Patents

Literature

56results about How to "Cracking will not" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

Continuous catalysis cracking method for producing fuel oil from mixed waste plastic

InactiveCN101260309AReduce energy consumptionGood cracking controllabilityLiquid hydrocarbon mixture productionFuel oilDomestic waste

The invention provides a method for successive catalytic pyrolysis of mixed waste plastics to produce burning oil, which relates to a technology to produce the burning oil through pyrolysis of waste plastics. A two-step successive running technology with an integration of catalyzed pyrolysis and pyrolysis catalyzed reforming is adopted, in the technology of pyrolysis in the first step, the successive running of the pyrolysis is accomplished through a fluid tube-type bed technology with an adjuvant transmission device, and a cheap non-toxic catalyst is added to raise the reaction speed of the plastic pyrolysis and decrease the temperature of the pyrolysis; in the second step of refining technology of catalyzed lysis, a fluidized-bed catalyst is adopted to perform the secondary pyrolysis reforming reaction on the cracked gas produced by step one, to increase the percentage of the extract fractions of gasoline and diesel in the liquid fuel produced by pyrolysis. The technology provided by the invention is a wholly concealed successive running procedure with the waste plastics as the raw material without the need of classification, washing or drying, the operation is flexible and the running cost is low, the technology is especially suitable for production of burning oil from mixed waste plastics from urban or suburban garbage with complicated components, the yield rate of the qualified burning oil reaches to more than 66 percent, as calculated on the basis of waste plastics, the technology has observable economic and social benefits.

Owner:TONGJI UNIV

High-flexibility and low-shrinkage fiber reinforced cement-based composite material

The invention belongs to the technical field of building materials, and in particular relates to a high-flexibility and low-shrinkage fiber reinforced cement-based composite material. The composite material is prepared by mixing cement, coal ash, silicon powder, gypsum, an expanding agent, a water reducing agent, a shrinkage reducing agent, a defoaming agent, a thickening agent, fine sand, fibers and water, wherein the total mass percentage of the cement, the coal ash, the silicon powder, the gypsum, the expanding agent, the water reducing agent, the shrinkage reducing agent, the defoaming agent, the thickening agent, the fine sand and the fibers is 77-85 percent, and the mass percentage of the water is 15-23 percent. The fiber reinforced cement-based composite material has the performance characteristics of low shrinkage, high flexibility, small crack width, quickness in condensation and early strength and is high in compressive strength and good in synergism with other materials.

Owner:TSINGHUA UNIV

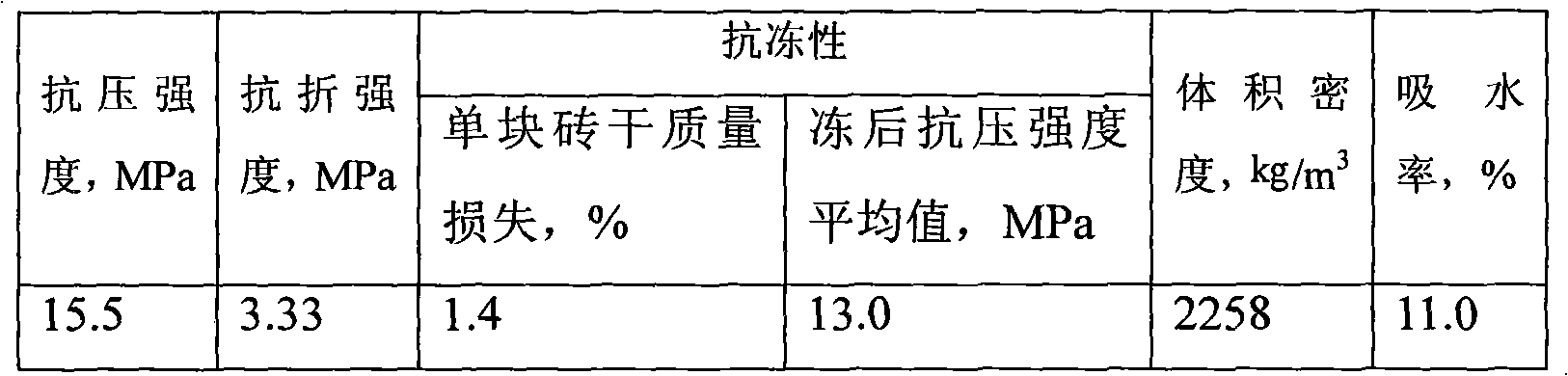

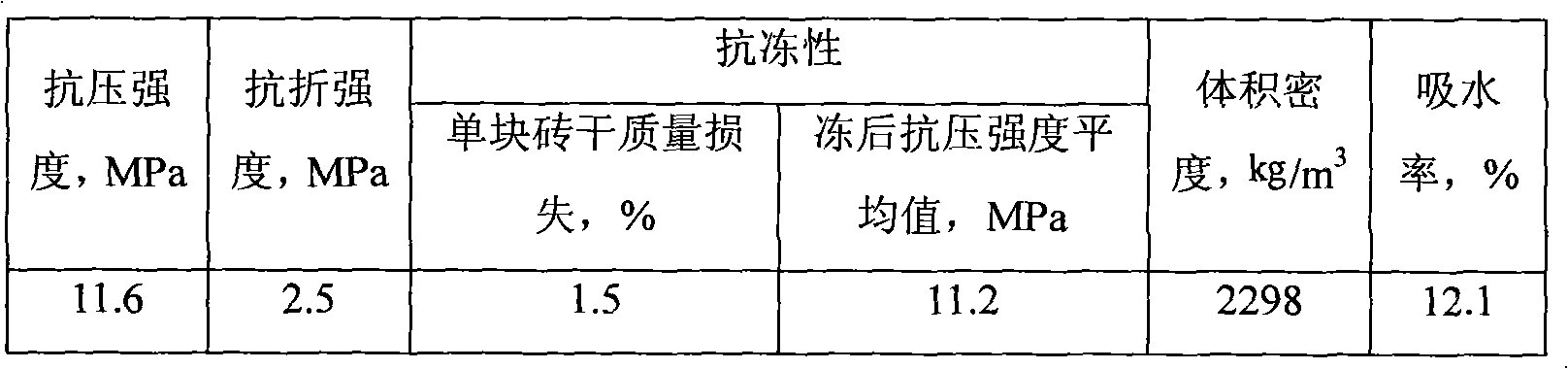

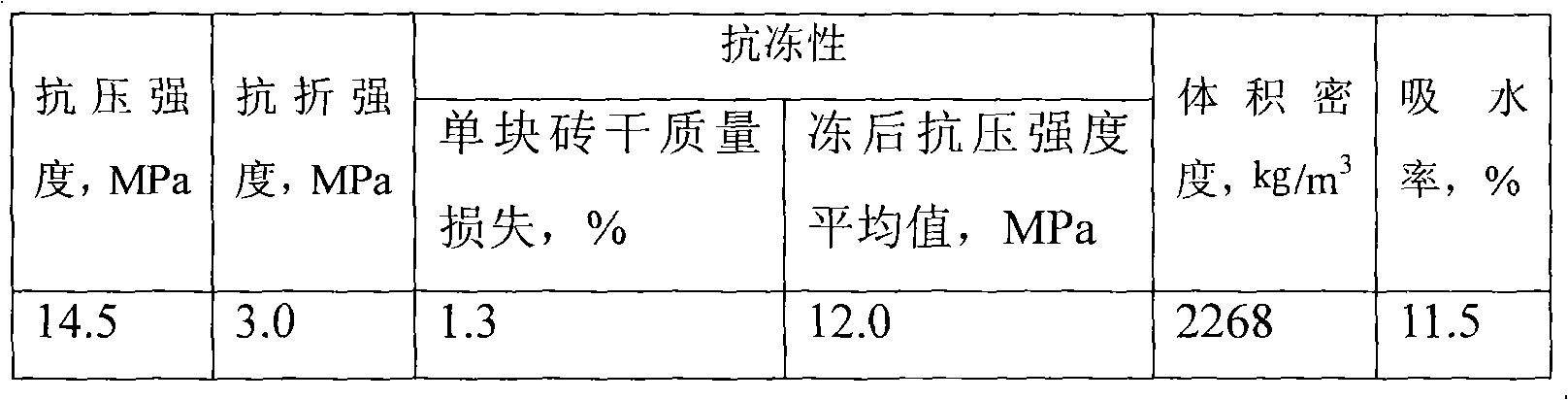

Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

ActiveCN101927524AReduce free calcium oxide contentLow iron contentSolid waste managementMixing operation control apparatusBrickSlag

The invention relates to a method for producing baking-free slag bricks by using steel slag sludge of a rotating furnace. The bricks are produced by taking tailings and tailing sludge of the rotating furnace as raw materials, taking slag silicate cement as an auxiliary material, adding a small amount of water into the raw materials and the auxiliary material, stirring the raw materials and the auxiliary material to uniformly mix the raw materials and the auxiliary material, pressing the mixture on a brick press, and naturally curing the pressed mixture. The bricks comprise the following compoennts in part by weight: 20 to 50 parts of tailings of the rotating furnace, 50 to 80 parts of tailing sludge of the rotating furnace and 0 to 5 parts of slag silicate cement. The adding amount of the added water is 0 to 5 percent of the total weight of the raw materials. The baking-free bricks are produced by taking the tailings and the tailing sludge of the rotating furnace as main raw materials, adding a small amount of slag silicate cement and water into the main raw materials, and pressing the mixture. The raw materials do not need to be treated and can be directly used and the mouled product is naturally cured, so that the energy is saved; and no any equipment is added, so that the problem that the tailings of the rotating furnace and the tailing sludge of the rotating furnace occupy space and pollute environment is solved by producing the baking-free slag bricks.

