Machining method of whole-wood and fresh-wood cutting board, protecting agent and protecting agent application method

A processing method and protective agent technology, which is applied in the processing of fresh wood cutting boards and the field of whole wood, can solve the problems of cutting board cracking, mildew, discoloration, discoloration, easy cracking by consumers, etc., and achieve the effect of beautiful and clear wood grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

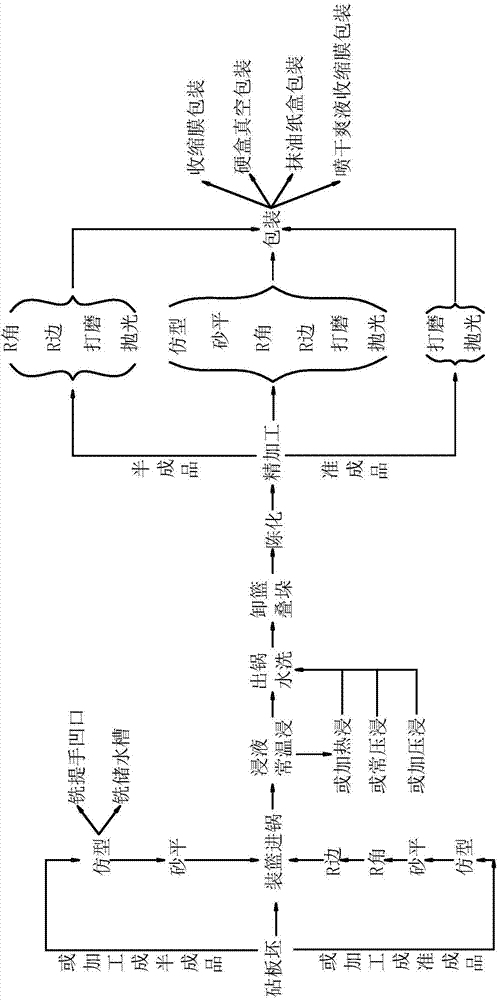

[0025] A kind of whole wood, the processing method of fresh wood chopping board, concrete processing steps are as follows:

[0026] ① Prepare the whole wood, fresh wood cutting board or semi-finished products or slabs;

[0027] ②Preparation of protective fluid with anti-mildew and anti-cracking;

[0028] ③In the basket, put the cutting board blank or semi-finished product or finished product into the empty impregnation basket in a vertical or side vertical manner;

[0029] ④Into the pot, put the chopping board blank or semi-finished product or finished product into the dipping pot filled with protective liquid through the spreader to soak; the spreader is an ordinary hoisting machine such as a crane.

[0030] ⑤ Take out the pot, soak the protective liquid until the required depth of immersion is reached, and take out the cutting board blank or semi-finished product or finished product;

[0031] ⑥ Cleaning, filter the cutting board blank or semi-finished product or finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com