Manufacturing method of compressor crankshaft

A technology of a compressor crankshaft and a manufacturing method, applied in the field of powder metallurgy, can solve the problems of easily polluted environment, low production efficiency, large energy consumption of casting process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

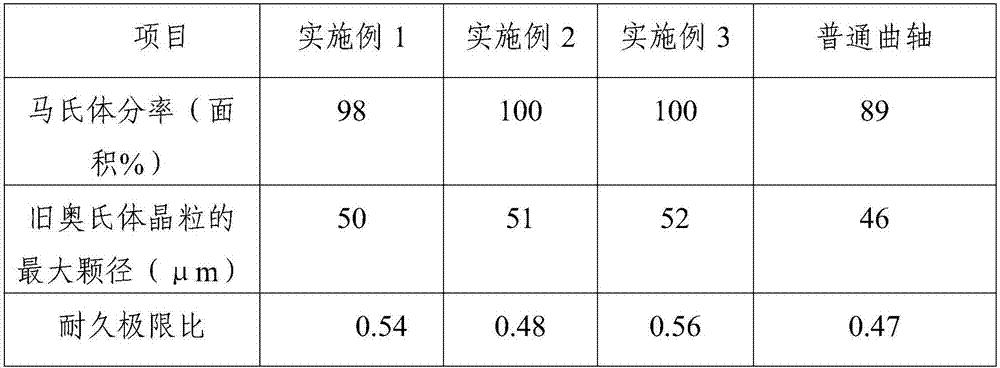

Embodiment 1

[0016] A method for manufacturing a compressor crankshaft, the preparation method is as follows:

[0017] (1) Mix iron powder, aluminum powder, copper powder, tin powder, niobium powder, vanadium powder, manganese, chromium, and nano-titanium dioxide powder at 80-100°C for 60-80 minutes, then heat to 180-200°C , then add boron, silicon nitride, cuprous thiocyanate, antimony trisulfide powder, and carbon powder, cool to 100-120°C, put into the mold, press into a billet, and then naturally cool to room temperature, and the pressing pressure is 100-120°C. 200MPa;

[0018] (2) Place the green compact obtained in step (1) in a closed sintering furnace for sintering. The heating process of sintering is that the heating rate between room temperature and 900 °C is 14 °C / min, and the temperature is kept at 900 °C for 30 minutes. The heating rate from ℃ to 1320℃ is 9℃ / min, and the temperature is kept at 1320℃ for 60min. The pressure in the closed sintering furnace is not more than 0.02...

Embodiment 2

[0021] Embodiment 2: a kind of manufacturing method of compressor crankshaft, preparation method is as follows:

[0022] (1) Mix iron powder, aluminum powder, copper powder, tin powder, niobium powder, vanadium powder, manganese, chromium, and nano-titanium dioxide powder at 80-100°C for 60-80 minutes, then heat to 180-200°C , then add boron, silicon nitride, cuprous thiocyanate, antimony trisulfide powder, and carbon powder, cool to 100-120°C, put into the mold, press into a billet, and then naturally cool to room temperature, and the pressing pressure is 100-120°C. 200MPa;

[0023] (2) Place the green compact obtained in step (1) in a closed sintering furnace for sintering. The heating process of sintering is that the heating rate between room temperature and 900 °C is 14 °C / min, and the temperature is kept at 900 °C for 30 minutes. The heating rate from ℃ to 1320℃ is 9℃ / min, and the temperature is kept at 1320℃ for 60min. The pressure in the closed sintering furnace is not...

Embodiment 3

[0028] A method for manufacturing a compressor crankshaft, the preparation method is as follows:

[0029] (1) Mix iron powder, aluminum powder, copper powder, tin powder, niobium powder, vanadium powder, manganese, chromium, and nano-titanium dioxide powder at 80-100°C for 60-80 minutes, then heat to 180-200°C , then add boron, silicon nitride, cuprous thiocyanate, antimony trisulfide powder, and carbon powder, cool to 100-120°C, put into the mold, press into a billet, and then naturally cool to room temperature, and the pressing pressure is 100-120°C. 200MPa;

[0030] (2) Place the green compact obtained in step (1) in a closed sintering furnace for sintering. The heating process of sintering is that the heating rate between room temperature and 900 °C is 14 °C / min, and the temperature is kept at 900 °C for 30 minutes. The heating rate from ℃ to 1320℃ is 9℃ / min, and the temperature is kept at 1320℃ for 60min. The pressure in the closed sintering furnace is not more than 0.02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com