Owner:鞍钢绿色资源科技有限公司

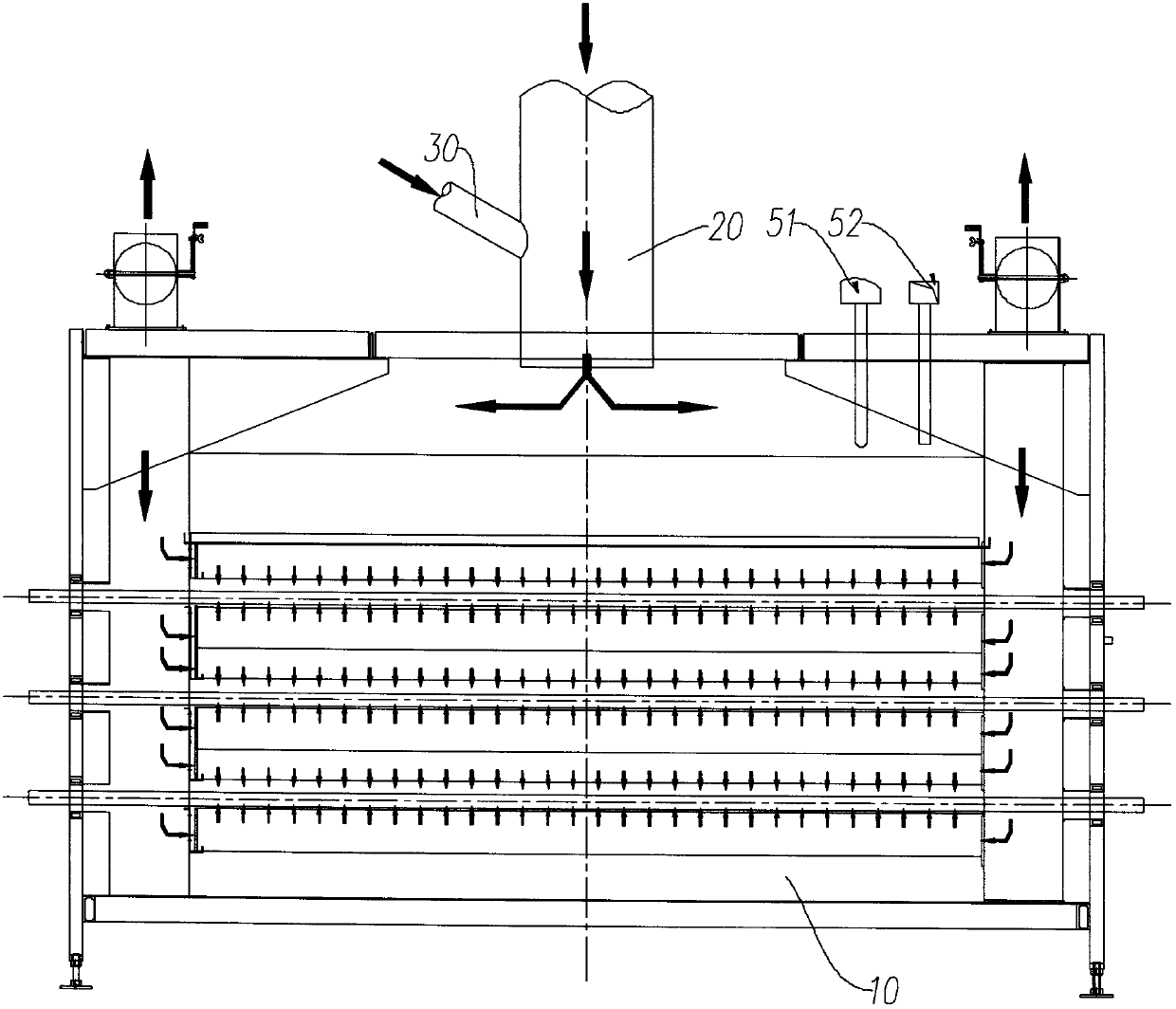

Method for drying ceramic blank and energy-saving rapid drying kiln used in method

ActiveCN103868340AAvoid crackingSmall temperature differenceDrying gas arrangementsMaterials scienceWater vapor

The invention discloses a method for drying ceramic blank. The method comprises the steps of leading a thermal medium to a drying kiln, mixing the thermal medium with steam, and mixing the steam with the thermal medium before the thermal medium enters the drying kiln. After optimization, humidity of the thermal medium is adjustable; and the humidity of the thermal medium is decreased progressively along with the drying degree of the ceramic blank. The invention further discloses the energy-saving rapid drying kiln used in the method.

Owner:GUANGDONG JUMPER THERMAL TECH

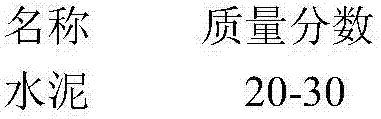

Integrated terrazzo floor and production method thereof

The invention belongs to the field of building construction, and particularly relates to an integrated terrazzo floor and a production method thereof. The production method comprises the steps of uniformly scattering a Yuhua stone aggregate on a primarily solidified concrete base 3-5 h after concrete pouring; and then, carrying out sleeking and levelling. The concrete comprises the following raw materials: cement, waste residues of glass, emery, marble powder, epoxy resin and water, wherein the weight ratio of cement to waste residues of glass to emery to marble powder to epoxy resin to water is 35 to 80 to 75 to 50 to 10 to 17. Construction of the floor is simple, the cost is low, and the obtained floor is abrasion-resistant and environment-friendly, and is long in service life.

Owner:FUZHOU ROYAL FLOOR

Low-concentration initial casting casting method and aluminium alloy cast ingot

A low-concentration starting casting method and an aluminum alloy ingot, relating to the technical field of aluminum alloy smelting and casting, the method firstly carries out the first batching according to each element and its content in the chemical composition of the aluminum alloy, wherein the content is 1.8wt%~ 8wt% elements are the main elements, and the main casting material is obtained through the normal procedure of smelting; according to the elements with the same chemical composition as the aluminum alloy, the main element content is 30% to 40% of the corresponding element content for the second batching, after smelting According to the normal procedure, the starting material is obtained; then the starting material is used for casting to form the ingot head; and then the main casting material is used to continue casting on the basis of the ingot head. The method can reduce the stress in the casting process, can completely avoid the cracking of the casting ingot, and does not affect the performance of the casting itself; the performance of the prepared aluminum alloy casting ingot is stable and will not crack at all.

Owner:SHANDONG NANSHAN ALUMINUM +1

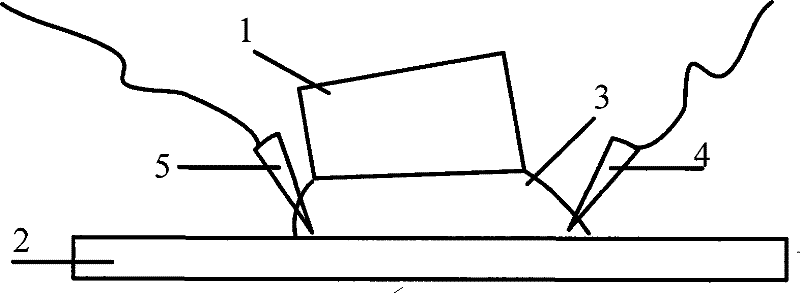

Matrix and welding method for matrix and diamond piece

ActiveCN105750674ASolve crackingDoes not affect strengthSoldering apparatusWelding/soldering/cutting articlesThermal expansionExpansion joint

The invention discloses a matrix and a welding method for the matrix and a diamond piece, and belongs to the technical field of surface processing and coating. The matrix is provided with a cross recess; the cross recess is provided with notches formed in the side surfaces; the section of the cross recess is rectangular, V-shaped or arc-shaped; the surface of the matrix is not limited to be horizontal, crossed, annular and / or grid-shaped. According to the welding method, the problem that a diamond is cracked due to different thermal expansion coefficients in a brazing process of a diamond brazing tool as a metal surface with a large thermal expansion coefficient has an expansion joint during cooling after high temperature welding is completed is solved. By the adoption of a method for slotting the surface of the metal matrix welded with the diamond (to achieve the effect of the expansion joint), the problem of cracks caused by different thermal expansion coefficients between the diamond and the tool matrix during welding is effectively avoided, and the whole strength of the diamond tool cannot be affected; therefore, a diamond material with an extremely low thermal expansion coefficient cannot be cracked.

Owner:LANGFANG SUPOWER DIAMOND TECH

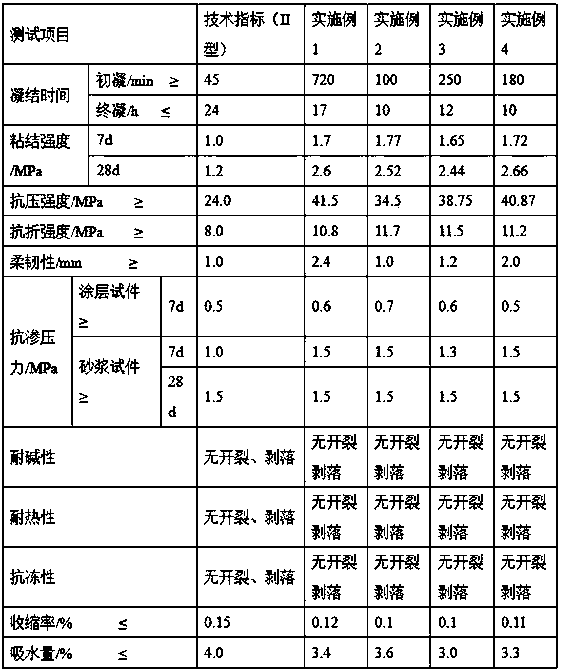

Modified-fiber-modified waterproof slurry and preparation method thereof

The invention relates to the field of building waterproofing, and discloses modified-fiber-modified waterproofing slurry and a preparation method thereof. The waterproofing slurry is prepared from thefollowing components by weight: a powder material comprising 50-70 parts of Portland cement, 20-35 parts of quartz sand, 5-13 parts of quartz powder, 2-3 parts of metakaolin, 0.1-0.3 part of a dry powder water reducer, 0.1 to 0.3 part of a dry powder defoamer, 0.01 to 0.05 part of cellulose ether, 0.1 to 0.3 part of an organosilicon water repellent, 0.3 to 0.5 part of zinc stearate and 0.1 to 0.3part of glass fiber reinforced modified fiber, and a liquid material comprising 50-70 parts of water, 30-50 parts of emulsion, 0.1-0.3 part of an antifoaming agent, 0.1-0.3 part of a bactericide, 0.1- 0.3 part of a water reducing agent and 0.3 - 0.5 part of an antifreeze; wherein the ratio of liquid material: powder material is 1: (2.5 - 3). The modified-fiber-modified waterproofing slurry has ultra-high flexural and compressive strength, and due to the presence of the modified fiber, powder and residue falling and water-repellent layer peeling off caused by an external force can be effectively prevented.

Owner:南通科顺建筑新材料有限公司

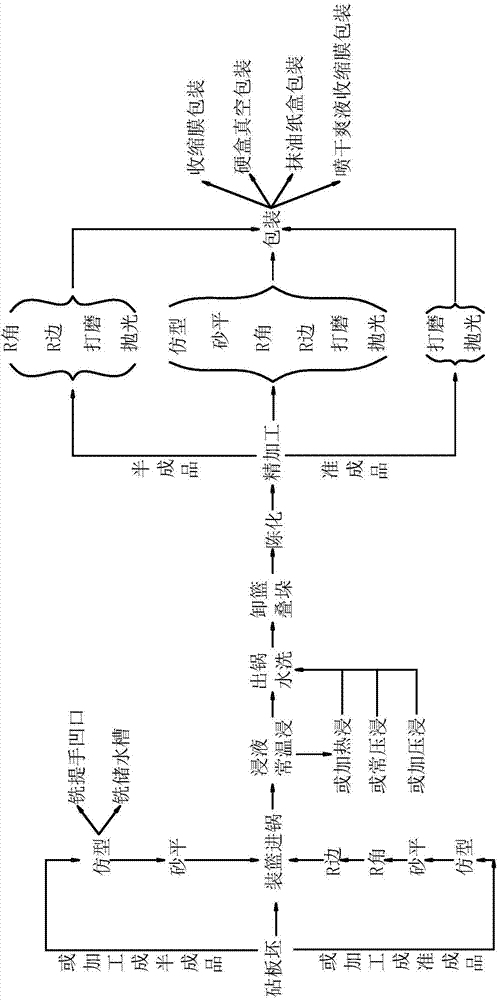

Machining method of whole-wood and fresh-wood cutting board, protecting agent and protecting agent application method

InactiveCN104742205ACracking will notAchieving zero breakthrough in factory mass productionWood treatment detailsPressure impregnationWork in processEngineering

The invention relates to a machining method of a whole-wood and fresh-wood cutting board. The machining method comprises the following steps: preparing a whole-wood and fresh-wood cutting board or a semi-finished product or a board blank; preparing a protection solution with mould-proof and anti-cracking functions; loading into a basket, feeding into a pot, discharging from the pot, washing, unloading from the basket, aging, finely machining and packaging. By adopting the machining method, a gap of the factory-oriented mass production in the field can be filled, the machined cutting board is maintained in an original shape and original ecology and is wet, fresh and saturated, wood grains are attractive and clear, the original color and original shape can be maintained, no metal hoop is needed on the periphery, the problems such as mildewing, color changing and cracking of the whole-wood and fresh-wood cutting board in the production process, the sales process and the application process of customers can be well solved, and the visual effect of the cutting board can be prevented from being seriously affected.

