Backpack high-pressure electric sprayer

An electric sprayer and knapsack technology, applied in the direction of DC motor speed/torque control, electrical components, injection devices, etc., can solve the problems of assembly and maintenance troubles, damage to motors and pumps, low work efficiency, etc., to achieve convenient operation, Simplified structure, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

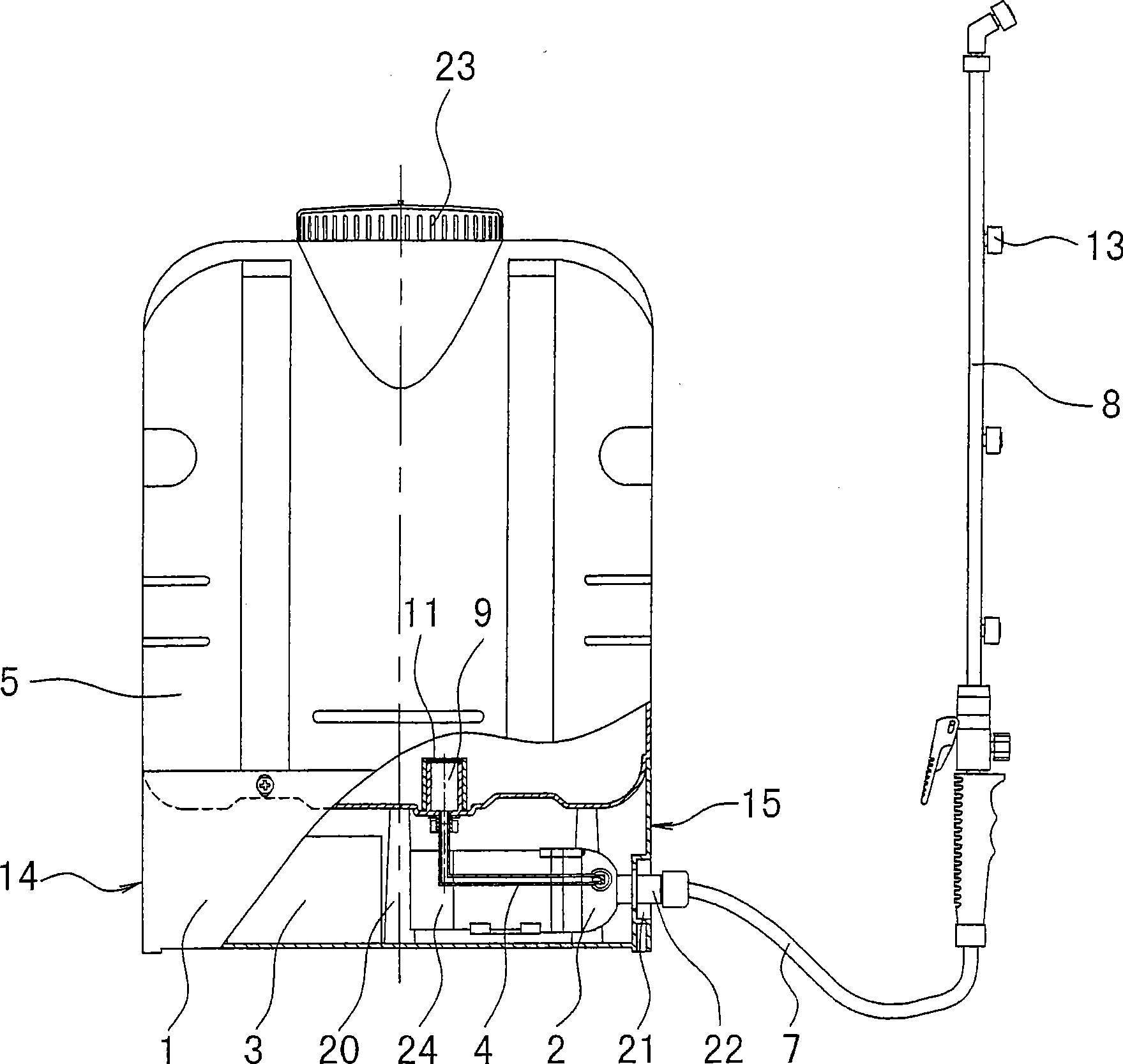

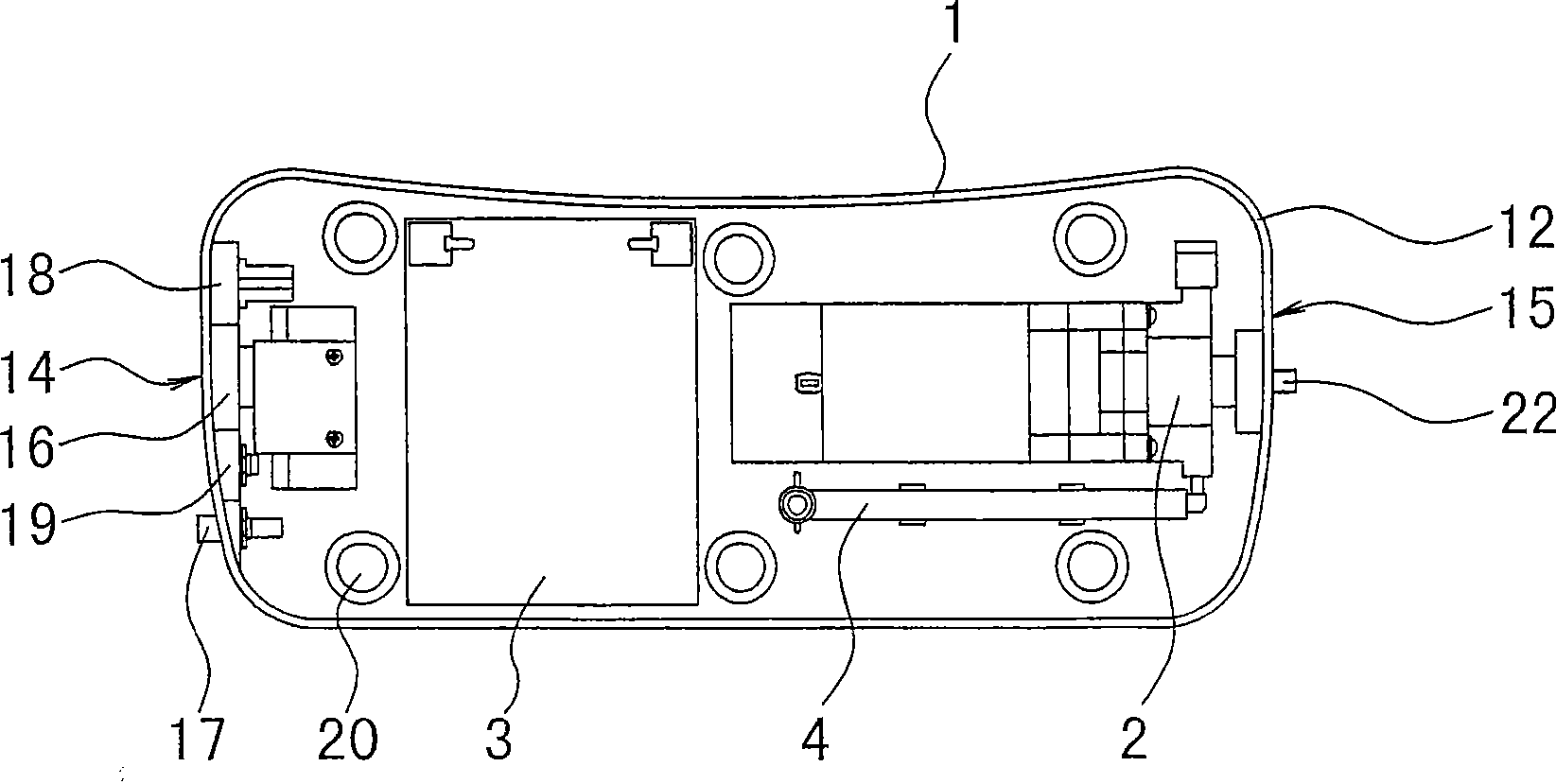

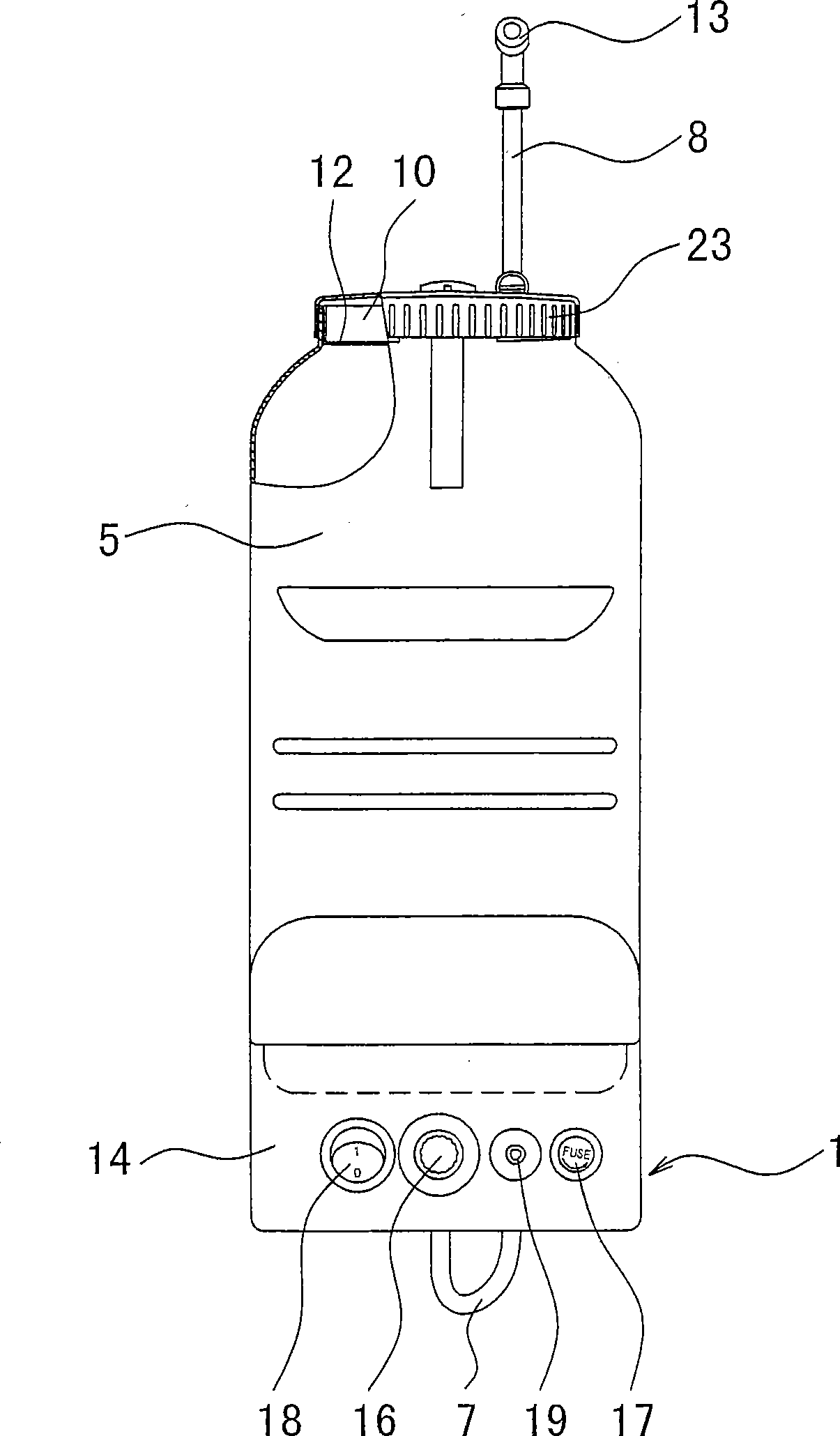

[0012] The invention relates to a backpack type high-pressure electric sprayer, such as figure 1 — Figure 5 As shown, it includes a base 1, an electric pump assembly and a storage battery 3 are installed in the base 1, and the electric pump assembly is a diaphragm pump 2 driven by a DC motor 24, the water inlet pipe 4 of the diaphragm pump 2 is connected to the water tank 5, and the diaphragm pump 2 The water outlet is connected to the spray bar 8 by the water outlet pipe 7, and the spray bar 8 is connected to the spray head 13. The water tank 5 is installed on the base 1, and the top of the water tank 5 is shaped on a liquid filling port 10. The liquid filling port 10 is equipped with a cover 23, and straps are installed on the water tank wall. It is characterized in that a support column 20 is formed in the base 1, and the top surface of the support column 20 is in contact with the bottom surface of the water tank 5 and is higher than the installation plane of the battery 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com