Method for preparing strong-flavor soybean oil by virtue of micro-channel reactor

A micro-channel reactor, soybean oil technology, applied in the production of fat/fat, fat production, etc., can solve the problems of preparation technology and research of fragrant soybean oil, which can reduce the production of bad flavor substances, improve efficiency, and easily Upgrade the zoom effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

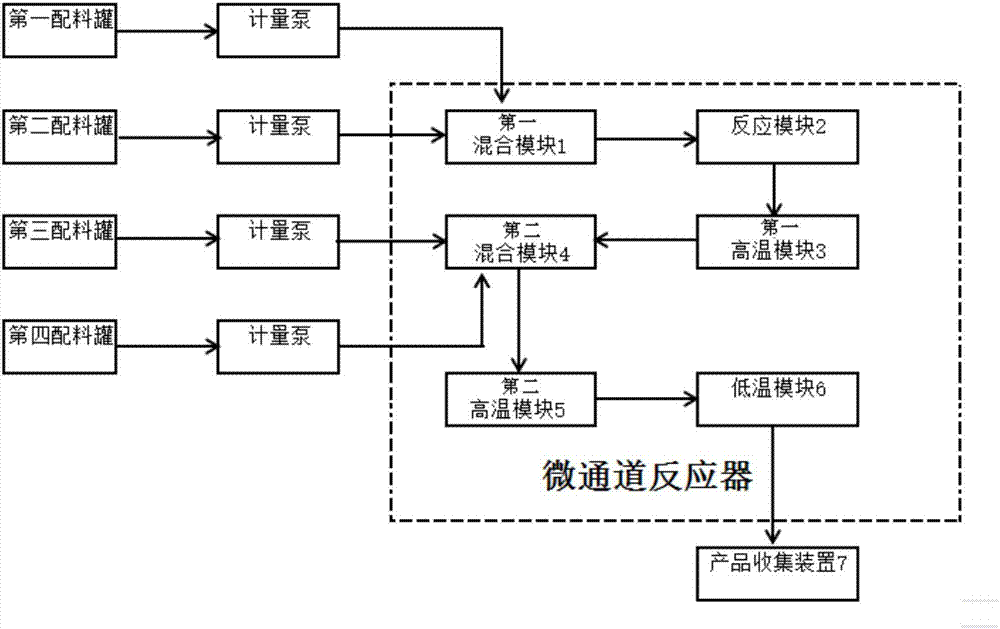

[0070] Embodiment 1: Utilize microchannel reactor to prepare fragrant soybean oil.

[0071] (1) Device: The micro-channel device adopts a self-made high-pressure micro-channel reactor. The length of the micro-channel is determined according to the flow rate and the reaction residence time. The channel length of each module used here is 10m, the pipe diameter is 0.1mm, and the heat transfer medium is heat-conducting oil. .

[0072] (2) Preparation of Luzhou-flavor soybean oil:

[0073] A- Microchannel Reactor Preparation:

[0074]Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the channel length of the microchannel, wherein the residence time in the first mixing module 1 is 30 seconds, and the residence time in the reaction module 2 is 30 seconds. The first high temperature module The residence time in 3 is 30 seconds, the residence time in the second mixing module 4 is 30 seconds, the residence time in the ...

Embodiment 2

[0082] Embodiment 2: Utilize microchannel reactor to prepare fragrant soybean oil.

[0083] (1) Apparatus: the same as that of Example 1.

[0084] (2) Preparation of Luzhou-flavor soybean oil:

[0085] A- Microchannel Reactor Preparation:

[0086] Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the passage length of the microchannel, wherein the residence time in the first mixing module 1 is 300 seconds, and the residence time in the reaction module 2 is 1200 seconds. The first high temperature module The residence time in 3 is 300 seconds, the residence time in the second mixing module 4 is 1200 seconds, the residence time in the second high temperature module 5 is 2200 seconds, and the residence time in the low temperature module 6 is 2200 seconds.

[0087] The temperature of each module of the reactor is controlled by the external circulation heat transfer oil system, wherein the temperature of the first...

Embodiment 3

[0094] Embodiment 3: Utilize microchannel reactor to prepare fragrant soybean oil.

[0095] (1) Apparatus: the same as that of Example 1.

[0096] (2) Preparation of Luzhou-flavor soybean oil:

[0097] A- Microchannel Reactor Preparation:

[0098] Control the residence time of the reaction system in each module by adjusting the flow rate of the delivery pump and the channel length of the microchannel, wherein the residence time in the first mixing module 1 is 100 seconds, and the residence time in the reaction module 2 is 300 seconds. The first high temperature module The residence time in 3 is 200 seconds, the residence time in the second mixing module 4 is 500 seconds, the residence time in the second high temperature module 5 is 500 seconds, and the residence time in the low temperature module 6 is 500 seconds.

[0099] The temperature of each module of the reactor is controlled by the external circulation heat transfer oil system, wherein the temperature of the first mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com