Owner:覃健林

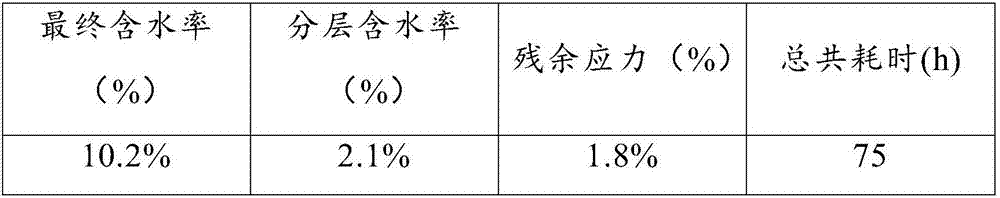

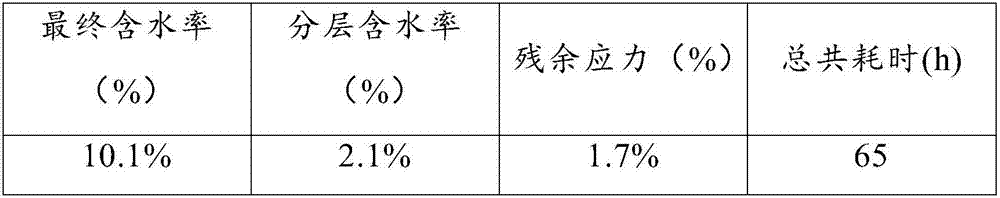

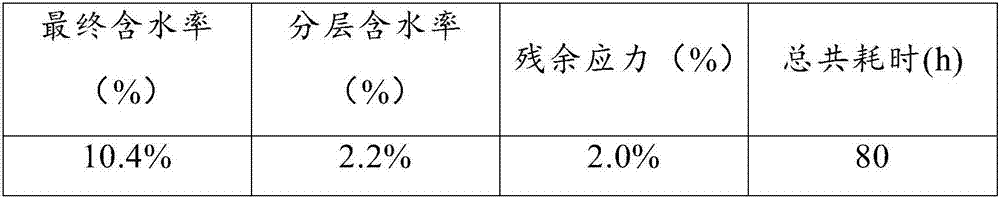

Vacuum drying method for phoebe zhennan board

InactiveCN107036394AIncrease temperatureUniform temperatureDrying solid materials without heatDrying gas arrangementsWater vaporPulp and paper industry

The invention discloses a vacuum drying method for a phoebe zhennan board. The vacuum drying method comprises the steps of preheating, steam heating, vacuumization, humidification treatment and the like. The preheating time is proportional to the board thickness. In the step of steam heating, the steam temperature is 50-70 DEG C, and a psychrograph is introduced into the process to monitor the humidity in a drying device. The vacuum degree of the drying device is kept at 0.008-0.012 MPa during vacuumization. When humidification treatment is conducted, the vapor temperature is 55-60 DEG C, the temperature difference of the psychrograph is controlled to be 5-6 DEG C, and the treatment time is 10-20 h. By adoption of the drying steps, the phoebe zhennan board cannot crack, color changes are small, the drying time is short, and the drying quality is high.

Owner:SICHUAN AGRI UNIV

Heat treatment process of steel 1008

The invention discloses a heat treatment process of steel 1008, and the steel 1008 comprises the following chemical components by mass: not more than 0.10% of C; 0.15-0.35% of Si; 0.30-0.50% of Mn; not more than 0.030% of P; not more than 0.050% of S. The heat treatment process comprises the following steps: firstly, removing surface oxide scale of steel 1008, coating lime soap; secondly, performing wire drawing lubrication by wire drawing powder, controlling the area-reduction rate at above 28%; finally, performing spheroidization of the steel 1008 at 630-660 DEG C. During application, the soap content in the wire drawing powder is high, and the area-reduction rate is controlled to be above 28%, which avoid cold heading cracking during cold heading; and with the method of the invention, cold heading steel wire 1008 does not crack during large deformation cold heading and cold extruding processes.

Owner:无锡翱天钢丝制品有限公司

Bend-resistance powder coating

InactiveCN102108249AImprove bending resistanceCracking will notPolyurea/polyurethane coatingsPowdery paintsMicrometerGram

The invention relates to the field of chemical powder coating, in particular to a bend-resistance powder coating. The invention aims to provide bend-resistance powder coating which can ensure powder coating films that are more than 60 micrometers thick on workpieces do not crack when the powder coating is sprayed on box bodies, the workpieces or various antitheft doors and the box bodies, the workpieces or the various antitheft doors are punched at 90 to 180 DEG, in order to overcome the low bend resistance drawback of the conventional powder coating. The technical scheme adopted by the invention is implemented as follows: the components of the bend-resistance powder coating include carboxyl resin, triglycidyl isocyanurate (TGIC), BaSO4(filler), delustering agent 803A, curing agent 32-18A and pigment, wherein the acid value of the carboxyl resin is 20 to 40 micrograms of KOH per gram, and the pigment is one or more of titanium white, ferrite yellow, iron oxide red and dry-ground black limestone powder.

Owner:ZHEJIANG CHAOLANG ADVANCED MATERIALS

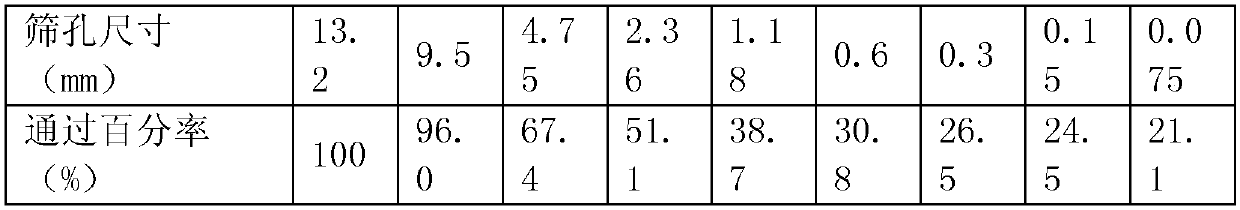

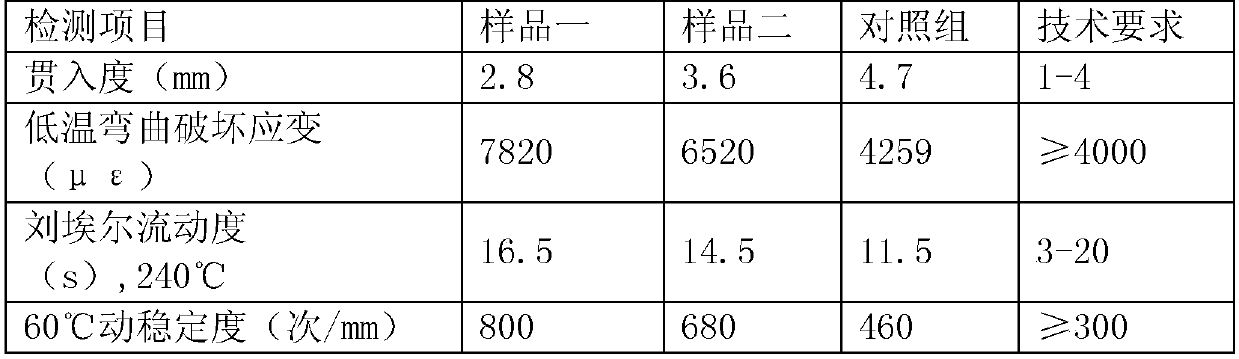

Finished cementing material for pouring type asphalt mixture and preparation method of finished cementing material

InactiveCN107739521AImproved high and low temperature performanceEnsure production safetyBuilding insulationsPetroleumAsphalt

The invention discloses a finished cementing material for a pouring type asphalt mixture and a preparation method of the finished cementing material. The finished cementing material is prepared from the following main components: 40 to 80 percent of native bitumen mother solution with needle penetration 5 to 20 (0.1mm), 1 to 8 percent of modifier, 18 to 55 percent of petroleum asphalt and 0.1 to 0.3 percent of stabilizer. The preparation method comprises the following steps: adding the modifier consisting of chlorinated polyethylene rubber and thermoplastic elastomer into the petroleum asphaltwith the temperature of 160 to 180 DEG C; carrying out full swelling and shearing, then mixing the modifier with the native bitumen mother solution at the temperature of 180 to 190 DEG C and then uniformly stirring; finally, adding the stabilizer, developing at the temperature of 170 to 190 DEG C for 2 to 3 hours, thus obtaining the finished cementing material for the pouring type asphalt mixture. The finished cementing material can be stored and transported for a long time and is convenient to use; the finished cementing material is suitable for preparing a high-performance pouring type asphalt mixture.

Owner:西咸新区众力沥青有限公司 +1

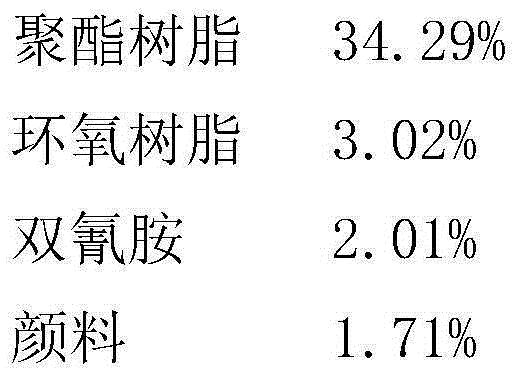

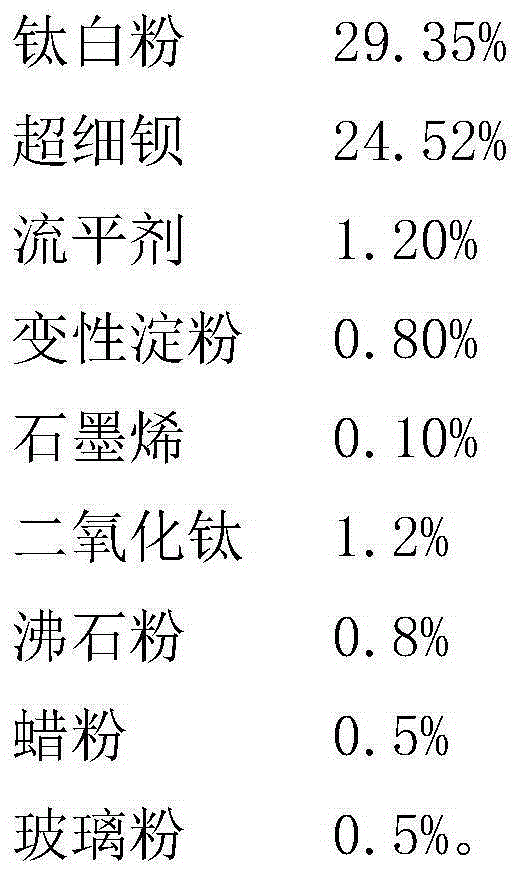

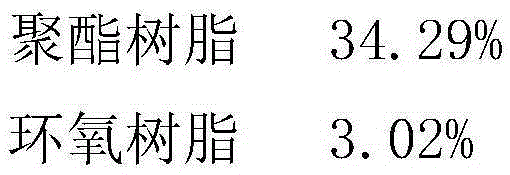

Bending-resistant powder coating

InactiveCN105400387ASimple ingredientsReasonable ratioEpoxy resin coatingsPolyester coatingsWaxTitanium dioxide

