Patents

Literature

43results about "Antimony sulfides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

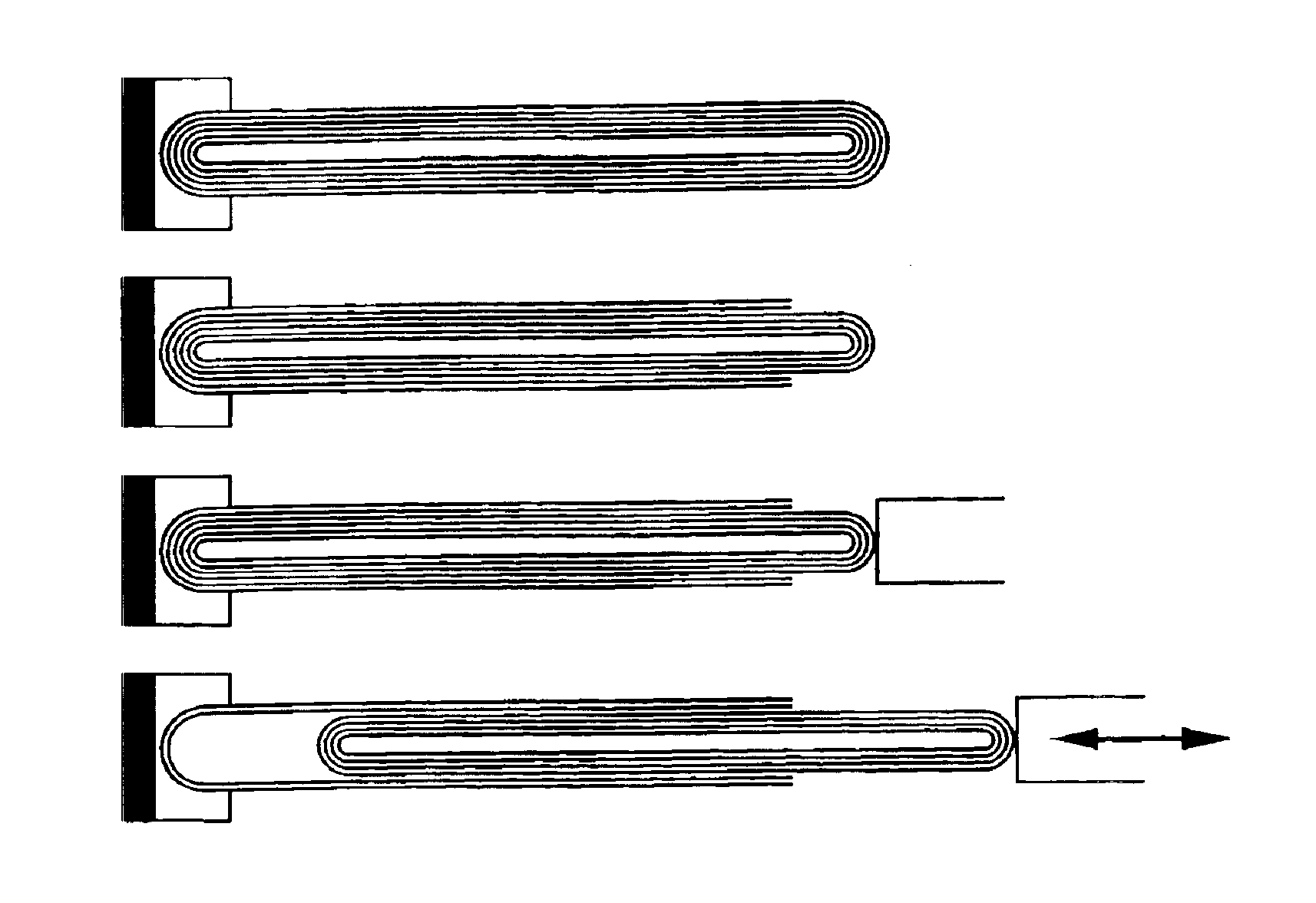

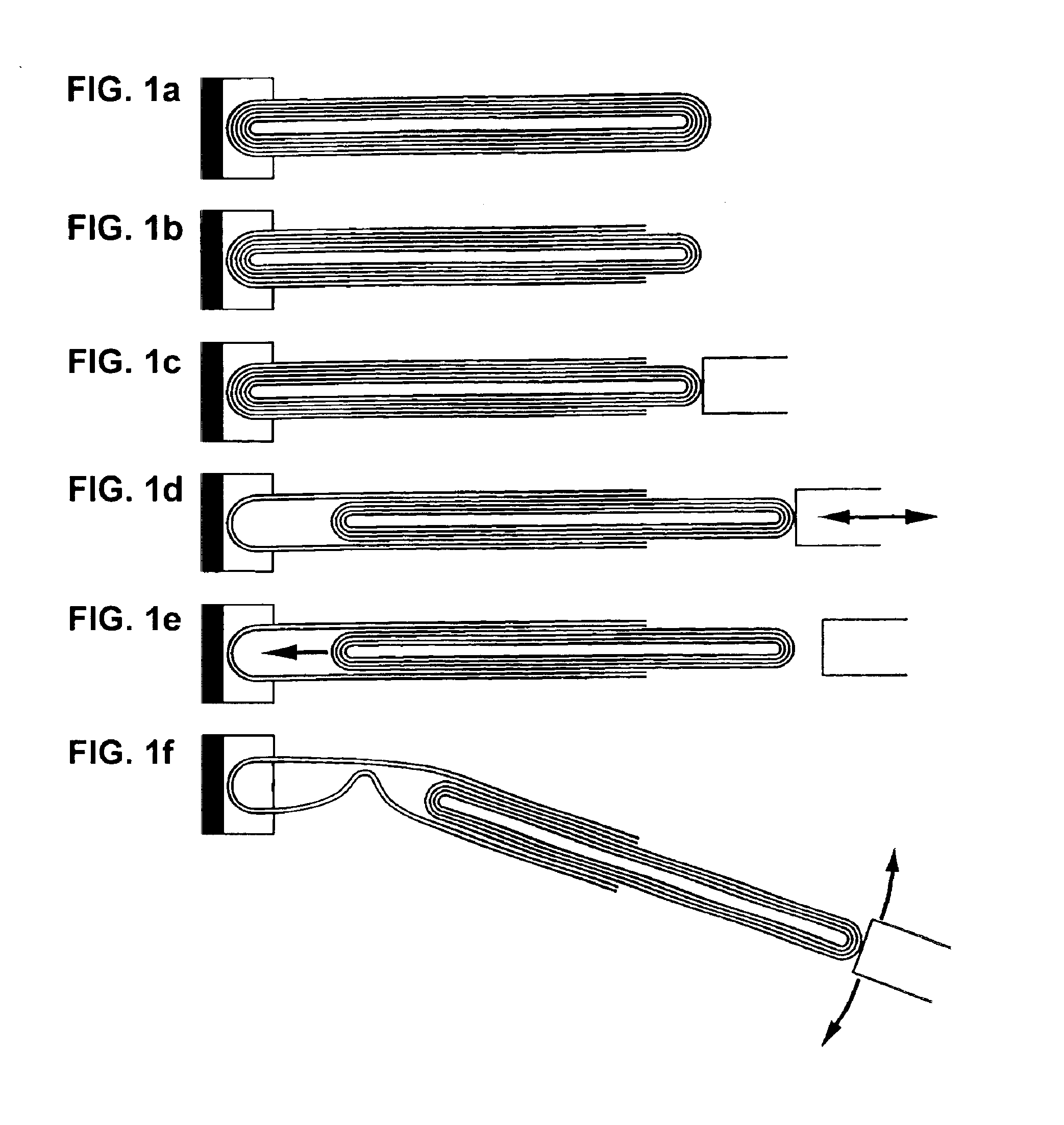

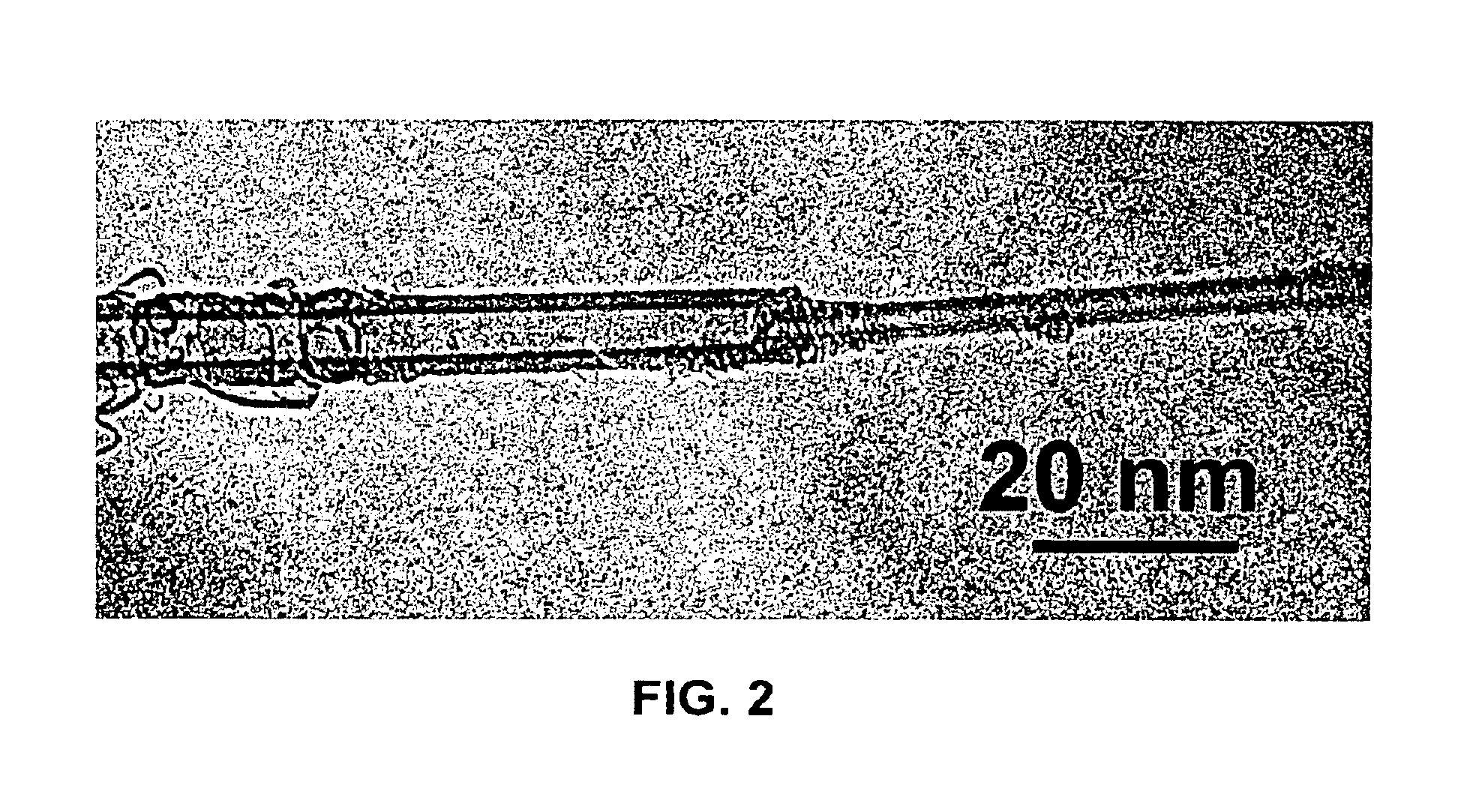

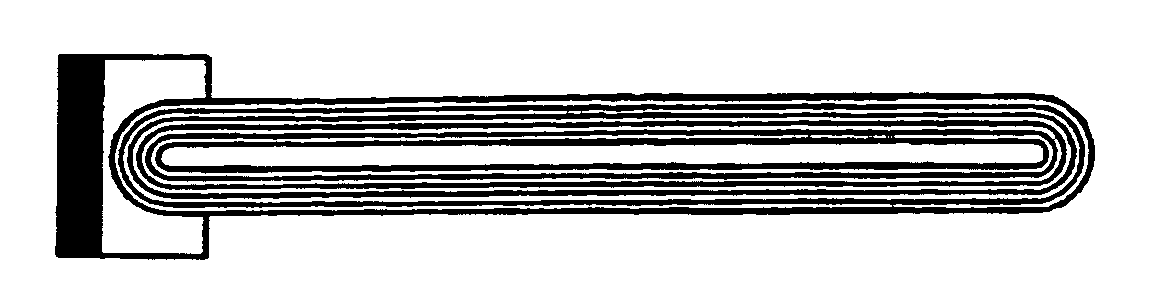

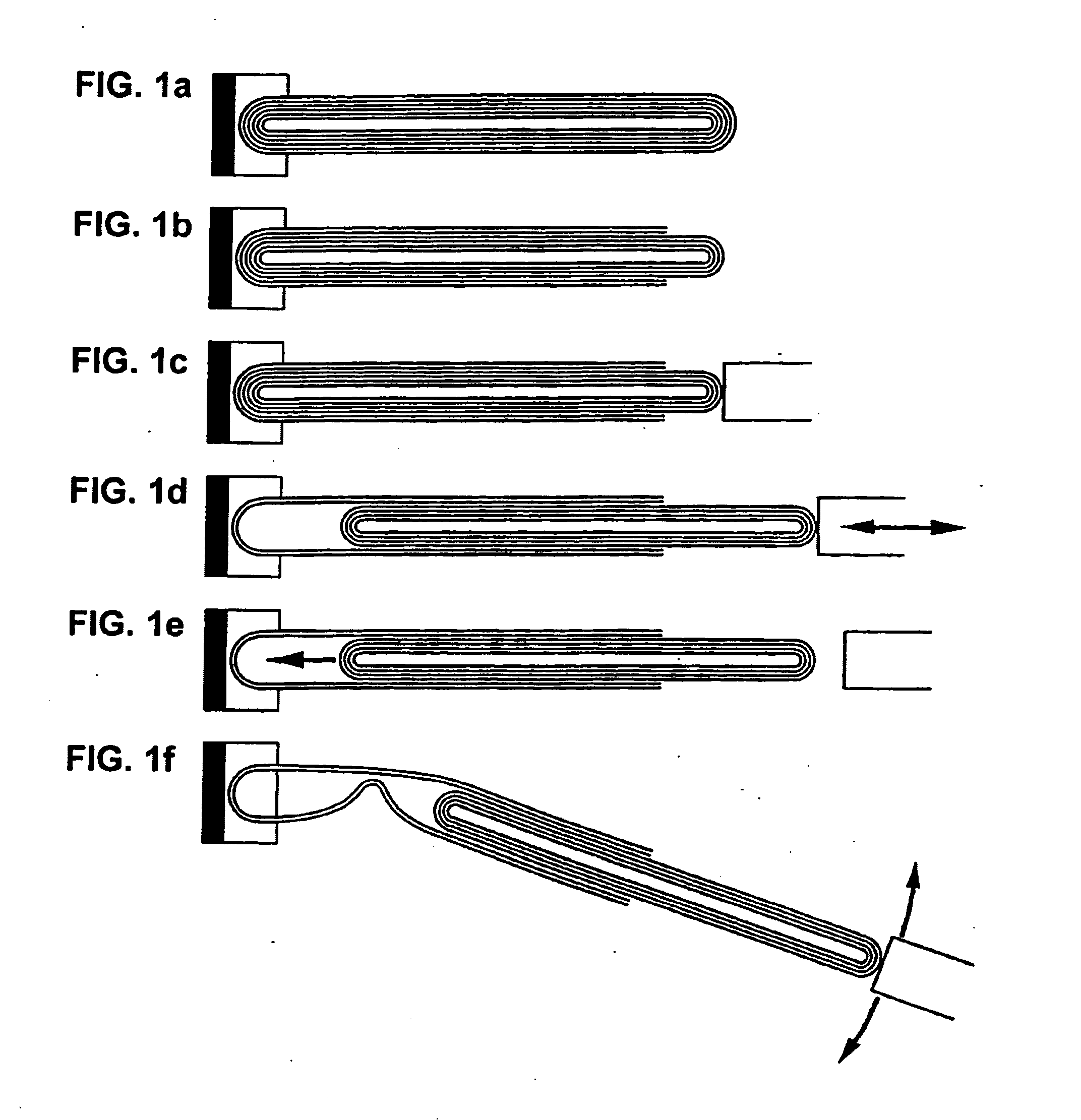

Telescoped multiwall nanotube and manufacture thereof

InactiveUS6874668B2Overcome disadvantagesMaterial nanotechnologyNitrogen compoundsNanomanipulatorConstant force

The invention relates to a method for forming a telescoped multiwall nanotube. Such a telescoped multiwall nanotube may find use as a linear or rotational bearing in microelectromechanical systems or may find use as a constant force nanospring. In the method of the invention, a multiwall nanotube is affixed to a solid, conducting substrate at one end. The tip of the free end of the multiwall nanotube is then removed, revealing the intact end of the inner wall. A nanomanipulator is then attached to the intact end, and the intact, core segments of the multiwall nanotube are partially extracted, thereby telescoping out a segment of nanotube.

