Preparation method of selenium antimony sulfide film and application thereof

A technology for antimony selenium sulfide and antimony sulfide, which is applied in the field of preparation of antimony selenium sulfide thin films, can solve problems involving organic solvents and the like, and achieve the effects of simple preparation process, environmental protection, low reaction temperature and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Aiming at the current situation of the preparation of antimony selenium sulfide thin films, this application provides a preparation method for antimony selenium sulfide thin films. The method uses a hydrothermal method to synthesize antimony selenium sulfide thin films. The cost of raw materials is low, the method is simple, and the quality of antimony selenium sulfide thin films is higher. Specifically, the embodiment of the present invention discloses a method for preparing an antimony selenium sulfide thin film, comprising the following steps:

[0034] Mix antimony potassium tartrate, sulfur source and selenium source, carry out hydrothermal reaction in a closed environment, and obtain a selenium sulfide antimony precursor film after drying;

[0035] The antimony selenium sulfide precursor film is annealed to obtain the antimony selenium sulfide thin film.

[0036] In the process of preparing antimony selenium sulfide thin film, the present application first selects r...

Embodiment 1

[0045] Mix 0.2671g antimony potassium tartrate, 0.7946g sodium thiosulfate, and 0-70mg selenourea into a 50ml reactor liner containing 40ml water, stir evenly until the solution turns yellow, and place the CdS-deposited FTO glass substrate on the into the above mixed solution; finally, seal the autoclave and place it in an oven and heat it to 135°C for 2 hours, then cool it down to room temperature naturally; after the autoclave is opened, the antimony selenium sulfide precursor film is rinsed with water and ethanol, and then blown with nitrogen. dry, then place the precursor film in a glove box (N 2 environment) at 350°C for 10 min to prepare antimony selenium sulfide thin films with different Se / S ratios.