A bending-resistant powder coating comprises the following components by weight: 34.29% of polyester resin, 3.02% of epoxy resin, 2.01% of dicyandiamide, 1.71% of a pigment, 29.35% of titanium dioxide, 24.52% of ultrafine barium, 1.20% of a leveling agent, 0.80% of modified starch, 0.10% of graphene, 1.2% of titanium dioxide, 0.8% of zeolite powder, 0.5% of wax and 0.5% of glass powder. The coating has simple ingredients and reasonable ratio; and the added graphene microchip enhances the electrostatic spraying performance. Compared with the conventional powder coating, the coating has the outstanding advantages of good resistance to bending. If a conventional powder coating is sprayed on a metal sheet workpiece and then stamped at 90-180 DEG C, the powder coating film cracks at the thickness of 60 mum on the workpiece; however, if the bending-resistant powder coating disclosed by the invention is sprayed on the sheet metal workpiece and stamped at 90-180 DEG C, the powder coating does not crack on the work piece when the film thickness reaches 80 mum.

Owner:滁州市友邦涂装有限公司

Halogen-free low-smoke high-flame-retardant high-oxygen-isolation cable material for power cable, and preparation method thereof

InactiveCN111303528AImprove flame retardant performanceIntegrity guaranteedPlastic/resin/waxes insulatorsPower cableHalogen