Owner:RGT UNIV OF CALIFORNIA

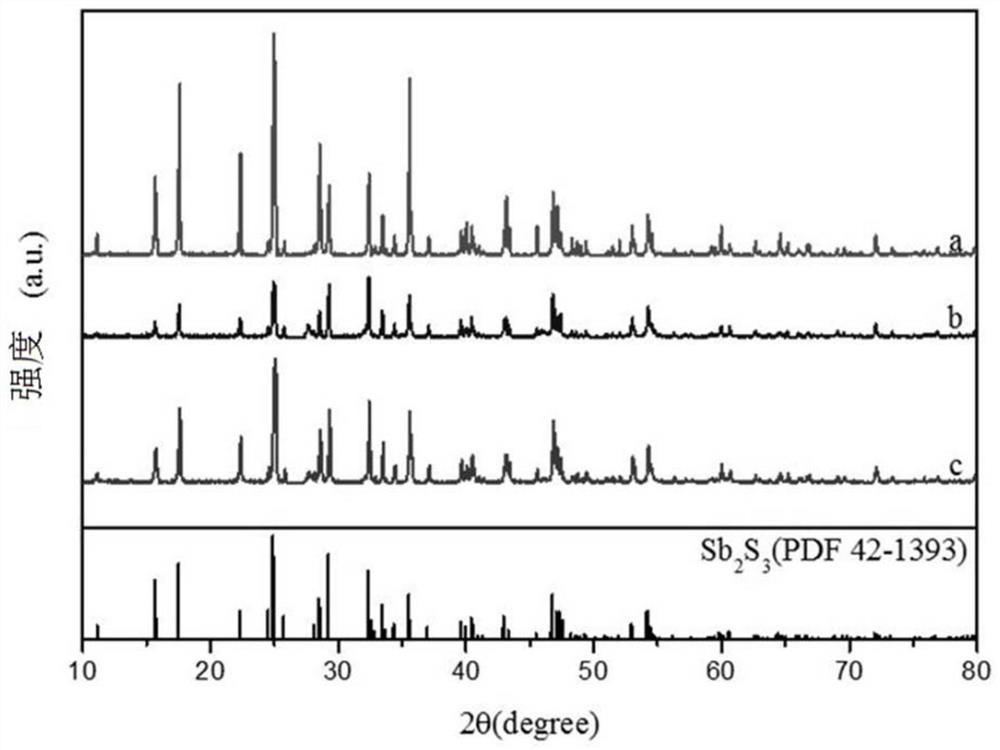

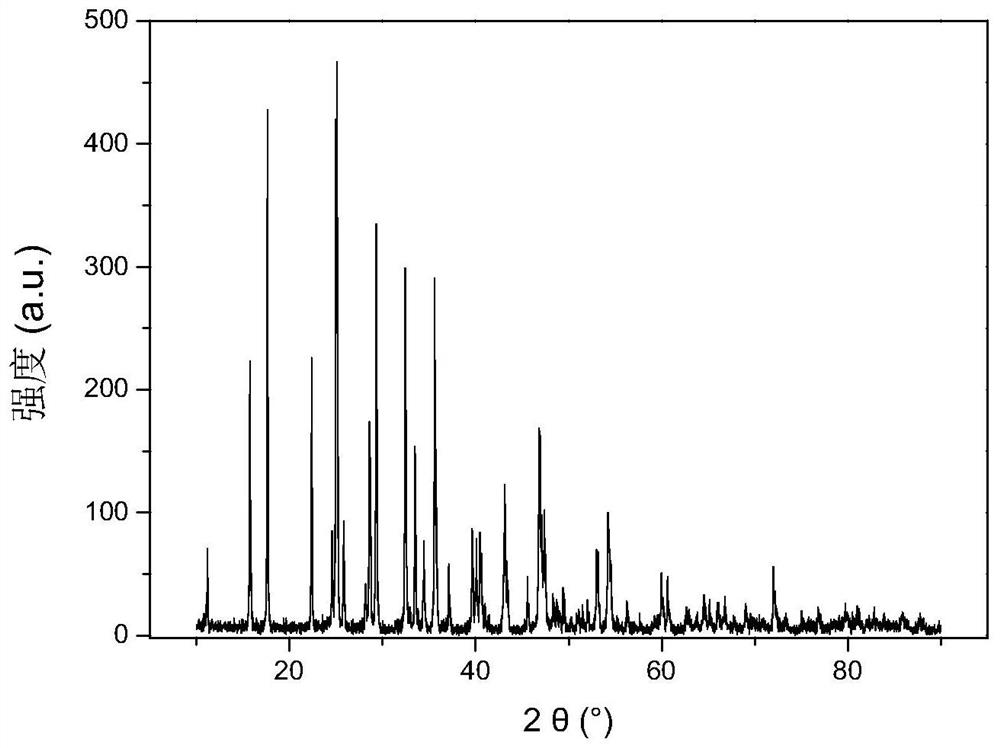

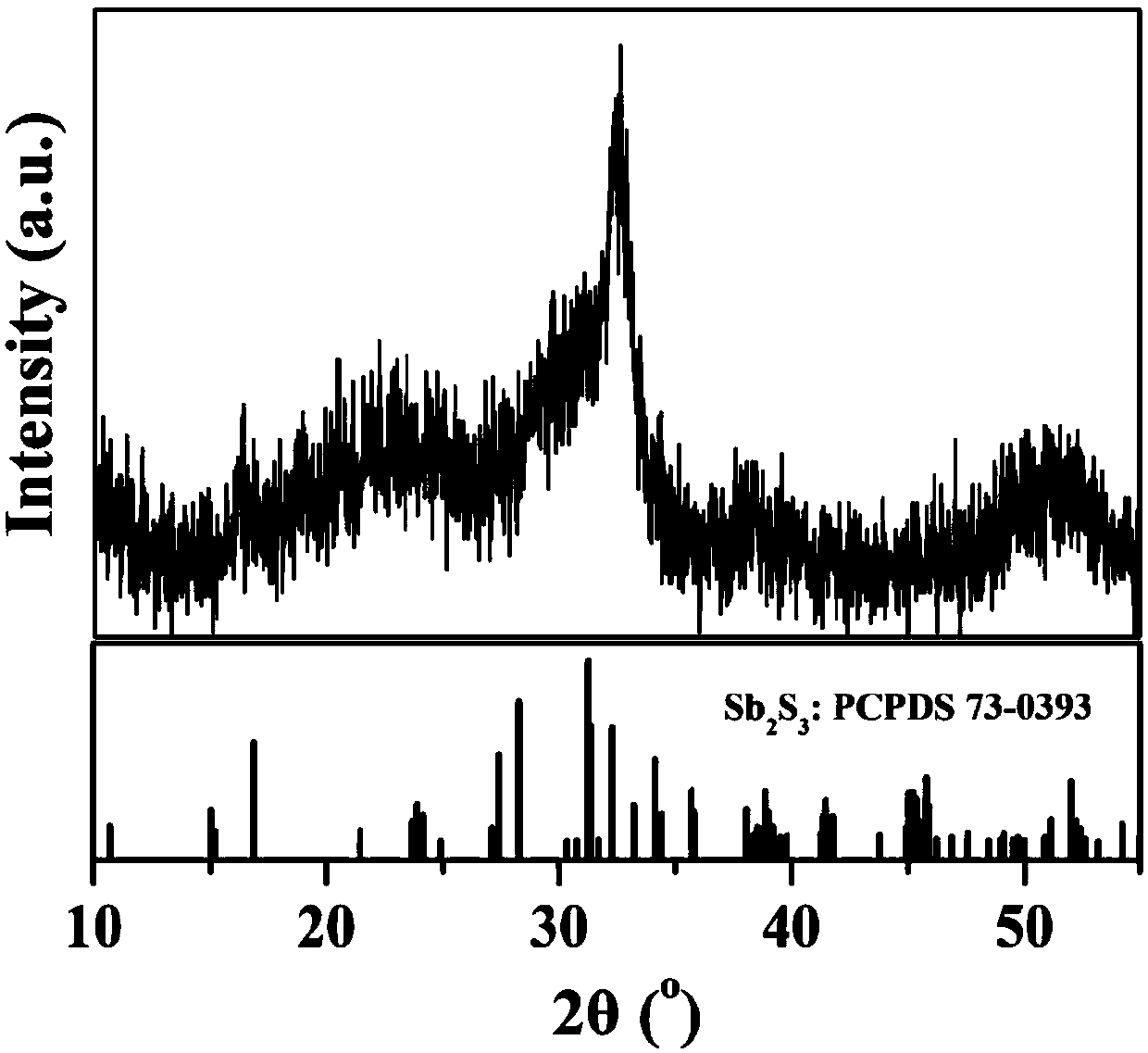

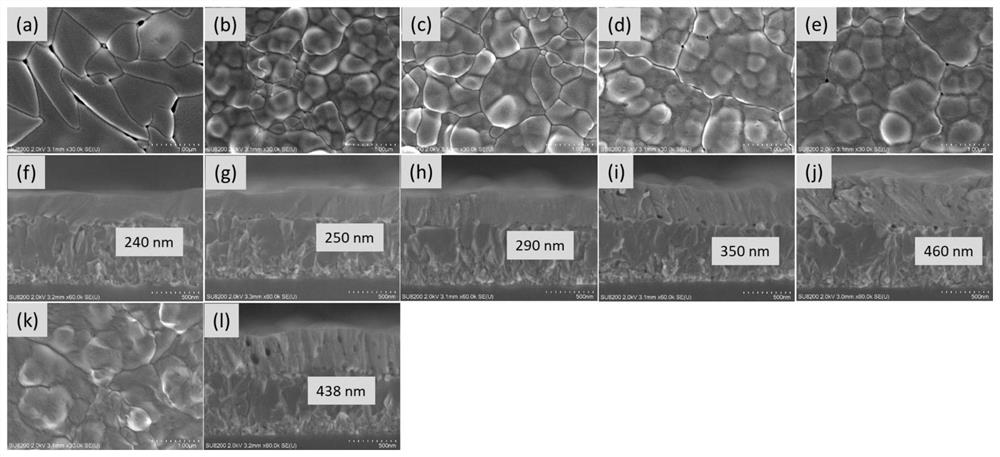

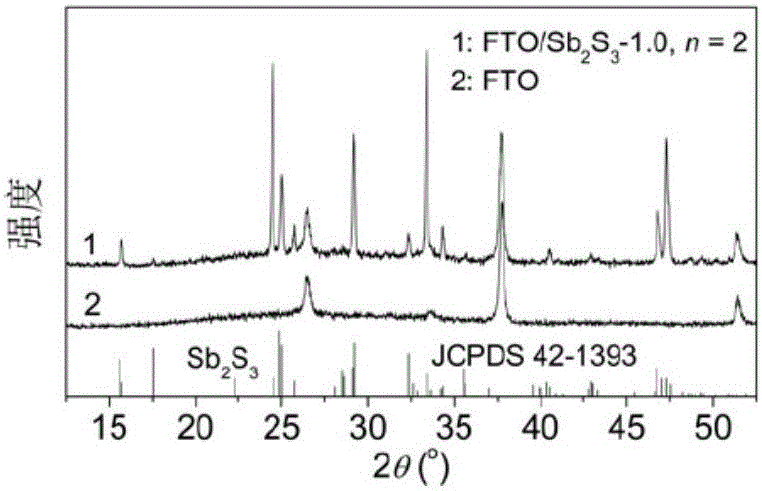

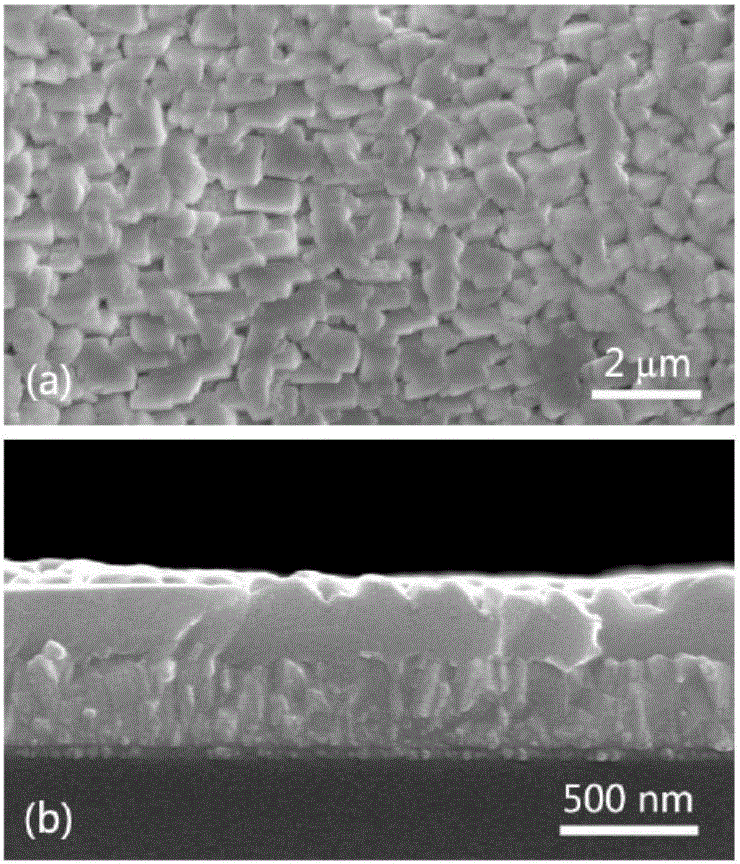

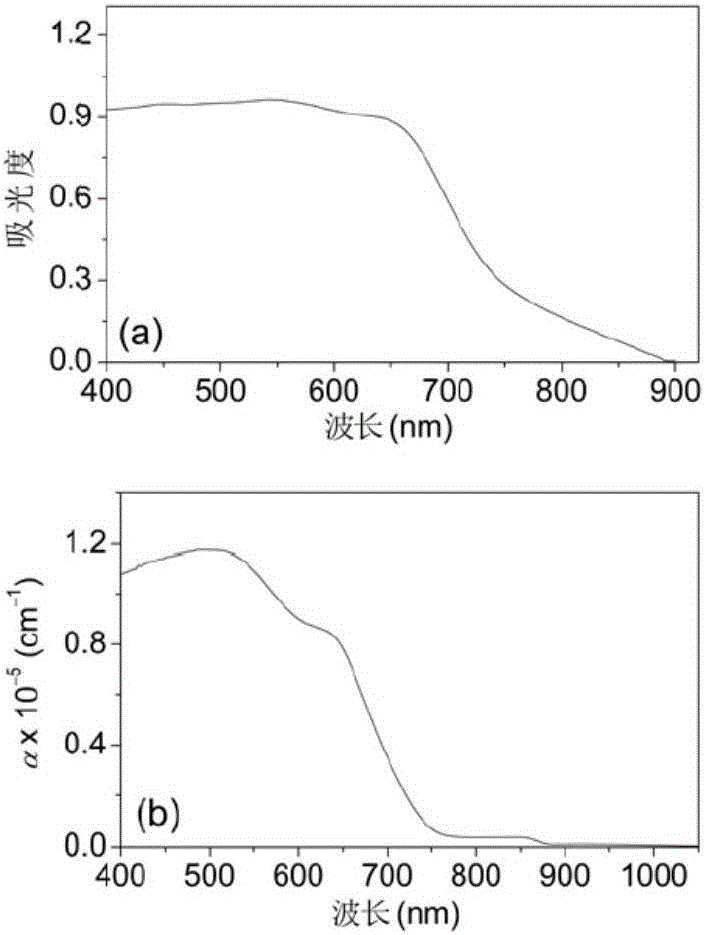

Solution processing preparation method of crystalline Sb2S3 thin film

PendingCN106277051ALarge Absorption CoefficientThickness is easy to controlAntimony sulfidesCoatingsSimple compoundOrganic solvent

The invention discloses a solution processing preparation method of a crystalline Sb2S3 thin film. The solution processing preparation method comprises the following steps of dissolving a simple compound in mixed organic solvent at room temperature to prepare a stable, transparent and uniform Sb2S3 reaction precursor solution; depositing a reaction precursor thin film on a substrate by a solution processing technology at room temperature and normal pressure; performing thermal treatment on the reaction precursor thin film to prepare the crystalline Sb2S3 thin film with great grain size, high density, controllable thickness and large absorption coefficient. A preparation technology disclosed by the invention has the advantages of simple and feasible method, low cost, and low toxicity and safety of used solvent; the defects of high requirement on equipment, complex preparation conditions, use of high-toxicity solvent, low degree of crystallinity of the Sb2S3 thin film and the like in the prior art are overcome; the solution processing preparation method has an important application value in the fields of photoelectric materials, photovoltaic materials, devices and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

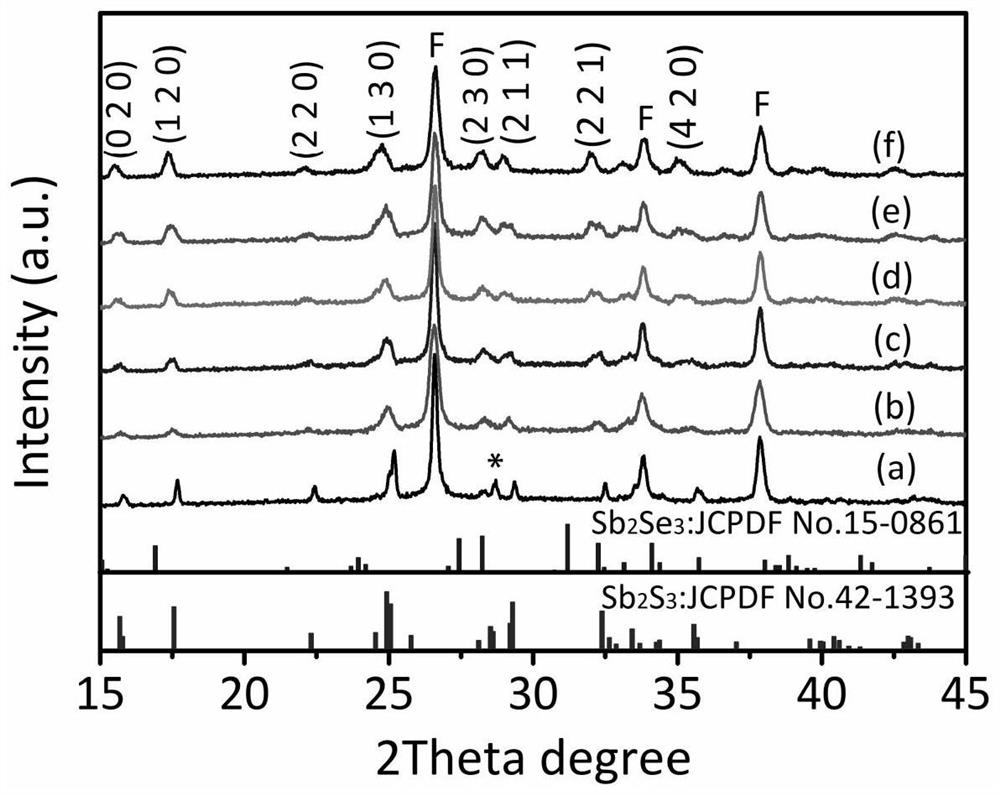

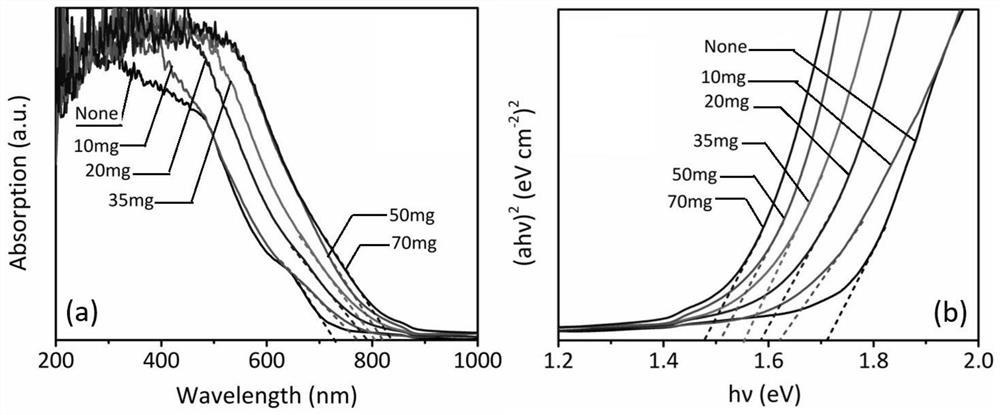

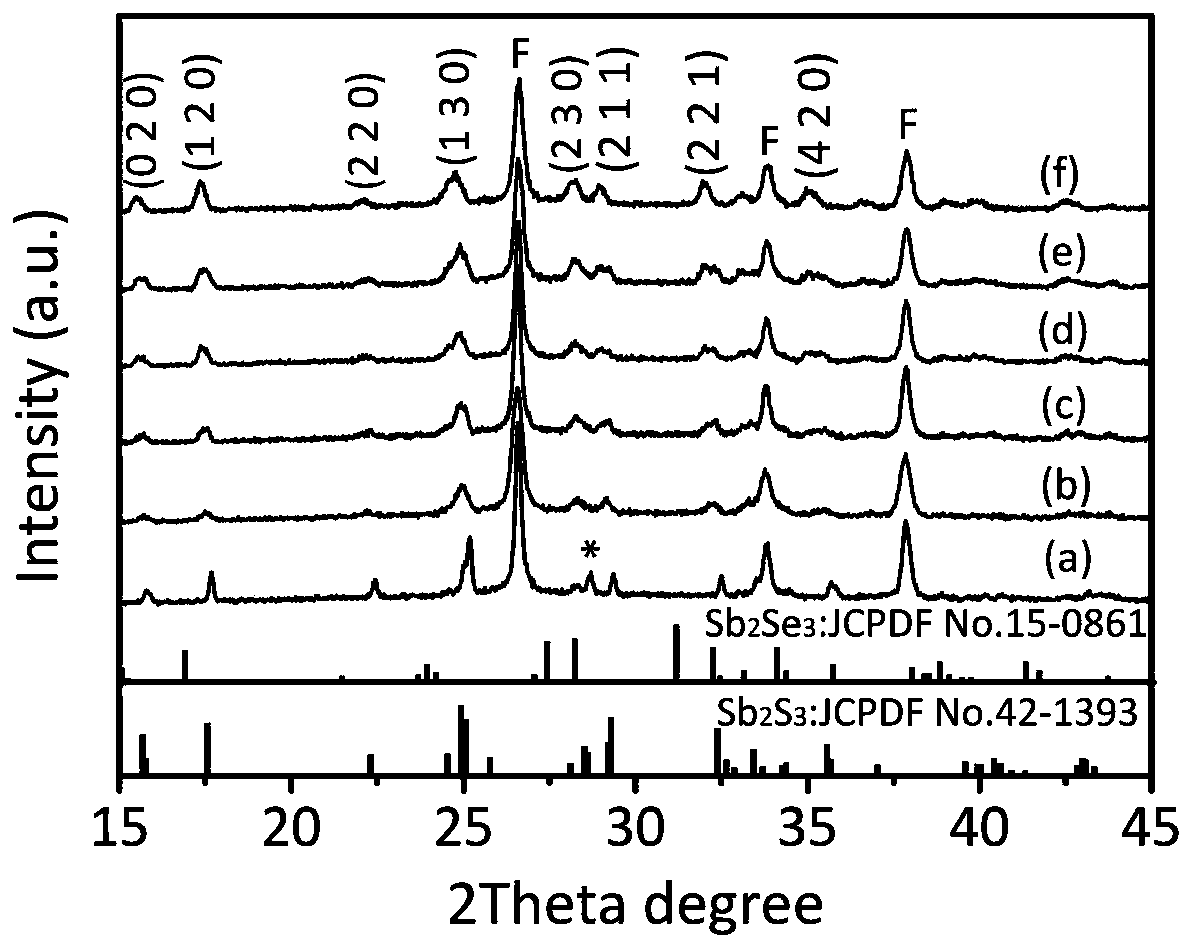

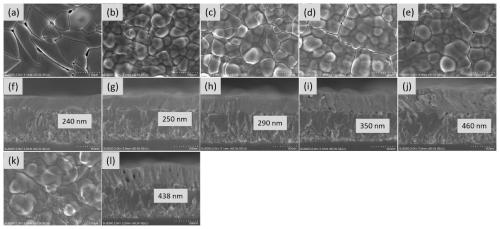

Preparation method of selenium antimony sulfide film and application thereof

ActiveCN111320395ALow costLow reaction temperatureCoatingsAntimony sulfidesOrganic solventElectrical battery

The invention provides a preparation method of a selenium antimony sulfide film, which comprises the following steps: mixing antimony potassium tartrate, a sulfur source and a selenium source, carrying out a hydrothermal reaction in a closed environment, and drying to obtain a selenium antimony sulfide precursor film; and annealing the selenium antimony sulfide precursor film to obtain the selenium antimony sulfide film. The invention also provides a solar cell device based on the selenium antimony sulfide thin film. According to the method, the compact and flat selenium antimony sulfide filmis synthesized in a hydrothermal system, the cost of used raw materials is low, the reaction temperature is low, an organic solvent is not needed, and the preparation process is simple and environmentally friendly.

