Antimony trisulfide nanodot/sulfur-doped carbon composite material, preparation method thereof and application of antimony trisulfide nanodot/sulfur-doped carbon composite material to sodium/potassium ion battery

A carbon composite material, nano-dot technology, applied in the preparation/purification of carbon, antimony sulfide, secondary batteries, etc., can solve the problems of volume expansion, insufficient material cycle stability, large volume expansion, etc., to improve electrical conductivity, The effect of improving electrochemical performance and suppressing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

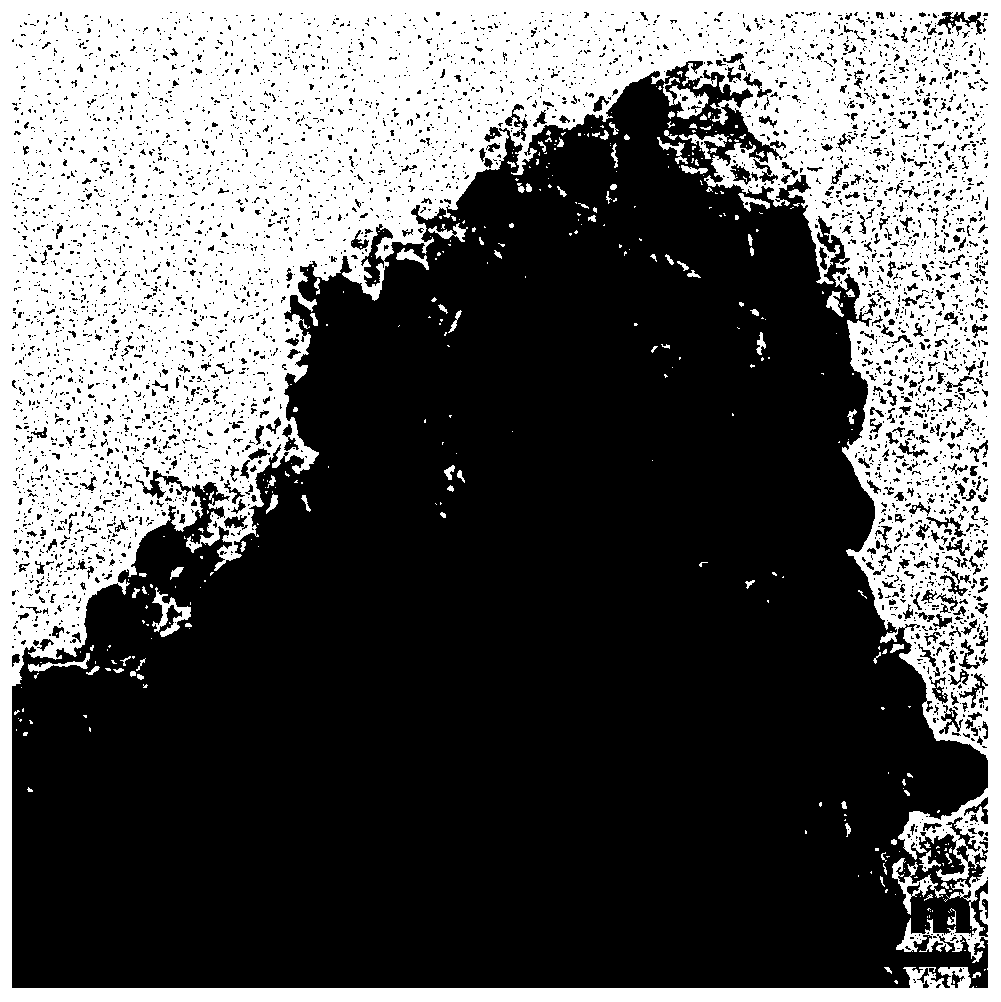

[0033] Put 6 grams of sodium antimony gluconate into a porcelain boat and put it in a tube furnace, and inject H 2 / Ar(5%H 2 ) protective gas, the heating rate is 10°C / min, and calcined at 600°C for 1 hour to obtain black porous powder. Take out the powder in the porcelain boat and grind it thoroughly, then wash it repeatedly several times with ethanol and water at intervals, and dry it in a vacuum oven at 70°C for 6 hours to obtain the black antimony / C nano-dot composite material with a nano-dot size of about 10 ~20nm. figure 1 It is the transmission electron microscope image of the antimony nanodot / carbon composite material.

