Low starch waste distiller's grain brewed Chinese liquor and brewing method thereof

A low-starch, liquor technology, applied in the field of winemaking, can solve the problems of low liquor content and poor liquor quality, and achieve the effects of reducing pollution, high utilization rate, and improving comprehensive utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

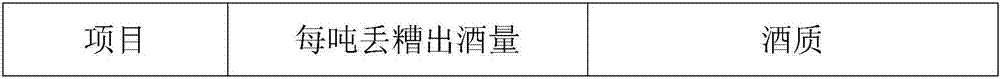

Embodiment 1

[0027] (1) Steaming and burning: 100Kg of sorghum is crushed into 4 petals, moistened with 60°C hot water for 6 hours, and steamed until there is no white heart inside.

[0028] (2) Preparation of esterification solution: 41.6Kg yellow water, 23.2Kg wine tail, 8Kg bottom pot water, 3.2Kg compound caproic acid bacteria liquid, 1.6Kg esterified red yeast rice, 1.6Kg medium-high temperature Daqu, 0.8Kg cellar mud, Mix evenly, adjust the pH value to 3.5 with 1mol / L hydrochloric acid, and culture at 32°C for 28 days to prepare 80Kg bio-esterification liquid.

[0029] (3) Fermentation with distilled grains: Cool the steamed sorghum to 25°C, mix with 500Kg of distilled grains, add 12Kg of medium-high temperature Daqu, mix well, sprinkle 4.8Kg of esterification liquid evenly before entering the cellar, and ferment for 10 days.

[0030] (4) Distillation to get wine: the yellow water in the fermentation tank is taken out and all is poured into the bottom of the retort, and the fermented...

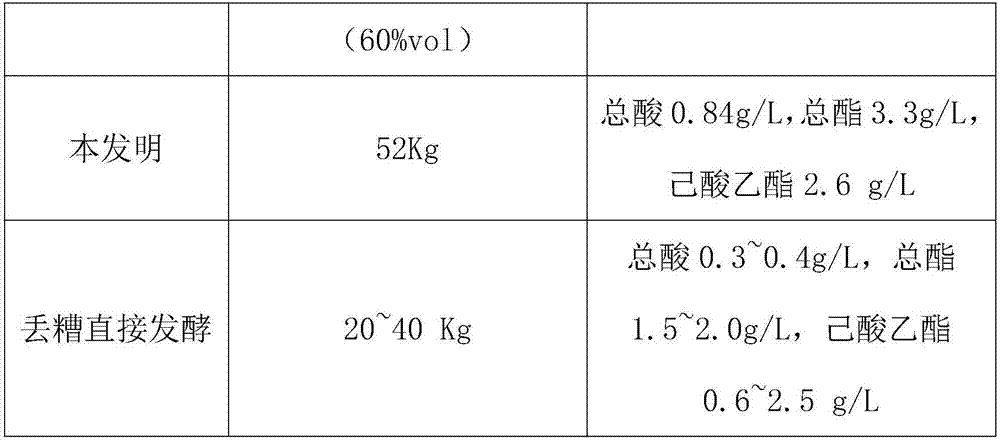

Embodiment 2

[0036] (1) Steaming and burning: 150Kg of sorghum is crushed into 6 petals, moistened with 65°C hot water for 7 hours, and steamed until there is no white heart inside.

[0037] (2) Preparation of esterification solution: 62.4Kg yellow water, 34.8Kg wine tail, 12Kg bottom pot water, 4.8Kg compound caproic acid bacteria liquid, 2.4Kg esterified red yeast rice, 2.4Kg medium-high temperature Daqu, 1.2Kg cellar mud, Mix evenly, adjust the pH value to 3.6 with 1mol / L hydrochloric acid, and culture at 33°C for 30 days to prepare 120Kg bio-esterification liquid.

[0038] (3) Fermentation with grains: Cool the steamed sorghum to 28°C, mix with 825Kg of grains, add 19.5Kg of medium-high temperature Daqu, mix well, sprinkle 8.4Kg of esterification liquid evenly before entering the cellar, and ferment for 12 days The above-mentioned waste grains can be the waste grains after the 6th step of embodiment 1 steams wine.

[0039] (4) Distillation to get wine: the yellow water in the fermenta...

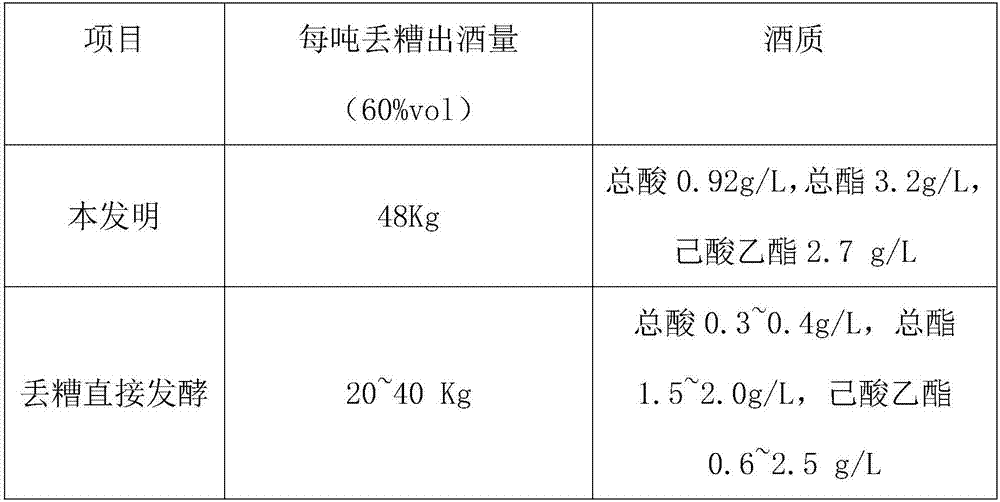

Embodiment 3

[0044] (1) Steaming and burning: 300Kg sorghum is crushed into 6 petals, moistened with hot water at 70°C for 8 hours, and steamed until there is no white heart inside.

[0045] (2) Preparation of esterification solution: 124.8Kg yellow water, 69.6Kg wine tail, 24Kg bottom pot water, 9.6Kg compound caproic acid bacteria liquid, 4.8Kg esterified red yeast rice, 4.8Kg medium-high temperature Daqu, 2.4Kg pit mud, Mix evenly, adjust the pH value to 3.8 with 1mol / L hydrochloric acid, and culture at 35°C for 35 days to prepare 240Kg bio-esterification liquid.

[0046] (3) Fermentation with distilled grains: cool the steamed sorghum to 30°C, mix with 1800Kg of distilled grains, add 45Kg of medium-high temperature Daqu, mix well, and evenly sprinkle 19.2Kg of esterification liquid before entering the cellar, and ferment for 15 days; Above-mentioned discarded grains can be the discarded grains after the 6th step of embodiment 2 distilled wine.

[0047] (4) distillation to get wine: th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com