Owner:UNIV OF SCI & TECH OF CHINA

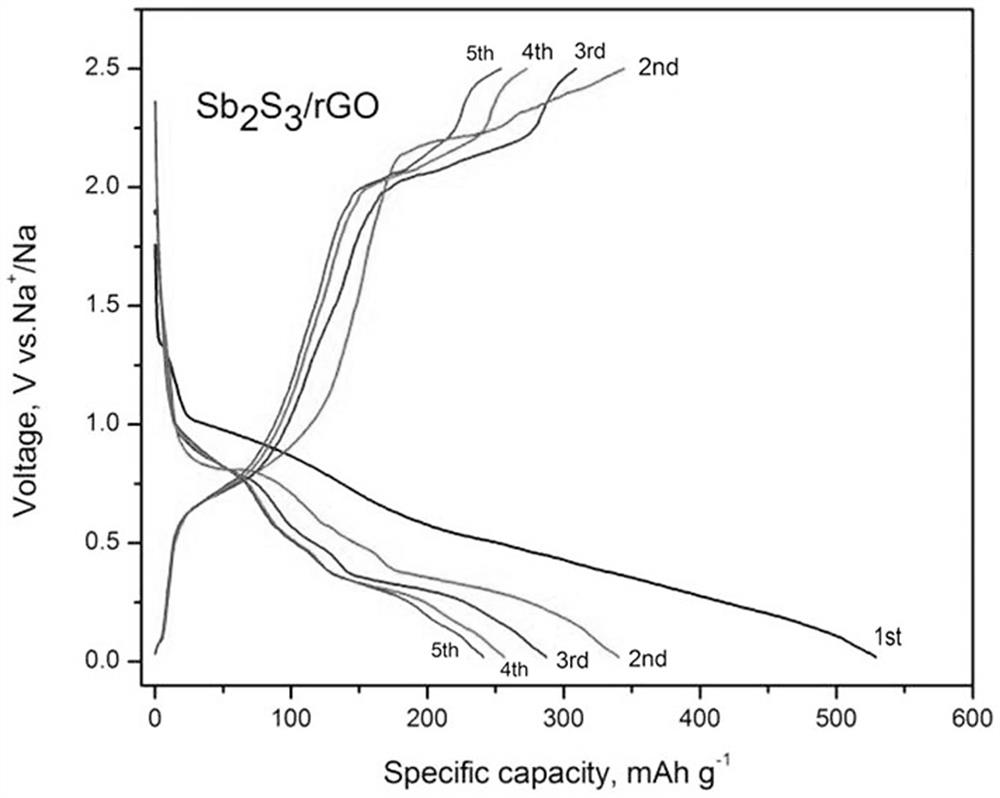

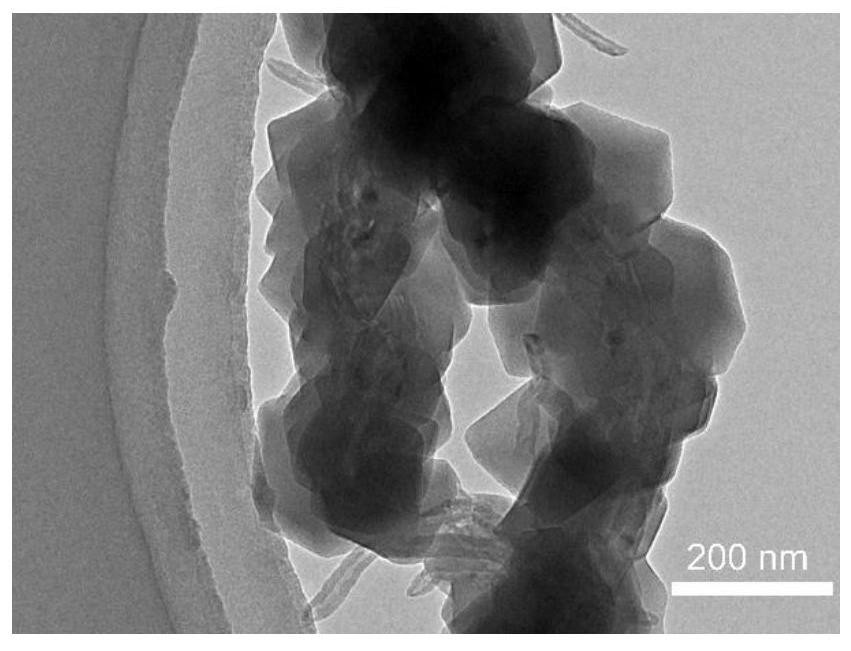

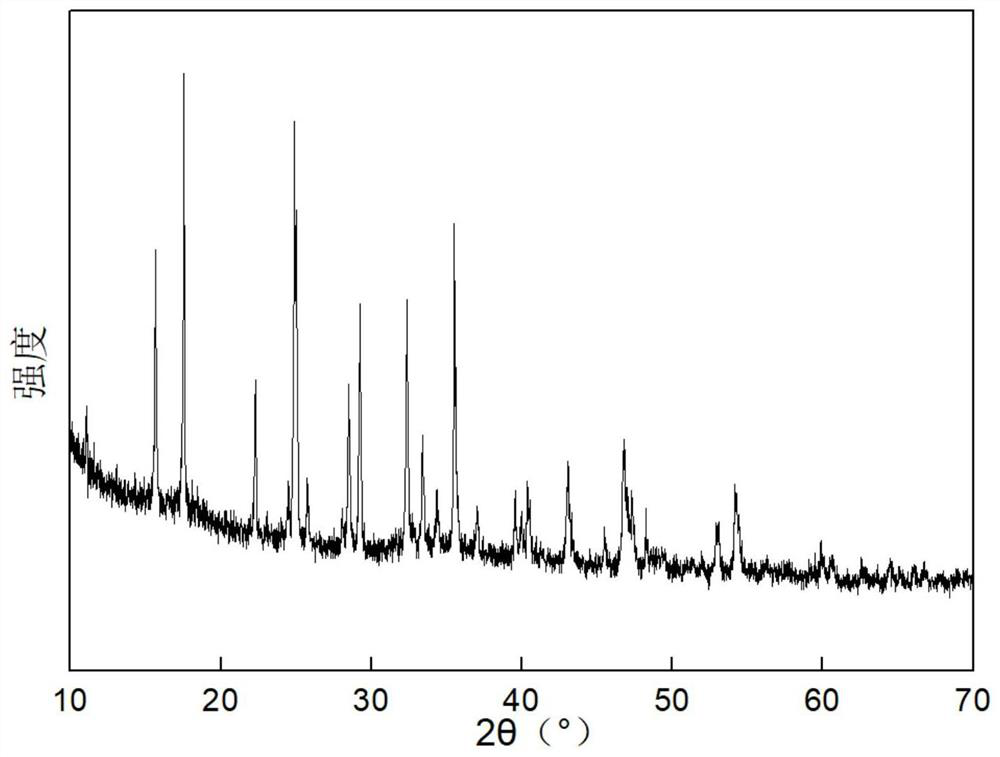

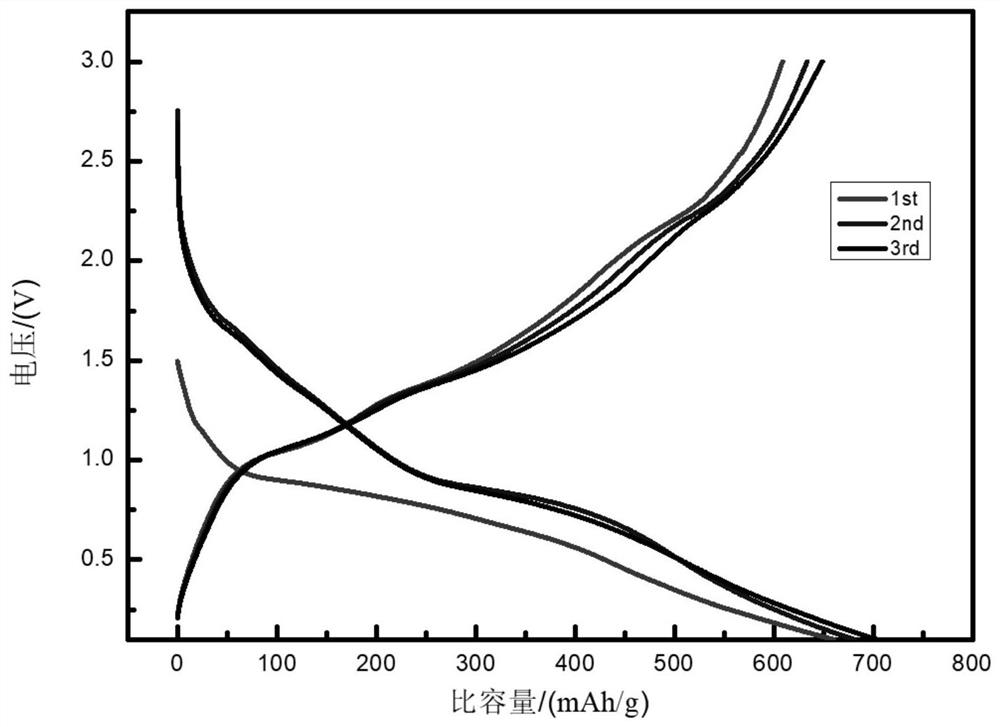

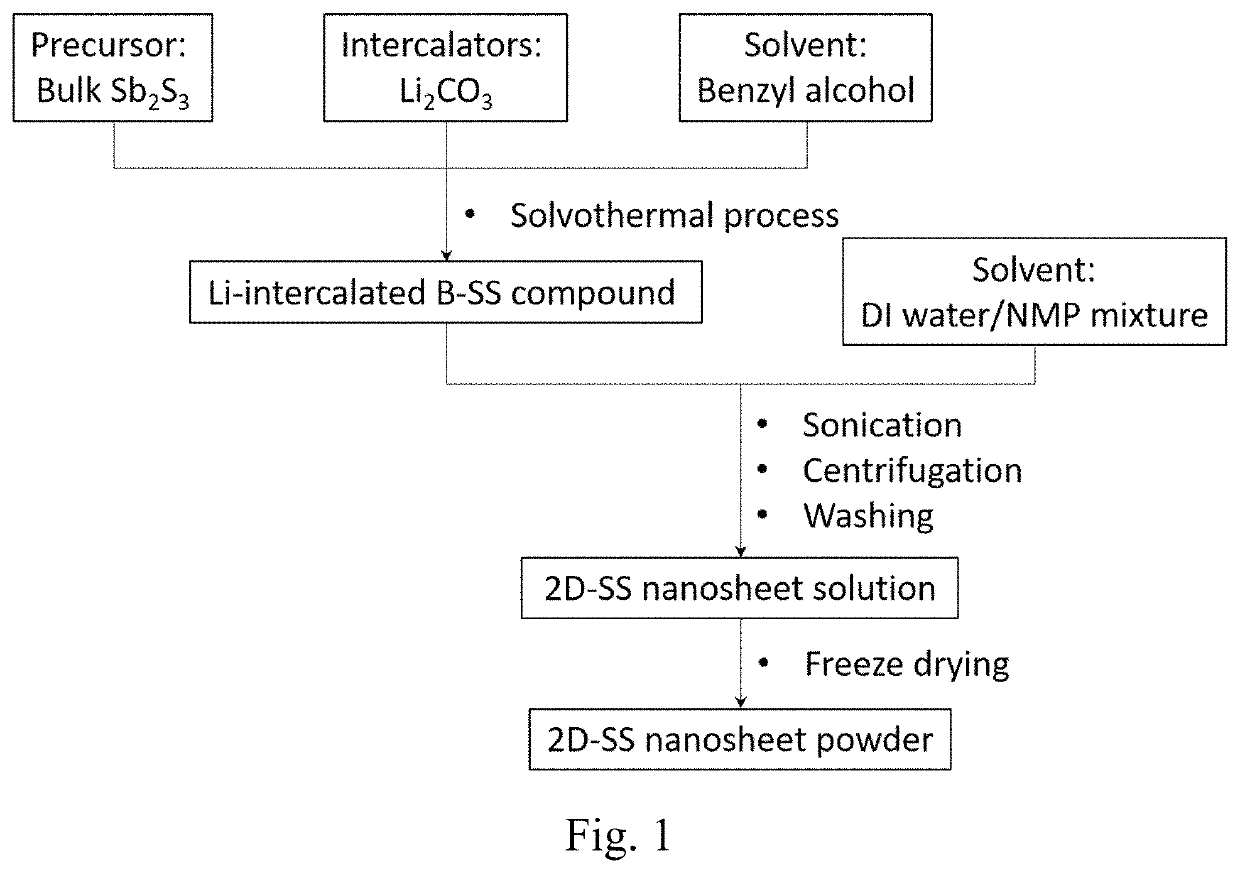

PREPARATION METHOD FOR ULTRATHIN SB2S3 NANOSHEET AS ANODE MATERIAL FOR Li/Na ION BATTERY APPLICATIONS

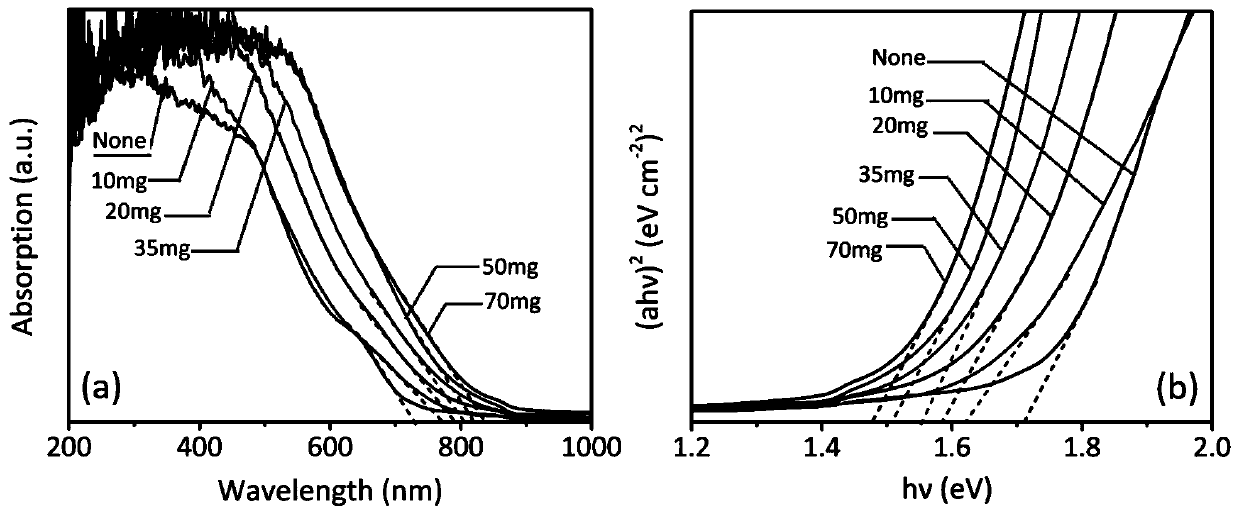

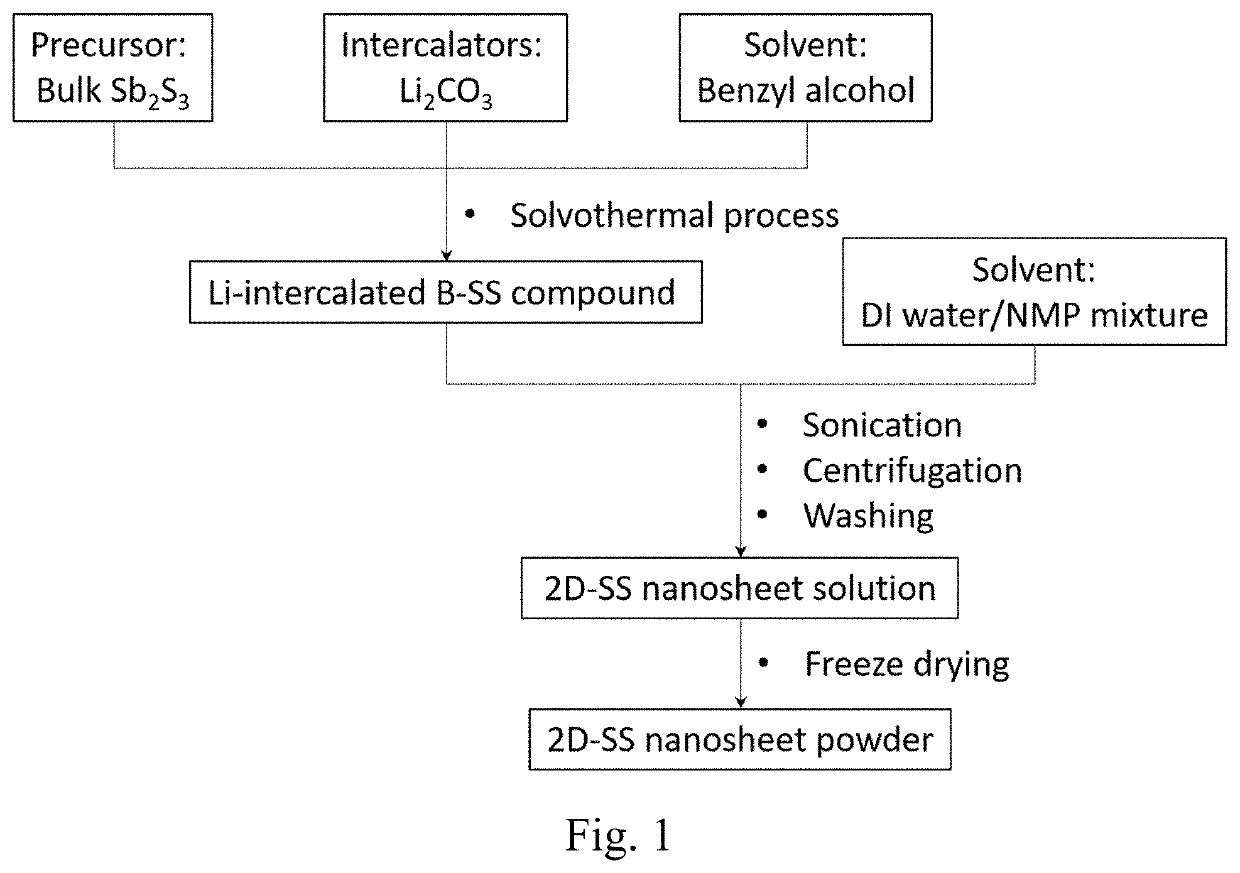

ActiveUS20200035997A1Short diffusion pathHigh crystallinityMaterial nanotechnologyElectrochemical processing of electrodesPhysical chemistryRedox

Methods of synthesizing few-layer two-dimensional (2D) Sb2S3 nanosheets using scalable chemical exfoliation are provided. The 2D Sb2S3 nanosheets can be developed as bi-functional anode materials in both lithium ion batteries and sodium ion batteries. The unique structural and functional features brought by 2D Sb2S3 nanosheets can offer short electron / ion diffusion paths and abundant active sites for surface redox reactions.

Owner:THE HONG KONG UNIV OF SCI & TECH

Telescoped multiwall nanotube and manufacture thereof

The invention relates to a method for forming a telescoped multiwall nanotube. Such a telescoped multiwall nanotube may find use as a linear or rotational bearing in microelectromechanical systems or may find use as a constant force nanospring. In the method of the invention, a multiwall nanotube is affixed to a solid, conducting substrate at one end. The tip of the free end of the multiwall nanotube is then removed, revealing the intact end of the inner wall. A nanomanipulator is then attached to the intact end, and the intact, core segments of the multiwall nanotube are partially extracted, thereby telescoping out a segment of nanotube.

Owner:RGT UNIV OF CALIFORNIA

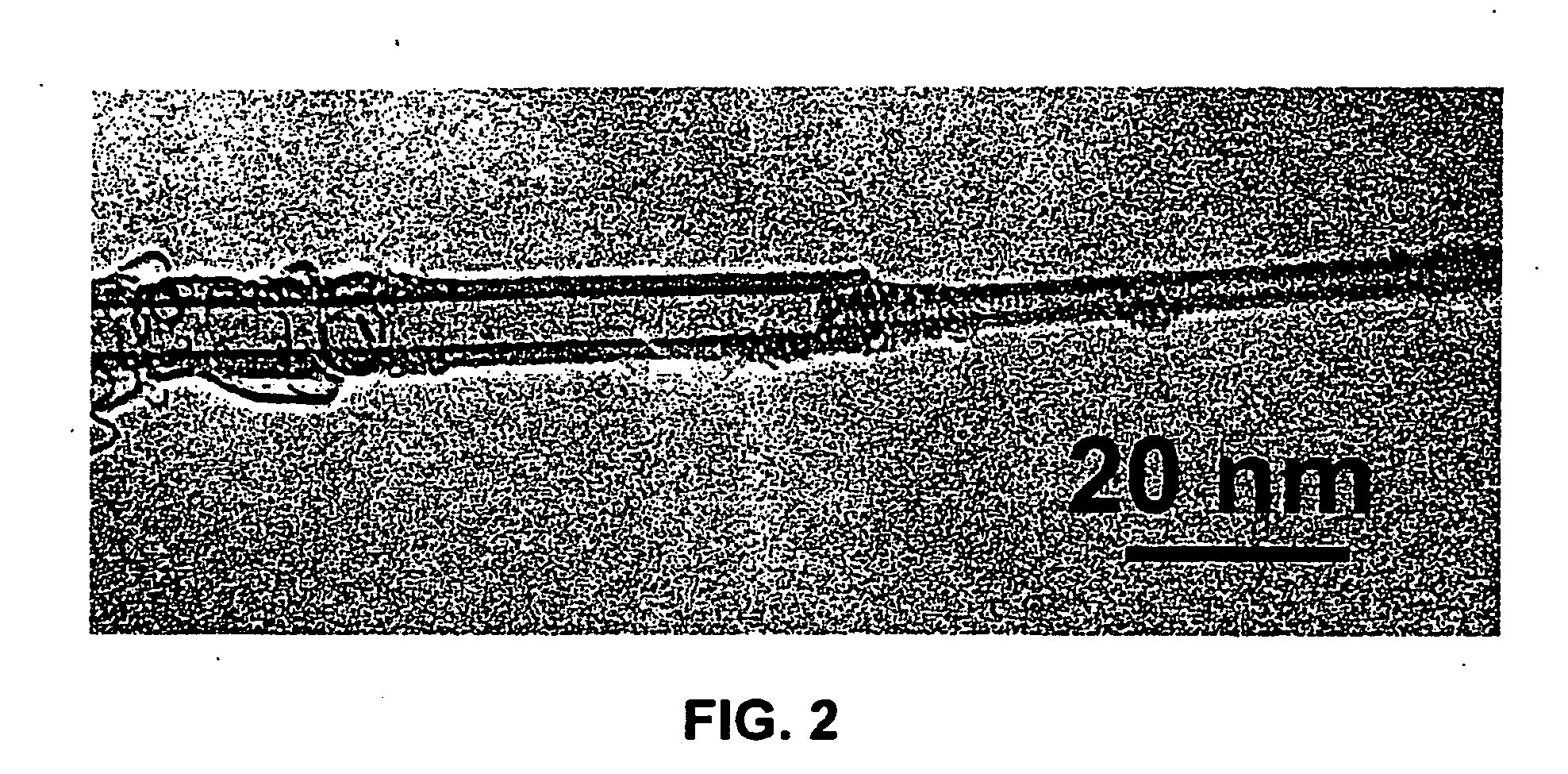

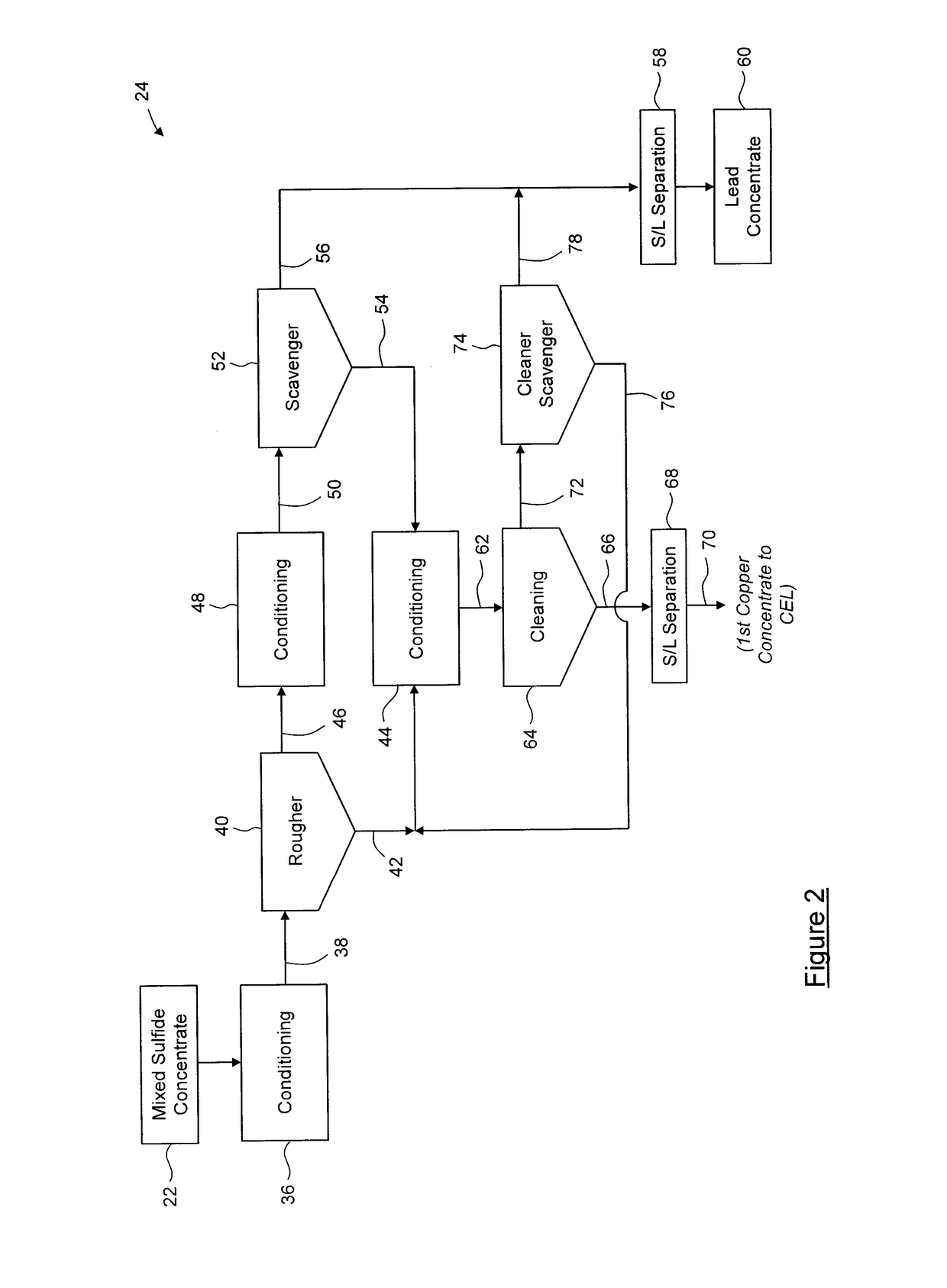

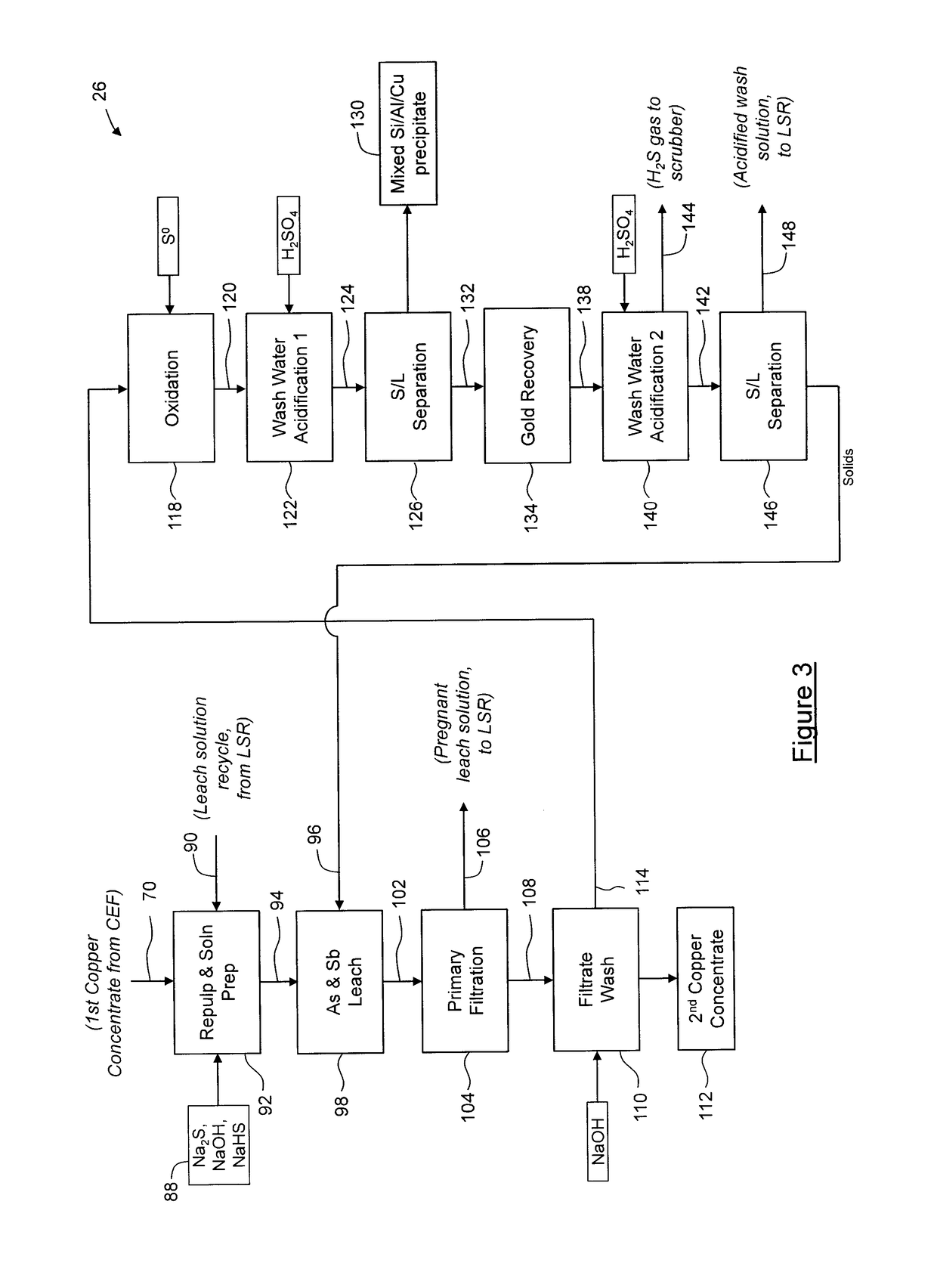

Process for separation of at least one metal sulfide from a mixed sulfide ore or concentrate

A stabilization process for an arsenic solution comprising thiosulfates, the process comprising: acidifying the arsenic solution to decompose the thiosulfates, to yield an acidified solution; oxidizing the acidified solution to oxidize residual As3+ to As5+ and reduced sulfur species to sulfates, to yield a slurry comprising elemental sulfur; separating elemental sulfur from the slurry to yield a liquid; oxidizing the liquid to oxidize residual reduced sulfur species, to yield an oxidized solution; and forming a stable arsenic compound from the oxidized solution.

