Light-cured single-component waterborne epoxide, waterproof material and preparation method of waterproof material

A water-based epoxy and waterproof material technology, applied in building insulation materials, building components, buildings, etc., can solve the problems of damage, easy sticking, low bonding strength of modified emulsified asphalt, etc., to improve low temperature flexibility, cost Low, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

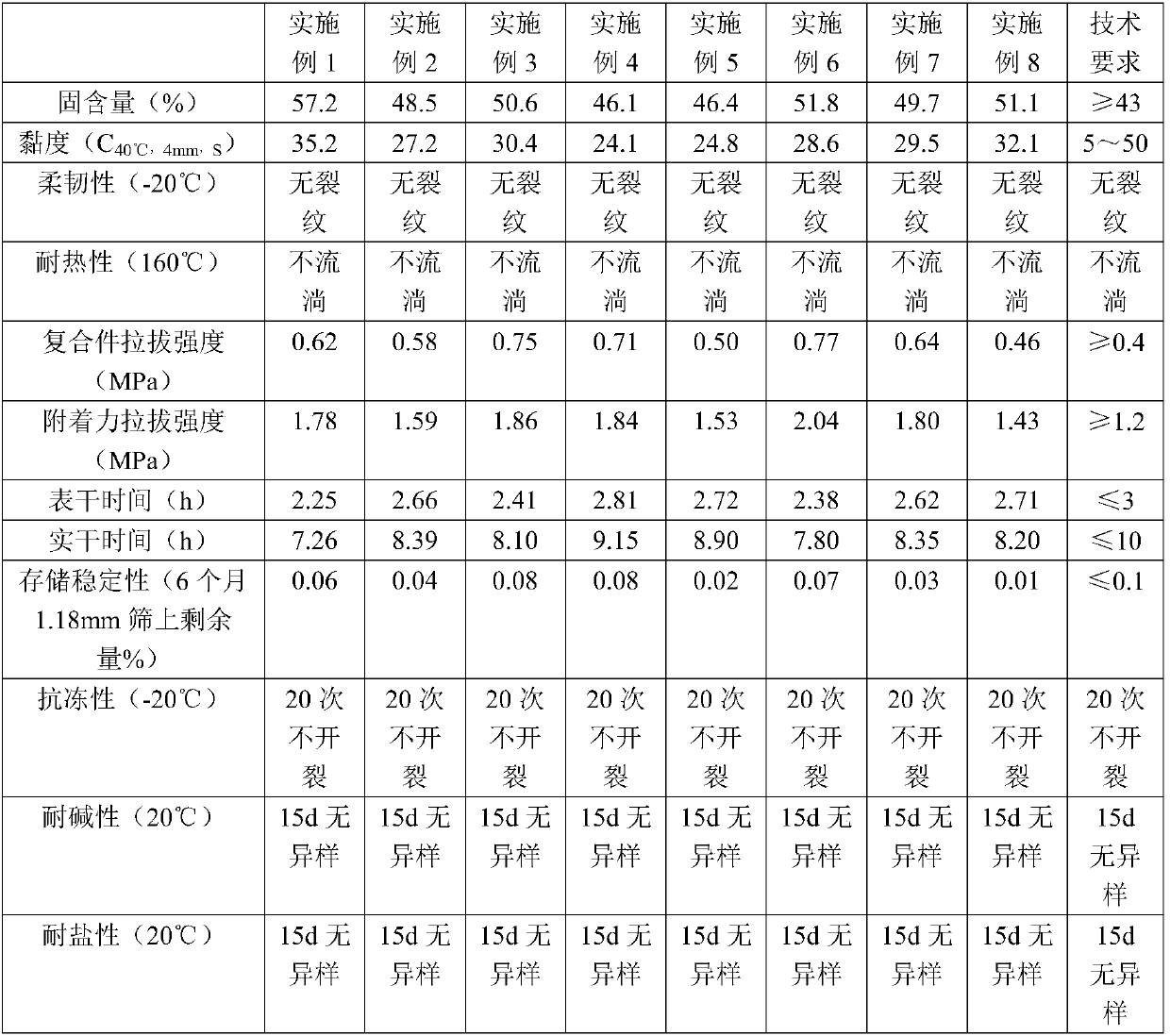

Examples

Embodiment 1

[0040] (1) First weigh 300g of water, 400g of epoxy resin E51, 10g of acrylic acid, 2g of polymerization inhibitor p-benzoquinone, and 30g of diethylaminoethanol into a 1L reactor, heat the reactor to 50°C and stir for 1 hour. Then put 40g of ethylene glycol monobutyl ether and 20g of unsaturated acid anhydride into the reactor and stir for 20min, then cool down the reactor to 20°C, add 10g of water-based photoinitiator Irgacure4265 and stir rapidly for 1h to obtain a photocurable single-component Waterborne epoxy resin;

[0041](2) Heat 500g of 30# asphalt to 185°C, add 10g of SBS modifier, cut in the colloid mill for 1.5h, add 40g of didodecylphenyl ether disulfonate emulsifier and 510g Water is emulsified to prepare emulsified SBS asphalt; then the emulsified asphalt prepared is cooled to room temperature; the emulsified asphalt cooled to room temperature is put into the reactor while stirring and added the SBR latex of 50g and the single prepared by 120g step (1) One-comp...

Embodiment 2

[0043] (1) First weigh 600g of water, 500g of epoxy resin E44, 30g of acrylic acid, 4g of polymerization inhibitor p-benzoquinone, and 50g of diethylaminoethanol into a 1.5L reactor, heat the reactor to 70°C and stir for 1.5 h, then put 60g ethylene glycol monobutyl ether and 30g unsaturated acid anhydride into the reactor and stir for 30min, then cool the reactor to 20°C, add 15g of water-based photoinitiator Darocur 1173 and then stir rapidly for 1.5h to obtain light Curing one-component water-based epoxy resin;

[0044] (2) Heat 600g of 70# asphalt to 175°C, add 30g of SBS modifier, shear in the colloid mill for 1.5h, add 20g of sodium dodecylbenzenesulfonate emulsifier and 630g of water for emulsification, Prepare emulsified SBS asphalt; then cool the prepared emulsified asphalt to room temperature; put the emulsified asphalt cooled to room temperature into the reaction kettle while stirring and add 100g of SBR latex and 100g of the one-component light-cured prepared by st...

Embodiment 3

[0046] (1) First weigh 600g of water, 600g of epoxy resin E51, 50g of acrylic acid, 6g of polymerization inhibitor p-benzoquinone, and 60g of diethylaminoethanol into a 1.5L reactor, heat the reactor to 60°C and stir for 2 hours , and then put 80g of ethylene glycol monobutyl ether and 40g of unsaturated acid anhydride into the reactor and stirred for 40min, then cooled the reactor to 25°C, added 15g of water-based photoinitiator Irgacure4265 and stirred rapidly for 2h to obtain a photocurable single-component 1 part water-based epoxy resin;

[0047] (2) Heat 500g of 50# asphalt to 180°C, add 20g of SBS modifier, cut in the colloid mill for 1.5h, add 30g of sodium dodecylbenzenesulfonate emulsifier and 520g of water for emulsification, Prepare emulsified SBS asphalt; then cool the prepared emulsified asphalt to room temperature; put the emulsified asphalt cooled to room temperature into the reaction kettle while stirring and add 80g of SBR latex and 200g of the one-component l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com