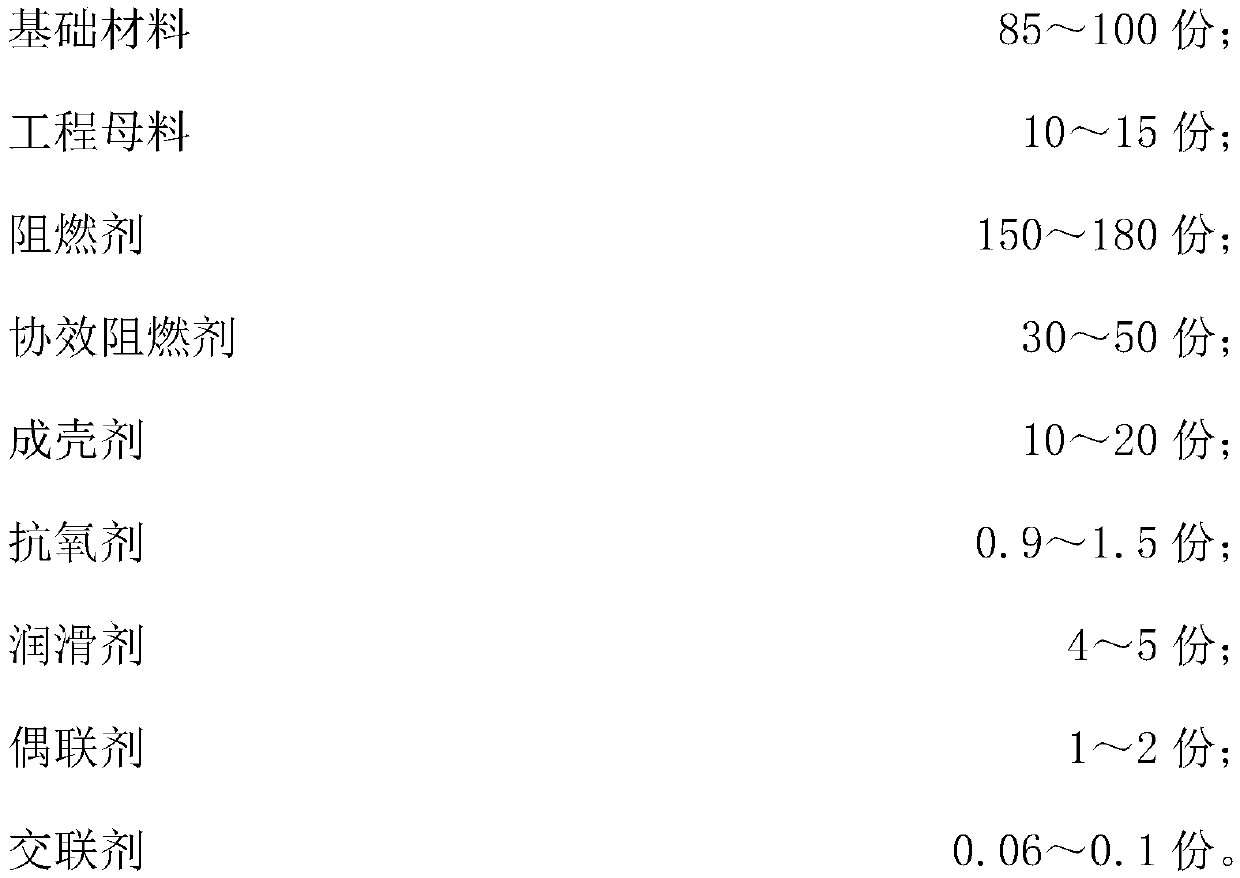

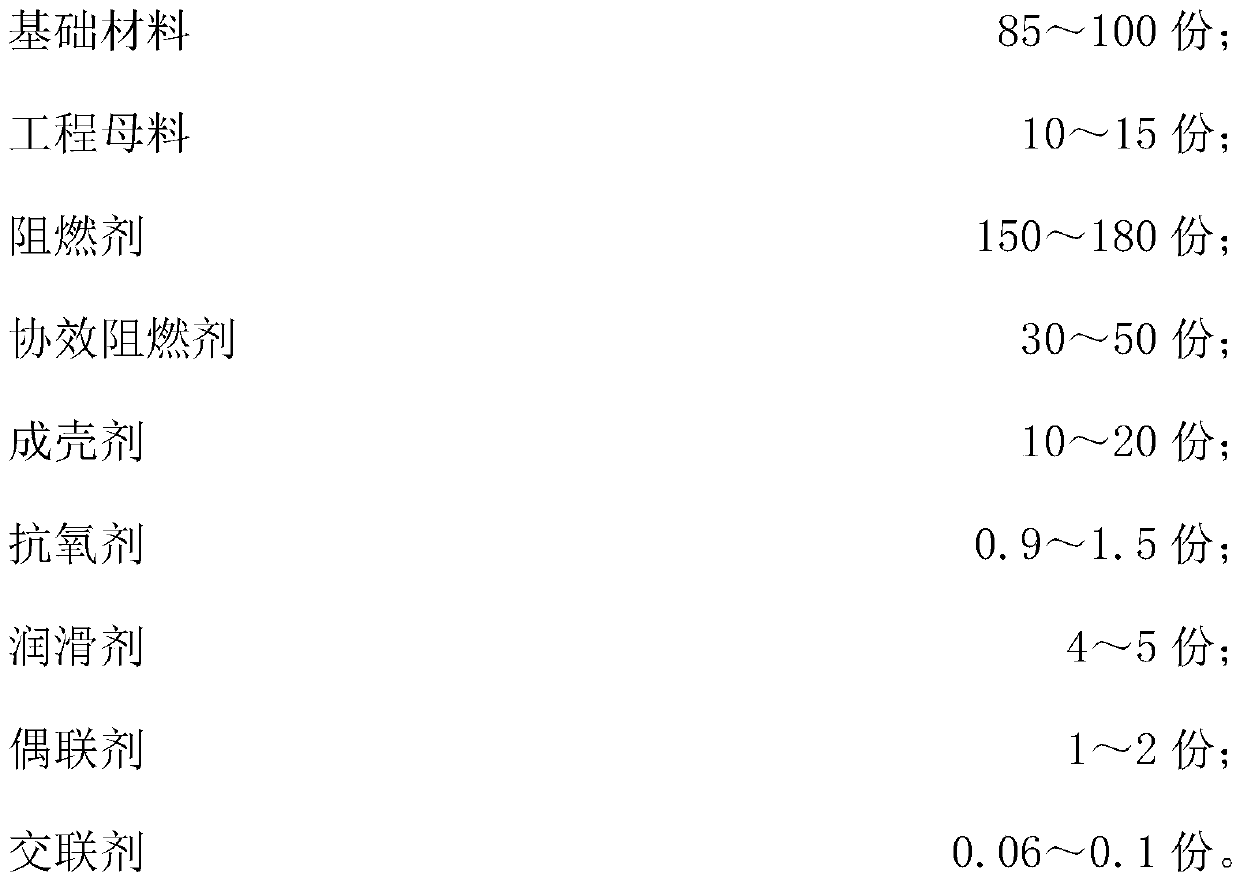

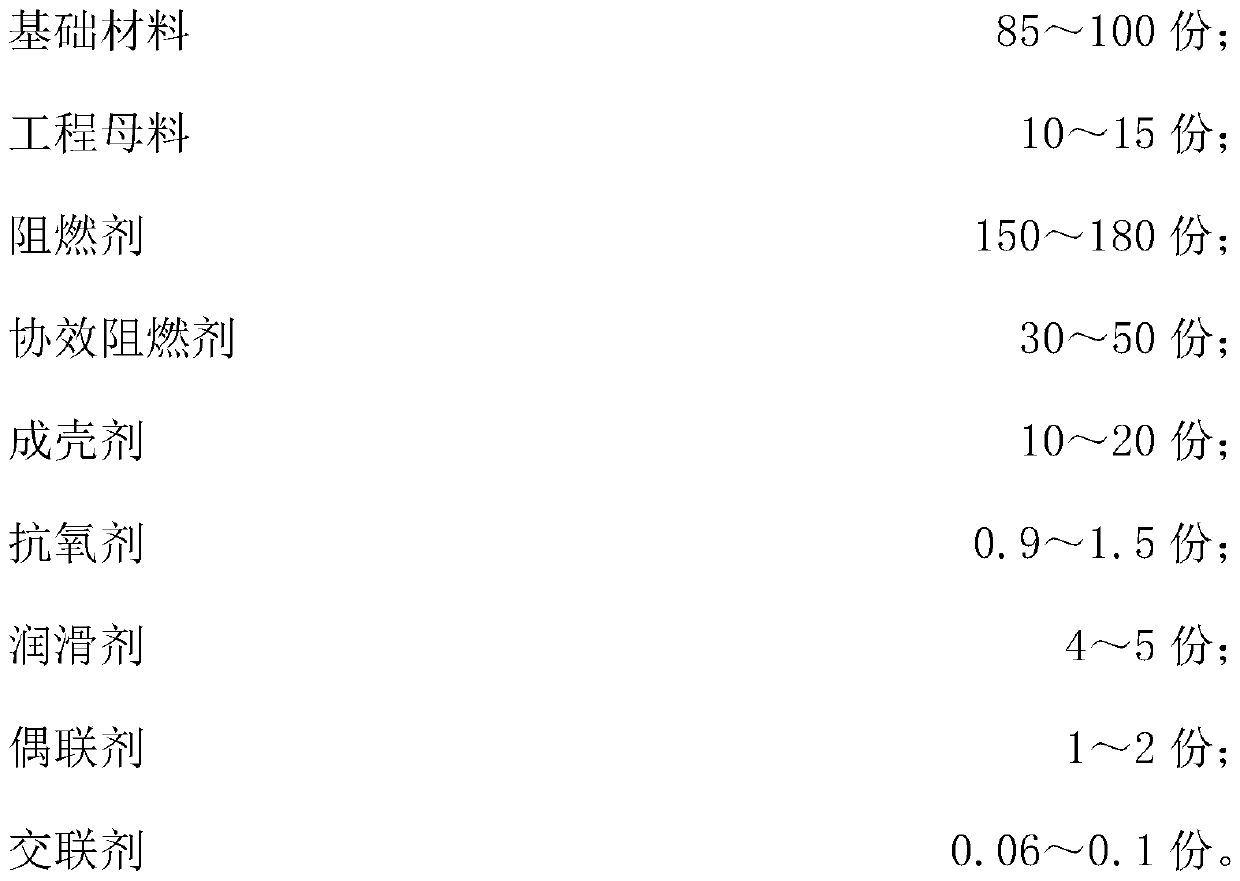

The invention relates to the technical field of chemical engineering, particularly to a halogen-free low-smoke high-flame-retardant high-oxygen-isolation cable material for a power cable, wherein thehalogen-free low-smoke high-flame-retardant high-oxygen-isolation cable material comprises the following components in parts by weight: 85-100 parts of a base material, 10-15 parts of engineering master batch, 150-180 parts of a flame retardant, 30-50 parts of a synergistic flame retardant, 10-20 parts of a shell forming agent, 0.9-1.5 parts of an antioxidant, 4-5 parts of a lubricant, 1-2 parts of a coupling agent, and 0.06-0.1 part of a cross-linking agent. The preparation method comprises the following steps: dissolving a cross-linking agent in a coupling agent; adding other components excluding a base material and engineering master batch into a high-speed mixer, stirring at a high speed for 10 minutes, and controlling the temperature at 60 DEG C; and adding the stirred material, the base material and the engineering master batch into an internal mixer, discharging the material when the temperature of the internally mixed material reaches 145-150 DEG C, performing double-cone forced feeding, and granulating by a double-screw single-screw double-stage extruder to obtain the halogen-free low-smoke high-flame-retardant high-oxygen-isolation cable material for the power cable.

Owner:杭州美临新材料科技有限公司

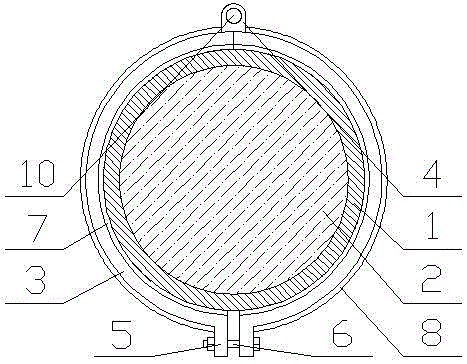

Injection molding hyperboloid reflector and injection molding method thereof

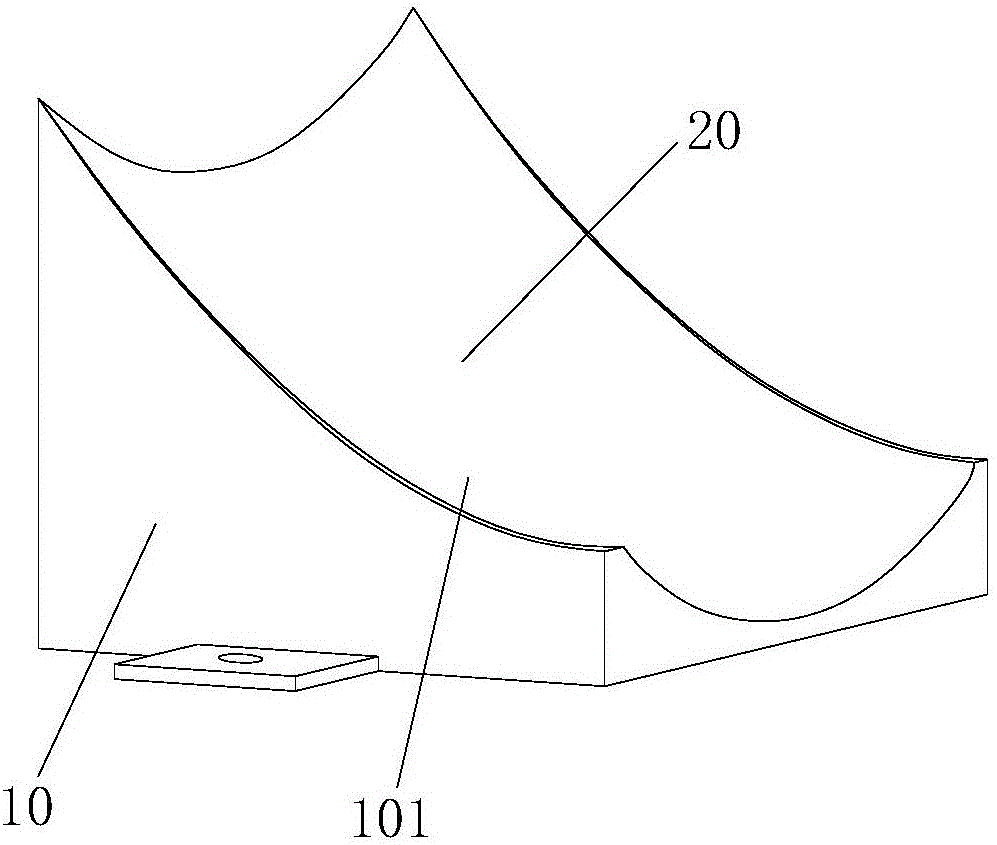

InactiveCN106094078AGood formabilityEasy to installMirrorsOptical articlesInjection molding processConcave surface

The invention provides an injection molding hyperboloid reflector and an injection molding method thereof. The injection molding hyperboloid reflector comprises a pedestal which is obtained by employing an injection molding process and provided with a hyperboloid concave surface, and a reflecting layer connected to the concave surface. The pedestal is integrated through injection molding; the reflecting layer is connected to the pedestal concave surface through the vacuum coating technology. The pedestal which is obtained through injection molding and provided with a hyperboloid concave surface has sound moldability, is convenient to install and transport, and can better protect the reflecting layer in a transportation process. The pedestal preferably employs engineering plastics capable of injection molding, has great weatherability, is hard to deform, guarantees the service life of the hyperboloid reflector, and is light; meanwhile, the tolerance between the dimension of the hyperboloid concave surface of the hyperboloid reflector and the dimension of a theoretically calculated curved surface is small, and the hyperboloid concave surface is almost identical with a designed curved surface, has excellent light condensing effects, and can improve a light utilization rate. The injection molding method is simple to operate.

Owner:SHENZHEN ANGTEER SOLAR ENERGY INVESTMENT

Crack resistant coating and preparation method thereof

The invention discloses a crack resistant coating and a preparation method thereof, and relates to the technical field of coatings, the crack resistant coating is prepared from the following raw materials by weight: 20-30 parts of silicone rubber, 25-40 parts of talcum powder, 15-35 parts of peach gum, 10-15 parts of an emulsifier, 20-25 parts of gloss oil and 3-7 parts of water; the preparation method comprises the following steps: A. smashing the silicone rubber and the peach gum into powder, adding the water and the emulsifier for mixing, and using an emulsification machine to prepare emulsion; B. adding the talcum powder into the emulsion, using a mixer for stirring and mixing in the stirring speed of 500r / min-800r / min for stirring time of 20 minutes-30 minutes to obtain a primer; and C. when in use, coating with a primer, then coating the outer layer of the primer with the gloss oil, and then curing to obtain the crack resistant coating. Compared with the prior art, the crack resistant coating solves the problem that coatings in the prior art are easy to crack.

Owner:赖禄波

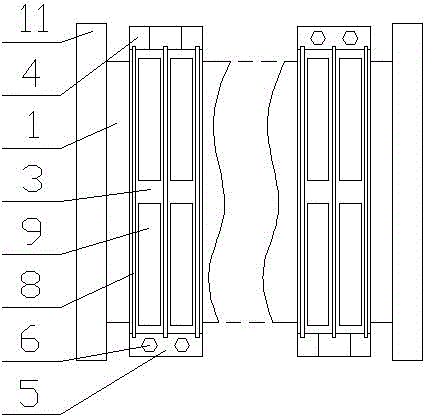

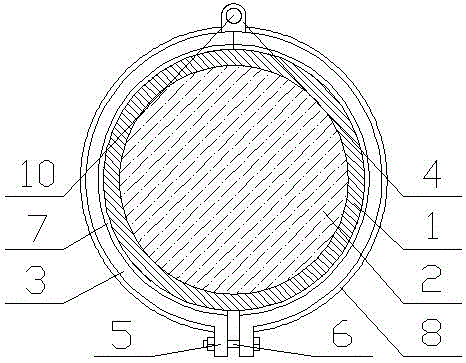

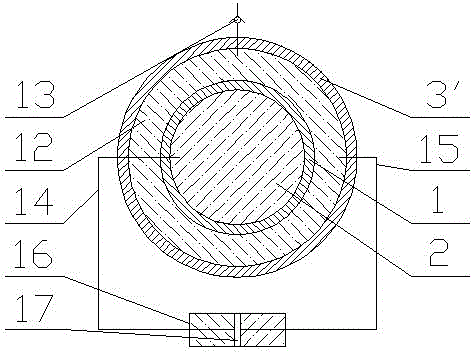

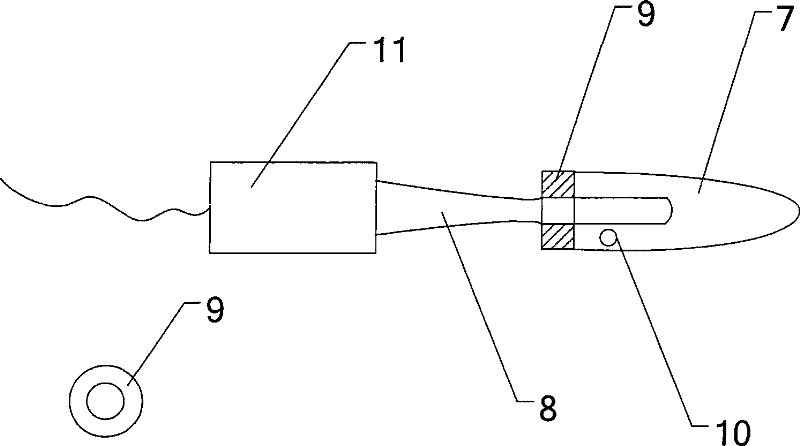

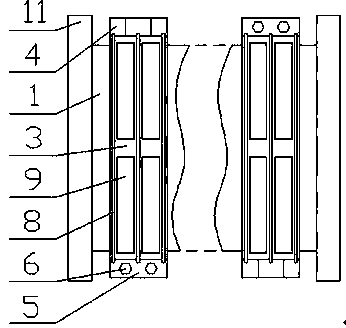

Cracking-resistant salt and chemical making equipment pipe

ActiveCN104565823AOffset the pressureExtended service lifePipeline systemsPipe protection against damage/wearStructural engineeringMechanical engineering

The invention discloses a cracking-resistant salt and chemical making equipment pipe. The cracking-resistant salt and chemical making equipment pipe comprises a salt and chemical making equipment pipe body, wherein a plurality of tightening rings sequentially sleeve the outer side wall of the salt and chemical making equipment pipe body along the length direction of the slat and chemical making equipment pipe body; each tightening ring consists of two symmetric half arcs; one sides of the tightening rings are connected to one another through hinges; the other sides of the tightening rings are fixed through bolts; the tightening rings apply a radial pre-compression force pointing to an axis to the salt and chemical making equipment pipe body; and the radial pre-compression force is equal to or greater than pressure of brine in the salt and chemical making equipment pipe body. By the structure, the radial pre-compression force is applied to the salt and chemical equipment pipe body of the cracking-resistant salt and chemical making equipment pipe, pressure of the brine in the salt and chemical making equipment pipe body on the salt and chemical making equipment pipe body is counteracted, even if the inside of the salt and chemical making equipment pipe body is subjected to pitting corrosion under a long-term effect of the brine in the salt and chemical making equipment pipe body, the circumstance that pitting corrosion portions crack due to pressure stress of the brine is avoided, and the service life of the salt and chemical making equipment pipe body is prolonged.