Owner:GOLDCORP

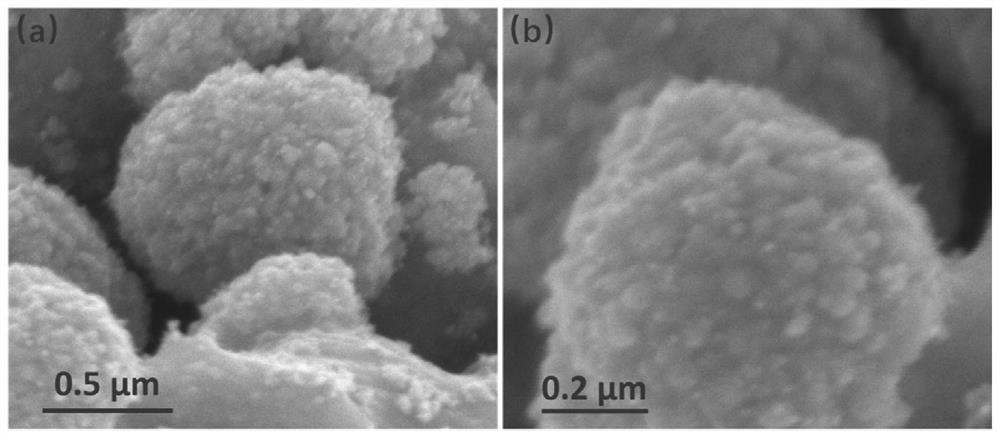

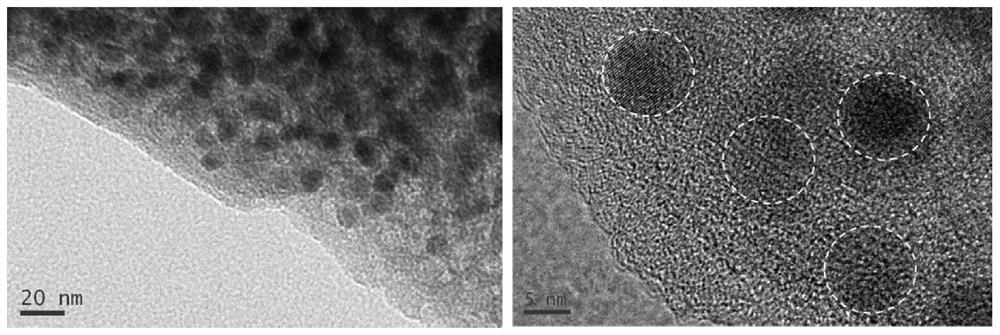

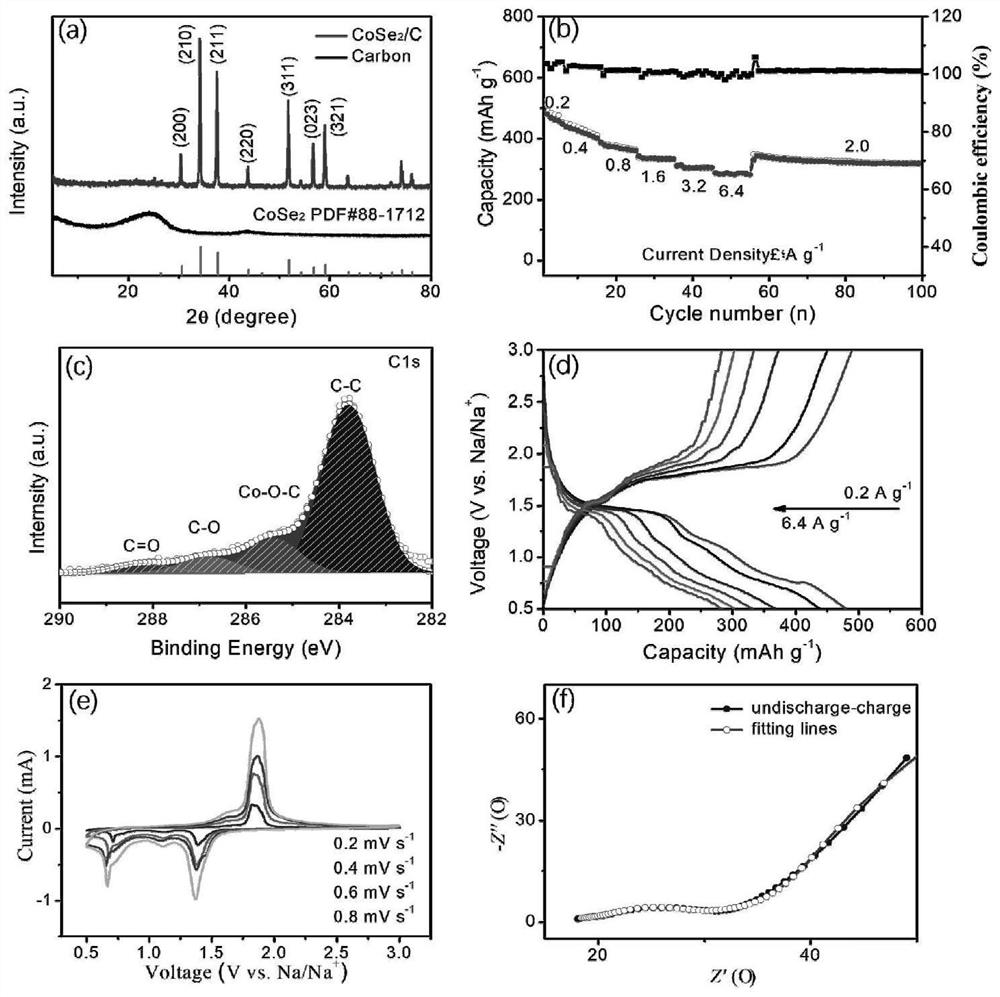

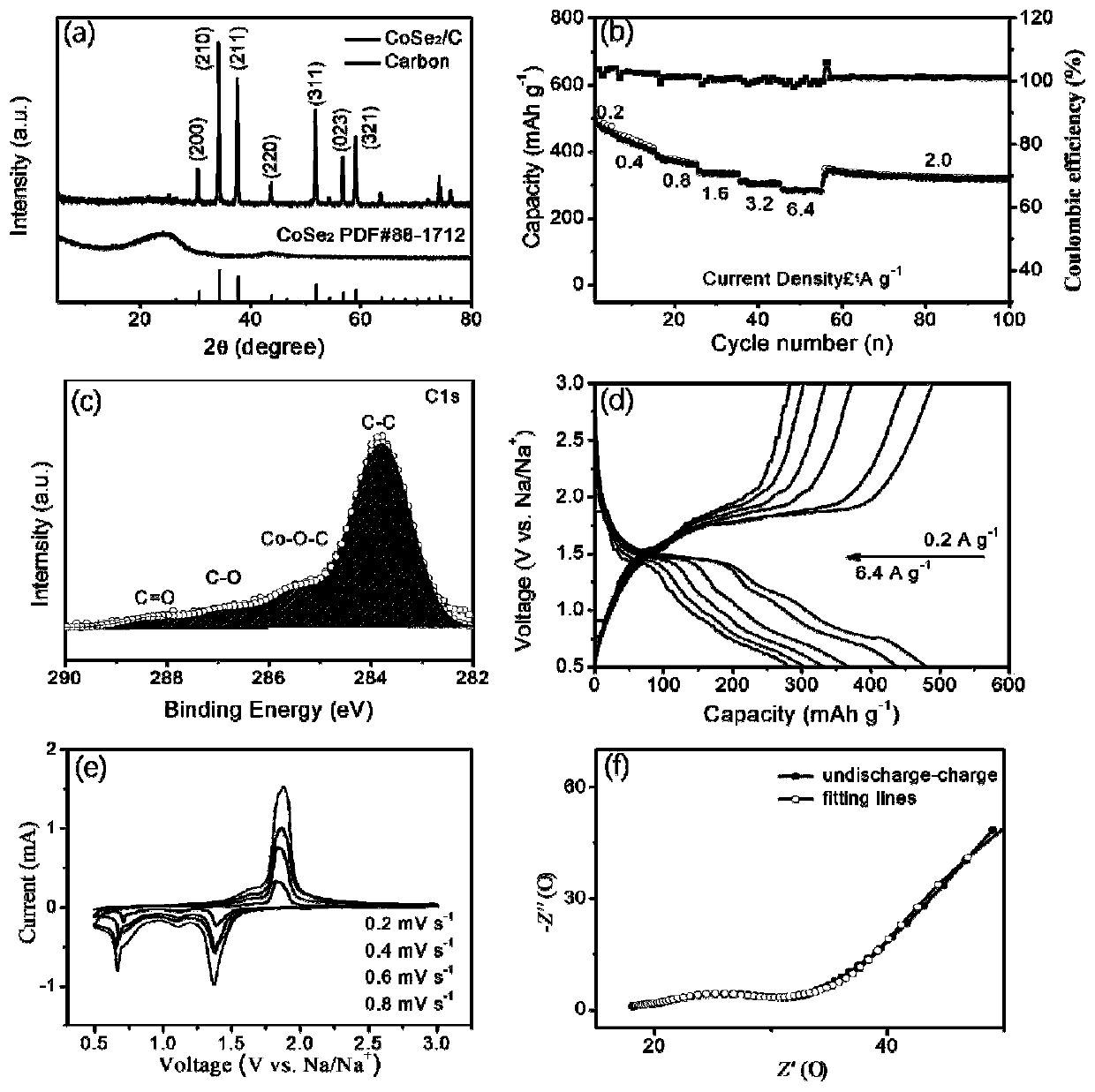

Transition metal chalcogen-group carbon-based heterostructure composite material with regular morphology and preparation method and application of transition metal chalcogen-group carbon-based heterostructure composite material

ActiveCN110683522AAlleviate volume expansionImproved magnification performanceHybrid capacitor electrodesCell electrodesCarbon coatingHeterojunction

The invention discloses a transition metal chalcogen-group carbon-based heterostructure composite material with a regular morphology and a preparation method and application of the transition metal chalcogen-group carbon-based heterostructure composite material. The preparation method comprises the following step: calcining starting materials including transition metal acetylacetonates and chalcogenides under a protective atmosphere to obtain the transition metal chalcogen-group carbon-based heterostructure composite material with the regular morphology, uniform multi-stage carbon coating andstable structure. When applied to preparation of an energy storage device, the transition metal chalcogen-group carbon-based heterostructure composite material with the regular morphology has excellent electrochemical performance. Particularly, compared with an existing material, the transition metal chalcogen-group carbon-based heterostructure composite material with the regular morphology has obvious advantages on the multiplying power and cycle stability of an energy storage device.

Owner:CENT SOUTH UNIV

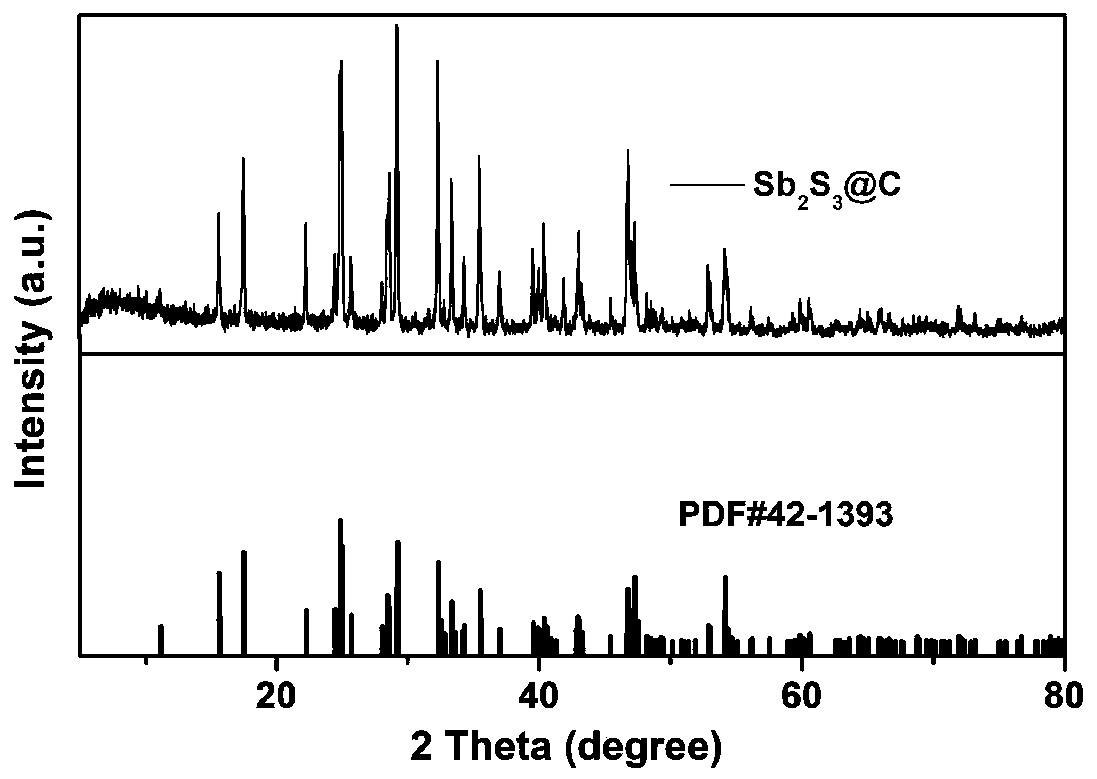

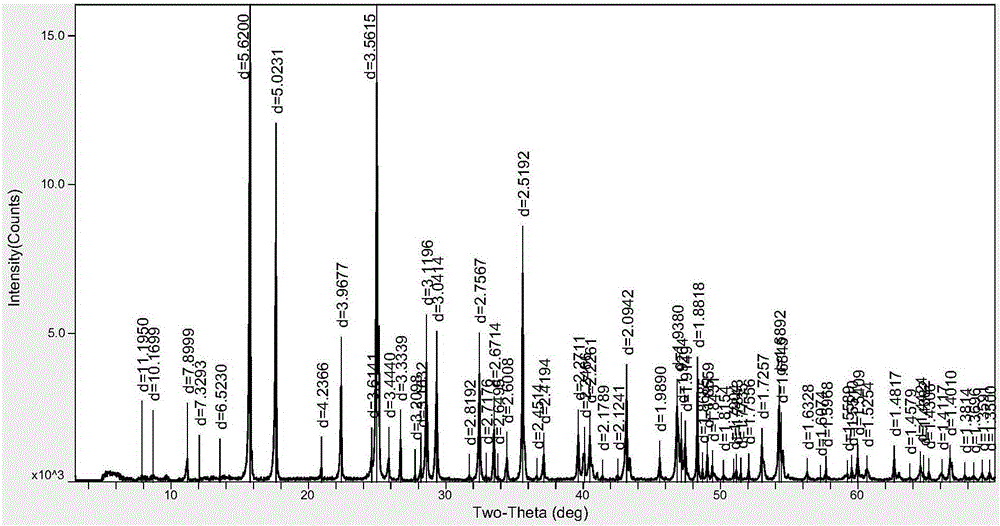

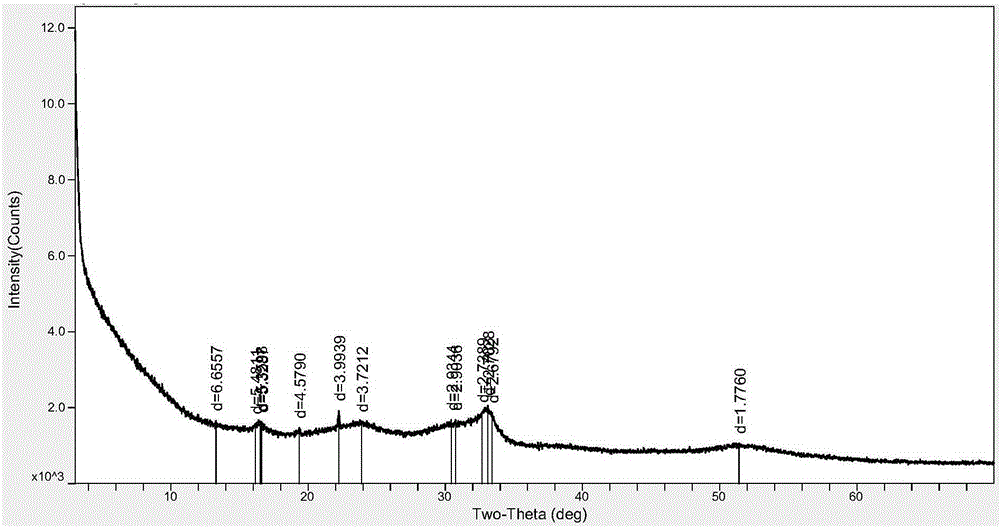

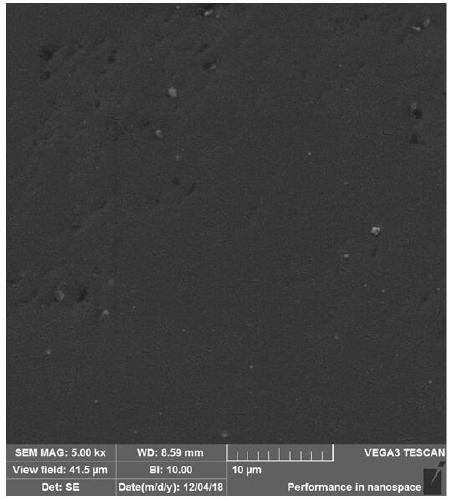

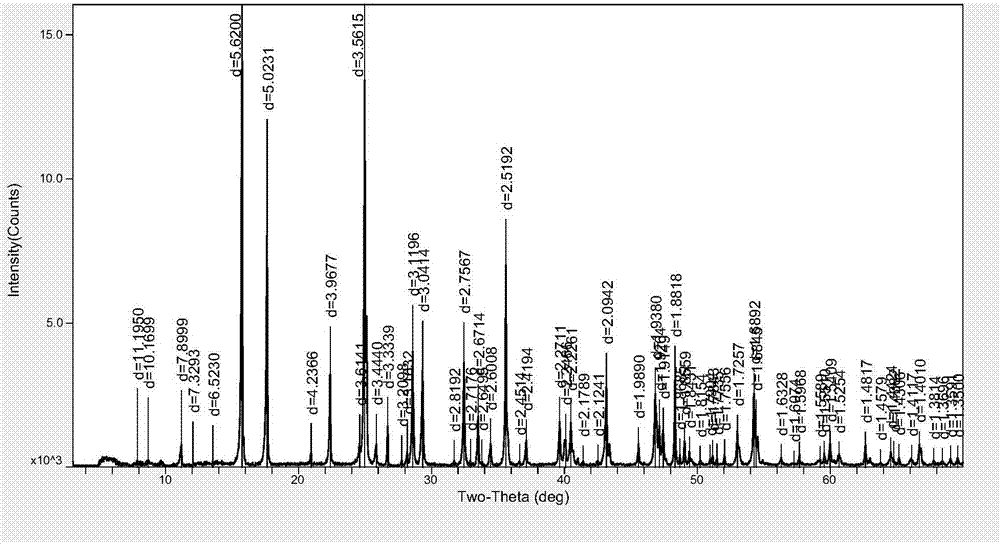

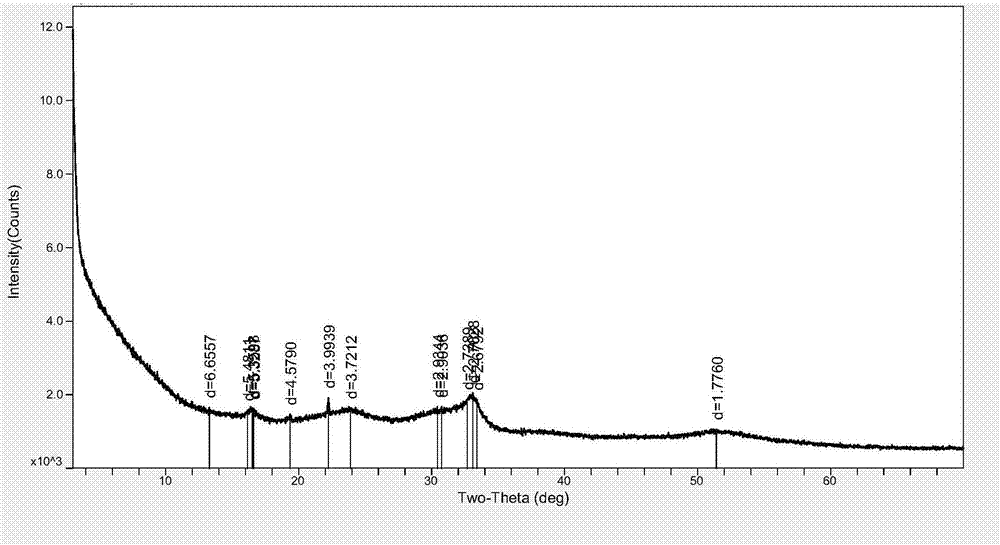

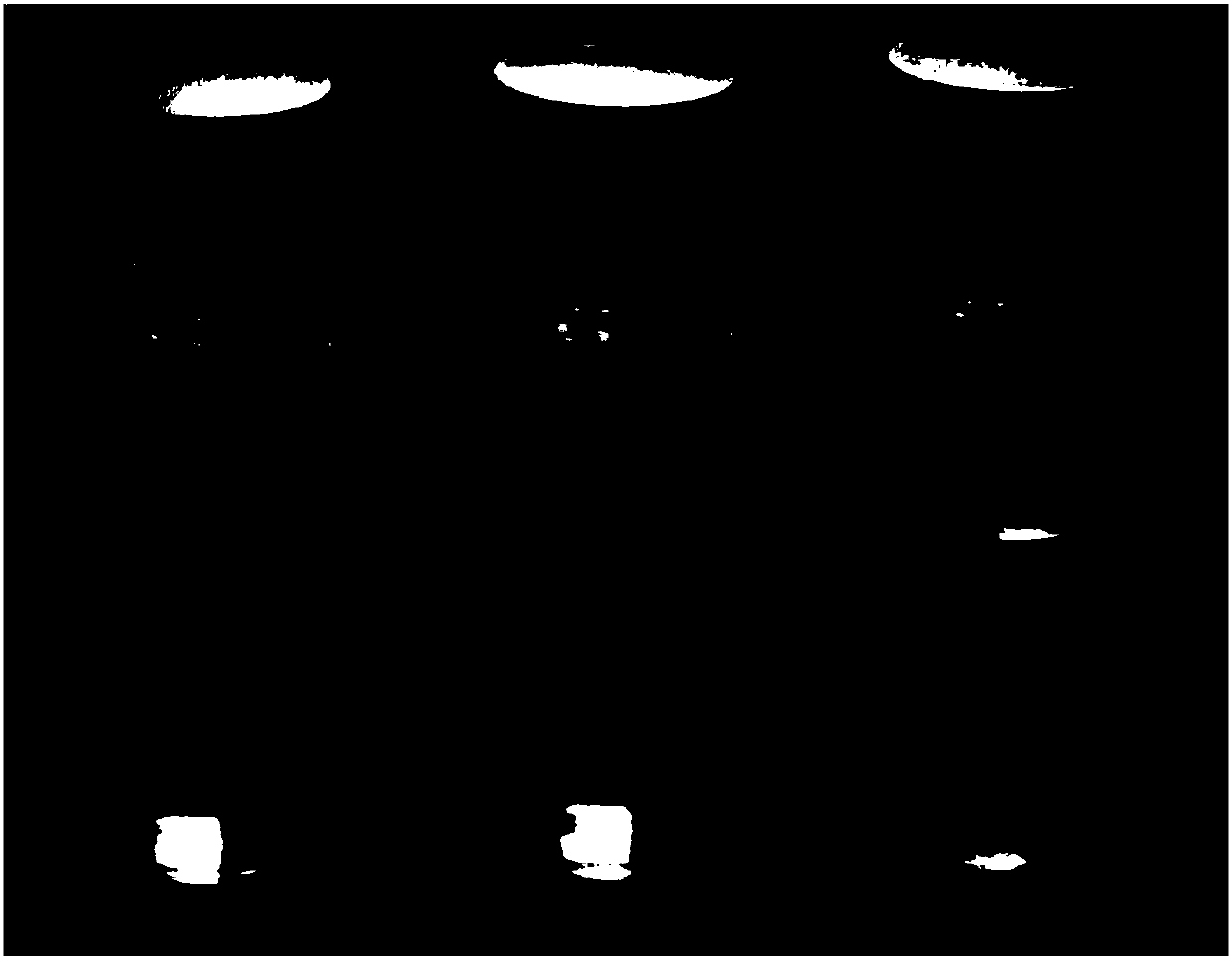

ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof

ActiveCN110931739AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyTin compoundsHydrogen atmosphereArgon atmosphere

The invention belongs to the technical field of batteries, and discloses a ZnS / SnS / antimony trisulfide [at] C hollow nanocube structure composite material, and a preparation method and application thereof. The composite material is prepared by the following steps: mixing water, tin tetrachloride, sodium citrate, zinc chloride and sodium hydroxide, washing with water, and drying to obtain H-ZHS; ultrasonically dispersing H-ZHS in an aqueous solution, adding sodium hydroxide or potassium hydroxide for etching, adding dopamine, stirring, washing with water and drying to obtain H-ZHS[at]PDA; adding H-ZHS[at]PDA and thiourea; vulcanizing in a hydrogen atmosphere at the temperature of 300-350 DEG C; cooling to room temperature, mixing the obtained H-SnS<2> / ZnS[at]PDA, antimony trichloride and absolute ethyl alcohol, carrying out hydrothermal reaction at 90-120 DEG C, washing with water, drying, carbonizing the obtained H-ZnS / SnS<2> / Sb<2>S<3>[at]PDA in an argon atmosphere at 500-530 DEG C, and cooling to room temperature, so as to obtain the H-SnS<2> / Sb<2>S<3>[at]PDA.

