Anti-cracking salt chemical engineering equipment pipeline

A salt chemical and anti-cracking technology, which is applied in pipeline protection, mechanical equipment, pipeline damage/wear prevention, etc. It can solve the problems of corrosion fatigue and can not significantly improve the service life of components, so as to prolong the service life and increase the maximum pre-pressure value , the effect of uniform pre-pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

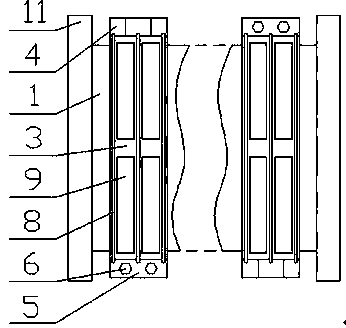

[0056] combine figure 1 with figure 2 It can be seen that the present invention includes a salt chemical equipment pipeline 1, on the outer wall of the salt chemical equipment pipeline 1, a plurality of tight hoops 3 are sequentially sleeved along the length direction of the pipeline, and the tight hoops 3 are in the shape of two symmetrical semicircular arcs structure, one side of the hoop 3 is connected by a hinge 4, and the other side is fixed by a bolt 6, and the hoop 3 is provided with a radial preload pointing to the axis for the pipeline 1 of the salt chemical industry equipment, and the radial preload It is equal to or greater than the brine 2 pressure in the pipeline 1 of the salt chemical equipment. By being provided with a tight hoop 3 on the surface of the salt chemical equipment pipeline 1, the tight hoop 3 applies a radial preload to the salt chemical equipment pipeline 1, offsetting the pressure of the brine 2 in the salt chemical equipment pipeline 1 for the ...

no. 2 example

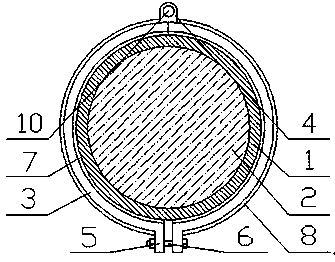

[0062] Such as image 3It can be seen that the present invention includes a salt chemical equipment pipeline 1, an oil pressure pipeline 3' is sleeved outside the pipeline of the salt chemical equipment pipeline 1, and the oil pressure pipeline 3' is coaxially arranged with the salt chemical equipment pipeline 1. A one-way oil inlet valve 13 is provided on the side wall of the pipeline 3', and a hydraulic oil 12 is provided between the oil pressure pipeline 3' and the pipeline 1 of the salt chemical equipment. By setting the oil pressure pipeline 3' on the surface of the salt chemical equipment pipeline 1, and filling the hydraulic oil 12 between the oil pressure pipeline 3' and the salt chemical equipment pipeline 1, the pressure of the hydraulic oil 12 is equal to or greater than that of the salt chemical equipment pipeline 1 inside the brine 2 pressure. The pressure of the hydraulic oil 12 on the pipeline 1 of the salt chemical equipment offsets the pressure of the brine 2...

no. 3 example

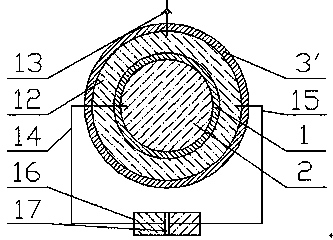

[0065] Such as Figure 4 It can be seen that the present invention includes a salt chemical equipment pipeline 1, an oil pressure pipeline 3' is sleeved outside the pipeline of the salt chemical equipment pipeline 1, and the oil pressure pipeline 3' is coaxially arranged with the salt chemical equipment pipeline 1. A hydraulic oil 12 is provided between the pipeline 3' and the pipeline 1 of the salt chemical equipment, and an oil inlet pipe 13' and a brine pipe B14' are respectively arranged on the side walls of the oil pressure pipeline 3', and one end of the oil inlet pipe 13' passes through The side wall of the oil pressure pipeline 3' communicates with the hydraulic oil 12 in the oil pressure pipeline 3', and the other end of the oil inlet pipe 13' communicates with the liquid outlet of the hydraulic pump 18 through the oil pipe C26; one end of the brine pipe B14' Respectively pass through the side wall of the oil pressure pipeline 3' and the side wall of the salt chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com