Preparation method of high-purity antimony sulfide

A high-purity technology of antimony sulfide, applied in antimony sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of large environmental pollution, low purity of antimony sulfide, difficulty in large-scale production, etc., to expand the scope of use, remove impurities, etc. The effect of high removal rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

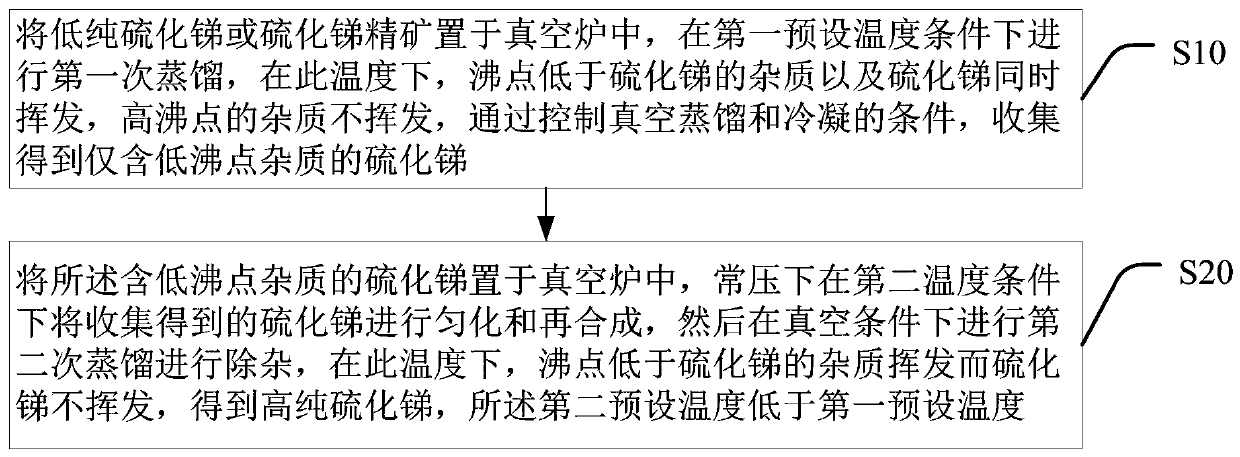

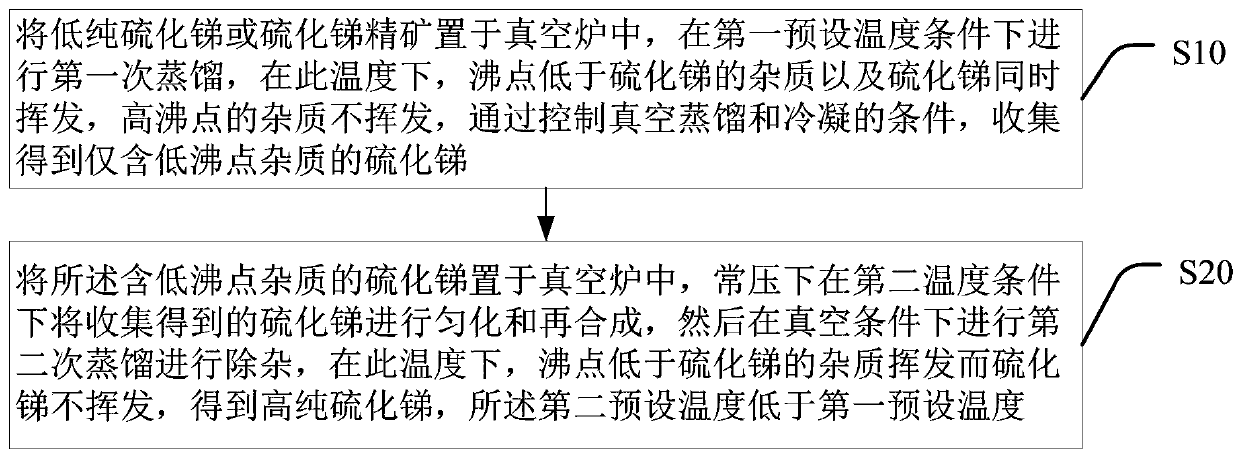

Method used

Image

Examples

Embodiment 1

[0035] 1. Mix 210Kg granular antimony alloy (containing Sb~99.9%, Pb~0.05%, Bi~0.053%, As~0.02%) and 85Kg sulfur powder with a stirrer, then add it into a closed container and heat to Insulate at 400°C and react for 2 hours to obtain 291.40Kg of low-purity antimony sulfide;

[0036] 2. Put the low-purity antimony sulfide in a vacuum furnace, the condensing area is 35cm away from the heating area, vacuumize to 5-50Pa, slowly raise the temperature to 950°C, keep it warm for 8h under this condition, control the temperature of the condensing area to 150°C, and distill Collect the mixture 285.4Kg of low-boiling impurity and antimony sulfide in volatile matter after completion;

[0037] 3. Put the mixture of low-boiling point impurities and antimony sulfide in a vacuum furnace that does not adhere to impurities, add 1% sulfur, and homogenize and synthesize the collected antimony sulfide at 560°C under normal pressure; Then evacuate to 5-50Pa, slowly raise the temperature to 630°C, ...

Embodiment 2

[0039] 1. Mix 210Kg of granular antimony alloy (containing Sb~97.42%, Pb~0.83%, Bi~0.53%, Cu~0.37%, Fe~0.29%, As~0.02%) with 85Kg of sulfur powder and 85Kg of sulfur powder After fully mixed with the container, add it into a closed container, heat it to 400°C and keep it warm, and the reaction time is 1.5h to obtain 293.35Kg of low-purity antimony sulfide;

[0040] 2. Put the low-purity antimony sulfide in a vacuum furnace, the condensing area is 80cm away from the heating area, vacuumize to 5-50Pa, slowly raise the temperature to 1200°C, keep it warm for 5h under this condition, control the temperature of the condensing area to 200°C, and distill Collect the mixture 285.43Kg of low-boiling impurity and antimony sulfide in volatile matter after completion;

[0041] 3. Put the mixture of low-boiling point impurities and antimony sulfide in a vacuum furnace that does not adhere to impurities, add 2% sulfur, and homogenize and synthesize the collected antimony sulfide at 580°C un...

Embodiment 3

[0043] 1. Put 300Kg of Sb-40% antimony sulfide concentrate in a vacuum furnace, the condensation area is 50cm away from the heating area, vacuumize to 5-50Pa, slowly raise the temperature to 1100°C, keep the temperature for 7 hours under this condition, and control the temperature of the condensation area At 200°C, 228.4Kg of a mixture of low-boiling impurities and antimony sulfide was collected in the volatile matter after the distillation;

[0044] 2. Put the mixture of low-boiling-point impurities and antimony sulfide in a vacuum furnace that does not adhere to impurities, add 2% sulfur, and homogenize and synthesize the collected antimony sulfide at 600°C under normal pressure; Then evacuate to 5-50Pa, slowly raise the temperature to 680°C, and keep it warm for 3 hours under this condition. After the distillation is completed, 158.6Kg of residue is collected. After testing, the obtained residue is Sb 2 S 3 , and its purity is 99.92%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com