Owner:GUANGDONG UNIV OF TECH +1

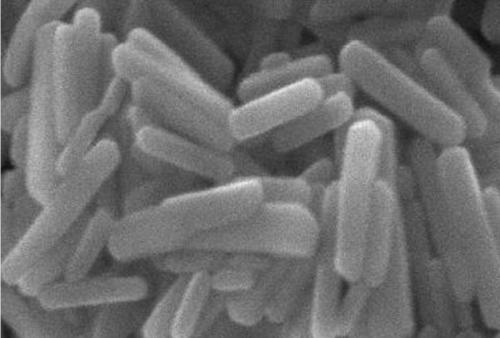

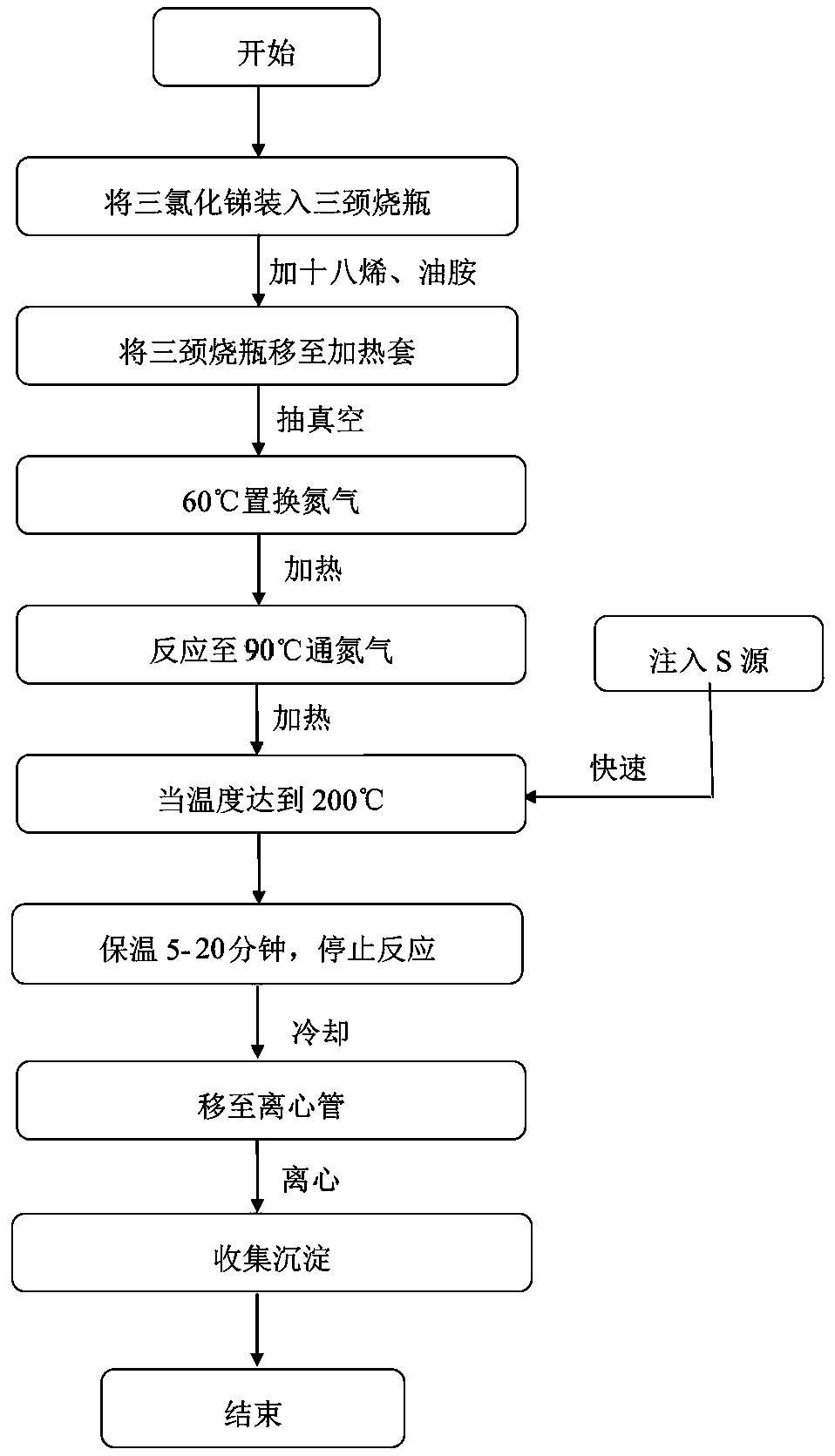

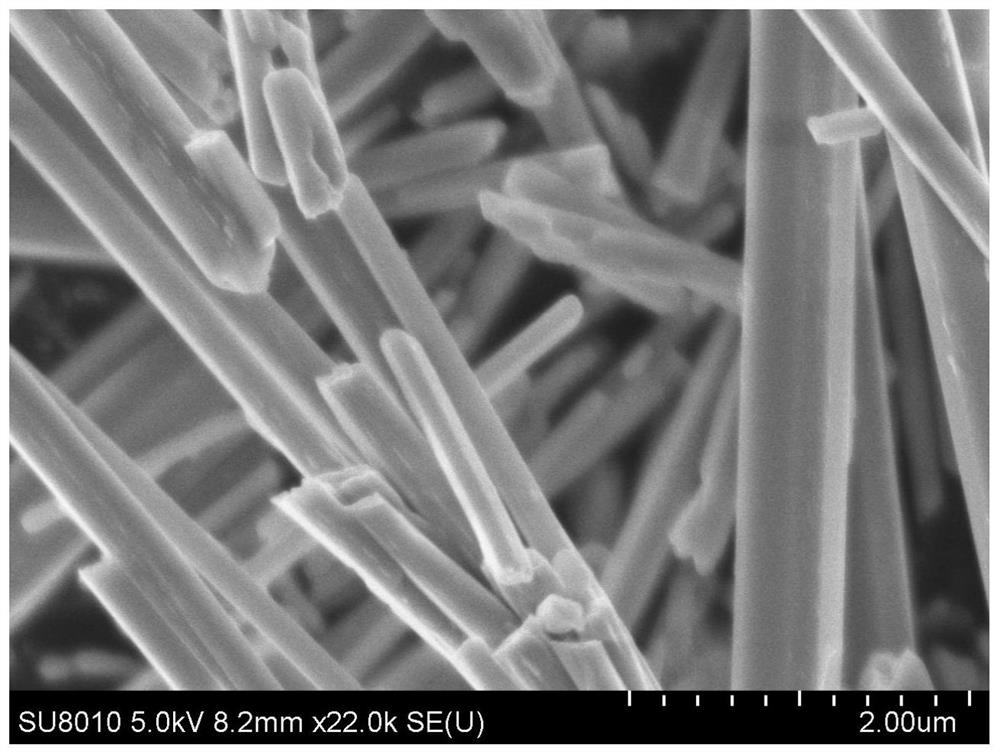

Synthesis method of Sb2S3 nanorods

InactiveCN110316756AShorten the timeSimple processNanotechnologyAntimony sulfidesSulfurSynthesis methods

The invention provides a synthesis method of Sb2S3 nanorods. The method comprises the following steps that 1, high-purity sulfur and oleylamine are added into a reaction flask, vacuumizing is performed, and stirring and heating are performed at the same time; 2, when the temperature reaches 60 DEG C, nitrogen is replaced three times; 3, when the temperature reaches 90 DEG C, a nitrogen valve is turned on, and a vacuum pump is turned off; after sulfur is dissolved completely, the reaction is stopped; 4, SbCl3 is added into the reaction flask, then, octadecene and oleylamine are added, vacuumizing is performed, and stirring and heating are performed at the same time; 5, when the temperature reaches 60 DEG C, nitrogen is replaced three times; 6, when the temperature reaches 100 DEG C, the nitrogen valve is turned on, the vacuum pump is turned off, when the temperature is increased to 200 DEG C, a sulfur source is injected, after the reaction is performed for 5-20 min, heating is stopped,and the nanorods are obtained after centrifuging. According to the method for synthesizing antimony sulfide through a thermal injection method, the reaction time is greatly shortened, the crystallinestate can be achieved directly without annealing, and working procedures are simpler.

Owner:HEBEI UNIVERSITY

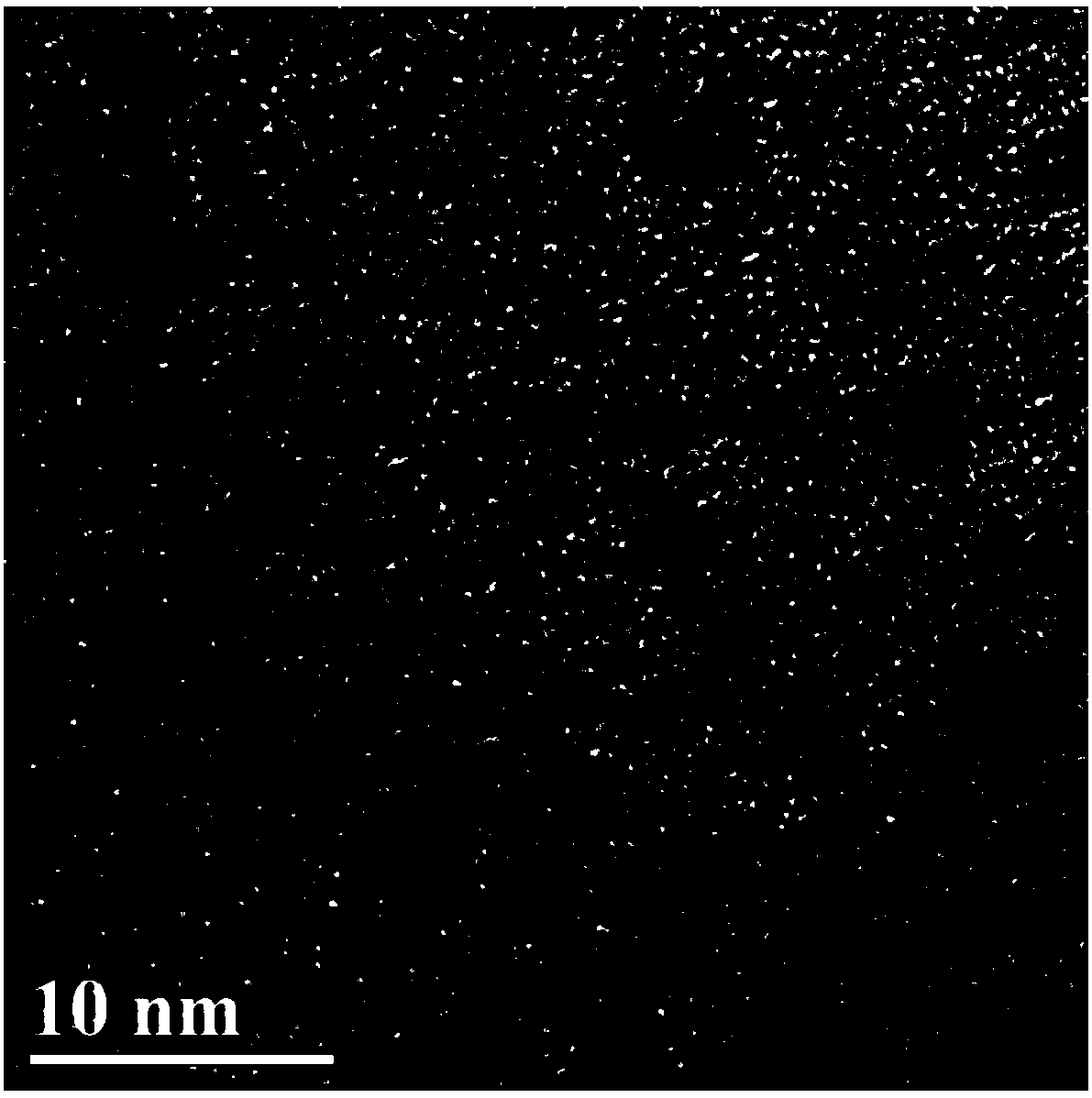

Antimony trisulfide nanodot/sulfur-doped carbon composite material, preparation method thereof and application of antimony trisulfide nanodot/sulfur-doped carbon composite material to sodium/potassium ion battery

ActiveCN110729478AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesCarbon compositesNanodot

The invention discloses an antimony trisulfide nanodot / sulfur-doped carbon composite material, a preparation method thereof and application of the antimony trisulfide nanodot / sulfur-doped carbon composite material to a sodium / potassium ion battery. Sb2S3 nanodots are uniformly distributed in pores and on the surface of sulfur-doped carbon, so that the composite material can be formed. According tothe preparation method, an organic antimony salt is placed in a reducing atmosphere so as to be subjected to reduction treatment, so that an antimony nanodot / carbon composite material can be obtained; the antimony nanodot / carbon composite material and a sulfur source are arranged in a protective atmosphere so as to undergo a solid-phase reaction, so that the antimony trisulfide nanodot / sulfur-doped carbon composite material can be formed. The Sb2S3 of the composite material is a nano point material; the nano point material has a unique volume effect, a surface effect, a quantum size effect, amacroscopic quantum tunnel effect and the like and can effectively enhance the electrochemical properties of the composite material; the sulfur-doped carbon carrier can enhance the conductivity of the composite material and can relieve the large volume expansion of the antimony trisulfide material in a charging / discharging process. The antimony trisulfide nanodot / sulfur-doped carbon composite material presents characteristics such as high capacity and favorable cycle stability when being used for sodium-ion and potassium-ion batteries.

Owner:CENT SOUTH UNIV

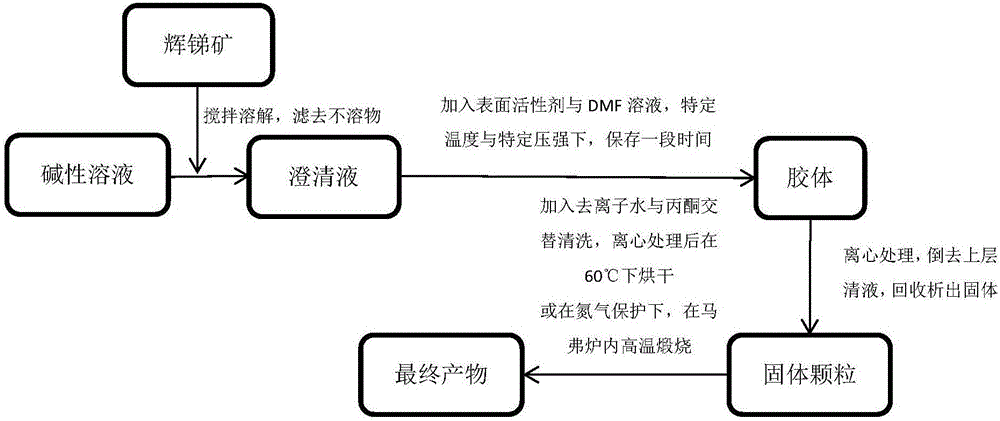

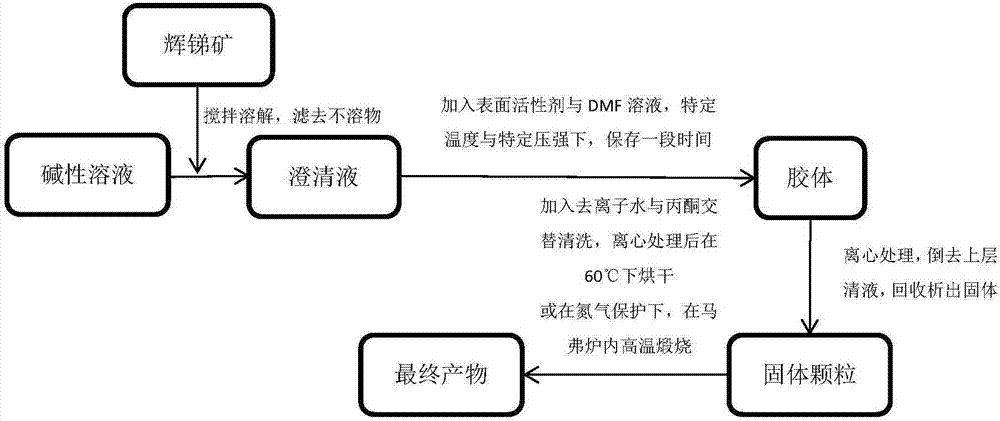

Preparation method of antimony sulfide nanoparticles under controllable conditions

InactiveCN106542577AEasy to operateNo synthesis requiredNanotechnologyAntimony sulfidesTemperature controlNanoparticle

The invention discloses a preparation method of antimony sulfide nanoparticles under controllable conditions. The preparation method mainly comprises the following steps: dissolving, temperature control, precipitation, and washing or calcination. An alkaline solution is used in the dissolving step to dissolve antimony sulfide powder; a surfactant and a DMF solution are added, and then the obtained solution is stored at a specific temperature under a specific pressure to wait for solid precipitation; and precipitated solid is immersed and cleaned with deionized water or acetone, the obtained solid is centrifuged and dried, or undergoes high temperature calcination in a muffle furnace under the protection of nitrogen. Compared with present nanometer antimony sulfide preparation methods, the preparation method disclosed in the invention has the advantages of simplicity in operation, no synthesis, common used reagents, good economic property, and suitableness for large-scale promotion and application.

Owner:ZHEJIANG UNIV

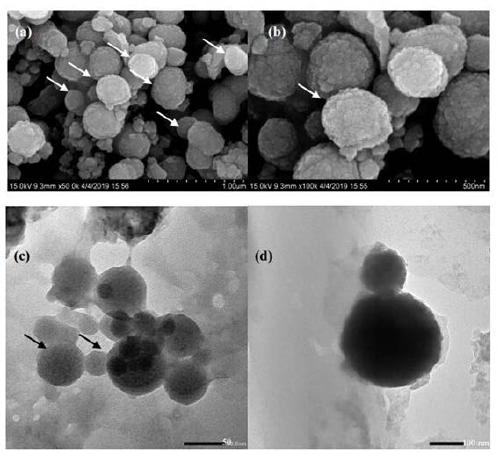

Microorganism for preparing broccoli-shaped antimony sulfide and application of microorganism

ActiveCN110257311AAccelerated photodegradationLow technical costBacteriaWater/sewage treatment by irradiationSulfite saltSodium sulfite

The invention belongs to the technical field of environmental engineering water treatment and particularly relates to a microorganism for preparing broccoli-shaped antimony sulfide and application of the microorganism. The microorganism refers to marine Halomonas sp.X3 which is preserved in the China Center for Type Culture Collection located in Wuhan University on May 30, 2019, and a preservation number is CCTCC M 2019409. The strain is an indigenous microorganism screened from marine sediments and can be used for preparing nano antimony sulfide by adopting potassium pyroantimonate and sodium thiosulfate or sodium sulfite as precursors. Nano antimony sulfide prepared from the microorganism is broccoli shaped and can serve as a photocatalyst for accelerating light degradation of azo dye compounds. Currently, antimony sulfide is prepared according to chemical methods mostly. Shaped-controllable antimony sulfide is prepared from the microorganism for the first time, and high innovativeness is realized.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

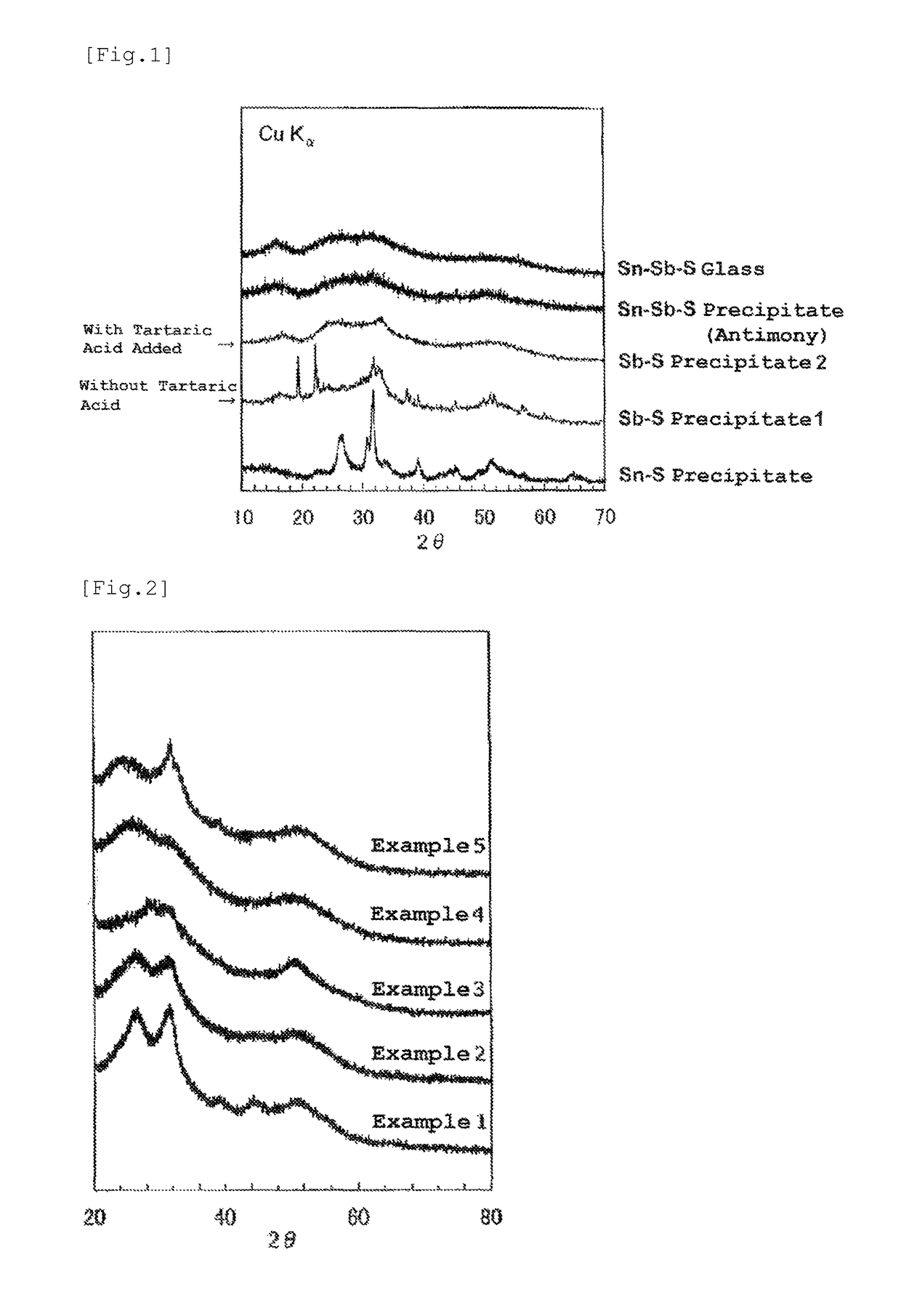

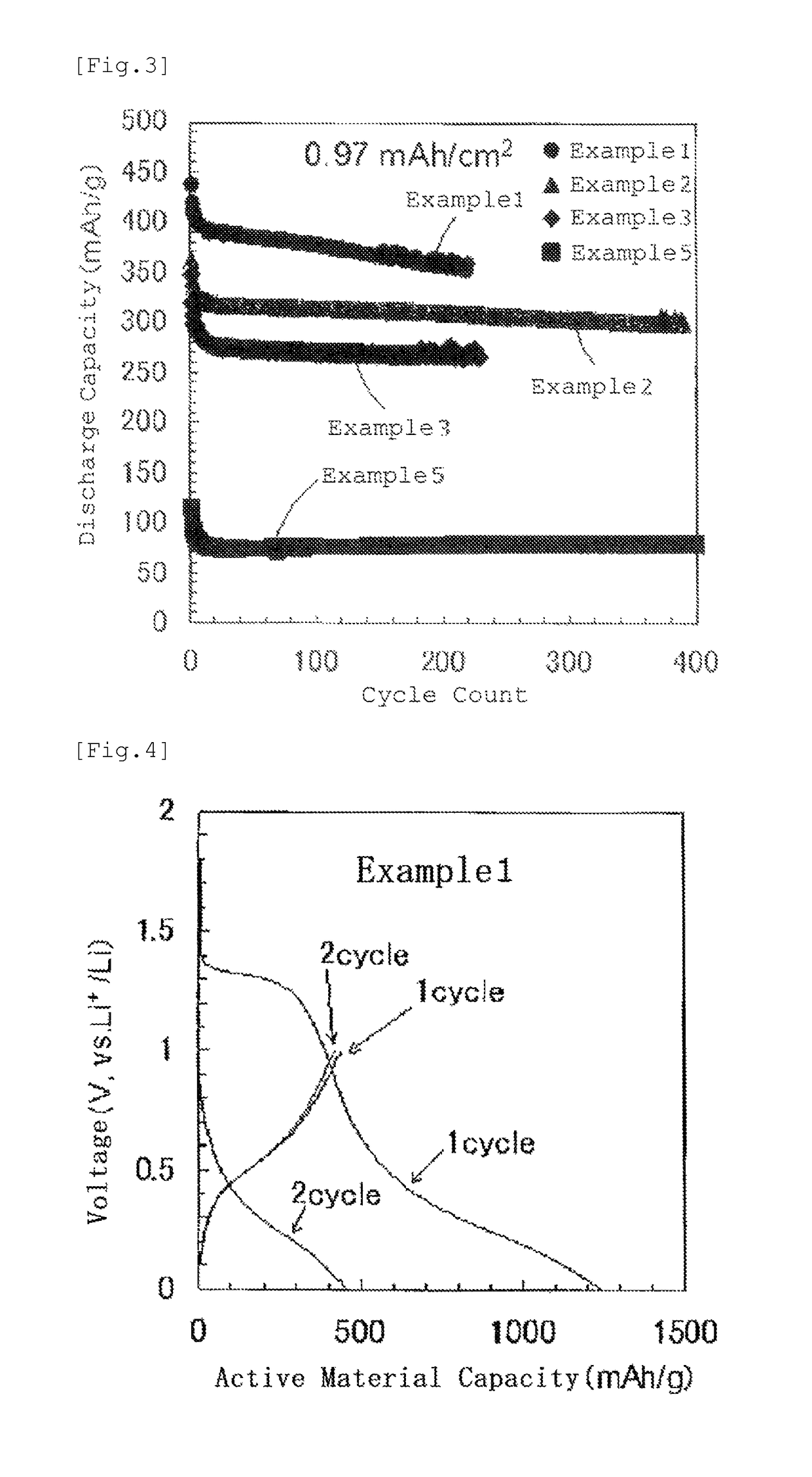

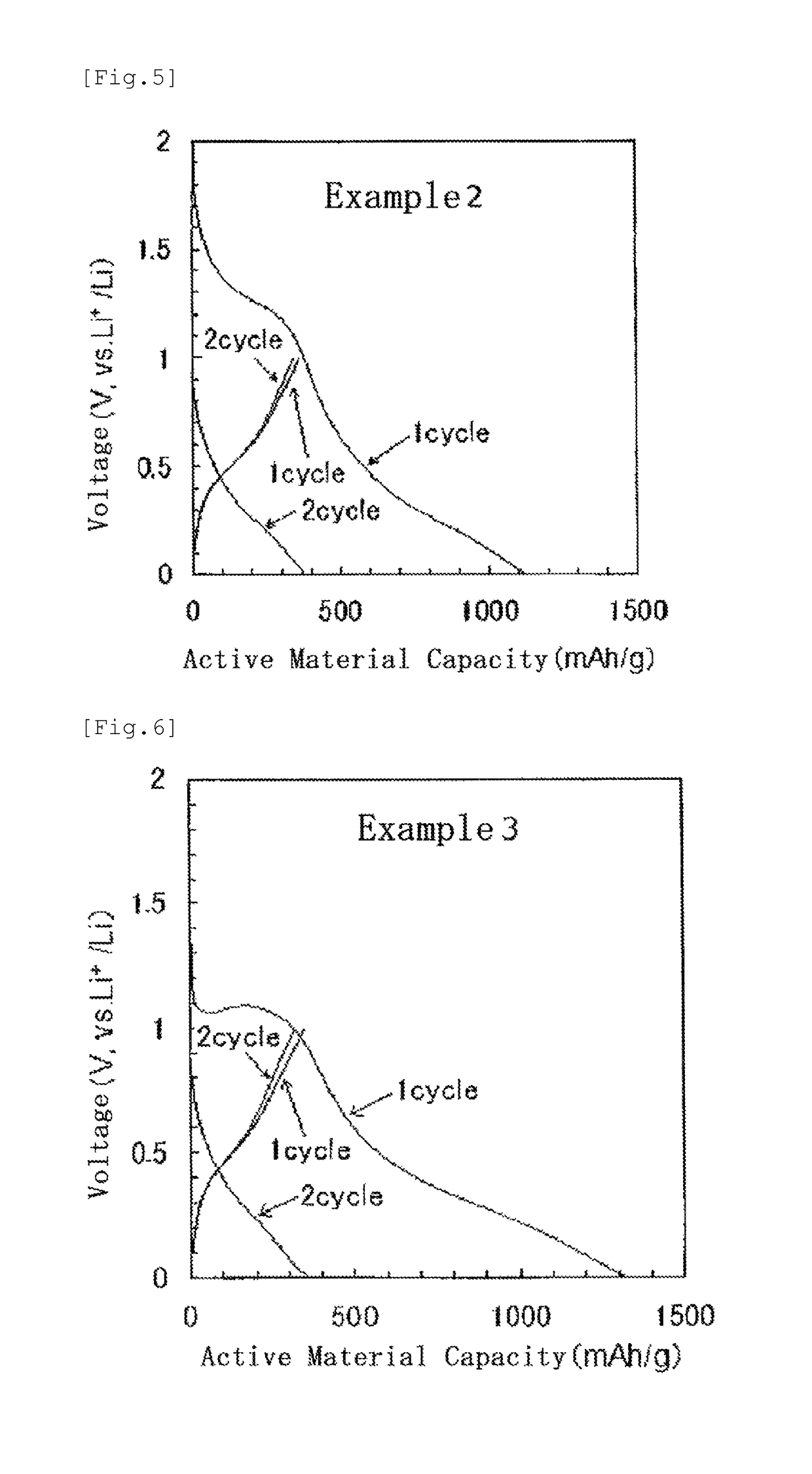

Lithium secondary battery negative electrode active material and method for manufacturing same

