High linearity sine wave generator followed by clock multiplier dividing

A sine wave generator, high linearity technology, applied in the direction of electrical components, etc., can solve the problems of inability to achieve frequency stability, linearity cannot be improved, large capacitance value, etc., to achieve simple design and implementation, high linearity, and improved linearity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

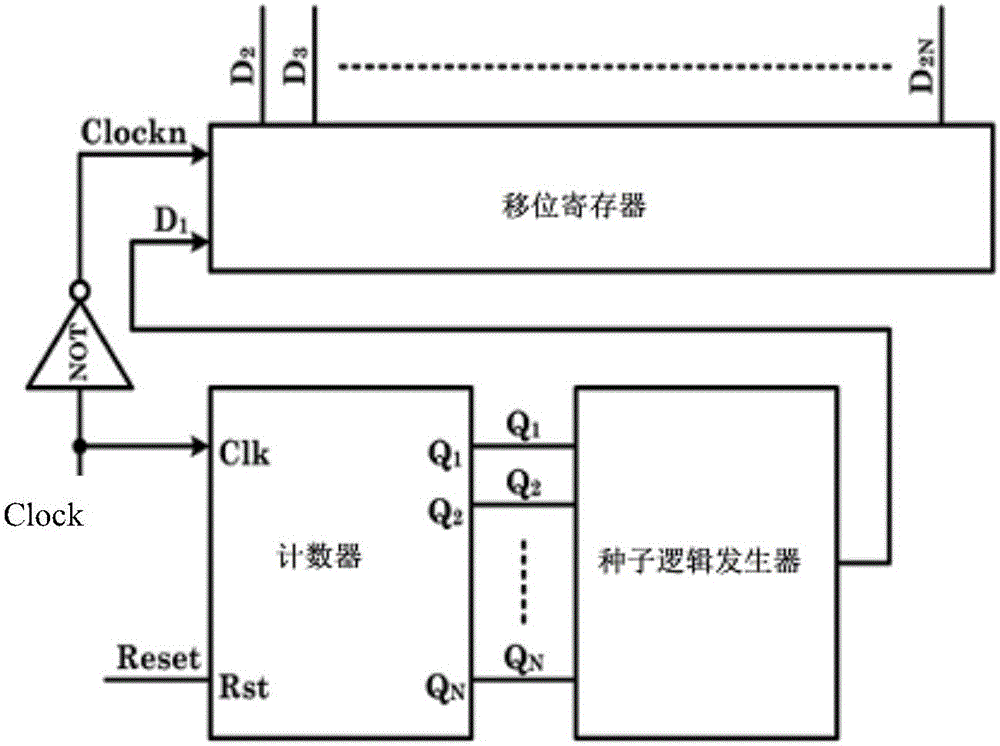

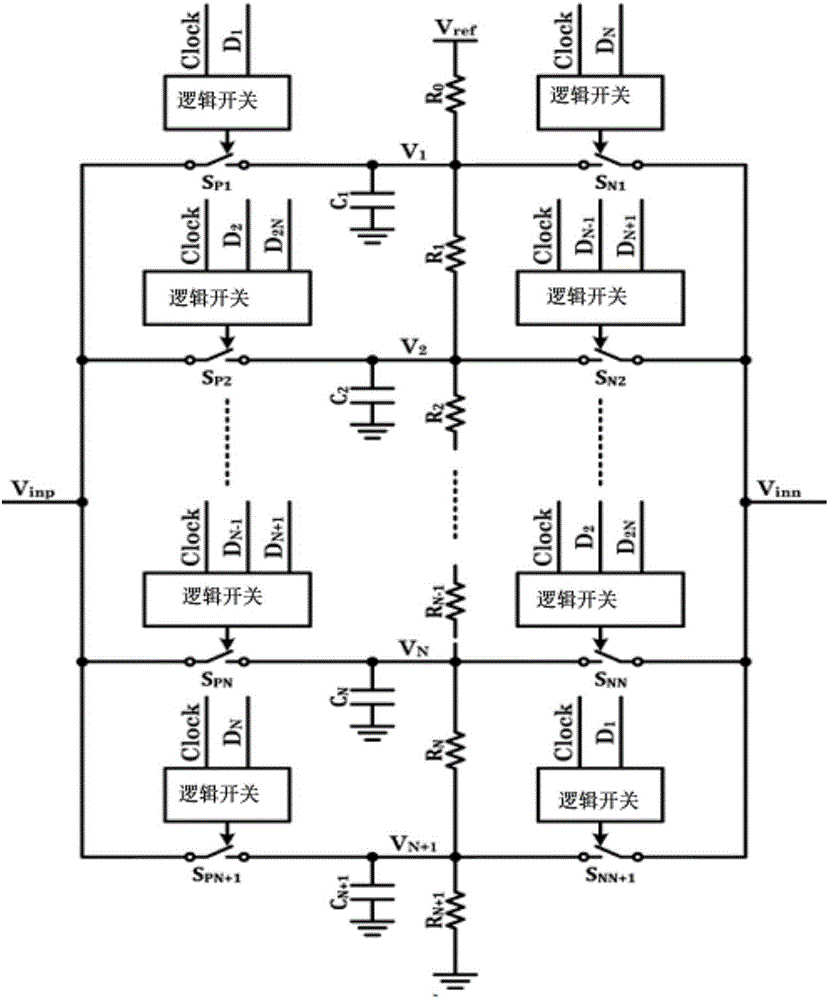

[0024] see figure 1 , figure 2 and image 3 , a high linearity sine wave generator except clock multiple follower, including a reference voltage input terminal Vref, a ground terminal, a fully differential amplifier and a plurality of series voltage dividing resistors, the voltage dividing resistors include the zero resistance R 0 , the first resistor R 1 , the second resistance R 2 ...the N+2th resistor Rn +2 , the zero resistance R 0 One end of is connected to the reference voltage input end, and the N+2th resistor Rn +2 The resistor is connected to the ground terminal, and a first voltage output point V 1 , the second voltage output point V2...the N+1th voltage output point V N+1 . Among them, the first voltage output point is set at the zero resistance R 0 with the first resistor R 1 Between, and so on, the setting position of N+1 voltage output points is between two voltage divider resistors.

