Modified-fiber-modified waterproof slurry and preparation method thereof

A technology of modified fiber and waterproof slurry, which is applied in the field of building waterproofing. It can solve the problems of slow increase in actual strength, cracking and dusting on the surface of mortar, and loss of waterproof effect, so as to prevent cracking, improve early strength, and dry quickly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

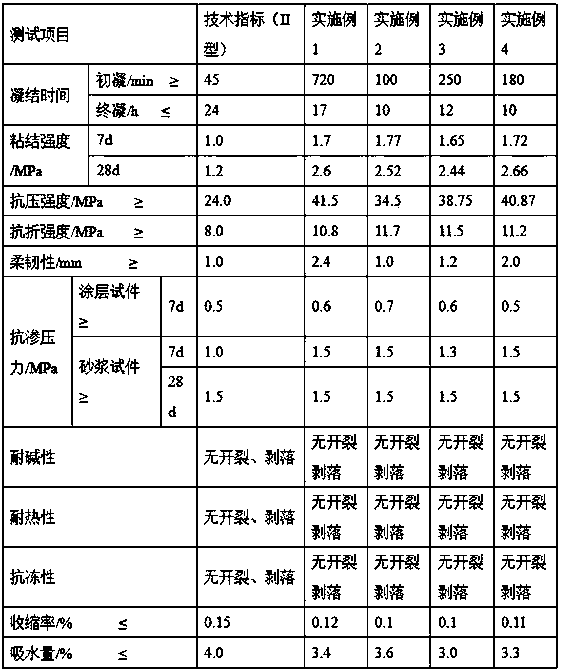

Examples

Embodiment 1

[0043] A modified fiber-modified waterproof slurry prepared from the following components in parts by weight:

[0044] Powder: 50 parts of Portland cement, 20 parts of quartz sand, 5 parts of quartz powder, 2 parts of metakaolin, 0.1 part of dry powder water reducer, 0.1 part of dry powder defoamer, 0.01 part of cellulose ether, silicone water repellent 0.1 part, 0.3 part of zinc stearate, 0.1 part of glass fiber reinforced modified fiber;

[0045] Liquid material: 50 parts of water, 30 parts of emulsion, 0.1 part of defoamer, 0.1 part of fungicide, 0.1 part of water reducer, 0.3 part of antifreeze;

[0046] Liquid material: powder material = 1: 2.5.

[0047] Wherein, in the powder, the Portland cement is No. 42.5 Portland cement; the quartz sand is 80 mesh quartz sand; the quartz powder is 250 mesh quartz powder processed by crushing quartz stone; The silicone water-repellent agent is an organosilane water-repellent agent; the dry powder water reducer is a dry powder polyca...

Embodiment 2

[0060] A modified fiber-modified waterproof slurry prepared from the following components in parts by weight:

[0061] Powder: 70 parts of Portland cement, 35 parts of quartz sand, 13 parts of quartz powder, 3 parts of metakaolin, 0.3 parts of dry powder water reducer, 0.3 part of dry powder defoamer, 0.05 part of cellulose ether, silicone water repellent 0.3 part, 0.5 part of zinc stearate, 0.3 part of glass fiber reinforced modified fiber;

[0062] Liquid material: 70 parts of water, 50 parts of emulsion, 0.3 parts of defoamer, 0.3 parts of bactericide, 0.3 parts of water reducer, 0.5 parts of antifreeze;

[0063] Liquid material: powder material = 1:3.

[0064] Wherein, in the powder, the Portland cement is No. 52.5 Portland cement; the quartz sand is 80 mesh quartz sand; the quartz powder is 250 mesh quartz powder processed by crushing quartz stone; The organosilicon water-repellent agent is an organosilane water-repellent agent; the dry powder water reducer is a dry pow...

Embodiment 3

[0077] A modified fiber-modified waterproof slurry prepared from the following components in parts by weight:

[0078] Powder: 60 parts of Portland cement, 27 parts of quartz sand, 9 parts of quartz powder, 2.5 parts of metakaolin, 0.2 part of dry powder water reducer, 0.2 part of dry powder defoamer, 0.03 part of cellulose ether, silicone water repellent 0.2 part, 0.4 part of zinc stearate, 0.2 part of glass fiber reinforced modified fiber;

[0079] Liquid material: 60 parts of water, 40 parts of emulsion, 0.2 part of defoamer, 0.2 part of fungicide, 0.2 part of water reducer, 0.4 part of antifreeze;

[0080] Liquid material: powder material = 1: 2.65.

[0081] Wherein, in the powder, the Portland cement is No. 42.5 Portland cement and No. 52.5 Portland cement, and the mixing ratio is 1:1; the quartz sand is 80 mesh quartz sand; the quartz powder is made of 250-mesh quartz powder processed by crushing quartz stone; the organosilicon water repellent is an organosilane water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com