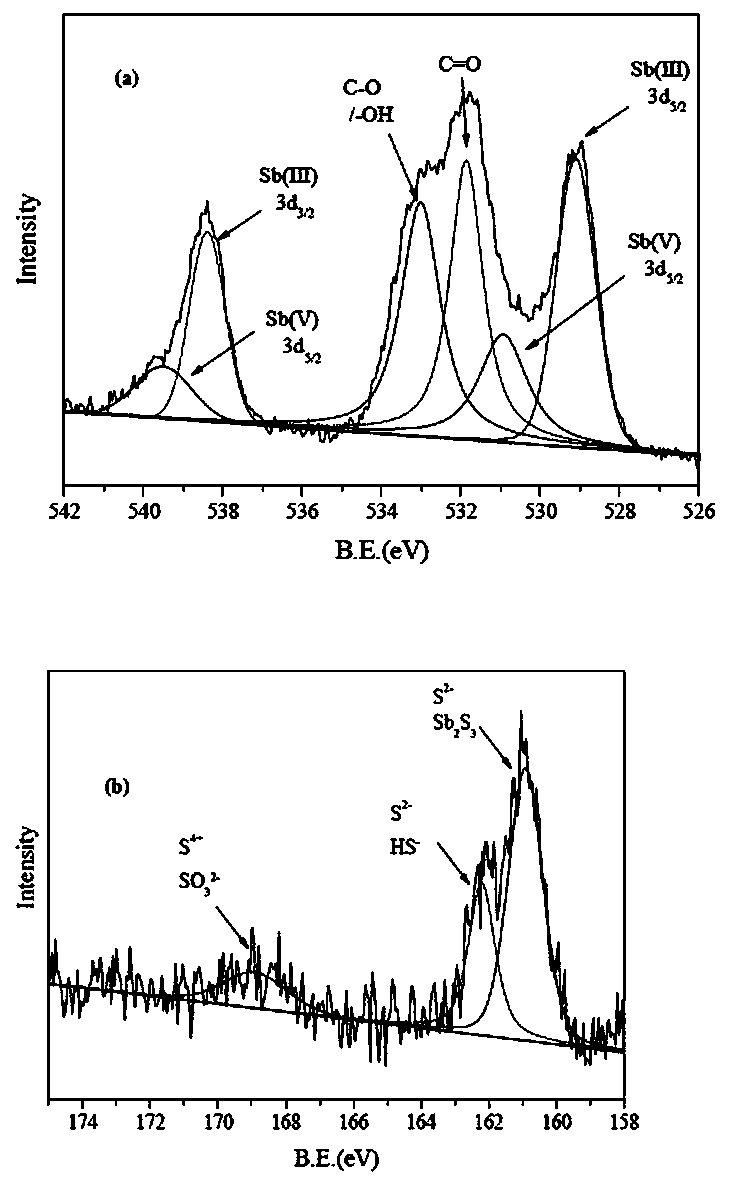

ActiveUS10141573B2Excellent output characteristic and cycle life characteristicEasily and inexpensively manufacture a negative electrode active materialTin compoundsNegative electrodesLithiumSulfide

The teachings herein are directed at a lithium secondary battery negative electrode active material consisting of a Sn Sb based sulfide that delivers a high electrode capacity density, excellent output characteristics, and excellent cycle life characteristics and also provide a method for manufacturing the lithium secondary battery negative electrode active material, said method being capable of easily manufacturing the high performance lithium secondary battery negative electrode active material at low cost without requiring a high-temperature processing step and special facilities as required in a glass melting method. The negative electrode active material preferably is prepared using a method that includes a step of obtaining a Sn Sb based sulfide precipitate by adding an alkali metal sulfide to a mixed solution of a tin halide and an antimony halide.

Owner:ISUZU GLASS +1

Coating liquid for forming sulfide semiconductor, sulfide semiconductor thin film, and thin film solar cell

InactiveUS20150107673A1Well formedIncrease the areaNanotechCell electrodesSemiconductor materialsSulfur

The present invention aims to provide a sulfide semiconductor-forming coating liquid capable of easily forming a sulfide semiconductor having a large area, the sulfide semiconductor being useful as a semiconductor material for photoelectric conversion materials. The present invention also aims to provide a sulfide semiconductor thin film produced using the sulfide semiconductor-forming coating liquid; and a thin film solar cell. The present invention provides a sulfide semiconductor-forming coating liquid, the coating liquid containing a complex containing a metal element of group 15 of the periodic table and sulfur.

Owner:SEKISUI CHEM CO LTD

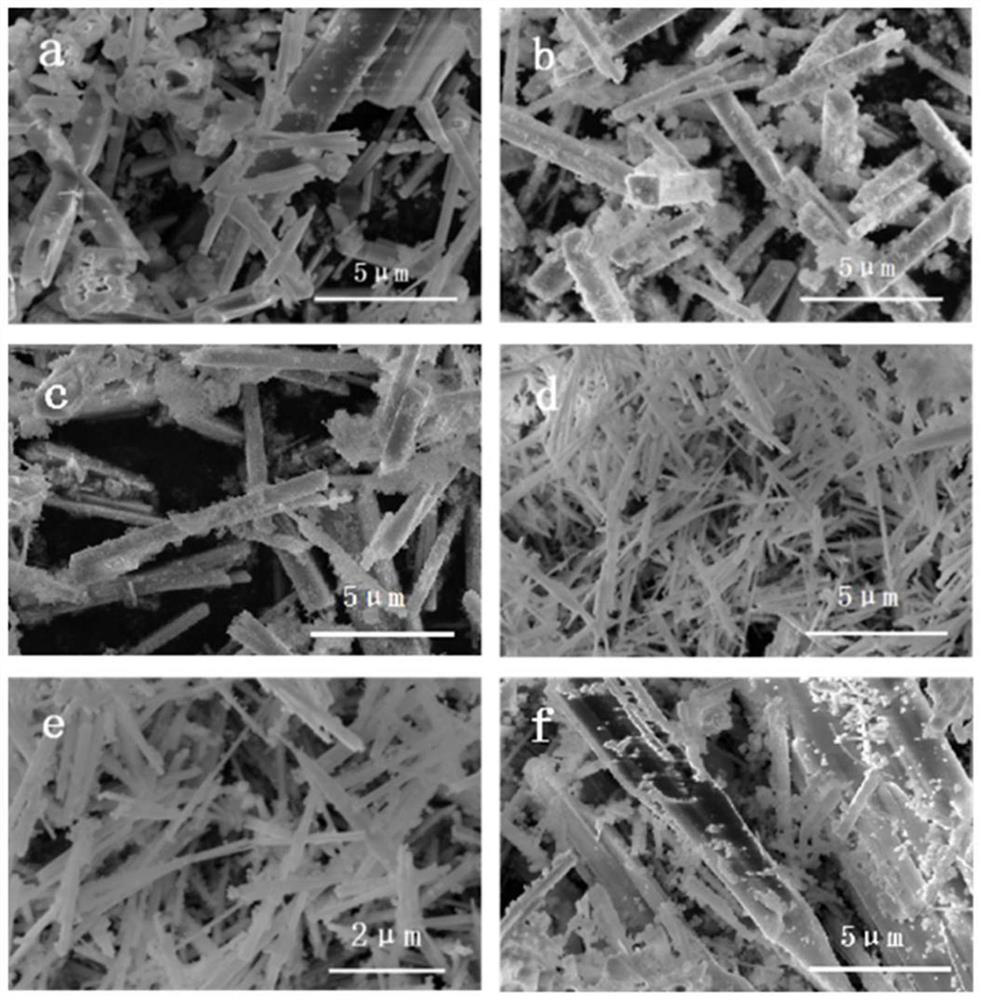

Preparation method and application of antimony sulfide nanorod

ActiveCN113651359ASolve for uniformitySolution conditionsMaterial nanotechnologySecondary cellsElectrical batterySodium-ion battery

The invention discloses a preparation method and application of an antimony sulfide nanorod. The preparation method comprises the following steps: by taking absolute ethyl alcohol and oleylamine as solvents, firstly dissolving an antimony source into an absolute ethyl alcohol beaker with a certain volume, ultrasonically stirring for several minutes, uniformly dissolving, then adding a sulfur source, stirring on a magnetic stirrer for 0.5 hour until the sulfur source is completely dissolved, finally adding an oleylamine solution into the mixed solution, continuously stirring for 0.5 hour, pouring into a high-pressure reaction kettle, carrying out a reaction, cooling to room temperature, respectively centrifuging three times by using cyclohexane and glacial acetic acid to obtain a black precipitate, and drying the black precipitate in a drying oven to prepare the uniform sulfide ladder nanorod. The method has the advantages of simple equipment, simple experimental operation, short production period, good particle dispersity, low cost and easiness in industrial production, and solves the common problems of remarkable volume effect, poor conductivity and the like in the sodium ion battery negative electrode material, so that the electrochemical performance of the electrode material is effectively improved.

Owner:JIANGSU UNIV

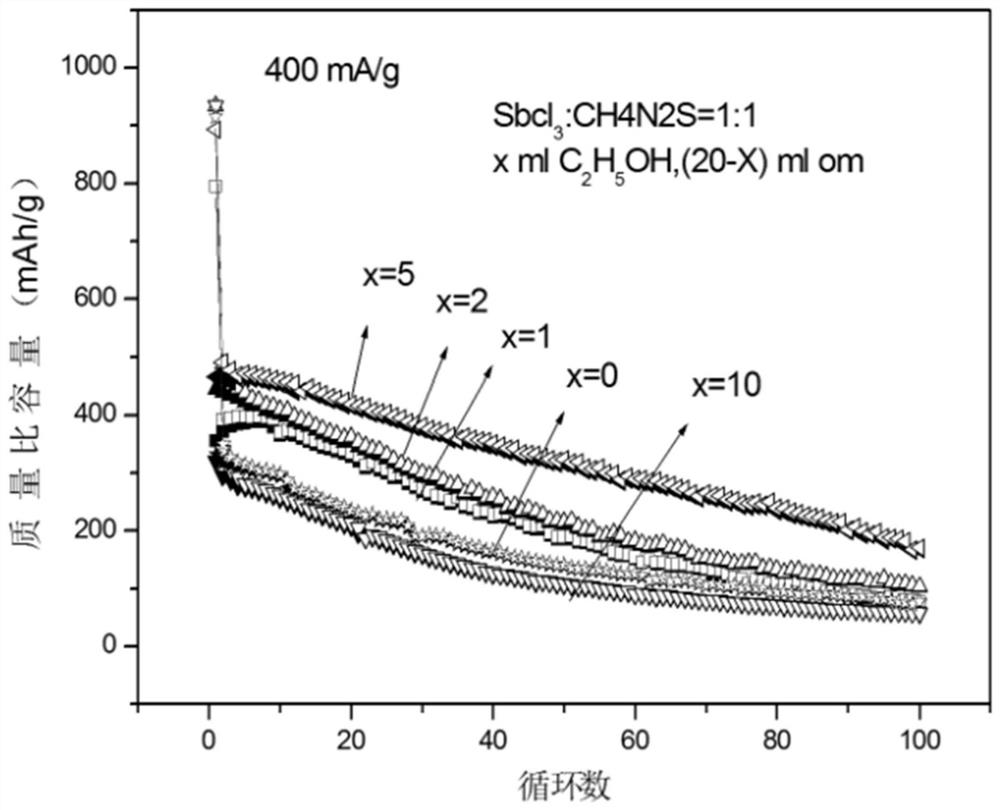

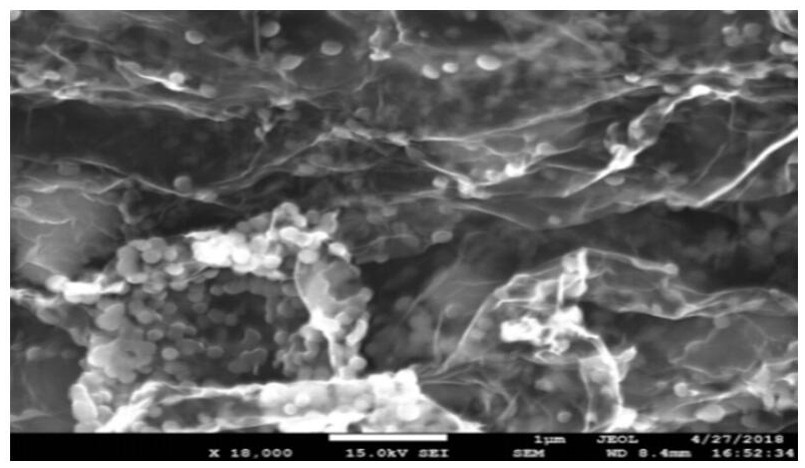

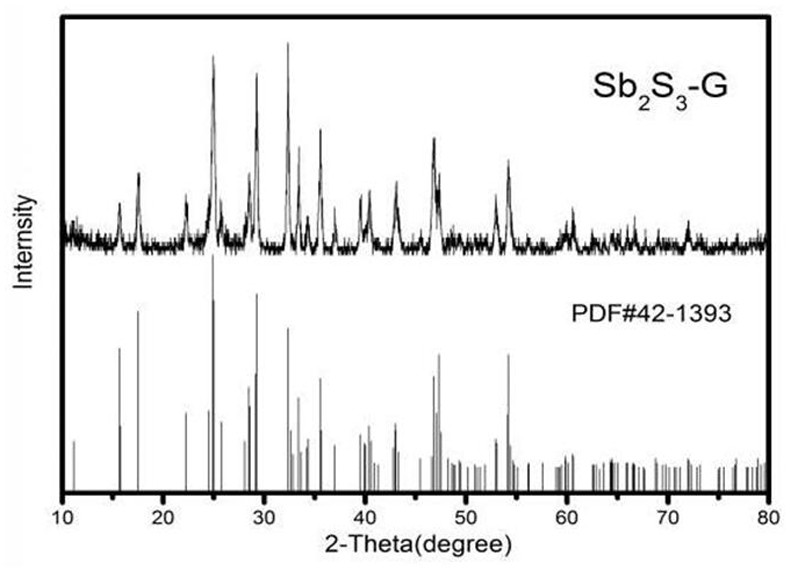

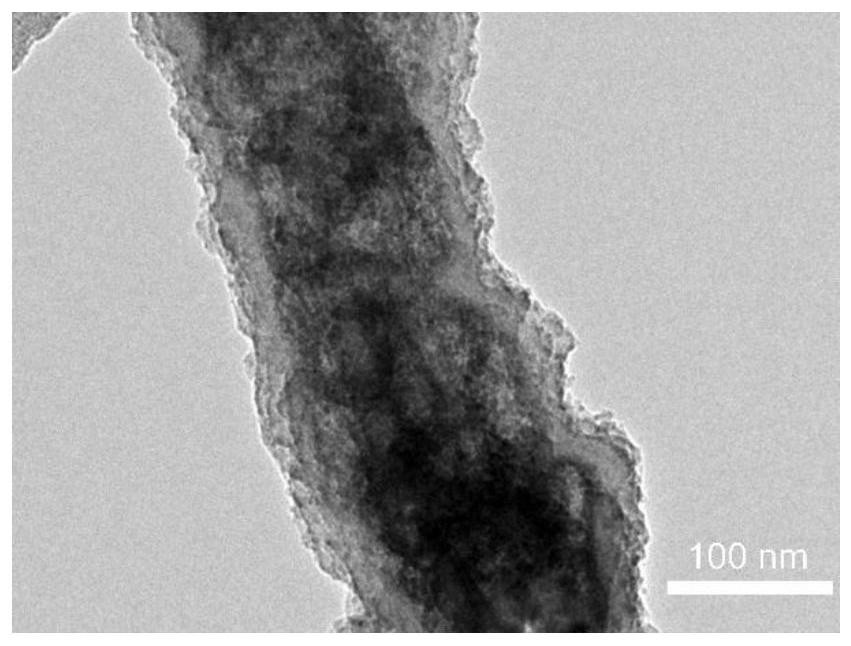

Preparation method of antimony sulfide/graphene composite micro-nano material

PendingCN113072098AImprove electrochemical performancePromote reductionGrapheneAntimony sulfidesMicro nanoYarn

The invention discloses a preparation method of an antimony sulfide / graphene composite micro-nano material. The preparation method comprises the following steps: weighing raw materials including graphene oxide dispersion liquid, antimony potassium tartrate, thioacetamide and absolute ethyl alcohol in proportion; mixing the graphene oxide dispersion liquid, antimony potassium tartrate and thioacetamide until the materials are dissolved; dropwise adding absolute ethyl alcohol into the solution, and stirring to obtain a mixed solution; pouring the mixed solution into a reaction kettle, and continuously heating and reacting at 120 DEG C for 12 hours or 18 hours; after the reaction is finished, cooling to normal temperature, taking out the material, and alternately cleaning with high-purity water and absolute ethyl alcohol for at least six times; and centrifugally separating the cleaned material, and drying at 60 DEG C for 12 hours to prepare the antimony sulfide / graphene composite micro-nano material. Graphene in the material shows a flexible thin-surface yarn-shaped appearance with good transparency and wrinkles, it is shown that graphene is well reduced, Sb2S3 nanoparticles are wrapped in a yarn layer of graphene, and it is shown that antimony sulfide and graphene have the excellent recombination rate, so that the electrochemical performance of the material is stable.

Owner:SHENZHEN DATANG BAOCHANG GAS POWER GENERATION

Method for preparing sodium-ion battery negative electrode material antimony sulfide from high-arsenic-antimony soot

InactiveCN112897580AAvoid lostAchieve secondary resource utilizationProcess efficiency improvementAntimony sulfidesArsenateElectrical battery

The invention discloses a method for preparing a sodium-ion battery negative electrode material antimony sulfide from high-arsenic-antimony soot. The method comprises the following steps: by taking high-arsenic-antimony soot (comprising specific components of As2O3, As4O6, Sb2O3 and the like) as a raw material, forming soluble arsenate from arsenic by adopting a pressurized oxidation-alkaline leaching method, and filtering to remove the soluble arsenate; then dissolving antimony (Sb2O3) existing in a solid phase by using diluted hydrochloric acid to obtain a relatively pure antimony trichloride solution; under a stirring condition, adding a proper amount of a water-soluble sulfur source into the obtained solution, and uniformly mixing; transferring the obtained mixed solution into a reaction kettle and carrying out hydrothermal reaction at a certain temperature; after the hydrothermal reaction is finished, washing with alcohol for multiple times, and drying to obtain a product. According to the patent, a tedious metal extraction preparation process is avoided, antimony is directly converted into the sodium ion battery negative electrode material with higher practical value, and the recovery rate of antimony can reach 85% or above.

Owner:CENT SOUTH UNIV

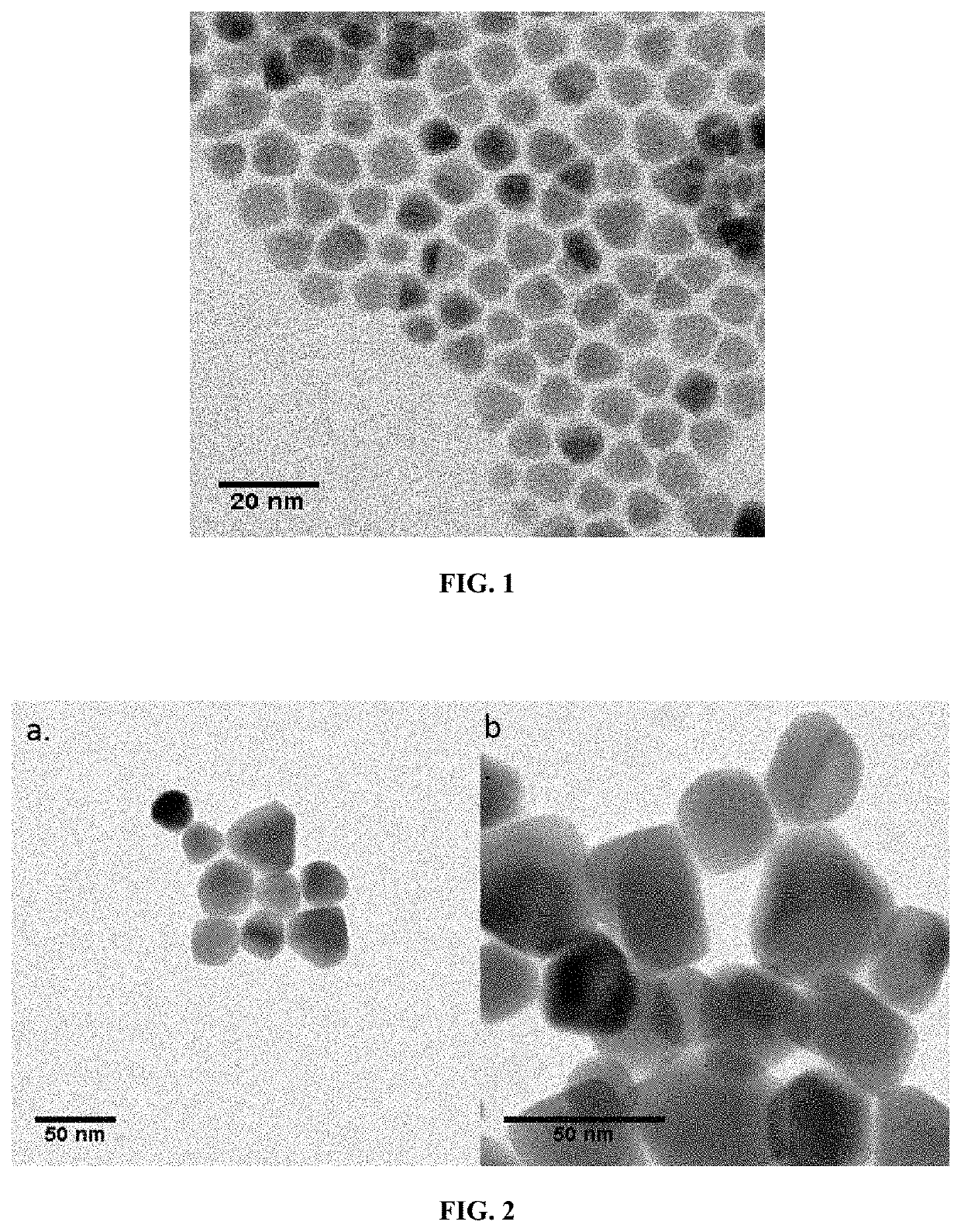

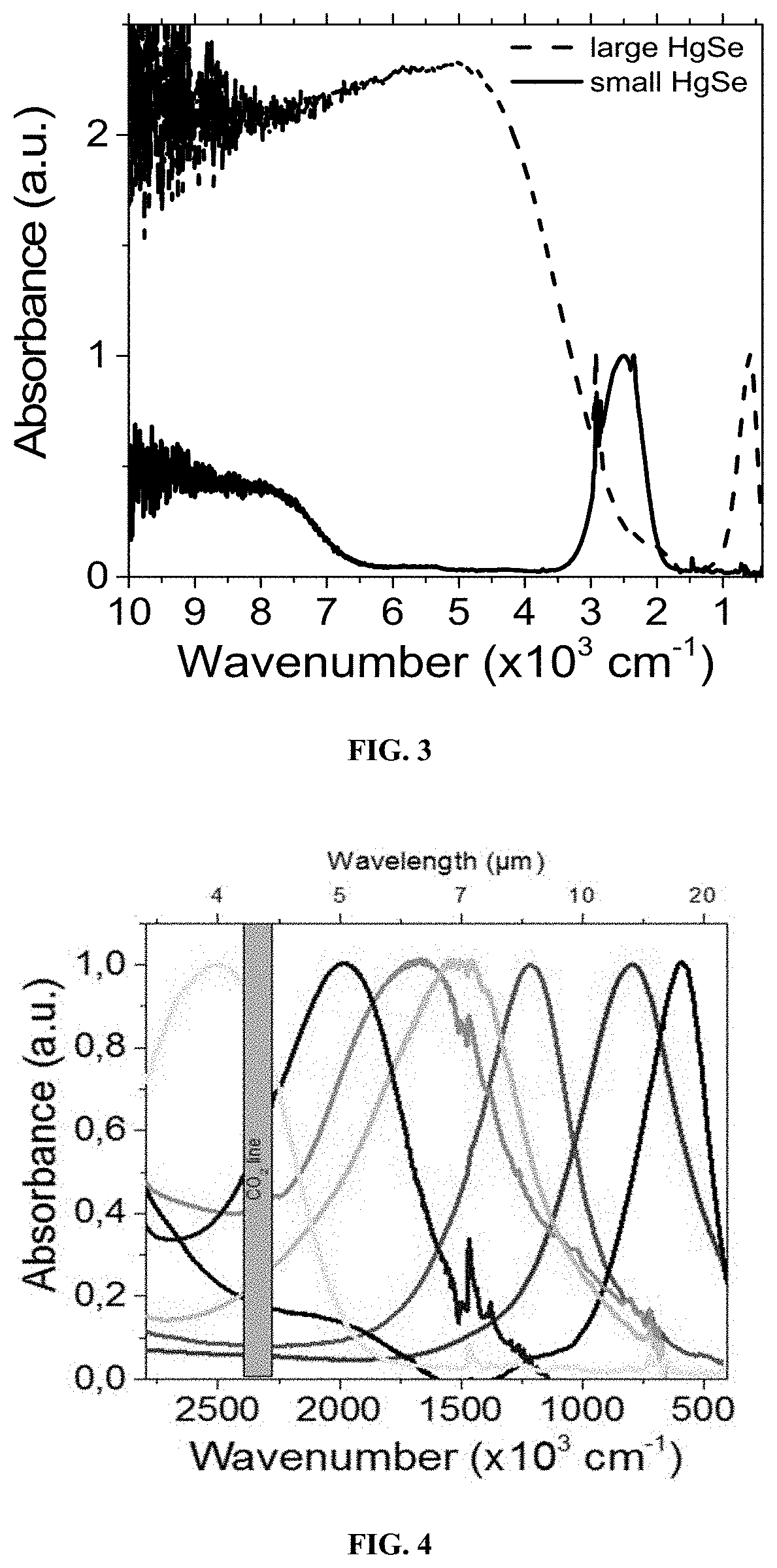

Mid and far-infrared nanocrystals based photodetectors with enhanced performances

