Nanocomposite foaming agent and its preparation method and foamed product

A composite foaming agent and nano-composite technology, applied in the field of preparation of nano-composite foaming agents, can solve the problems of foaming efficiency and quality reduction, difficulty in controlling cell size, difficulty in uniform dispersion, etc. Small, to avoid the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

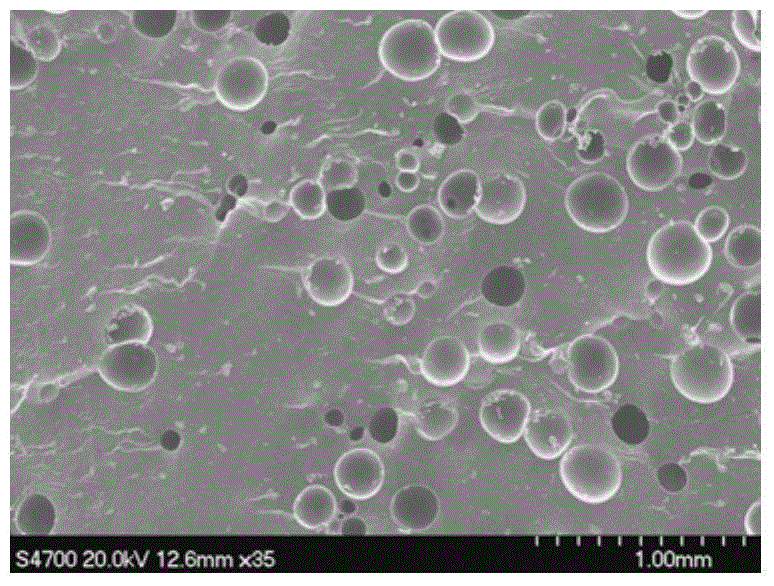

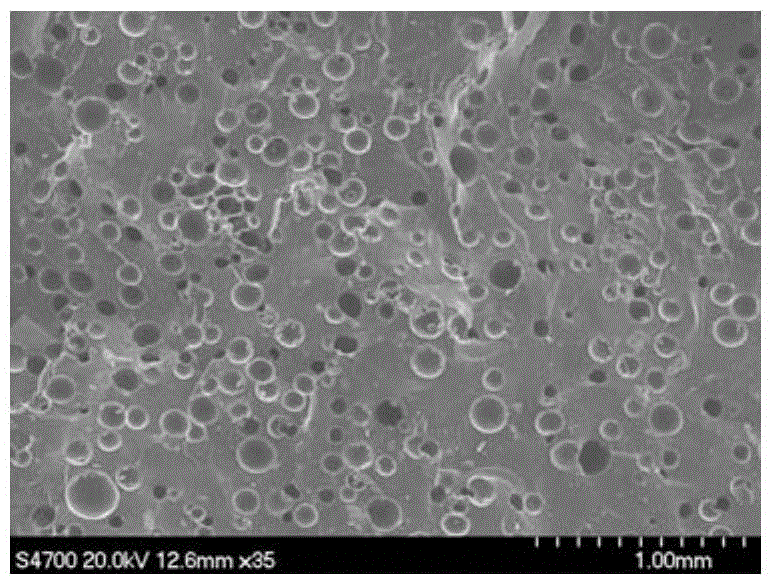

Image

Examples

preparation example Construction

[0035] The invention provides a nano-composite foaming agent and a method for preparing the nano-composite foaming agent. The preparation method is characterized in that the calcium-based montmorillonite is acidified and modified first, and then the montmorillonite is decomposed by ultrasonic action. peel off. Dissolve the organic foaming agent in a certain amount of solvent, add it to the stripped montmorillonite system, stir and react at a certain temperature, and through a suitable washing process, the OBSH in the layer can be evenly dispersed in the montmorillonite after being precipitated. Between the soil layers, the OBSH outside the layer is removed at the same time, and dried to constant weight to obtain a nanocomposite foaming agent.

[0036] In the present invention, "nano" in the so-called "nanocomposite foaming agent" describes the composite process, because the monolithic layer thickness of montmorillonite is about 1 μm, and the original soil particle size of mont...

Embodiment 1

[0056] The preparation of embodiment 1 composite blowing agent

[0057] (1) Preparation of hydrogenated montmorillonite

[0058] Weigh 1g of calcium-based montmorillonite (particle size 20-40μm), and disperse it into 100ml of deionized water with electromagnetic stirring at 25°C, then add 10ml of 1mol / L HCl, and react at 85°C for 4h. After the reaction was completed, the precipitate was centrifuged, washed with deionized water until neutral, and dried at 75°C for 12 hours to achieve a constant weight, that is, to obtain hydrogenated montmorillonite, which was denoted as H-MMT.

[0059] (2) Preparation of 4,4-oxobisbenzenesulfonyl hydrazide / montmorillonite composite foaming agent by stripping and recombining

[0060] Weigh 1g of H-MMT and disperse it into 25mL of deionized water at room temperature. After electromagnetic stirring for 2h, ultrasonic stripping at 25°C for 10min, add 75mL of DMF to the system, and then sonicate for 60min. Then, 20 mL of DMF solution dissolved wi...

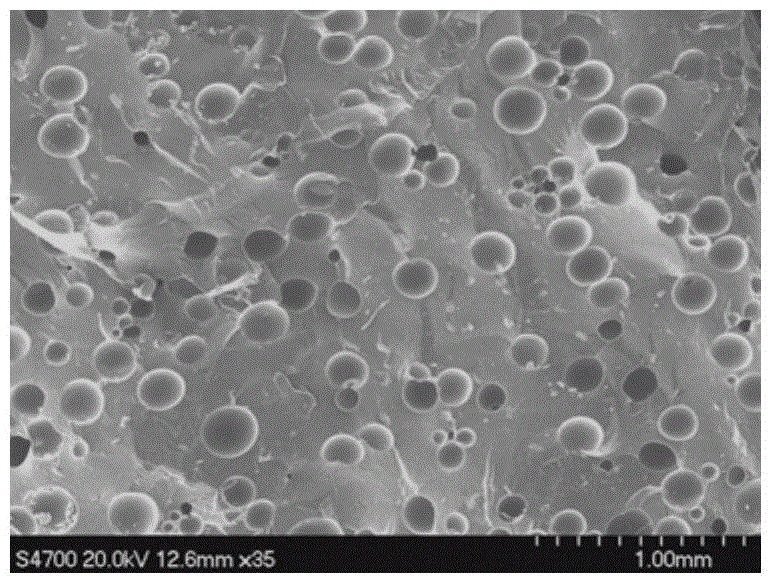

Embodiment 2

[0061] The preparation of embodiment 2 composite foaming agent

[0062] (1) Preparation of hydrogenated montmorillonite

[0063] Weigh 1g of calcium-based montmorillonite (particle size 40-70μm), and disperse it into 100ml of deionized water under electromagnetic stirring at 25°C, then add 10ml of 1mol / L HCl, and react at 75°C for 4h. After the reaction was completed, the precipitate was centrifuged, washed with deionized water until neutral, and dried at 80°C for 12 hours to reach a constant weight, that is, to obtain hydrogenated montmorillonite, which was denoted as H-MMT.

[0064] (2) Preparation of 4,4-oxobisbenzenesulfonyl hydrazide / montmorillonite composite foaming agent by stripping and recombining

[0065] Weigh 1g of H-MMT and disperse it into 40mL of deionized water at room temperature. After electromagnetic stirring for 2h, ultrasonic stripping at 25°C for 30min, add 75mL of DMF to the system, and then sonicate for 15min. Then, 8 mL of DMF solution in which 3 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com