Owner:江苏淮盐矿业有限公司

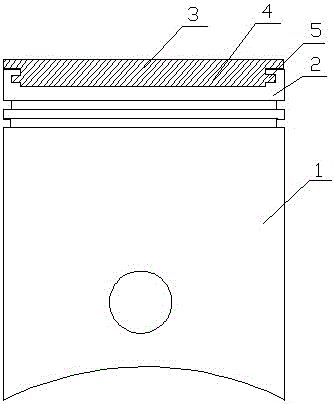

Preparation method for wear-resisting layer embedded at top of diesel engine piston

InactiveCN105863869AProduction Technology ScienceEasy to makeMachines/enginesPistonsCorrosion resistantSilicon nitride

The invention relates to a preparation method for a wear-resisting layer embedded at the top of a diesel engine piston. The preparation method is characterized in that kaolin is adopted as the main raw material, and raw materials such as nanometer zirconium oxide and silicon nitride are added; the production technology is scientific; the manufacturing is convenient; the production cycle is short; the production cost is low; the method is eco-friendly and environment-friendly; the wear-resisting layer at the top of the piston can effectively preventing the influence of high temperature of a combustion chamber on a copper nickel magnesium aluminum alloy piston body; the coefficient of thermal expansion is close to zero; the wear-resisting layer does not absorb water; the insulating property is good; the structure is compact and uniform; the impact resistance and corrosion resistance are good; the compressive strength is high; the shrinkage rate is small; the wear-resisting layer is high temperature resistant and wear resisting, and does not crack; the Mohs hardness of the wear-resisting layer reaches 8.2; the service life is long; the comprehensive performance is excellent; and large-batch industrial production is facilitated.

Owner:JIANGSU TAIPU POWER MACHINERY

Zirconia-carbon refractory material for continuous casting and preparation method thereof

ActiveCN103553655ALower high temperature elastic modulusPrevent osmotic erosionPorosityTectorial membrane

The invention relates to a thermal-shock resistant, corrosion resistant zirconia-carbon-containing refractory material which is mainly applied to a submersed nozzle used in steel-making and continuous casting. According to the zirconia-carbon refractory material, zirconia particles are combined with carbon to form a network structure; gaps of the network structure are filled with graphite with high heat conductivity to raise thermal shock resistance of the material; high-temperature metal plastic molybdenum disilicide with the surface coated with a dense silicon dioxide protective film is added to alleviate thermal stress of the material during the using process; and macrovoid ratio and contact area of melt cinder and zirconia in use are minimized to reduce washout and erosion of melt cinder to the zirconia-carbon refractory material. Total porosity of the material is less than 20%, wherein the volume fraction of pores with the size of below 10 microns is more than 85% of that of the total pores. The zirconia-carbon refractory material provided by the invention has good erosion resistance. Thermal shock resistance is not reduced. The zirconia-carbon refractory material will not be cracked or damaged when in use.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Heat insulation decoration line

InactiveCN107366410ANot subject to temperature changesSmall cellClimate change adaptationHeat proofingToxic materialEngineering

The invention relates to a heat insulation decoration line, which belongs to a novel outer wall decoration line and component, and is suitable to be arranged on an EPS and XPS heat insulation wall body of an outer wall, so that the European, classical and elegant decoration styles can be shown; and the outer wall of a main body building can be enabled not to generate cold and heat bridge effects. For the European styles of a high-rise building, the construction period is long; cracks can occur after a long time; and the durability is poor. Therefore the heat insulation decoration line and component are used; the installation is convenient; economical performance is realized; and the durability is long. The heat insulation decoration line and component are compounded by using demolded B2 grade fireproof graphite polystyrene as a main body, sticking alkaline-resistant fiberglass gridding cloth and adding a special bonding outer protection layer. The heat insulation decoration line and component is not influenced by temperature change, achieves cold-resistant and heat-resistant effects, and cannot be influenced by humid climate and acid rain. The heat insulation decoration line can achieve the fire-proof performance, cannot give out toxic substances and is an environment-friendly high-quality product.

Owner:TIANJIN QICAI TECH DEV

Processing process of mosaic table surface

The invention provides a processing process of a mosaic table surface. The processing process comprises the following steps: downwardly putting the cut front surface of a mosaic into a mould; flatly filling a drop height space between a grate of the mould and the thickness of the mosaic with fine sand, and laying a layer of glass fiber net on the back surface of the mosaic; uniformly coating the glass fiber net and the back surface of the mosaic with special mosaic glue; uniformly coating a mosaic table support with viscous glue with the thickness of 1-3 mm, downwardly pressing the glue-coated surface onto the mosaic, and storing at normal temperature for 20-26 hours; uniformly coating the mosaic surface with a crack sealer, and storing at normal temperature for 22-26 hours; uniformly coating the mosaic surface and cracks with a protecting agent, and performing surface polishing. The processing process is suitable for all mosaic materials on the market at present; the mosaic table surface is richer in texture, more diversified in color and high in selectivity for customers, and has better market competition advantage in comparison with like products; the mosaic cannot drop and cannot be cracked and faded.

Owner:天津磊鑫盛家具有限公司

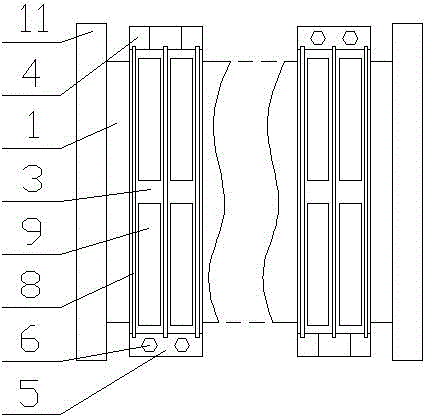

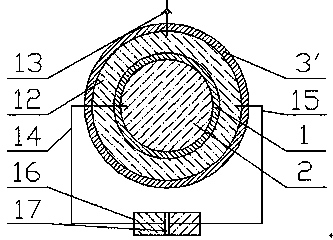

Optical device assembly system and method for fixing optical elements

InactiveCN101546020APrecise temperature controlAvoid heat damageMountingsTemperature controlElectricity

The invention discloses an optical device assembly system and a method for fixing optical elements. An optical device comprises the optical elements and a heat sink; a metal layer is plated on at least one surface of each optical element; the assembly system comprises an optical element fixing device, andoptical element fixing device comprises a control module as well as a solder filling device and at least one temperature control bar which are respectively electrically connected with the control module, wherein the solder filling device is used for filling solder between the metal layers of the optical elements and the heat sink, the temperature control bar is used for melting the solder, and the temperature of the temperature control bar can be controlled by the control module. When being used for melting the solder, the temperature control bar can precisely control the temperature of the solder and avoid the insufficient flowability brought by over low solder temperature, thereby ensuring the adjustment precision; in addition, the heat injury possibly brought by the optical elements can be avoided; the real-time temperature adjustment can be realized by adopting an electric control system, and the temperature of the solder can be adjusted according to the element adjusting state which can be controlled to be in a melted or semi-melted state.

Owner:PHOEBUS VISION OPTO ELECTRONICS TECH +1

Anti-cracking salt chemical equipment pipeline

InactiveCN106402579AOffset the pressureExtended service lifePipe protection against damage/wearEngineeringPitting corrosion

The invention discloses an anti-cracking salt chemical equipment pipeline. The anti-cracking salt chemical equipment pipeline comprises a salt chemical equipment pipeline, wherein a plurality of tight hoops are sequentially arranged on the pipeline outer side wall of the salt chemical equipment pipeline in a sleeving manner in the length direction of the pipeline; the tight hoops are of two-symmetrical semi arc structures; one sides of the tight hoops are connected hinges; the other sides of the tight hoops are fixed through bolts; the tight hoops apply radial prepressure, pointing to the axis, to the salt chemical equipment pipeline; and the radial prepressure is equal to or larger than brine pressure inside the salt chemical equipment pipeline. According to the anti-cracking salt chemical equipment pipeline, through the pressure, radial prepressure is applied to the salt chemical equipment pipeline, the pressure of brine inside the salt chemical equipment pipeline to the salt chemical equipment pipeline is counteracted, even though the pipeline interior of the salt chemical equipment pipeline has pitting corrosion due to the long-term action of brine, pitting corrosion parts do not crack under the compressive stress of brine, and the service life of the salt chemical equipment pipeline is greatly prolonged.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

