Exquisite glaze, exquisite ceramic and preparation process of exquisite ceramic

A technology of Linglong glaze and Linglong, which is applied in the field of Linglong ceramics and its preparation technology, can solve the problems that flat or large-scale products cannot be produced, Linglong eyes have poor transparency and permeability, and Linglong eyes cannot be repaired or leaked, so as to broaden the firing range. The effect of increasing the range of forming, improving the regularity and consistency, and increasing the qualified rate of firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Linglong eye glaze can be prepared as follows: quartz powder (325 mesh) 24-45%, nepheline powder (325 mesh): 20-40%, kaolin (325 mesh) 0-18%, borax 2-16%, Zinc oxide 2-7%, zirconium silicate 0-4%, diyttrium trioxide 0.1-3%, calcium carbonate 6-16%, magnesium carbonate 0-8%, phosphorus pentoxide 0-2%, strontium carbonate 0.5% ~6%, Lithium Carbonate 2~10%, Rubidium Oxide 1~2.5%, Hafnium Dioxide 1~2%, the above raw materials are mixed evenly, melted at 1520°C, put into cold water and quenched into frit.

[0030] Put the frit into a ball mill, add water, high alumina ball stone and kaolin 5% to grind it into a glaze slurry, the fineness is controlled at less than 0.03% on a million-hole sieve, and then dried at 80-100°C to make a powder and pass through 250 mesh Sieve, mix and stir the prepared dry powder according to the glaze moisture content of 10-15%, and then use it.

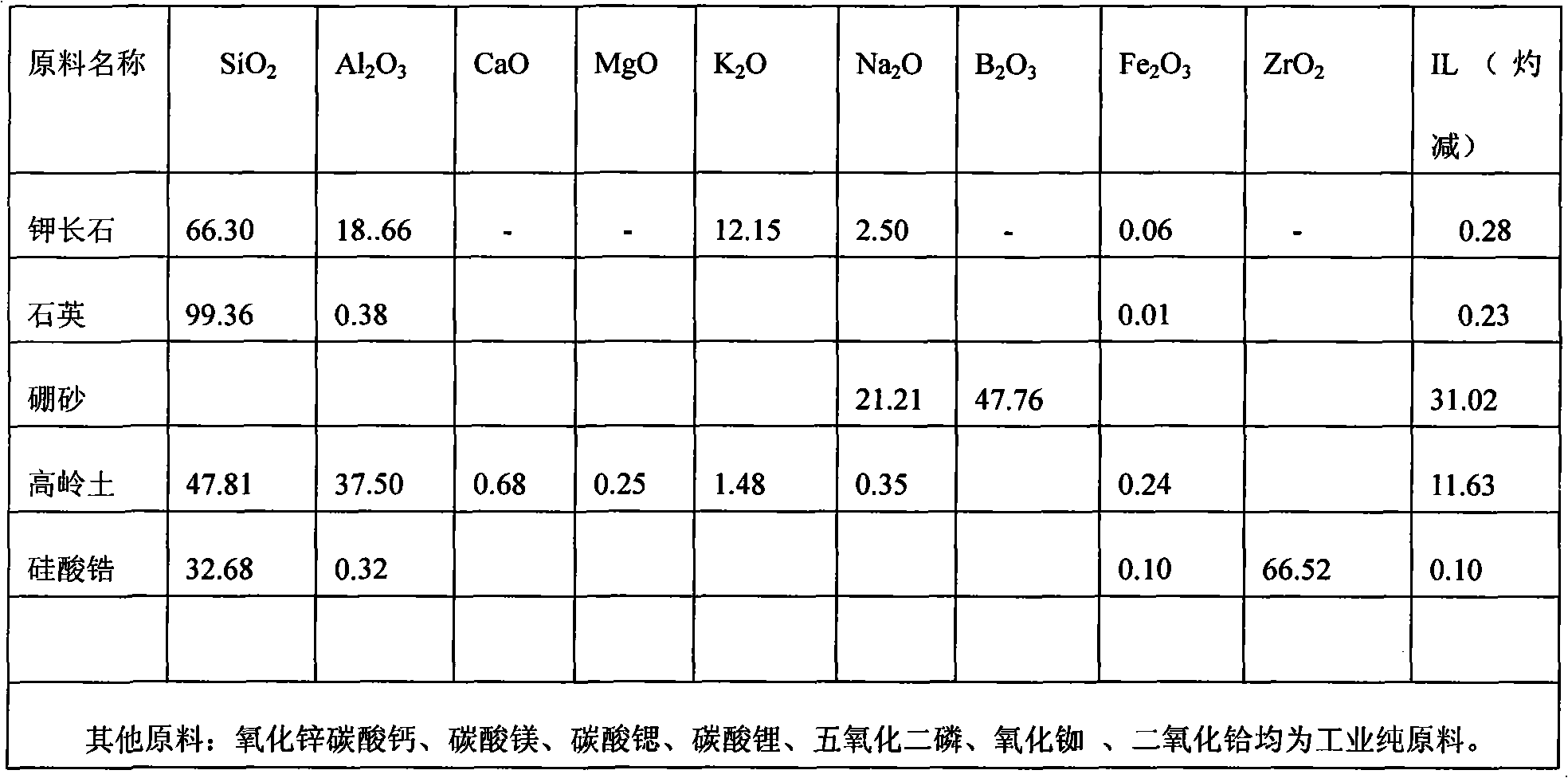

[0031] Table 1 is the chemical composition of the raw materials used in Example 1

[0032]

Embodiment 2

[0033] Implementation 2 Preparation of high-temperature glaze-fired Linglong ceramics

[0034] Taking the production of 350ml crystal exquisite cup as an example

[0035] Take the refined mud with a moisture content of 22-25%, roll and form it as required, and then dry it naturally with a mold. After the product can be taken out of the mold, the cup handle is bonded. The cup is naturally dried for 2-4 hours, and then the product is dried with hot air at 80-90°C. After the product is completely dried, the blank is repaired and then sent to the kiln for low-temperature bisque firing at 600-1050°C for subsequent glazing. After the biscuit firing is completed, apply glaze on the 350ml cup and perform high-temperature glaze firing at 1200-1400°C. The products after glaze firing are inspected. The qualified products are sent to the next process to punch 5mm round exquisite holes according to the design pattern. Inspection is carried out, and qualified products are poured with Lingl...

Embodiment 3

[0036] Embodiment 3 Preparation of low-temperature glaze-fired Linglong ceramics

[0037] Taking the production of 350mm crystal exquisite fish dish as an example

[0038] Take the refined mud with a moisture content of 22-25%, carry out plastic molding according to the requirements, demold and dry naturally for 4-8 hours, and then dry the product with hot air at 80-90°C. When the product is completely dried, carry out Repair and wash the blank, and then send it to the kiln for high-temperature biscuit firing at 1200-1400°C for subsequent punching work, and conduct biscuit inspection. The 350mm fish plate biscuit that passes the inspection is sent to the next process to punch 5mm round exquisite holes according to the design pattern. Inspection will be carried out after the hole is completed. The qualified products will be poured with Linglong glaze, and the products filled with Linglong glaze will be fired. Apply the upper glaze, and then perform glaze firing. The glaze firi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com