ActiveUS10944065B2Promote absorptionTotal current dropThermoelectric device with dielectric constant thermal changeArsenic sulfidesPhotovoltaic detectorsPhotodetector

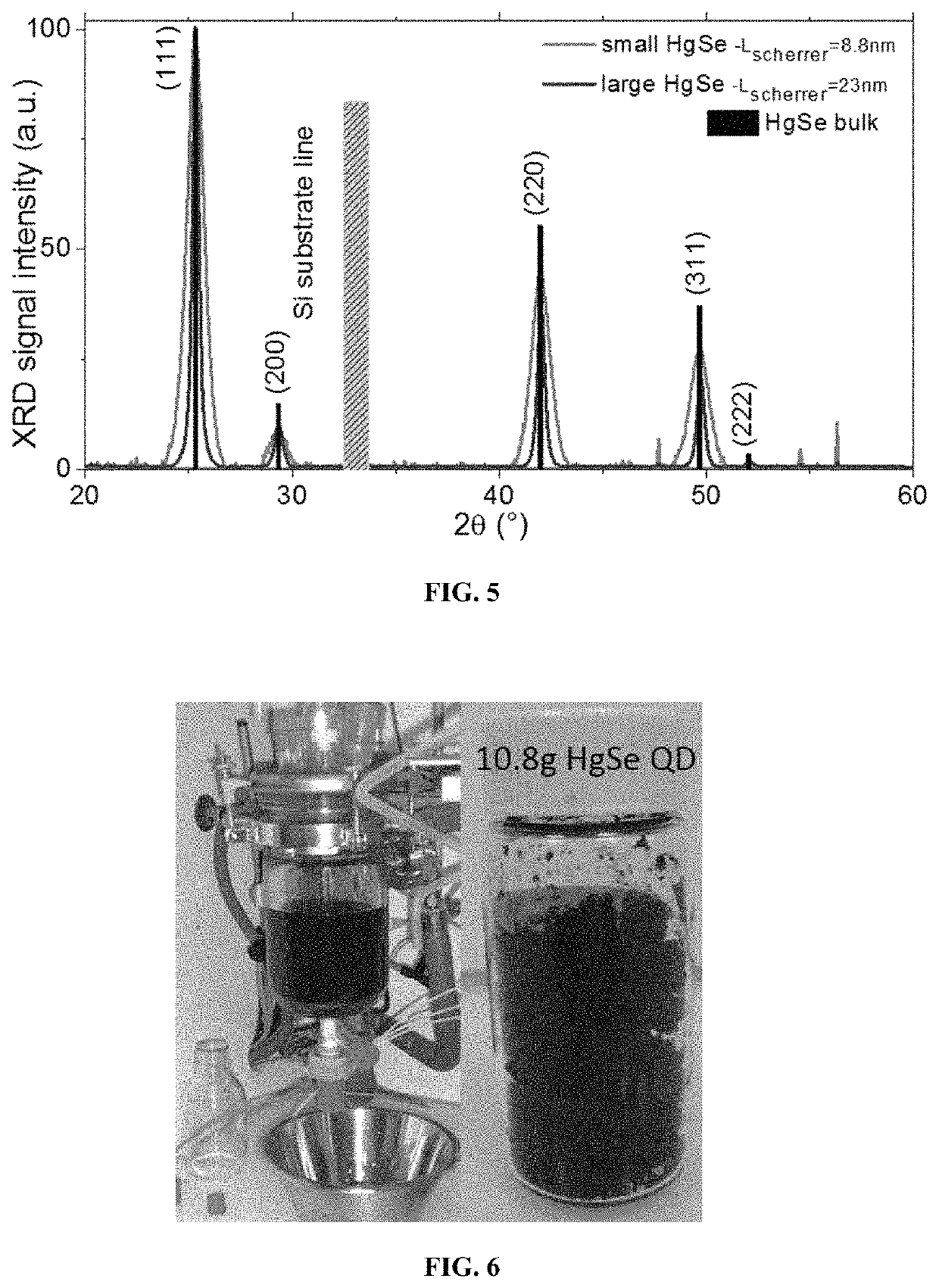

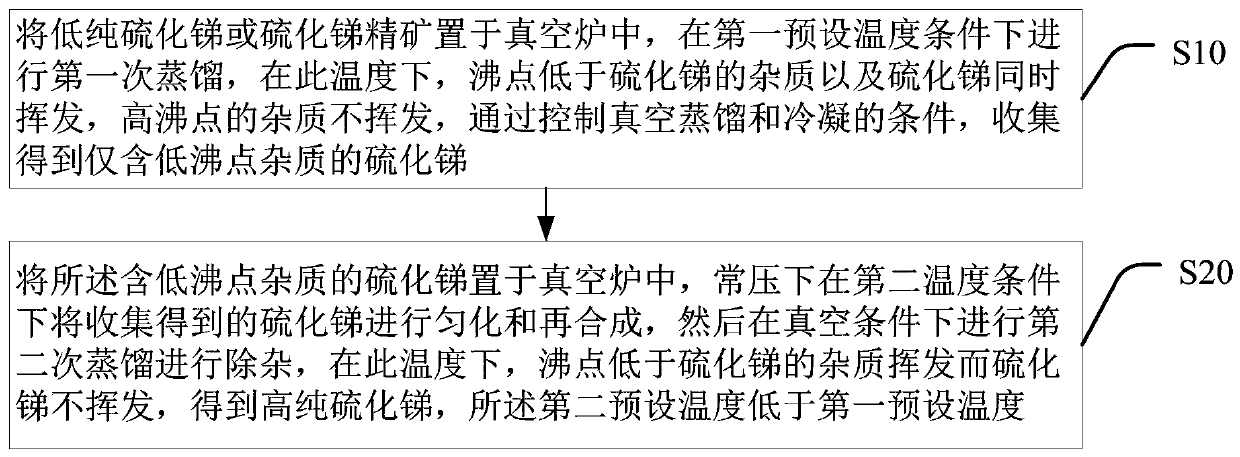

Disclosed is a plurality of metal chalcogenide nanocrystals coated with multiple organic and inorganic ligands; wherein the metal is selected from Hg, Pb, Sn, Cd, Bi, Sb or a mixture thereof; and the chalcogen is selected from S, Se, Te or a mixture thereof; wherein the multiple inorganic ligands includes at least one inorganic ligands are selected from S2−, HS−, Se2−, Te2−, OH−, BF4−, PF6−, Cl−, Br−, I−, As2Se3, Sb2S3, Sb2Te3, Sb2Se3, As2S3 or a mixture thereof; and wherein the absorption of the C—H bonds of the organic ligands relative to the absorption of metal chalcogenide nanocrystals is lower than 50%, preferably lower than 20%.

Owner:NEXDOT

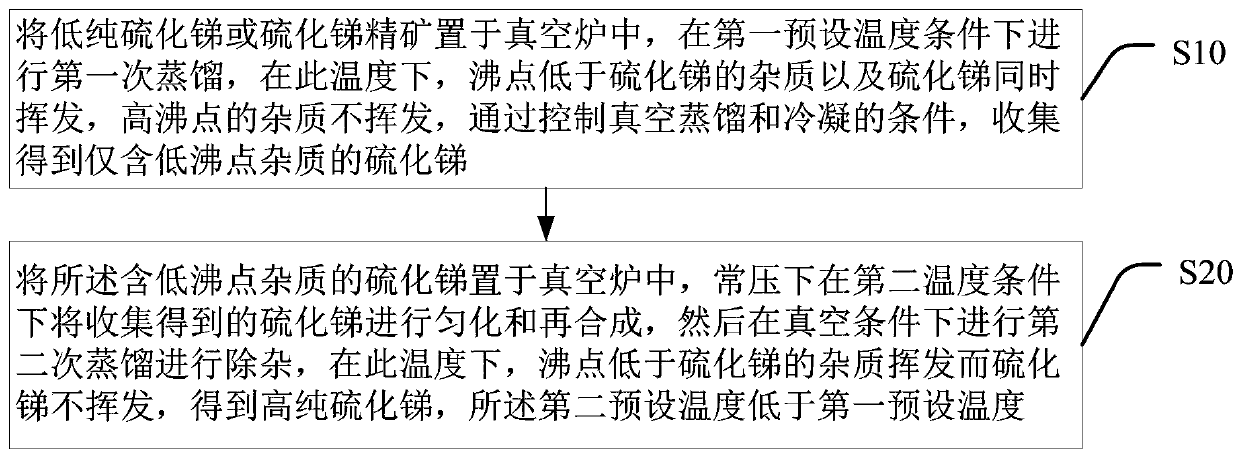

Preparation method of high-purity antimony sulfide

The invention discloses a preparation method of high-purity antimony sulfide. The method comprises the following steps: putting low-purity antimony sulfide or antimony sulfide concentrate into a vacuum furnace, carrying out first distillation under a first preset temperature condition to volatilize impurities with boiling points lower than that of antimony sulfide and antimony sulfide at the sametime, and collecting antimony sulfide only containing low-boiling-point impurities by controlling vacuum distillation and condensation conditions; placing the antimony sulfide containing the low-boiling-point impurities into another vacuum furnace; and homogenizing and re-synthesizing the collected antimony sulfide under the normal pressure and the second preset temperature condition, then carrying out secondary distillation under the vacuum condition for impurity removal, so that impurities with the boiling point lower than that of antimony sulfide volatilize wherein antimony sulfide remains,thereby preparing high-purity antimony sulfide, the second preset temperature being lower than the first preset temperature. According to the method, chemical agents such as acid and alkali are not used, three-waste emission is avoided, the technological process is simple and easy to operate, and the production efficiency is high; the purity of antimony sulfide prepared by the method is up to 99.9% or above.

Owner:KUNMING DIBOO TECH

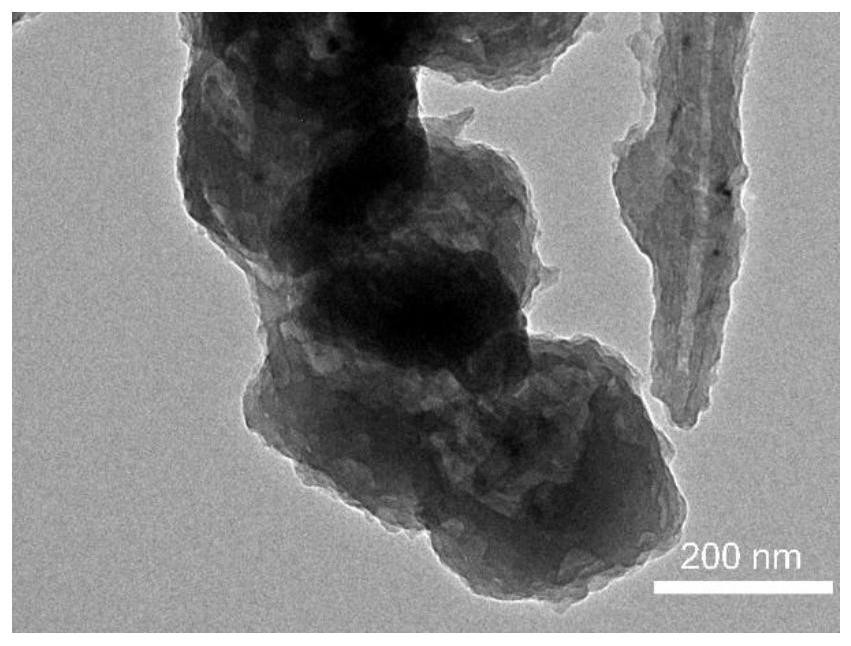

Carbon nanotube-in-tube@antimony sulfide/antimony composite material and preparation method and application thereof

InactiveCN113659121AImprove conductivityImprove structural stabilityCarbon compoundsSecondary cellsIon exchangeSulfide

The invention discloses a carbon nanotube-in-tube@antimony sulfide / antimony composite material, a preparation method thereof and application in preparation of a negative electrode of a lithium ion battery. In the carbon nanotube-in-tube@antimony sulfide / antimony composite material, the carbon nanotube-in-tube is of a tube-in-tube structure which takes a carbon nano tube as an inner tube and an amorphous carbon nano tube as an outer tube, and the antimony sulfide / antimony is a mixture of antimony sulfide and metal antimony formed by reducing the antimony sulfide, and is tightly fixed in the carbon nanotube middle tube. The preparation method comprises the following steps: growing ZIF-8 particles on the surface of the carbon nanotube, then coating the surface of the carbon nanotube with a layer of RF resin, performing vulcanization treatment and ion exchange, and finally performing carbonization and calcination to obtain a final product. The conductivity and the structural stability of antimony sulfide can be improved, and the rate capability, the cycle performance and the reversible capacity of antimony sulfide can be improved.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

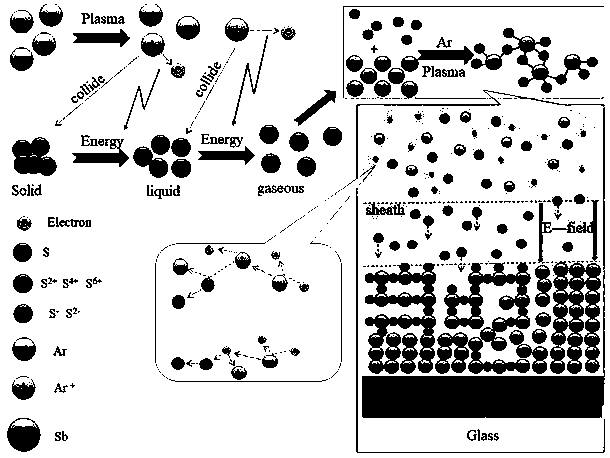

Method for preparing antimony sulfide film through low-temperature plasma vulcanization

PendingCN111348682AHigh reactivityImprove bindingAntimony sulfidesSemiconductor devicesChemical physicsPhysical chemistry

The invention relates to a method for preparing an antimony sulfide film through low-temperature plasma vulcanization, and belongs to the technical field of photoelectric functional materials. The method comprises the steps: preparing a metal antimony, antimony oxide or antimony hydroxide film, carrying out low-temperature plasma treatment on a solid sulfur source by using a low-temperature plasmagenerator to form plasma-state sulfur, and carrying out low-temperature plasma vulcanization treatment on the film by using the plasma-state sulfur to obtain the antimony sulfide film. In an inert gas environment, inert gas is ionized under the action of an electric field to obtain high-activity inert gas ions and electrons, and the high-activity inert gas ions and electrons collide with a solidsulfur source to generate plasma-state sulfur; ambient temperature rise caused by mutual collision among various particles increases the thermal motion of the solid sulfur source, and further promotesthe generation of plasma-state sulfur. The plasma-state sulfur has high activity, so that vulcanization of the film can be quickly realized to obtain the antimony sulfide film. The antimony sulfide film is uniform in component, flat and compact in structure and large in grain size.

Owner:KUNMING UNIV OF SCI & TECH

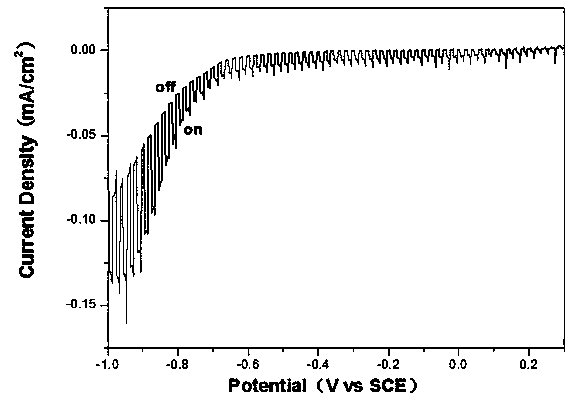

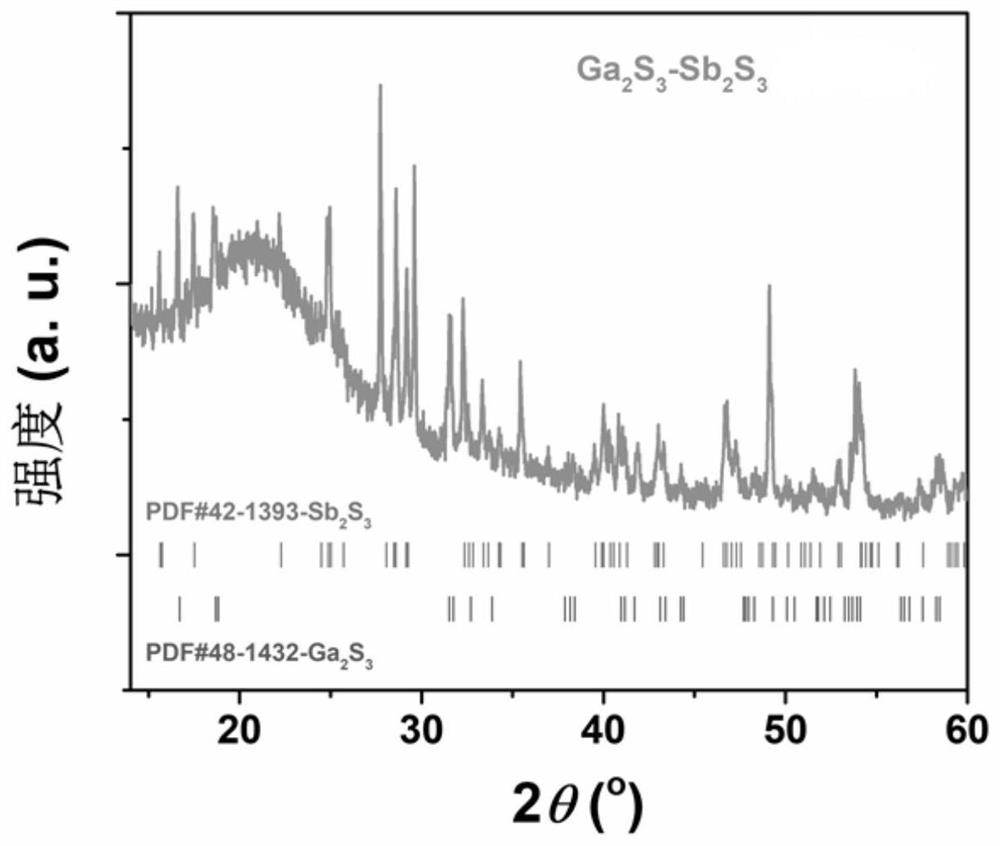

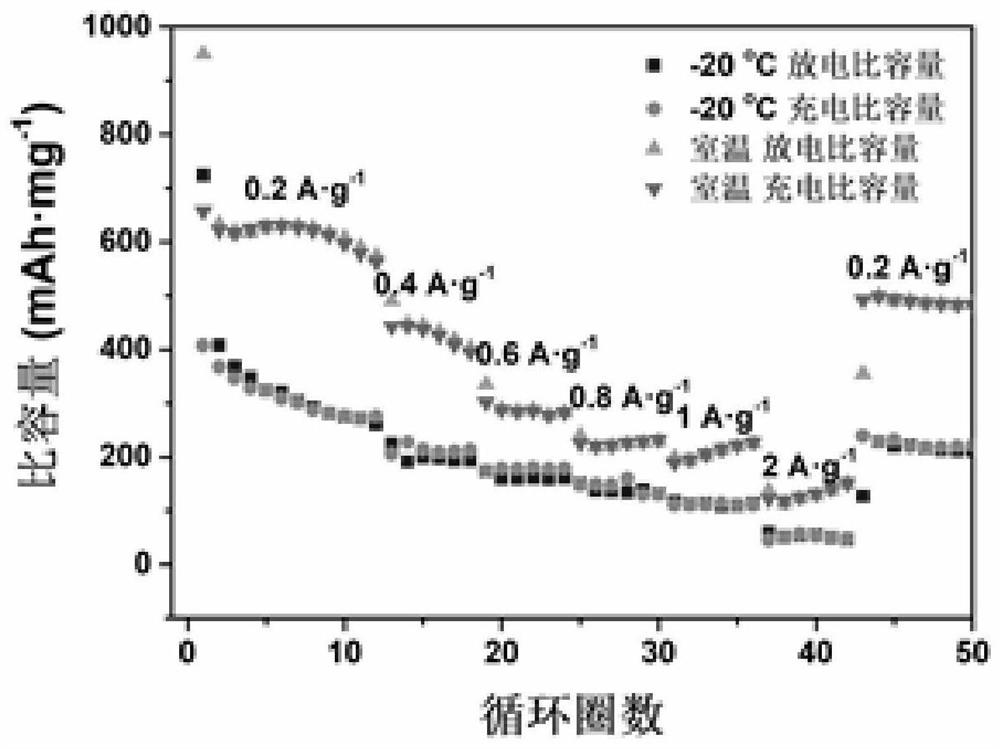

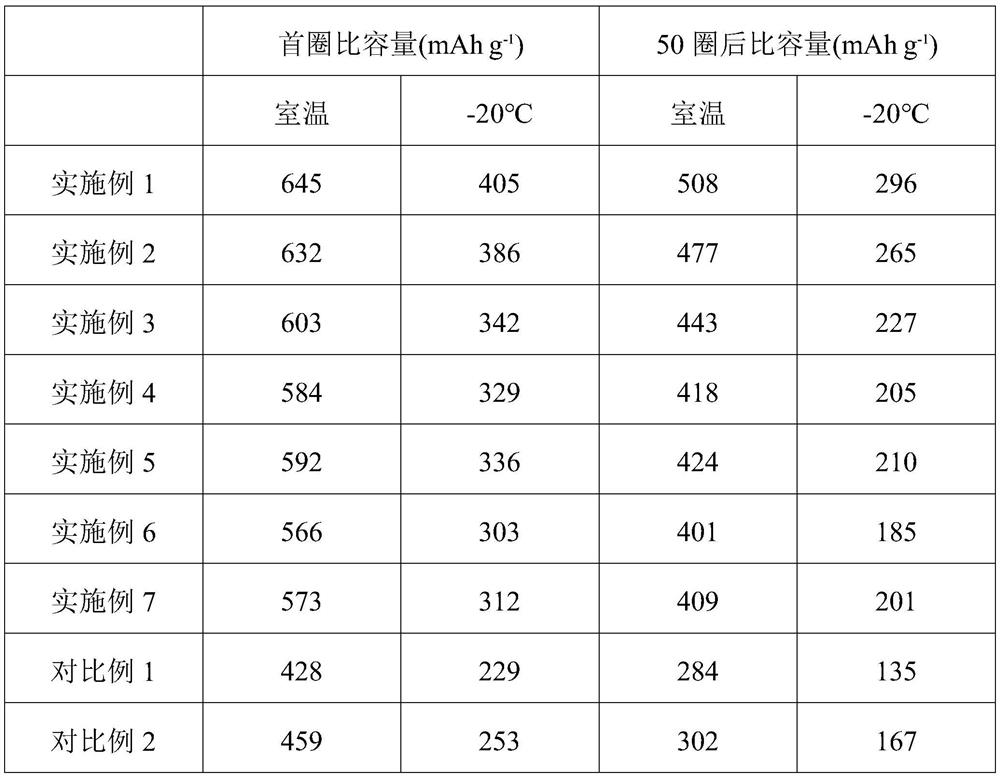

Composite sulfide as well as preparation method and application thereof

PendingCN114031108AIncreased diffusion rateHigh first cycle specific capacityGallium/indium/thallium compoundsNegative electrodesElectrical batteryPhysical chemistry

