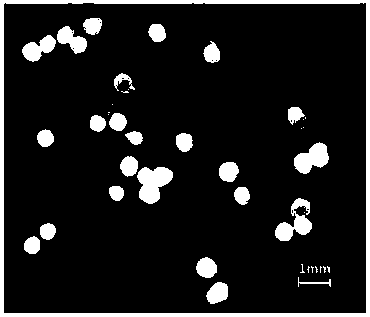

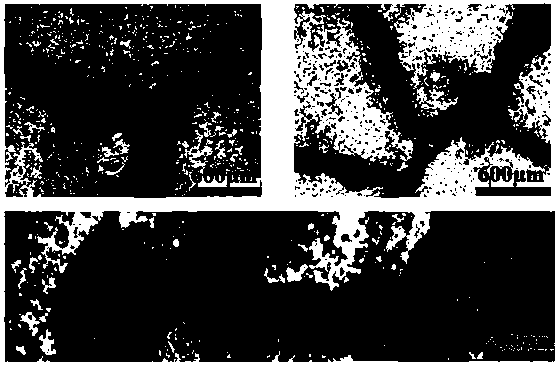

SAPs microcapsules and cement-based self-repairing material

A technology for repairing materials and microcapsules, which is applied in the field of anti-cracking and self-repairing of cracks in cement-based materials, can solve the problems of increasing the yield of microcapsules, affecting the repair efficiency, and easily breaking the microcapsules. Increased durability and improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Put 6.6g of sodium acrylate and 330g of deionized water into the reactor, stir to dissolve it completely, prepare a sodium acrylate aqueous solution, add 33g of sodium hydroxide to the solution, stir to dissolve, add 0.1g of potassium persulfate, start Stir and raise the temperature to 90°C to initiate polymerization, and the reaction ends in about 30 minutes to obtain a 2.0 wt% sodium polyacrylate prepolymer solution;

[0037] (2) Place the four-necked flask containing the above sodium polyacrylate prepolymer solution in a 60°C water bath, add 0.5g sodium lauryl sulfate and stir until it is dissolved, then add 23.1g bisphenol A type ring Oxygen resin, continue to stir for 2h, stirring speed 500r / min, to obtain a mixed solution.

[0038] (3) Prepare coagulation bath solution. Add 10g of N,N'-methylenebisacrylamide to 500mL of deionized water and dissolve to obtain a N,N'-methylenebisacrylamide solution;

[0039] The mixed solution obtained in step (2) is dripped into the...

Embodiment 2

[0043] (1) Put 4.2g of acrylamide and 420g of deionized water into the reactor, stir to dissolve it completely, prepare an aqueous solution of acrylamide, add 21g of sodium hydroxide, stir to dissolve, add 0.1g of potassium persulfate, start stirring, water bath The temperature is 55°C, polymerization is initiated, and the reaction is completed in about 30 minutes to obtain a polyacrylamide prepolymer solution;

[0044] (2) Place the four-necked flask containing the above polyacrylamide prepolymer solution in a 70℃ water bath, add 0.42g sodium alkyl sulfate and stir until it is dissolved, then add 2.1g bisphenol A epoxy resin , Continue to stir for 15 minutes, stirring speed 250r / min, to obtain a mixed solution.

[0045] (3) Prepare coagulation bath solution. Add 2.5 g of phosphoric acid maleic anhydride to 500 mL of deionized water and dissolve to obtain a phosphoric acid maleic anhydride solution;

[0046] The mixed solution obtained in step (2) is dripped into the maleic anhydri...

Embodiment 3

[0050] (1) Put 10.5g of sodium acrylate and 300g of deionized water into the reactor, stir to dissolve it completely, prepare an aqueous solution of sodium acrylate, add 30g of sodium hydroxide to the solution, stir to dissolve, add 3.1g of potassium persulfate, start Stir, heat up to 90°C, initiate polymerization, and complete the reaction in about 30 minutes to obtain a 3.5 wt% sodium polyacrylate prepolymer solution;

[0051] (2) Place the four-necked flask containing the above sodium polyacrylate prepolymer solution in a 70°C water bath, add 1.55g of sodium dodecylbenzene sulfonate and stir to dissolve it, and then add 126g of fluorocarbon to the flask Resin, stirring speed 650r / min, continue stirring for 1.5h to obtain a mixed solution.

[0052] (3) Prepare coagulation bath solution. Add 12.5g of N,N'-methylenebisacrylamide to 500mL of deionized water and dissolve to obtain a N,N'-methylenebisacrylamide solution;

[0053] The mixed solution obtained in step (2) is dripped into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com