A light-weight concrete-filled steel tube composite column for steel structure buildings and its construction method

A technology of concrete-filled steel pipe columns and concrete-filled steel pipes, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of the surrounding concrete being heavy, destroying the surrounding concrete, and poor seismic performance, and achieves simple structure, improved mechanical performance, and no material The effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

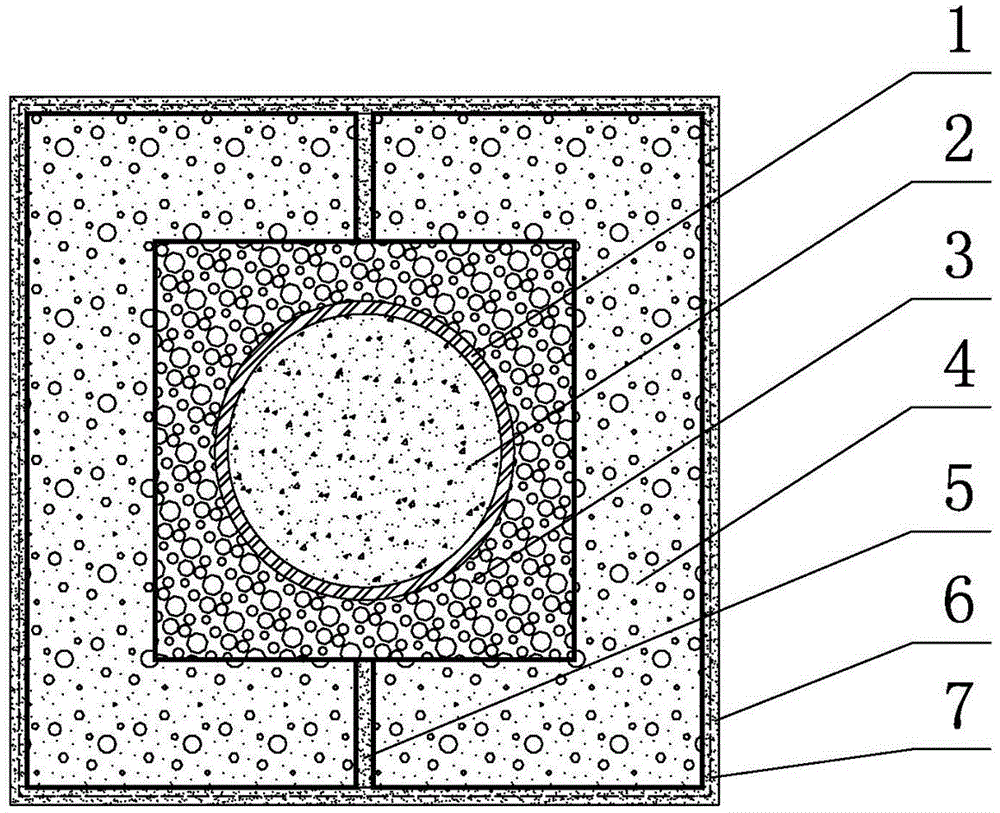

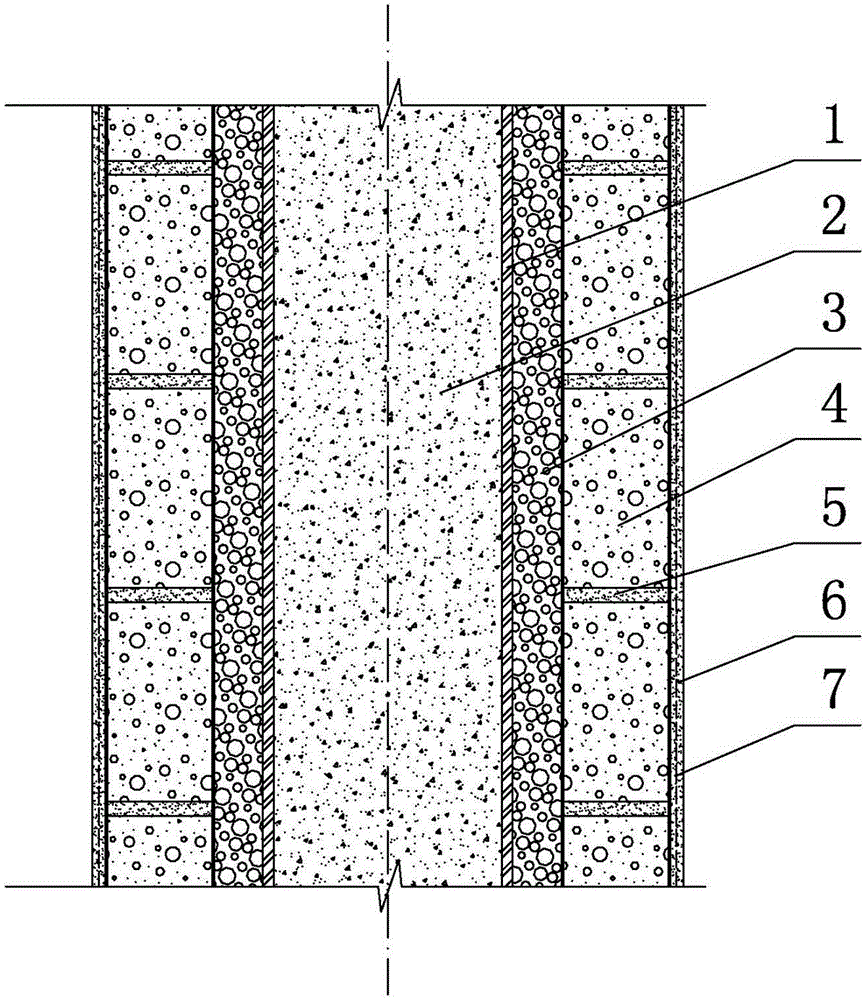

[0039] see figure 1 and figure 2 As shown, the lightweight concrete-filled steel tube composite column of the steel structure building consists of core steel pipe 1, concrete 2, lightweight thermal insulation mortar 3, lightweight thermal insulation block 4, masonry mortar 5, crack-resistant mortar 6, and glass fiber mesh cloth 7 components, wherein the lightweight thermal insulation mortar 3 uses polystyrene granular foam concrete slurry, and the lightweight thermal insulation block 4 uses polystyrene granular concrete blocks. The cross section of the steel pipe 1 is circular.

[0040] The construction method of this lightweight steel tube concrete composite column is as follows:

[0041] Step 1: Cutting the core steel pipe 1 in the steel tube concrete according to the design requirements, and pouring high-strength concrete that meets the standards or design requirements in the core steel tube 1 to form a steel tube concrete column;

[0042] Step 2. Weld and fix the steel...

Embodiment 2

[0048] See eg figure 1 , figure 2 As shown, the lightweight concrete-filled steel tube composite column of a steel structure building is composed of steel pipe 1, concrete 2, lightweight thermal insulation mortar 3, lightweight thermal insulation block 4, masonry mortar 5, crack-resistant mortar 6, and glass fiber mesh 7; The difference from Example 1 is that foamed cement paste is used for the lightweight thermal insulation mortar, and foamed concrete blocks are used for the lightweight thermal insulation blocks.

[0049] The construction method of this lightweight steel tube concrete composite column is as follows:

[0050] Step 1: Cutting the core steel pipe 1 in the steel tube concrete according to the design requirements, and pouring high-strength concrete that meets the standards or design requirements in the core steel tube 1 to form a steel tube concrete column;

[0051] Step 2. Fix the steel tube concrete column and other steel structural components in the building...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com