[0025] Such as figure 2 , the first voltage output point V 1 To...

Embodiment 2

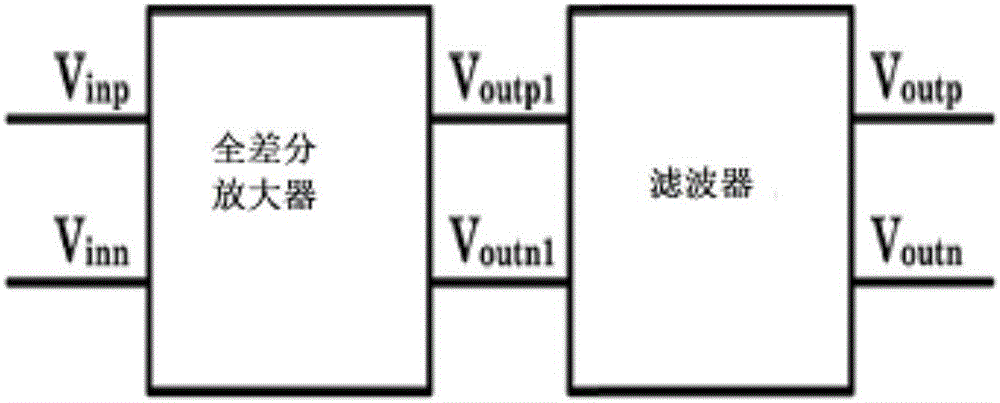

[0043] see Figure 4 , input a stable frequency clock signal from the crystal oscillator to a high linearity sine wave generator followed by clock multiples. In addition to the high linearity sine wave generator followed by the clock multiple, the differential output clock follows the stable frequency sine wave signal to the substrate of the sensor, and the positive terminal outputs V outp Connect the upper substrate V of the sensor st , the negative terminal outputs V outn Connect the lower substrate V of the sensor sb [The connection can also be reversed to output V for the positive terminal. outp Connect the lower substrate V of the sensor sb , the negative terminal outputs V outn Connect the upper substrate V of the sensor st 】. The substrate of the sensor V ctr Connect the negative terminal input of the front-end amplifier, connect the feedback capacitor C f One end, connected to the feedback resistor R f one end. The positive input of the front-end amplifier i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com