Baijiu brewing method for accelerating ripening and preventing retrogradation

A technology of liquor and regeneration, which is applied in the field of brewing technology, can solve the problems of toxicity and harm, and achieve the effects of promoting oxidation, accelerating coordination, and preventing regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

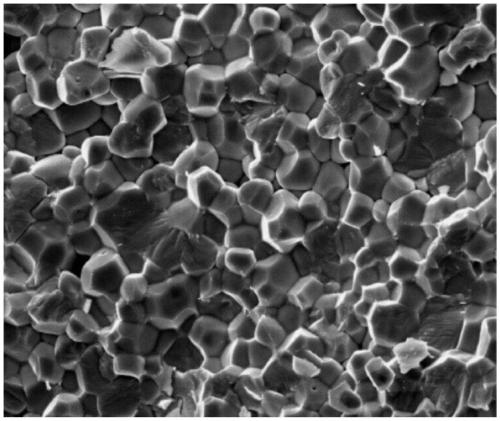

Image

Examples

Embodiment 1

[0042] The fermentation device adopts a mud cellar, and the shape of the cellar pool is a cube, and the length × width × height of the cellar pool = 4m × 3m × 2m.

[0043] In cellar pond, add the cellar mud 4000kg that is mixed with 10% enamel powder, the distiller's grains 8000kg that is mixed with 0.2% enamel powder and sorghum 2000kg and fermented koji medicine 400kg.

[0044] The particle size of the Ru enamel powder is -800 mesh.

[0045] Ferment for 50 days according to conventional brewing methods, and then distill according to conventional methods to obtain liquor.

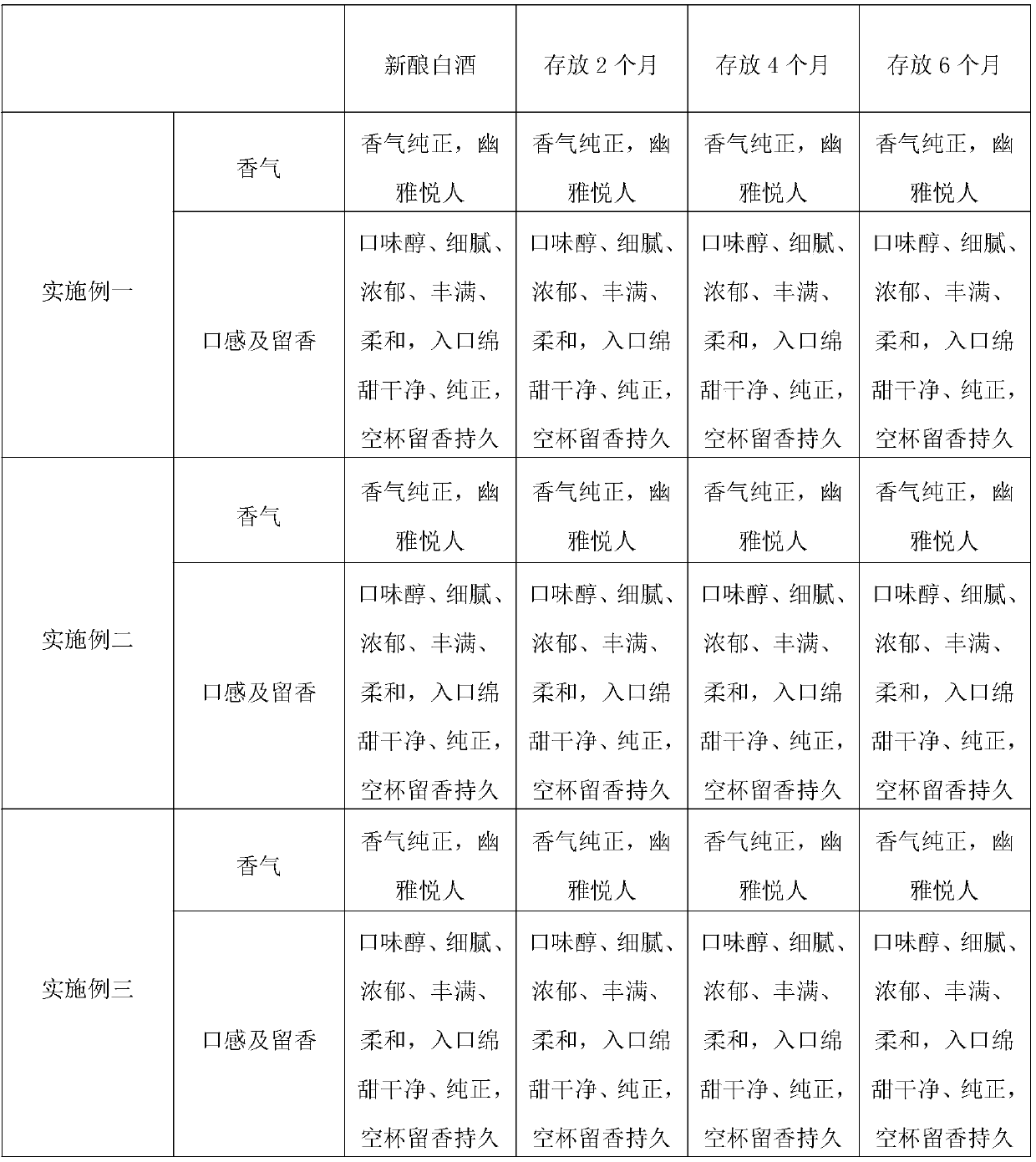

[0046] The aroma and taste of the newly brewed liquor are shown in Table 1.

[0047] The aroma and mouthfeel ripening degree of new-brewed liquor stored in a 500mL glass bottle under the same storage environment as in Example 1 for 2 months, 4 months, and 6 months are shown in Table 1. The changes of the total acid, total ester and total aldehyde content in the corresponding period were measured respecti...

Embodiment 2

[0049] Carry out comparative experiment with embodiment one, carry out liquor brewing according to the processing condition identical with embodiment one, and its difference is: (1) fermented koji medicine dosage is 500kg; (2) the particle size of Ru porcelain glaze powder is-1200 order; ( 3) The fermentation time is 60 days.

[0050] The aroma and taste of the newly brewed liquor are shown in Table 1.

[0051] The aroma and mouthfeel ripening degree of new-brewed liquor stored in a 500mL glass bottle under the same storage environment as in Example 1 for 2 months, 4 months, and 6 months are shown in Table 1. The changes of the total acid, total ester and total aldehyde content in the corresponding period were measured respectively, and the results are shown in Table 2. After storage for 6 months, the content of important aldehydes and alcohols in the samples was measured, and the results are shown in Table 3.

Embodiment 3

[0053] Carry out a comparative experiment with Example 1, and carry out liquor brewing according to the same process conditions as Example 1, the difference is: (1) the fermentation device (cellar pool) is a cylinder, and the diameter of the cellar pool × height = 3m × 3.36m; (2) Add 4000 kg of pit mud mixed with 8% Ru porcelain glaze powder and 8000 kg of distiller's grains mixed with 0.4% Ru porcelain glaze powder in the Ru porcelain cellar pool; (3) The dosage of fermented koji is 360kg; (4) The particle size of the enamel powder is -1000 mesh; (5) The fermentation time is 40 days.

[0054] The aroma and taste of the newly brewed liquor are shown in Table 1.

[0055] The aroma and mouthfeel ripening degree of new-brewed liquor stored in a 500mL glass bottle under the same storage environment as in Example 1 for 2 months, 4 months, and 6 months are shown in Table 1. The changes of the total acid, total ester and total aldehyde content in the corresponding period were measur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com