Finished cementing material for pouring type asphalt mixture and preparation method of finished cementing material

A kind of asphalt mixture and pouring technology, which is applied in the direction of building insulation materials, buildings, building components, etc., can solve the problems of poor material uniformity, affecting the performance of cement, fusion, etc., achieve high temperature and low temperature performance improvement, and ensure production safety , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

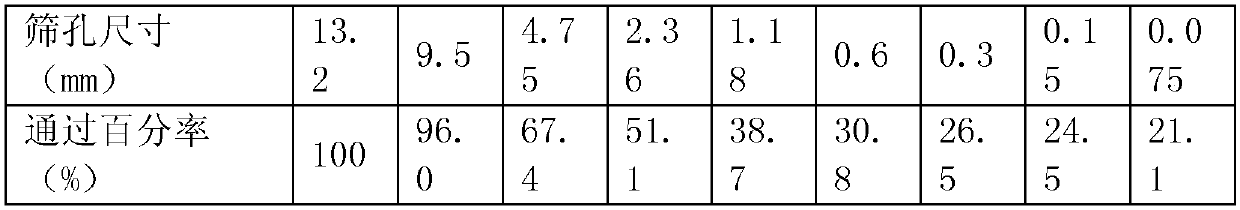

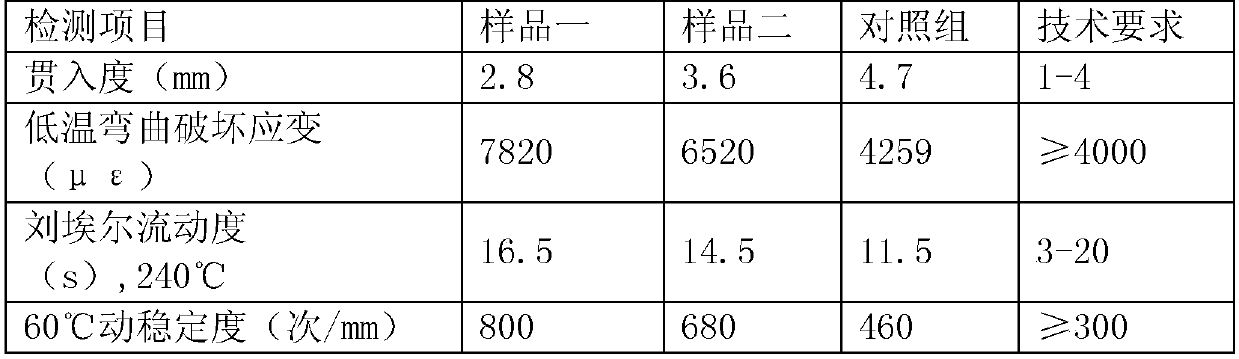

Embodiment 1

[0029] Example 1: Add 3% of SBS modifier 4303 and 2% of chlorinated polyethylene rubber into 50% of Zhenhai 90# asphalt at 160°C, after fully swelling and shearing, enter the premix tank; The 44.7% natural bitumen mother liquor with penetration of 20 (0.1mm) was heated to 190°C, pumped into the premix tank by the bitumen pump, and the two were fully stirred, then 0.3% sulfur stabilizer was added, and the mixture was grown at 180°C for 2 Sample 1 was obtained within hours.

Embodiment 2

[0030] Example 2: 4% SBS modifier 4303, 1% 60-mesh rubber powder, and 34.5% Zhenhai 70# asphalt at 170°C were added to the premix tank after fully swelling and shearing; 60% of the natural asphalt mother liquor with a penetration of 10 (0.1mm) is heated to 180°C, and pumped into the premix tank by an asphalt pump. After the two are fully stirred, add 0.5% sulfur stabilizer and grow at 180°C for 2 hours That is, the second sample is obtained.

[0031] Control group: After heating the conventional SBS I-C modified asphalt (using 4303 SBS modifier, and the amount of the modifier accounts for 4.5% of the modified asphalt mass) to 170 °C, put in 300 mesh natural asphalt powder, and modify it. The ratio of bitumen to natural bitumen is: 80:20. After mixing the two evenly, a control sample was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com