The invention provides a composite sulfide and a preparation method and application thereof. The preparation method comprises the steps that a precursor and a sulfur source are subjected to heat treatment at the temperature of 450 DEG C-650 DEG C to obtain the composite sulfide, wherein the precursor comprises XSb, and X comprises Ga and / or In. The precursor and the sulfur source are subjected to heat treatment at a specific temperature to prepare the composite sulfide, and the prepared composite sulfide has excellent low-temperature performance. The sodium-ion battery prepared from the composite sulfide has relatively high first-circle specific capacity, relatively good rate capability, relatively good cycling stability and excellent low-temperature electrochemical performance.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

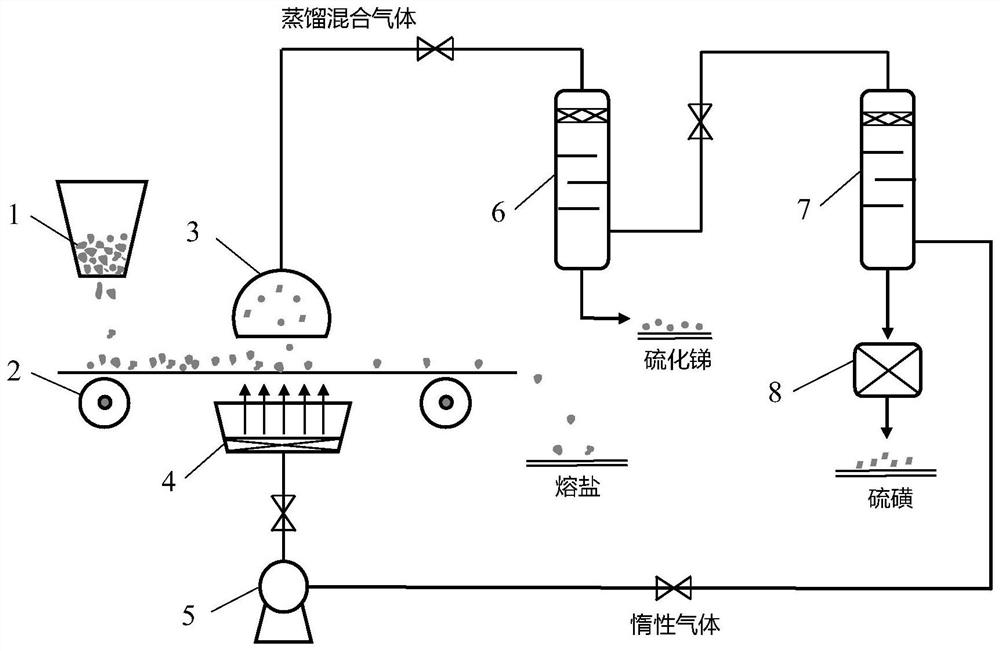

Method and system for purifying antimony sulfide concentrate molten salt electrolysis smoke dust and preparing sulfur

PendingCN114702070AEfficient separationImprove applicabilitySulfur preparation/purificationProcess efficiency improvementElectrolysisDistillation

The invention discloses a method and a system for purifying antimony sulfide concentrate molten salt electrolysis smoke dust and preparing sulfur. The method comprises the following steps: uniformly spreading the antimony sulfide concentrate molten salt electrolysis sulfur-containing smoke dust on a belt conveyor through a feeding funnel, transporting to a distillation area, and distilling volatile antimony sulfide and elemental sulfur in the smoke dust into a gas phase by high-temperature inert gas with a certain flow rate; then distilled mixed gas sequentially passes through a first condensing tower and a second condensing tower to be subjected to two-stage condensation, and antimony sulfide and elemental sulfur are separately separated out. The antimony sulfide and the molten salt are returned to the electrolysis process again, and the liquid sulfur is prepared into a high-grade sulfur product by a pelletizer. In addition, inert gas is recycled through the gas pressurizing machine and the heater. The method disclosed by the invention is simple and practical, and good effects can be obtained on purification of the flue gas generated by electrolysis of the antimony sulfide molten salt and preparation of sulfur.

Owner:CENT SOUTH UNIV

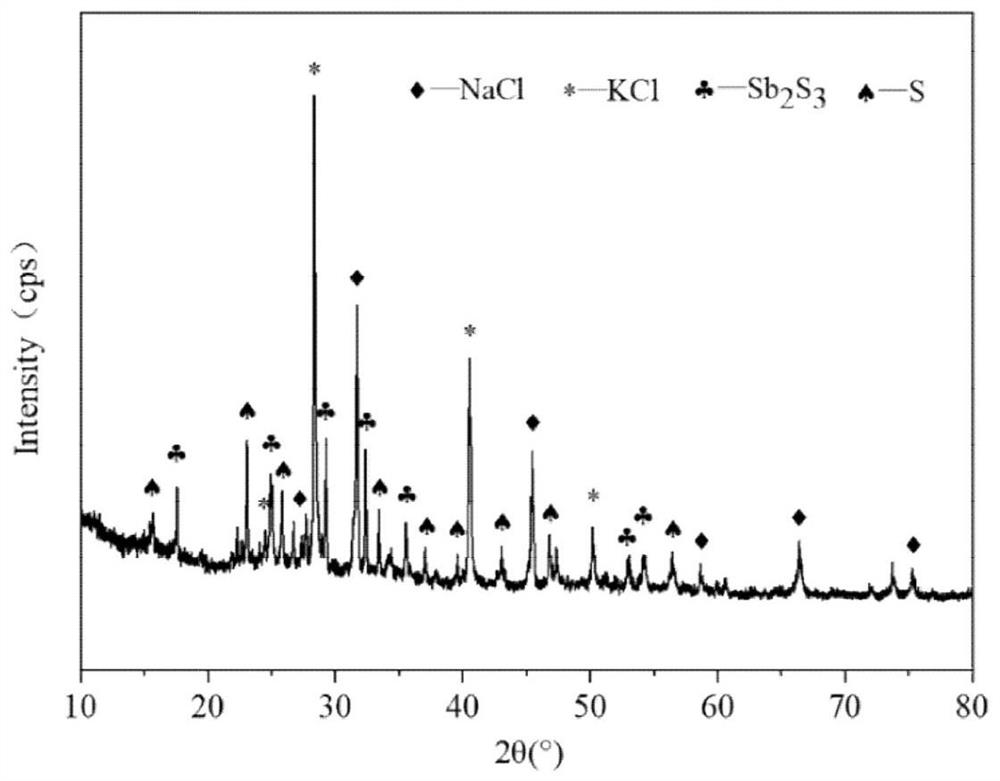

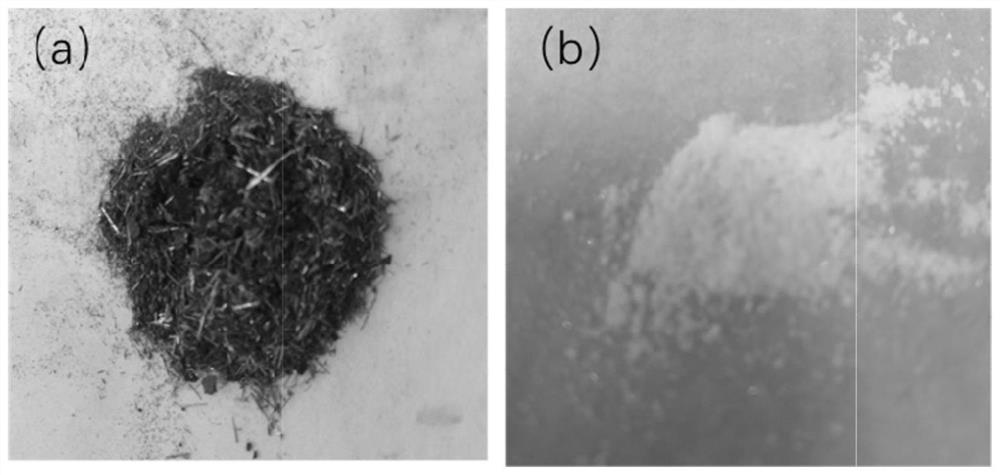

A preparation method of nano antimony sulfide particles under controllable conditions

InactiveCN106542577BEasy to operateNo synthesis requiredNanotechnologyAntimony sulfidesTemperature controlNanoparticle

The invention discloses a preparation method of antimony sulfide nanoparticles under controllable conditions. The preparation method mainly comprises the following steps: dissolving, temperature control, precipitation, and washing or calcination. An alkaline solution is used in the dissolving step to dissolve antimony sulfide powder; a surfactant and a DMF solution are added, and then the obtained solution is stored at a specific temperature under a specific pressure to wait for solid precipitation; and precipitated solid is immersed and cleaned with deionized water or acetone, the obtained solid is centrifuged and dried, or undergoes high temperature calcination in a muffle furnace under the protection of nitrogen. Compared with present nanometer antimony sulfide preparation methods, the preparation method disclosed in the invention has the advantages of simplicity in operation, no synthesis, common used reagents, good economic property, and suitableness for large-scale promotion and application.

Owner:ZHEJIANG UNIV

Preparation method of monodisperse antimony sulfide quantum dot

ActiveCN107758740ALower synthesis costGood dispersionNanotechnologyAntimony sulfidesSpray coatingComputational chemistry

The invention belongs to the technical field of preparation of a compound semiconductor nanometer material and relates to a preparation method of a monodisperse antimony sulfide quantum dot. The synthesis route is conducted according to the following mode: dissolving thioacetamide and antimony acetate into an organic solvent separately, heating a thioacetamide solution, rapidly cooling an antimonyacetate solution, performing rapid reaction on the thioacetamide solution and the antimony acetate solution to synthesize and obtain an antimony sulfide quantum dot and performing sealing preservation. The prepared monodisperse antimony sulfide quantum dot has high dispersibility, can form stable dispersing liquid in the common solvents such as deionized water, ethanol, ethylene glycol monomethylether and dichloromethane, so the antimony sulfide quantum dot has compatibility with the low-cost technologies of ink-jet printing, spin-coating and spray-coating, and realizes device application.

Owner:重庆复源新材料科技有限公司

A kind of preparation method and application of antimony selenium sulfide thin film

ActiveCN111320395BLow costLow reaction temperatureCoatingsAntimony sulfidesOrganic solventElectrical battery

The invention provides a preparation method of an antimony selenium sulfide thin film, comprising the following steps: mixing antimony potassium tartrate, a sulfur source and a selenium source, performing a hydrothermal reaction in a closed environment, and obtaining a selenium antimony sulfide precursor film after drying; The antimony selenium sulfide precursor film is annealed to obtain the antimony selenium sulfide thin film. The application also provides a solar cell device based on the antimony selenium sulfide film. The invention synthesizes a dense and flat selenium antimony sulfide thin film in a hydrothermal system, the cost of raw materials used is low, the reaction temperature is low, no organic solvent is needed, and the preparation process is simple and environment-friendly.

Owner:UNIV OF SCI & TECH OF CHINA

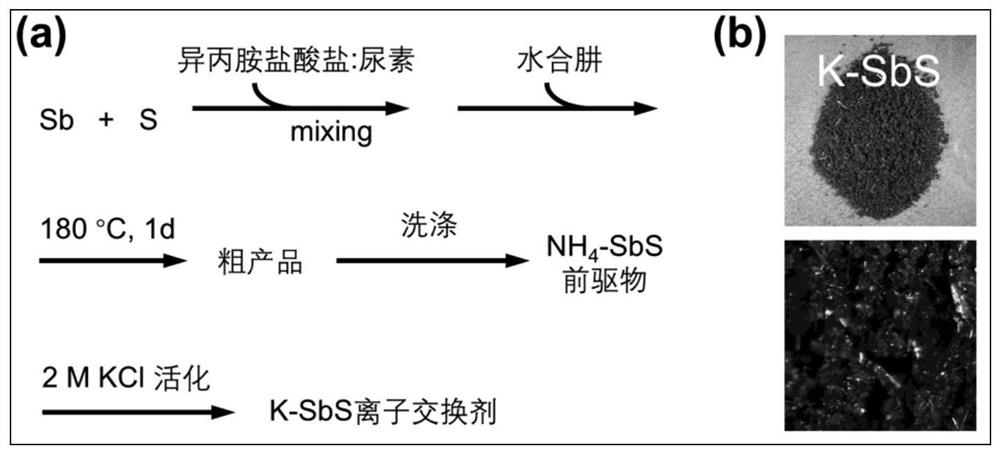

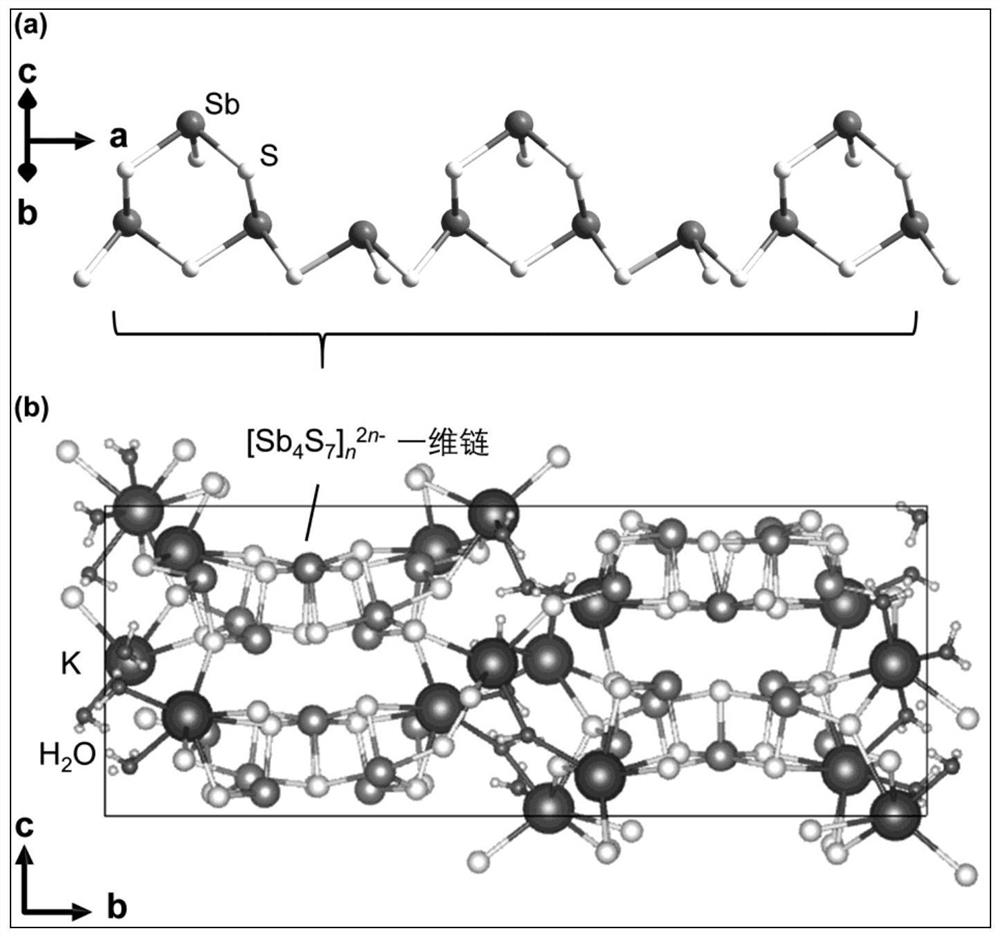

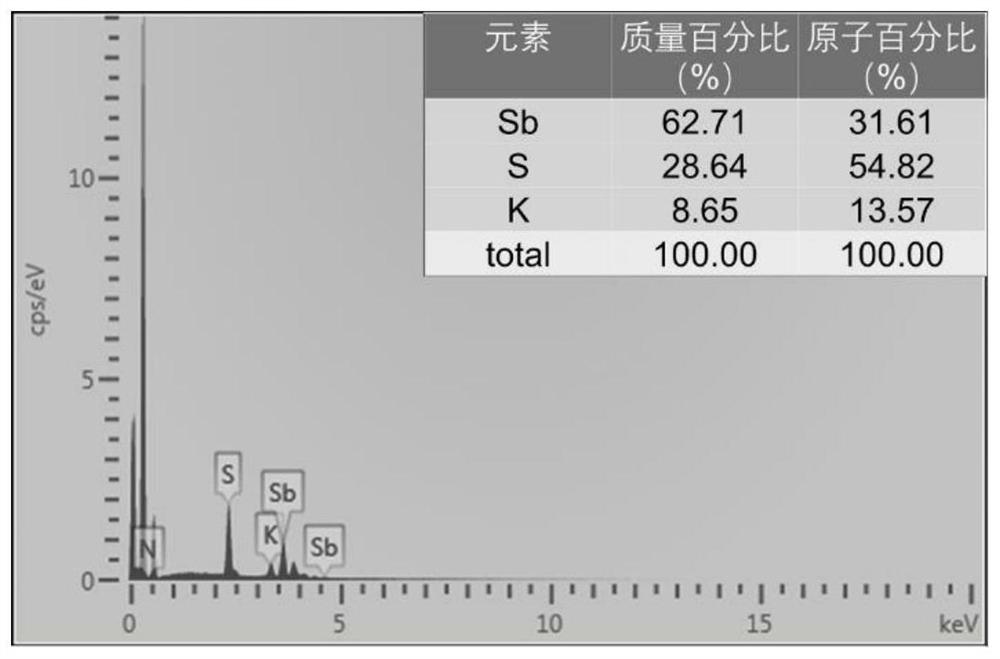

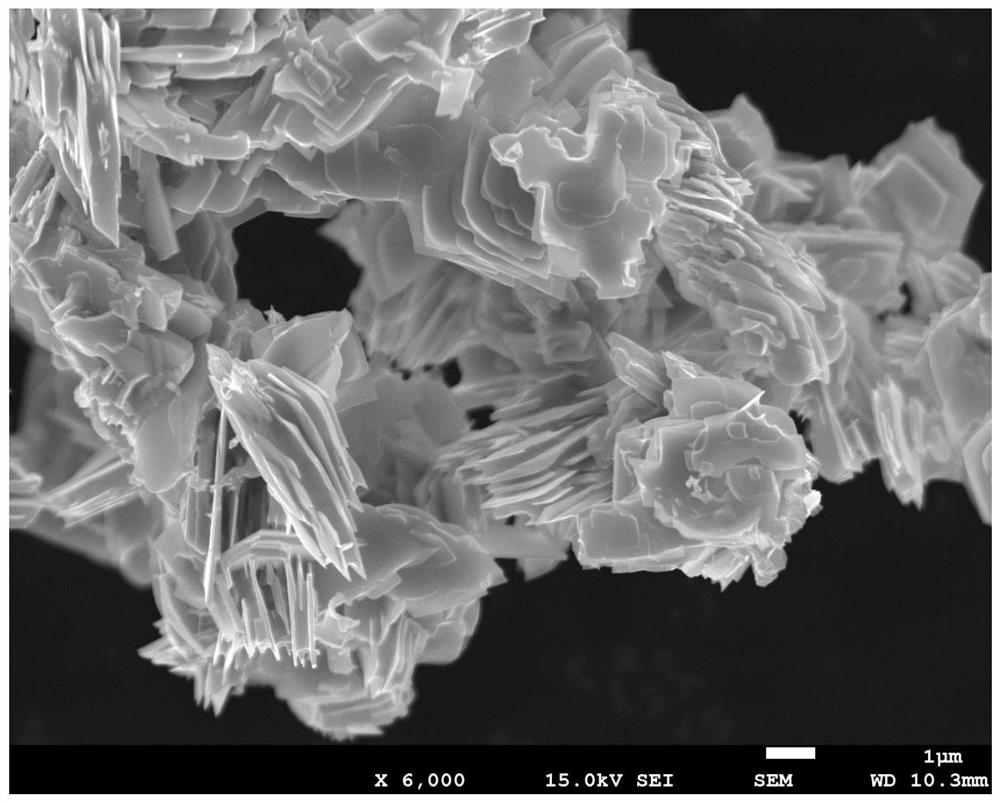

Cs < + > and Sr < 2 + > co-adsorption-separation difunctional ion exchanger as well as preparation method and application thereof

ActiveCN114669269AEasy to makeIncrease productionCation exchanger materialsOther chemical processesPhysical chemistryIon exchange

The invention relates to a Cs < + > and Sr < 2 + > co-adsorption-separation difunctional ion exchanger as well as a preparation method and application thereof. The molecular formula of the ion exchanger is K2Sb4S7. 2H2O; in the preparation method, Sb and S elementary substance are reacted by utilizing a eutectic solvothermal technology, and then hydrated K < + > ions are introduced into crystal lattices for activating treatment, so that the K2Sb4S7. 2H2O (K-SbS) ion exchanger which can be produced in batches and has excellent acid-base and irradiation tolerance is prepared; the exchanger respectively shows co-adsorption (pH 4-11) and separation (pH 2-3) functions on Cs < + > and Sr < 2 + > mixed ions under different solution acidity conditions, and the two functions can be repeatedly switched along with the change of pH. The K-SbS ion exchanger disclosed by the invention has the characteristics of large adsorption capacity, fast dynamic response, high separation coefficient and convenience in elution.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Antimony molybdenum sulfide-carbon composite material and preparation method and application thereof

ActiveCN113735168ALarge specific surface areaAdjustable shapeMaterial nanotechnologyCell electrodesCarbon compositesSulfide compound

The invention relates to the technical field of new-energy electrode material preparation, in particular to an antimony molybdenum sulfide-carbon composite material and a preparation method and application thereof. The preparation method comprises the following steps: 1) preparation of antimony sulfide: dissolving antimony chloride, a chelating agent and a sulfur source in a reaction solution, carrying out uniform mixing through stirring, transferring the obtained mixture to a high-pressure reaction kettle lining, conducting a reaction at a temperature of 160-220 DEG C for 10-16 h, and after the reaction is finished, centrifuging, washing and drying a product to obtain antimony sulfide; and 2) preparation of antimony molybdenum sulfide-carbon: adding the obtained antimony sulfide serving as a precursor, sodium molybdate dehydrate serving as a molybdenum source, a sulfur source and a carbon source into a reaction solution together, conducting uniform stirring, transferring the formed mixture to the high-pressure reaction kettle lining, carrying out reacting at 160-220 DEG C for 10-16 hours, and after the reaction is finished, centrifuging, washing and drying the product, carrying out calcining at high temperature in argon flow, and washing and drying the calcined product. According to the invention, a solvothermal process is adopted to synthesize antimony sulfide, and the antimony-molybdenum sulfide-carbon composite material is synthesized by taking the antimony sulfide as a template through a secondary solvothermal process in combination with a high-temperature calcination method.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method for ultrathin SB2S3 nanosheet as anode material for Li/Na ion battery applications

ActiveUS11302909B2High crystallinityUltrathin thicknessMaterial nanotechnologyElectrochemical processing of electrodesChemical physicsPhysical chemistry

Methods of synthesizing few-layer two-dimensional (2D) Sb2S3 nanosheets using scalable chemical exfoliation are provided. The 2D Sb2S3 nanosheets can be developed as bi-functional anode materials in both lithium ion batteries and sodium ion batteries. The unique structural and functional features brought by 2D Sb2S3 nanosheets can offer short electron / ion diffusion paths and abundant active sites for surface redox reactions.

Owner:THE HONG KONG UNIV OF SCI & TECH

A transition metal chalcogenide carbon-based heterostructure composite material with regular morphology and its preparation method and application

ActiveCN110683522BSimple methodConditions are easy to controlHybrid capacitor electrodesCell electrodesCarbon coatingElectrochemistry

The invention discloses a transition metal chalcogenide carbon-based heterostructure composite material with regular morphology and its preparation method and application. Raw materials including transition metal acetylacetonate and chalcogen compounds are placed under protection Calcined under the atmosphere, the transition metal chalcogenide carbon-based heterostructure composite material with regular shape, uniform multi-level carbon coating and stable structure can be obtained, which can be applied to the preparation of energy storage devices, showing excellent electrochemical performance. In particular, the rate and cycle stability of energy storage devices have obvious advantages compared with existing materials.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000011.png)

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000012.png)

![ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof ZnS/SnS/antimonous sulfide [at] C hollow nanocube structure composite material, and preparation method and application thereof](https://images-eureka.patsnap.com/patent_img/523d5043-e134-42d5-a959-7bd75fe40c59/HDA0002283133150000021.png)