Injection molding hyperboloid reflector and injection molding method thereof

A hyperboloid reflector and hyperboloid technology, which is applied to mirrors, other household appliances, optical components, etc., can solve the problems of inability to process reflectors, etc., and achieve the effects of improving light utilization, easy process operation, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

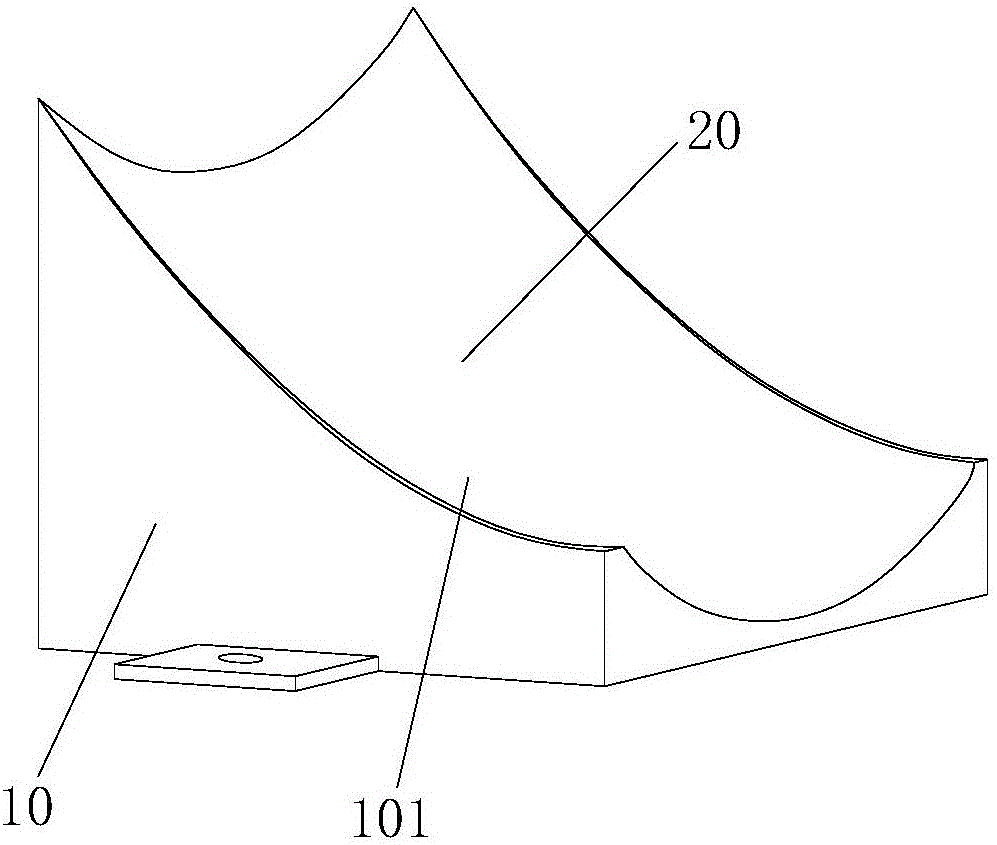

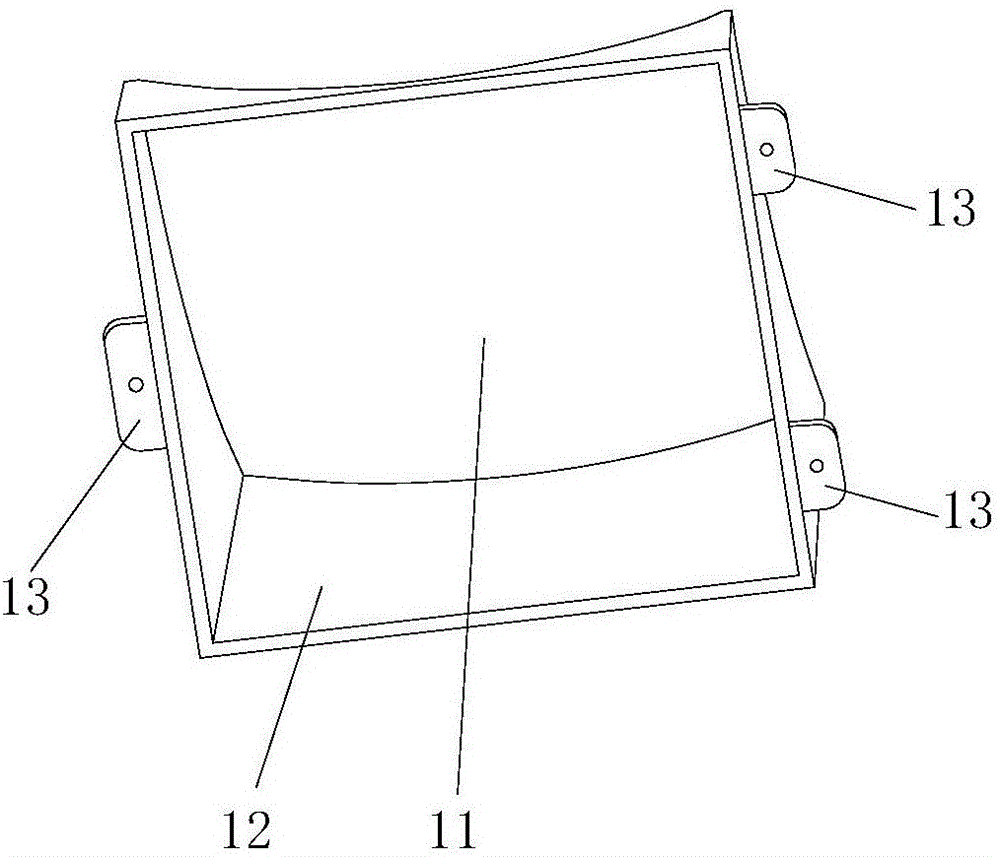

[0033] combine figure 1 and figure 2 As shown, an injection molded hyperboloid reflector of the present invention includes a base 10 with a hyperboloid concave arc surface 101 obtained by injection molding by injection molding process, and a reflective layer 20 .

[0034] In order to ensure the smoothness of the reflective layer 20 , it is necessary to ensure that the roughness Ra of the concave arc surface 101 of the base 10 is 0.3-0.7 μm.

[0035] The base 10 is made of engineering plastics. Specifically, one of PMMA, PC, PPO and ABS or a composite injection molding material of at least two of them is preferably used.

[0036] The reflective layer 20 is coated on the concave arc surface 101 of the base 10 by a vacuum coating process. Wherein, the vacuum coating process may specifically adopt vacuum sputtering, vacuum evaporation or vacuum electroplating. The specific vacuum coating process can be determined according to the specific material of the reflective layer 20 ...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a relational equation that the curved surface of the hyperboloid concave arc surface 101 of the hyperboloid mirror satisfies. The relationship of the concave arc surface 101 of the hyperboloid on the base 10 of the reflector in