Heat insulation decoration line

A technology of decorative lines and lines, applied in thermal insulation, climate change adaptation, building components, etc., can solve problems such as long construction period, difficult installation, and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

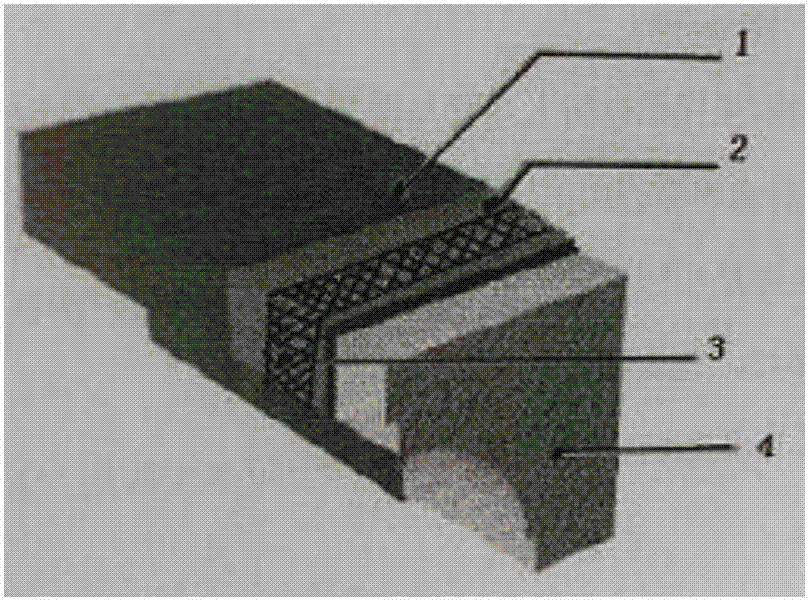

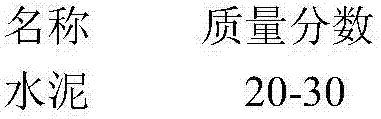

[0016] Example 1 as figure 1 As shown, a kind of thermal insulation decorative line, from the outside to the inside is 1-decorative layer 2-special mortar layer 3-pasted alkali-resistant glass fiber mesh layer 4-graphite polystyrene insulation line, the special mortar layer is made of Composed of cement, river sand, rubber powder, cellulose, defoamer, and water. The proportion of the mortar layer is as follows: cement 25kg, river sand 55kg, rubber powder 0.5kg, cellulose 0.1kg, defoamer 0.01kg, water 10kg. The thickness of the decorative layer is 1mm, the thickness of the mortar layer is 2mm, and the density of the graphite polystyrene insulation line is 18kg / m 3 .

Embodiment 2

[0017] Example 2 as figure 1 As shown, a kind of thermal insulation decorative line, from the outside to the inside is 1-decorative layer 2-special mortar layer 3-pasted alkali-resistant glass fiber mesh layer 4-graphite polystyrene insulation line, the special mortar layer is made of Composed of cement, river sand, rubber powder, cellulose, defoamer, and water. The proportion of the mortar layer is as follows: cement 30kg, river sand 52kg, rubber powder 0.6kg, cellulose 0.2kg, defoamer 0.02kg, water 20kg. The thickness of the decorative layer is 2mm, the thickness of the mortar layer is 3mm, and the density of the graphite polystyrene insulation line is 19kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com