Assembly type non-dismantling concrete formwork and manufacturing method thereof

A concrete formwork and concrete technology, which is applied to building structures, building components, walls, etc., can solve the problems of low degree of industrialization of buildings, large manpower consumption of formwork, and large amount of wood used, so as to shorten the construction period, improve the building assembly rate, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

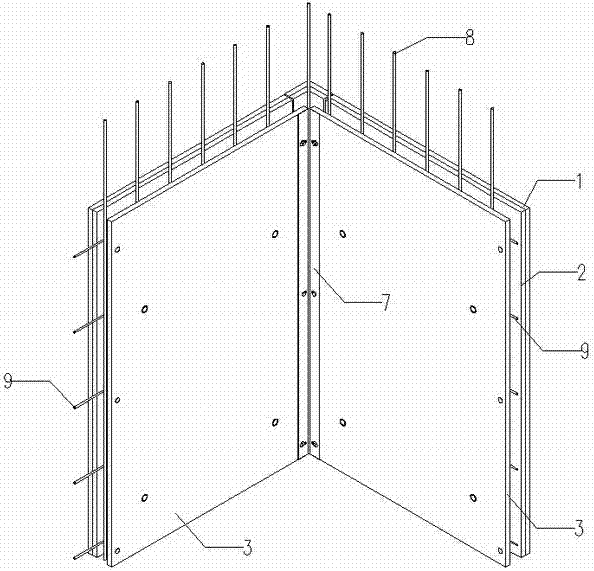

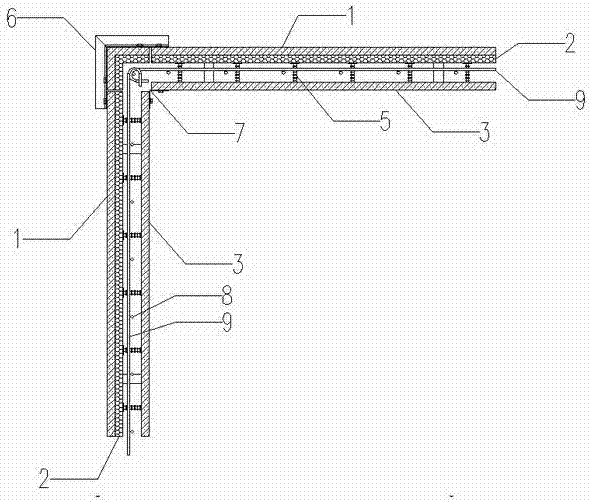

[0040] Attached below Figure 1-8 The technical scheme of band insulation board among the present invention is described in detail:

[0041] An assembled non-detachable concrete formwork, which includes a straight section formwork and a corner section formwork;

[0042] The straight section template includes an outer concrete protection layer 1, an insulation board 2 and an inner concrete protection layer 3 from outside to inside;

[0043] The formwork of the corner section includes an "L"-shaped concrete protective layer 11 and an "L"-shaped insulation board 12 attached to the inner side from the outside to the inside;

[0044] The outer concrete protection layer 1, the insulation board 2 and the inner concrete protection layer 3 are connected as a whole through tie rods 5 evenly distributed in the inner cavity;

[0045] A steel wire flat mesh 4 is arranged inside the outer concrete protective layer 1 , the inner concrete protective layer 3 and the "L" shaped concrete prote...

Embodiment 2

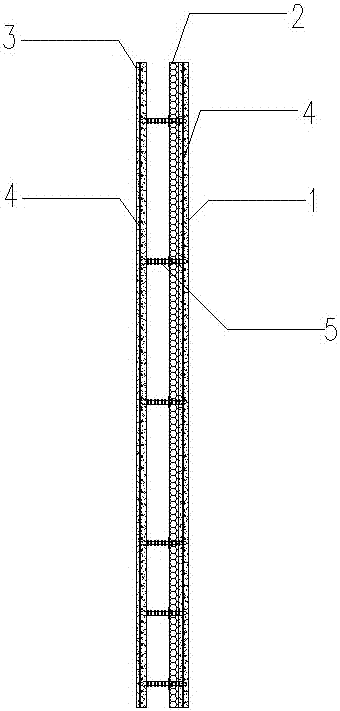

[0052] Attached below Figure 9 And the content of embodiment 1 describes in detail the technical scheme without insulation board among the present invention:

[0053] An assembled non-detachable concrete formwork, which includes a straight section formwork and a corner section formwork;

[0054] The straight section template includes an outer concrete protective layer 1 and an inner concrete protective layer 3 from outside to inside;

[0055] The formwork of the corner section only has an "L" type concrete protective layer 11;

[0056] The outer concrete protective layer 1 and the inner concrete protective layer 3 are connected as a whole through tie rods 5 evenly distributed in the inner cavity;

[0057] A steel wire flat mesh 4 is arranged inside the outer concrete protective layer 1 , the inner concrete protective layer 3 and the "L" shaped concrete protective layer 11 .

[0058] In a further solution, the structural vertical steel bars 8 are bound in the vertical direc...

Embodiment 3

[0064] The technical scheme of the manufacturing method in the present invention is described in detail below in conjunction with accompanying drawing and the content of embodiment 1,2:

[0065] A method for manufacturing a prefabricated demolition-free concrete formwork, the manufacturing steps of which are as follows:

[0066] A. Install and bind the vertical reinforcement of the structure;

[0067] B. Lift the straight section formwork and install it according to the setting-out position. When falling, install the vertical steel bars of the structure in the designated area and fix it;

[0068] C. From the opening position of the end of the straight section formwork, penetrate the transverse reinforcement of the structure from the end, place the transverse reinforcement of the structure on the tie rod, and the tie rod is designed with a limit groove for fixing the transverse reinforcement;

[0069] D. Repeat steps B and C to install the straight section formwork, structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com