Fabricated spliced partition thin formwork

A prefabricated, formwork technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of narrow width, heavy weight, manual handling, etc., to achieve the effect of shortening time and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

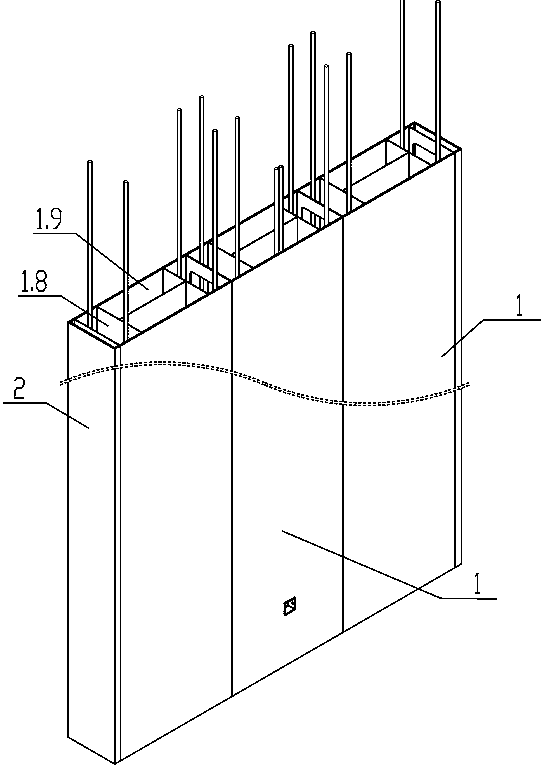

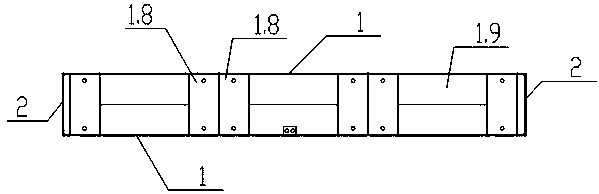

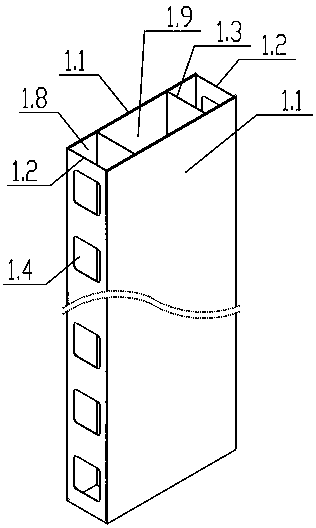

[0047] Attached below figure 1 , 2 , 3, 4, 7, 8, 9, 10 describe the present invention in detail:

[0048] A prefabricated mosaic partition wall light and thin formwork, the formwork includes two parts, namely the middle splicing model board 1 and the end edge sealing model board 2;

[0049] The structure of the middle splicing model board 1 is composed of two types of cavities; the cavity area enclosed by the end rib 1.2 and a middle rib 1.3 adjacent to it and the panel 1.1 is the concrete pouring cavity 1.8, and the cavity For installing steel bars and pouring concrete;

[0050] The cavity area enclosed by the middle rib 1.3 and the two side panels 1.1 is the conduit installation cavity 1.9, which is used for installing conduits and sockets;

[0051] The concrete pouring cavity 1.8 and the line pipe installation cavity 1.9 are arranged side by side along the length direction of the intermediate splicing formwork 1 and are separated from each other.

[0052] A middle parti...

Embodiment 2

[0070] Attached below figure 1 , 2 , 5, 6, 7, 8, 9, 10 describe the present invention in detail:

[0071] In this embodiment, it is an additional preferred solution to provide an intermediate partition 1.5 in the middle of the wire pipe installation cavity 1.9. Other structural features and schemes are equal to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com