the X-axis, Y axis and Z-axis direction in the three-dimensional coordinate system is as follows: with a corner of the concave arc surface 101 as the origin, Z=( x 2 +y 2 ) / 2n, the value range of n is 300mm~700mm; where Z is the height in the Z-axis direction, X is the length in the X-axis direction, Y is the length in the Y-axis direction, and the units of X and Y are millimeters. The values of X and Y are continuous numerical intervals, X is in the range of (0,400mm], and Y is in the range of (0,380mm].

[0041] The focal length of the hyperboloid reflector of present embodiment 2 is between 100mm~190mm; And the focal length of the square Fresnel condenser lens (380mm×380mm) of similar size is ...

Embodiment 3

[0043] The present embodiment 3 is the preparation method of the injection molded hyperboloid mirror of the present invention, comprising the following steps:

[0044] Step 1, preparing the base by injection molding: preparing a mold, the mold has a cavity consistent with the outline of the reflector base; filling the cavity of the mold with plastic melt, heat preservation and pressure, cooling, and demoulding to obtain base;

[0045] Step 2, connecting a reflective layer on the concave arc surface of the base prepared in step 1; obtaining an injection molded hyperboloid mirror.

[0046] In step 1 of Example 3, in order to ensure that the roughness Ra of the concave arc surface of the base reaches the range of 0.3-0.7 μm, it is necessary to match the concave arc surface of the mirror base in the mold cavity to The inner wall of the matching convex arc is specially treated so that the roughness Ra of the inner wall of the convex arc is 0.1-0.5 μm. Specifically, the roughness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com