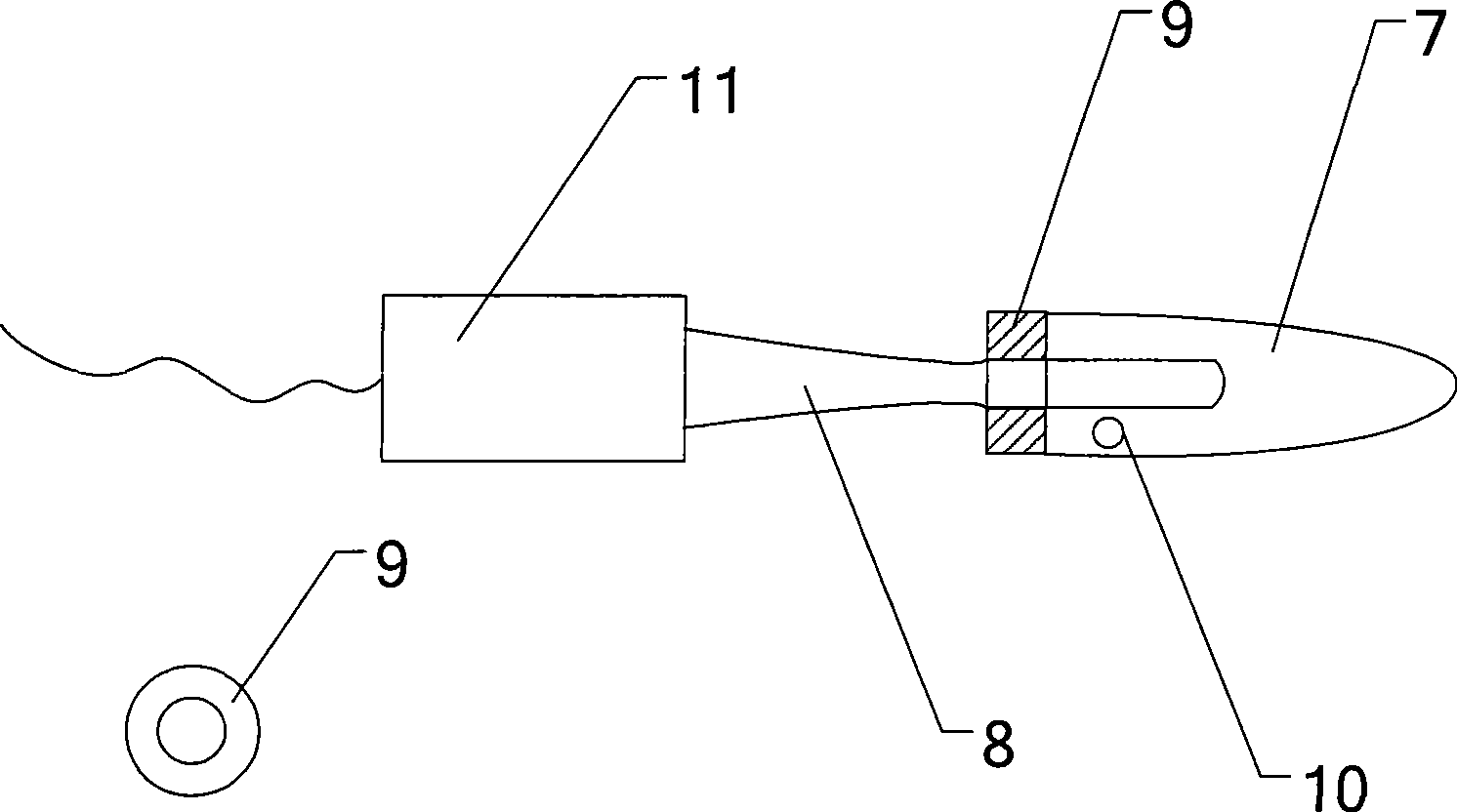

Continuous catalytic cracking method for producing fuel oil from mixed waste plastic

InactiveCN101260309BQuality improvementNo secondary pollutionLiquid hydrocarbon mixture productionCatalytic pyrolysisPtru catalyst

The invention provides a method for successive catalytic pyrolysis of mixed waste plastics to produce burning oil, which relates to a technology to produce the burning oil through pyrolysis of waste plastics. A two-step successive running technology with an integration of catalyzed pyrolysis and pyrolysis catalyzed reforming is adopted, in the technology of pyrolysis in the first step, the successive running of the pyrolysis is accomplished through a fluid tube-type bed technology with an adjuvant transmission device, and a cheap non-toxic catalyst is added to raise the reaction speed of the plastic pyrolysis and decrease the temperature of the pyrolysis; in the second step of refining technology of catalyzed lysis, a fluidized-bed catalyst is adopted to perform the secondary pyrolysis reforming reaction on the cracked gas produced by step one, to increase the percentage of the extract fractions of gasoline and diesel in the liquid fuel produced by pyrolysis. The technology provided by the invention is a wholly concealed successive running procedure with the waste plastics as the raw material without the need of classification, washing or drying, the operation is flexible and the running cost is low, the technology is especially suitable for production of burning oil from mixed waste plastics from urban or suburban garbage with complicated components, the yield rate of the qualified burning oil reaches to more than 66 percent, as calculated on the basis of waste plastics, the technology has observable economic and social benefits.

Owner:TONGJI UNIV

Optical device assembly system and method for fixing optical elements

InactiveCN101546020BPrecise temperature controlAvoid heat damageMountingsTemperature controlElectricity

The invention discloses an optical device assembly system and a method for fixing optical elements. An optical device comprises the optical elements and a heat sink; a metal layer is plated on at least one surface of each optical element; the assembly system comprises an optical element fixing device, andoptical element fixing device comprises a control module as well as a solder filling device and at least one temperature control bar which are respectively electrically connected with the control module, wherein the solder filling device is used for filling solder between the metal layers of the optical elements and the heat sink, the temperature control bar is used for melting the solder, and the temperature of the temperature control bar can be controlled by the control module. When being used for melting the solder, the temperature control bar can precisely control the temperature of the solder and avoid the insufficient flowability brought by over low solder temperature, thereby ensuring the adjustment precision; in addition, the heat injury possibly brought by the optical elements can be avoided; the real-time temperature adjustment can be realized by adopting an electric control system, and the temperature of the solder can be adjusted according to the element adjusting state which can be controlled to be in a melted or semi-melted state.

Owner:PHOEBUS VISION OPTO ELECTRONICS TECH +1

Anti-cracking salt chemical engineering equipment pipeline

InactiveCN110748748AExtended service lifeOffset the pressurePipe protection against damage/wearMechanical engineeringEnvironmental geology

The invention discloses an anti-cracking salt chemical engineering equipment pipeline. The anti-cracking salt chemical engineering equipment pipeline comprises a salt chemical engineering equipment pipeline body. The outer side wall of the salt chemical engineering equipment pipeline body is sequentially sleeved with a plurality of lock rings in the length direction of the pipeline body. Each lockring is of a structure with two symmetrical semi-circular arcs. One side of each lock ring is connected through a hinge, and the other side of each lock ring is fixed with a bolt. The lock rings haveradial pre-pressing force, pointing to the axis, on the salt chemical engineering equipment pipeline body, and the radial pre-pressing force is equal to or larger than the brine pressure inside the salt chemical engineering equipment pipeline body. According to the above structure of the anti-cracking salt chemical engineering equipment pipeline, the radial pre-pressing force is applied to the salt chemical engineering equipment pipeline body to offset the pressure of brine, inside the salt chemical engineering equipment pipeline body, on the salt chemical engineering equipment pipeline body,even though the inside of the salt chemical engineering equipment pipeline body generates corrosive pitting under the long-term action of the brine, the corrosive pitting positions can not crack under the pressure stress of the brine, and the service life of the salt chemical engineering equipment pipeline body is greatly prolonged.

Owner:刘静

Adhesive for preventing cracking of corrugated cardboard

ActiveCN109609055ACracking will notGood flexibilityNon-macromolecular adhesive additivesStarch adhesivesCardboardAdhesive

The invention relates to the technical field of packaging material processing, in particular to an adhesive for preventing cracking of corrugated cardboards. The adhesive comprises the following raw materials in parts by weight: 20-30 parts of corn starch, 8-18 parts of waxy corn syrup, 5-12 parts of konjac flour, 1-4 parts of modified bentonite, 1-5 parts of kaolinite, 3-8 parts of glycerin, 1-6parts of silica, 1-5 parts of sodium hydroxide, 3-10 parts of borax, 2-9 parts of resin and 28-40 parts of softened water. The finished adhesive is mainly used to coat the creases of the corrugated cardboard when it is folded into cartons or other boxes, which can effectively prevent the cracking of the folded parts. The corrugated board can be coated with the adhesive at the place to be folded before folding, and the folded place can be softened to enhance the flexibility of the folded place, so that the corrugated board will not crack due to folding; the adhesive can also be applied to the folding place after folding, and the applied adhesive can quickly penetrate and soak around the folding place, soften the folding place, so that the corrugated board will not crack due to folding.

