials, transportation and packaging, etc., can solve problems such as uncentered material leakage, inaccurate manual positioning of the bottle mouth, cumbersome and inconvenient cleaning operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

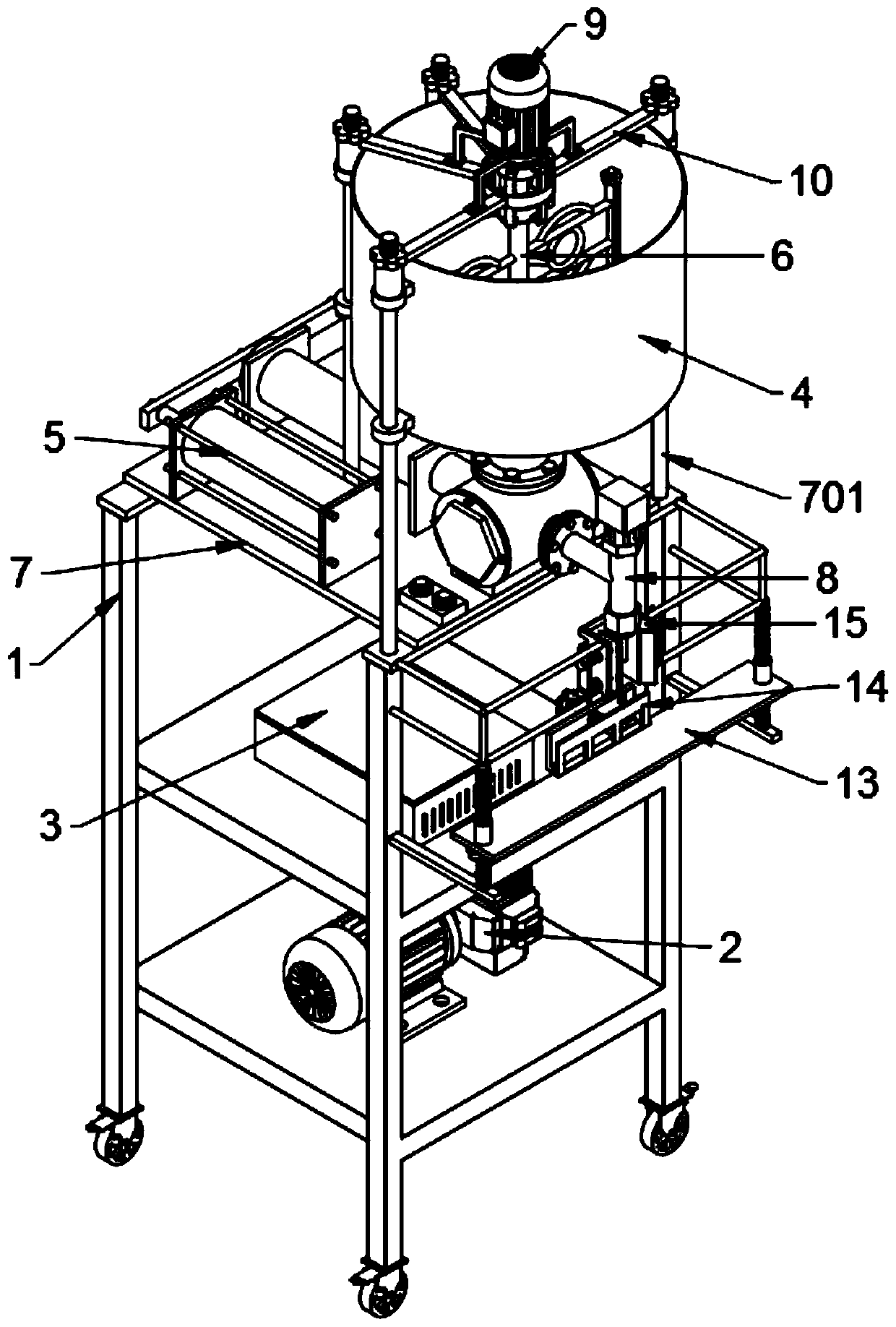

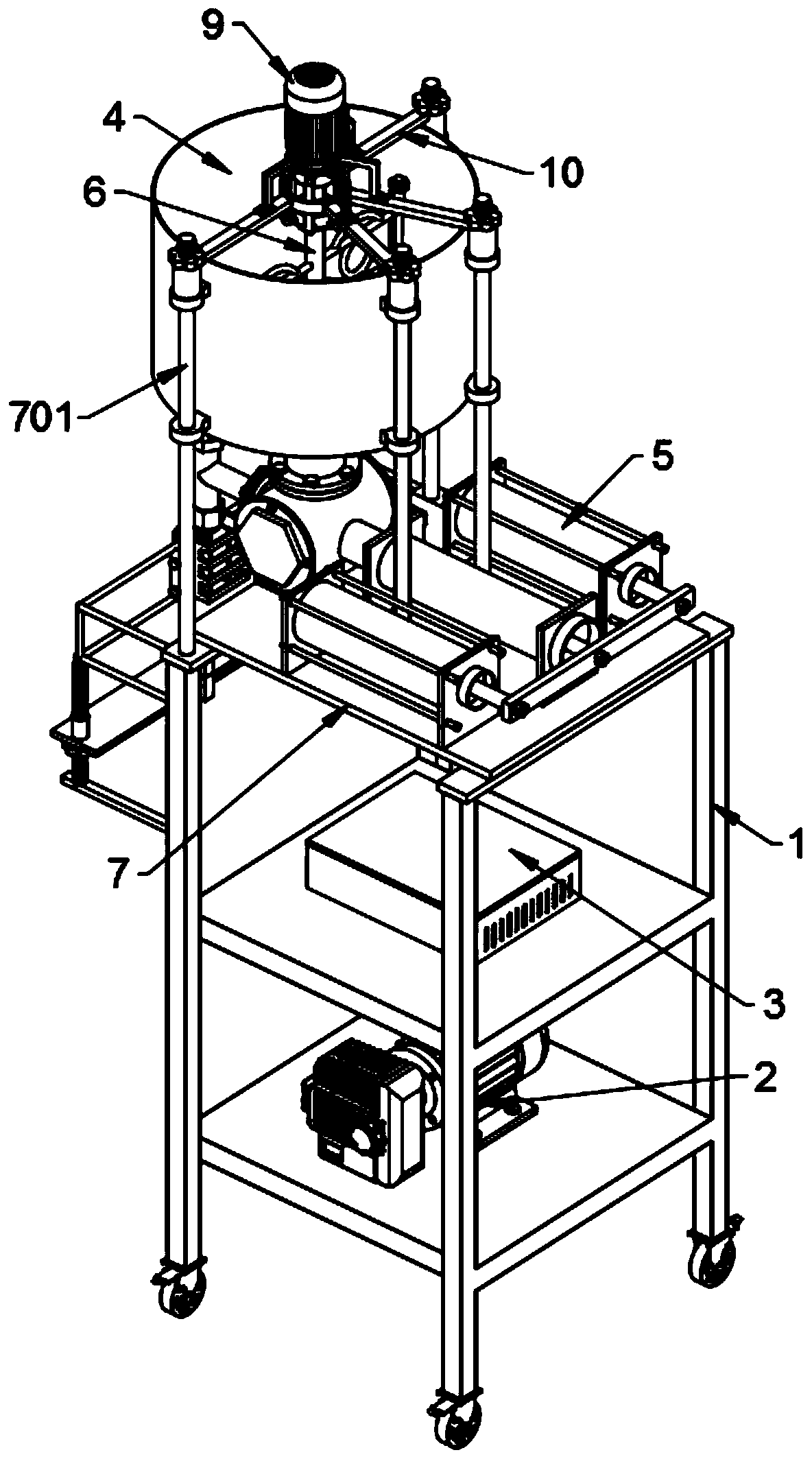

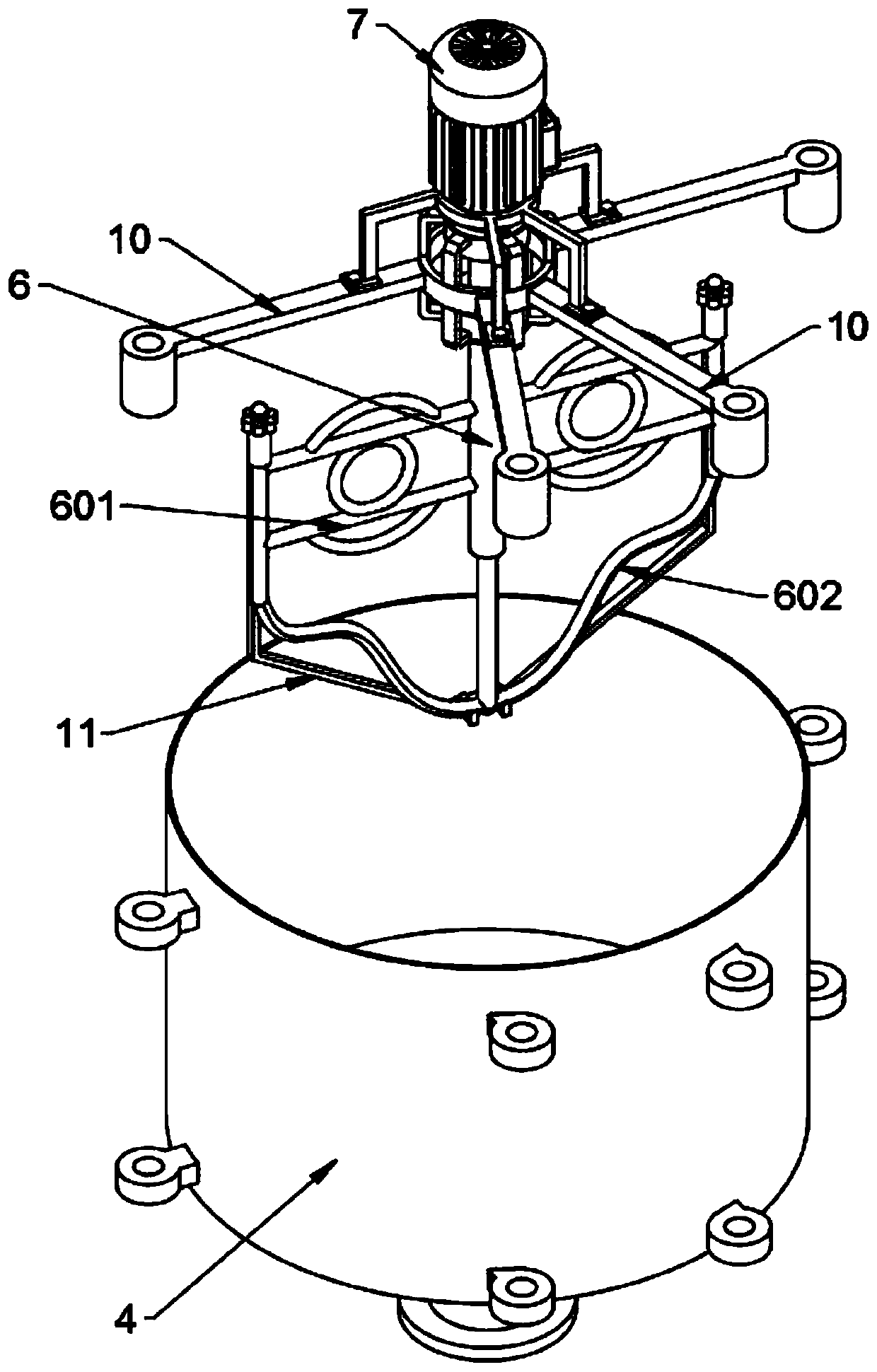

[0031] as attached figure 1 to attach Figure 8 Shown:

[0032]The present invention provides a kind of anti-leakage filling equipment for facial cleanser production. Positioning plunger 603, mounting plate 7, support shaft 701, discharge pipe 8, stirring motor 9, motor support plate 10, brush holder 11, bearing seat 12, support placement plate 13, positioning plate 1301, threaded strut 1302, Abutment frame 14, positioning frame 15, splint 1501, vertical positioning plate 1502 and sliding bar 1503; the top welding support of four support rods 1 has a mounting plate 7, and two installation plates between four support rods 1 An air pump 2 and an electrical box 3 are respectively supported and installed on the top; a caster with a brake is welded on the bottom of the four supporting rods 1; two cylinders 5 are symmetrically supported on the top of the mounting plate 7, and the two A metering cylinder is installed on the plate between the cylinders 5, and the telescopic rods of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com