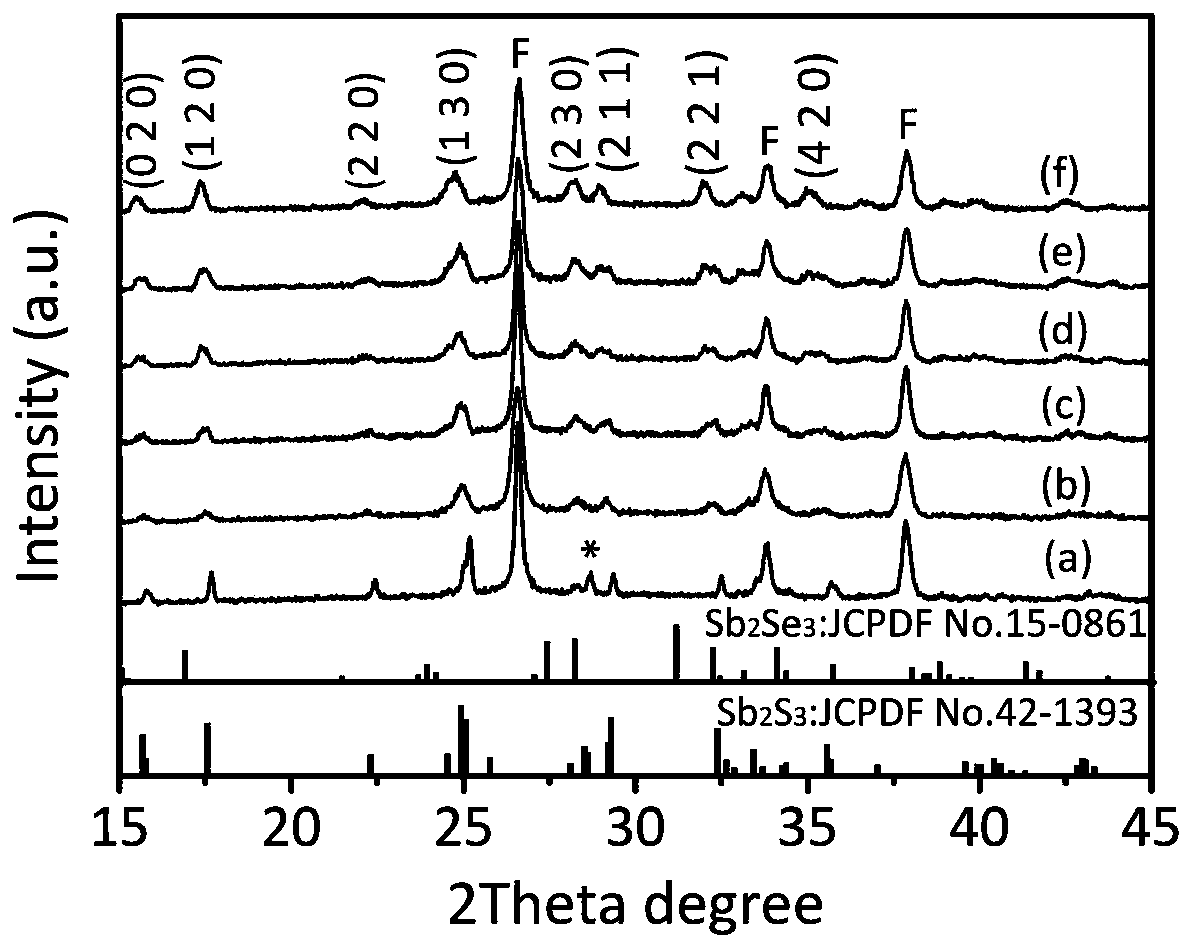

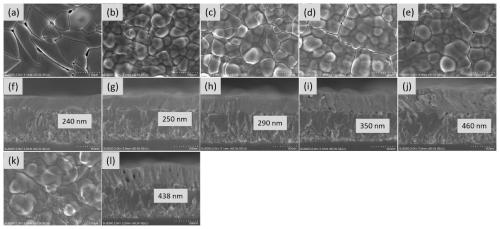

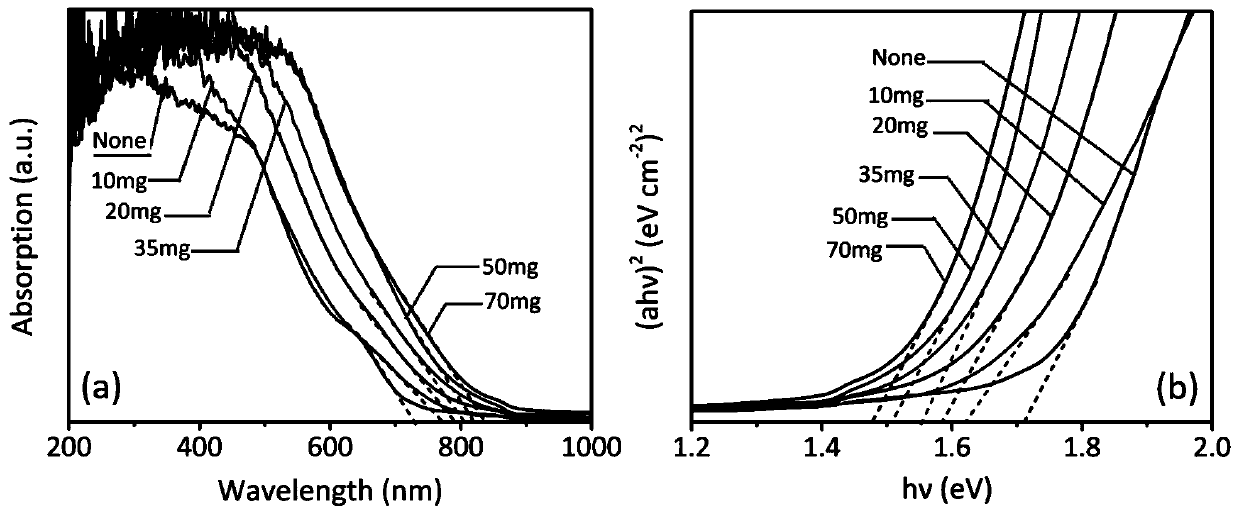

[0046] The FTO / CdS / Sb that utilizes X-ray powder diffractometer to obtain in embodiment 1 2 (S, Se) 3 The film was analyzed by X-ray diffraction, and its X-ray diffraction spectrum was obtained as figure 1 as shown, figure 1 For sample Sb 2 S 3 (a) and different amo...

Embodiment 2

[0051] Mix 0.2671g antimony potassium tartrate, 0.7946g sodium thiosulfate and 20mg selenourea into a 50ml reactor liner containing 40ml water, stir evenly until the solution turns yellow, then put the CdS-deposited FTO glass substrate into the In the above mixed solution; finally, seal the autoclave and place it in an oven and heat it to 100°C-170°C for 2 hours, and then naturally cool to room temperature; Blow dry, then put the precursor film in the glove box (N 2 environment) at 350° C. for 10 minutes to prepare antimony selenium sulfide thin films with different hydrothermal temperatures.

[0052] The FTO / CdS / Sb that utilizes X-ray powder diffractometer to obtain in embodiment 2 2 (S, Se) 3 The film was analyzed by X-ray diffraction, and its X-ray diffraction spectrum was obtained as Figure 4 as shown, Figure 4 In this embodiment, the hydrothermal temperature is respectively (a) 100 ℃, (b) 120 ℃, (c) 135 ℃, (d) 150 ℃ and (e) Sb of 170 ℃ 2 (S, Se) 3 The XRD pattern ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com