Owner:遵义市友联包装实业有限公司

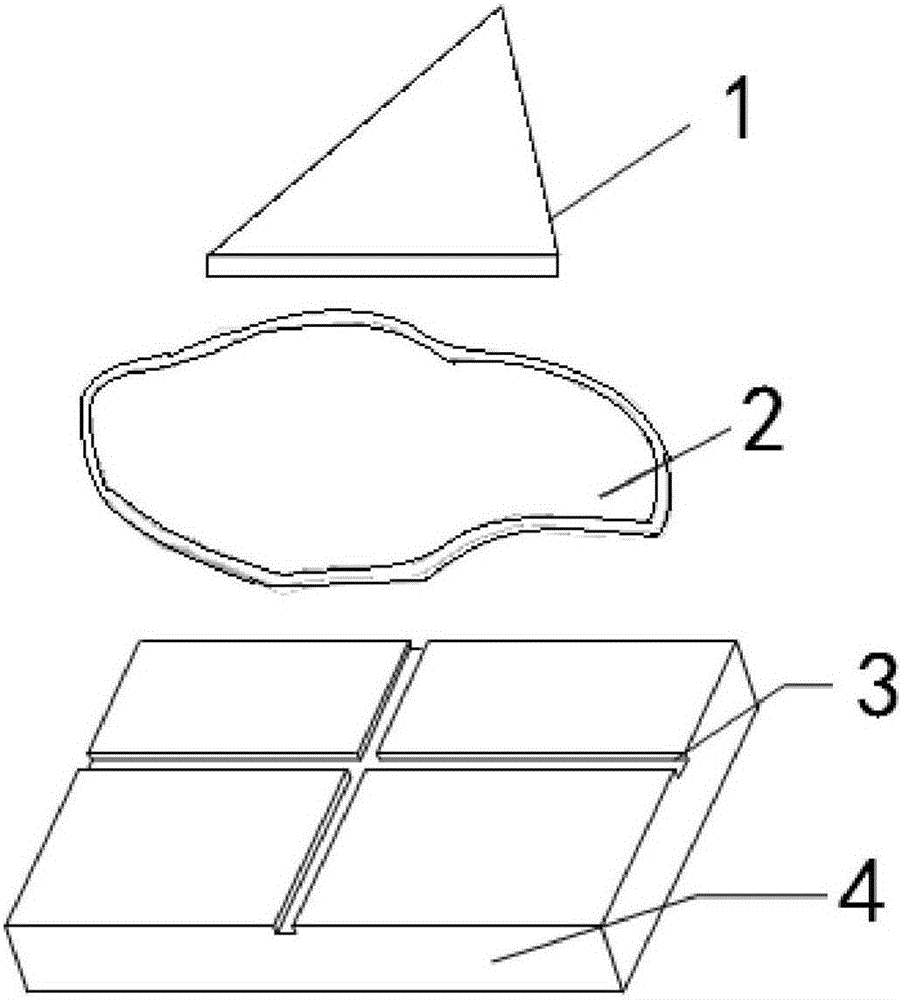

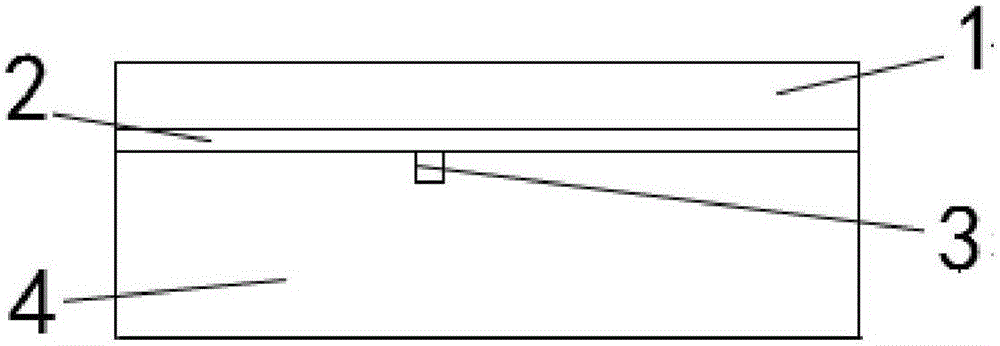

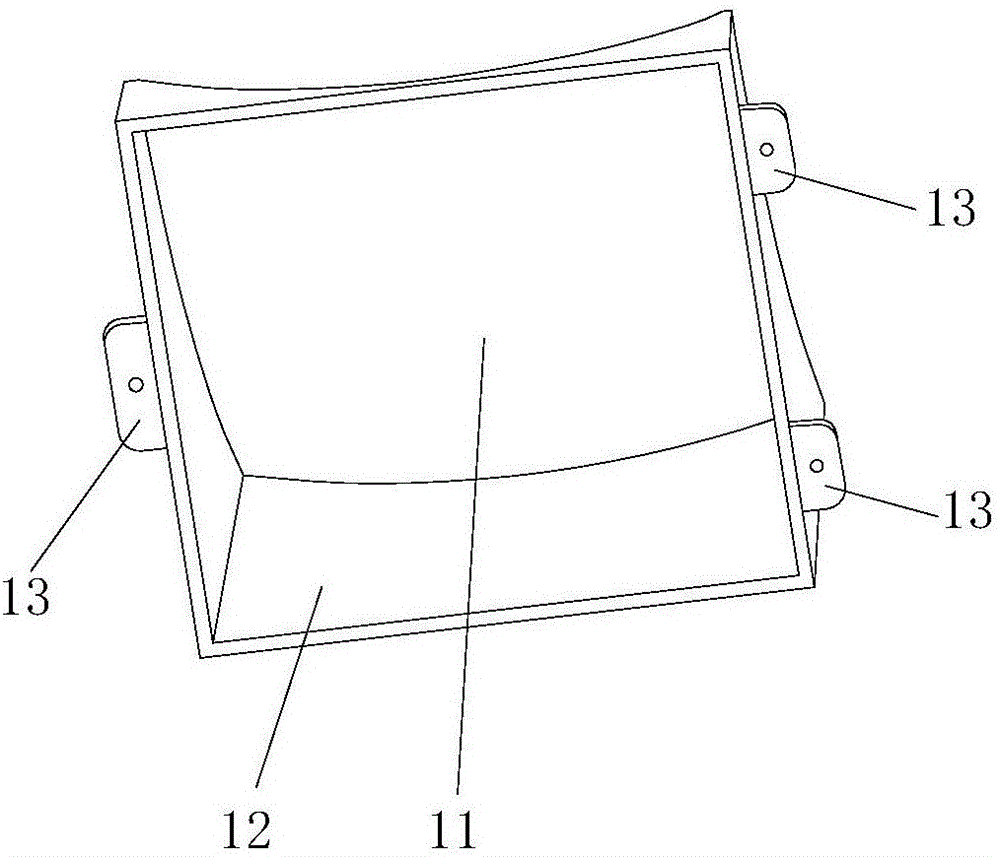

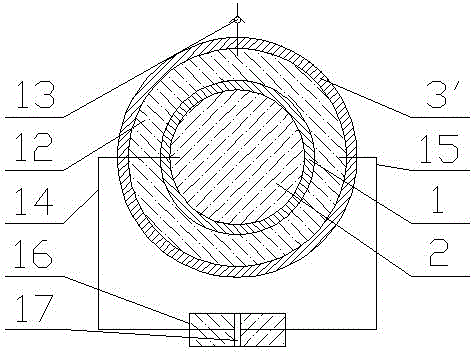

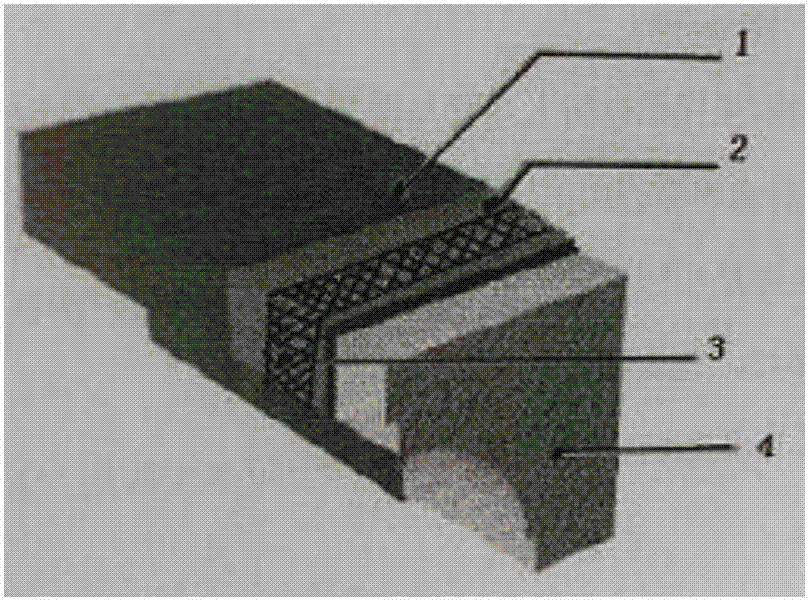

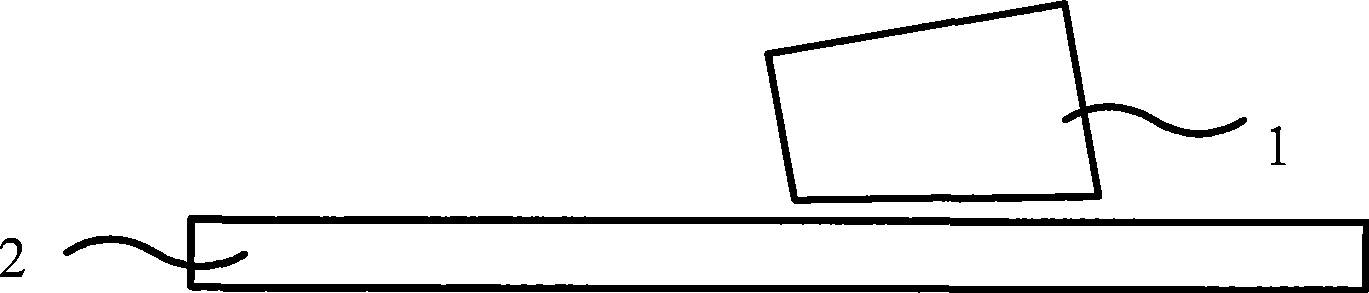

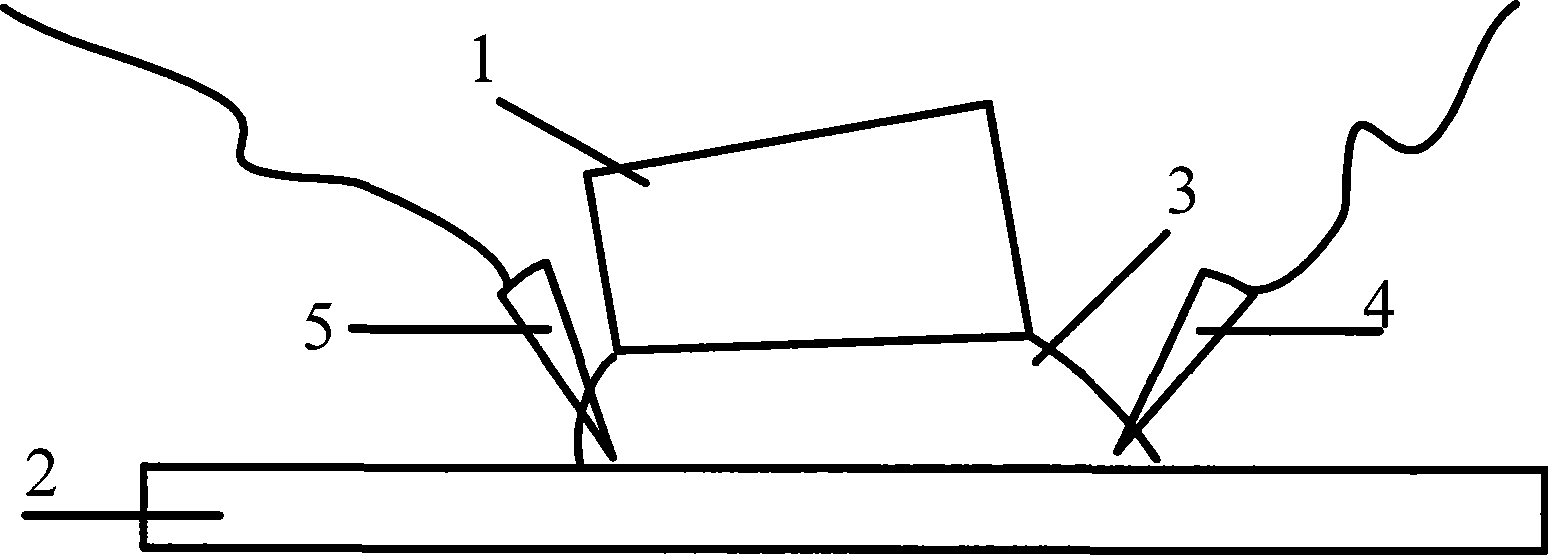

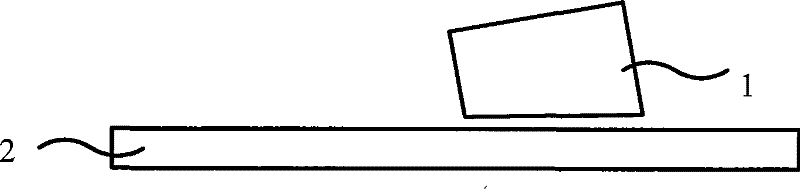

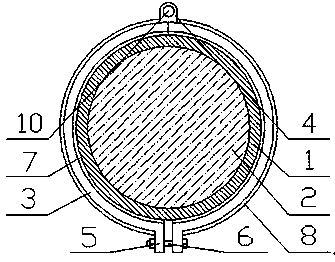

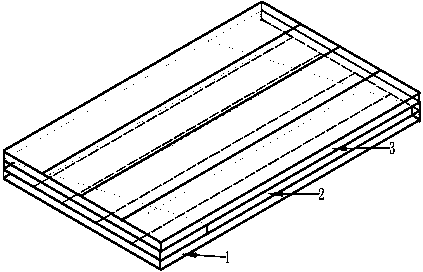

Crack-resistant glued laminated bamboo

InactiveCN111098363AHigh strengthAvoid crackingLayered productsWood veneer joiningFiberComposite material

The invention discloses crack-resistant glued laminated bamboo, which comprises a first bamboo blank layer (1) placed longitudinally, a second bamboo blank layer (2) placed obliquely at a certain angle and a third bamboo blank layer placed longitudinally (3). The first bamboo blank layer (1), the second bamboo blank layer (2) and the third bamboo blank layer (3) placed longitudinally are bonded and hot-pressed to form a whole. The crack-resistant glued laminated bamboo has the advantages of increasing tensile force of transverse fibers between the adjacent bamboo blank layers and preventing the bamboo blank layers from cracking.

Owner:湖南阳明竹咏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com