Embodiment 2

[0035] Put 6 grams of antimony hexamethyltetramine into a ceramic boat and put it in a tube furnace, and pass H 2 / Ar(5%H 2 ) protective gas, the heating rate is 10°C / min, and calcined at 600°C for 1 hour to obtain black porous powder. Take out the powder in the porcelain boat and grind it thoroughly, then wash it several times with ethanol and water at intervals, and dry it in a vacuum oven at 70°C for 6 hours to obtain the black antimony nanodot / carbon composite material, the size of the nanodot is about 15 ~30nm.

Embodiment 3

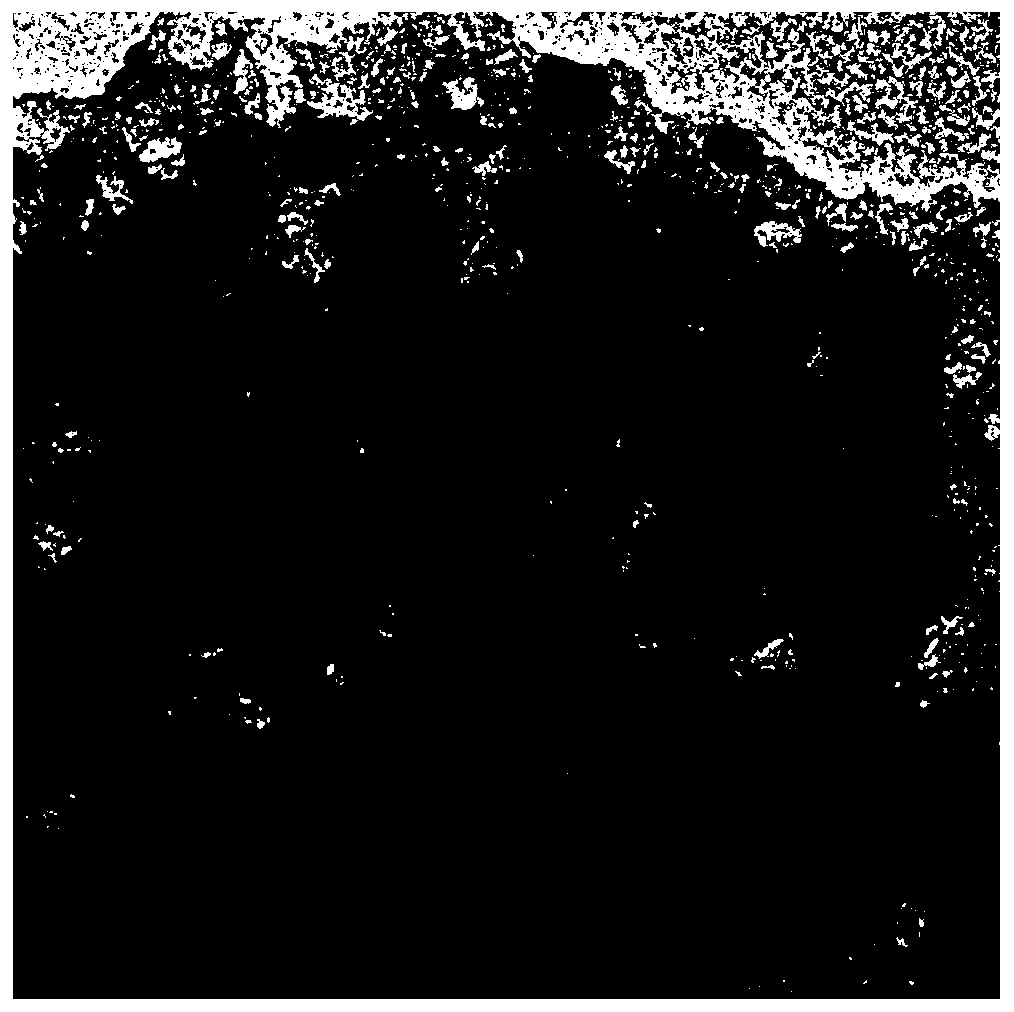

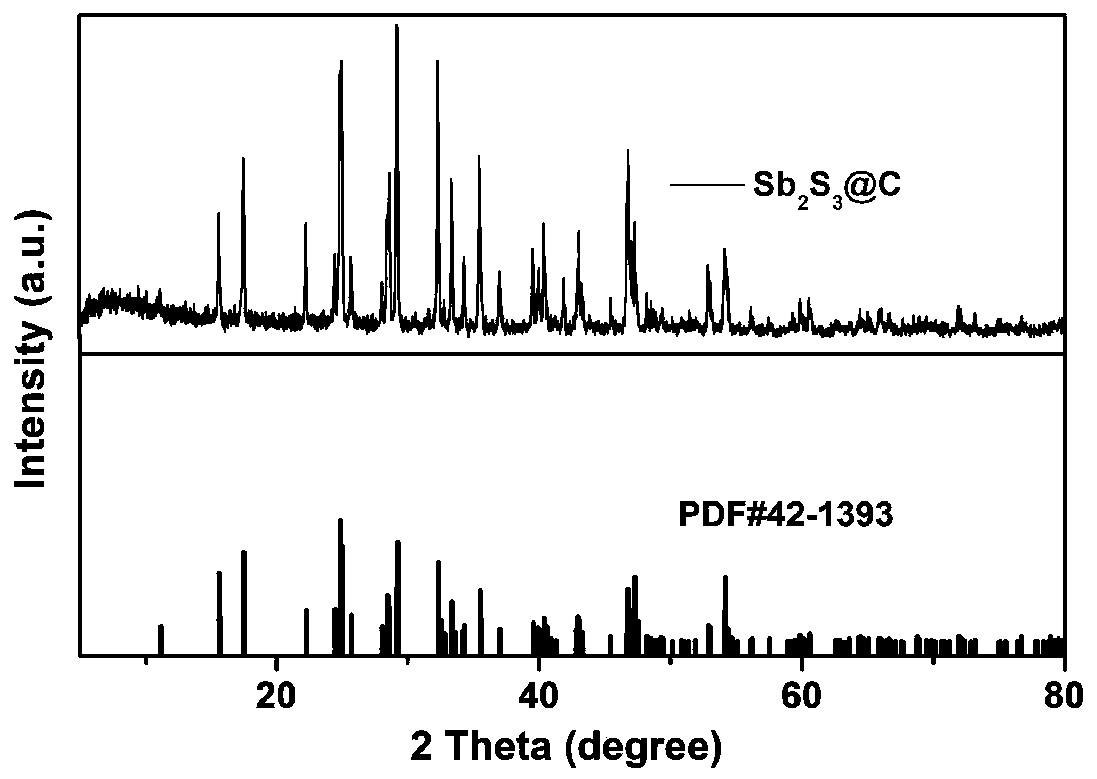

[0037] The antimony nano-dot / carbon composite material 300mg and 900mg sulfur powder of the product obtained in Example 1 were ground evenly in an agate agate mortar, then it was placed in a tube furnace, and Ar protective gas was introduced at a heating rate of 5°C / min. Calcined at 500°C for 5h to obtain black Sb 2 S 3 Nano-dot / sulfur-doped carbon composite material, the size of the nano-dot is about 15-25nm. figure 2 for Sb 2 S 3 TEM image of nanodot / sulfur-doped carbon composite.

[0038] by Sb 2 S 3 / C nano-dot composite material, for infrared and Raman analysis testing, Figure 9 a The mid-infrared results show that Sb 2 S 3 The absorption peaks of nanodots / sulfur-doped carbon composites are located at 1387 and 1124 cm -1 Left and right, attributed to the C-C and C-S bonds, respectively, confirming the existence of the C-S bond; at the same time, the Raman test results are as follows Figure 9 As shown in b, located at 144, 251, 310 and 451cm -1 The absorption...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com