Method and system for purifying antimony sulfide concentrate molten salt electrolysis smoke dust and preparing sulfur

A technology of molten salt electrolysis and dust purification, applied in chemical instruments and methods, preparation/purification of sulfur compounds, sulfur, etc., can solve problems such as difficult to realize the recovery and utilization of antimony sulfide, environmental pollution of the surrounding environment, difficult recycling and utilization, etc. Achieve the effect of simple and practical method, strong continuity and high applicability of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

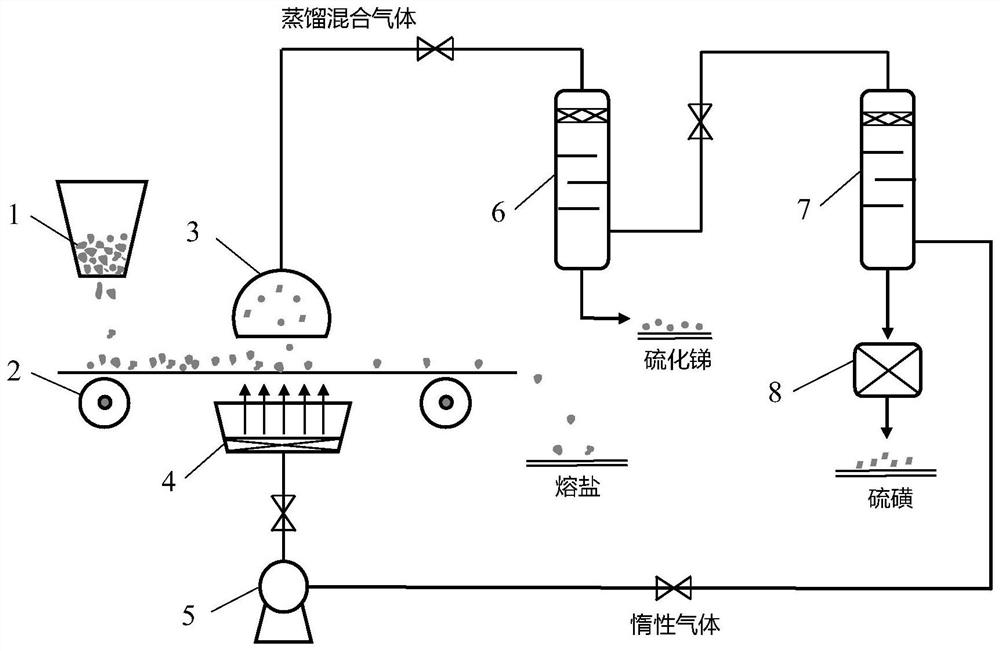

[0065] The material of the conveyor belt in this embodiment is graphite, and the length of the distillation and desulfurization zone formed by heating the middle of the belt conveyor by a gas heater is 0.8 m.

[0066] The process of antimony sulfide concentrate molten salt electrolysis fume purification and sulfur production is as follows:

[0067] The chemical composition of sulfur-containing soot A obtained by molten salt electrolysis of an antimony sulfide concentrate is as follows: the mass proportion of molten salt is 10wt%, the mass proportion of antimony sulfide is 35%, and the mass proportion of elemental sulfur is 55%.

[0068] First, adjust the thickness of soot on the conveyor belt to be 2 cm, the running speed to be 0.2 cm / s, the distillation temperature to be 600°C, and the nitrogen flow rate to be 0.1 cm / s. The condensing temperature of the first condensing tower was controlled to be 540°C and the gas flow rate was 0.05cm / s, and the temperature of the second cond...

Embodiment 2

[0070] The material of the conveyor belt in this embodiment is alumina, and the length of the distillation and desulfurization zone formed by heating the middle of the belt conveyor by a gas heater is 0.8 m.

[0071] The process of antimony sulfide concentrate molten salt electrolysis fume purification and sulfur production is as follows:

[0072] The chemical composition of sulfur-containing soot B obtained by molten salt electrolysis of an antimony sulfide concentrate is: the mass proportion of molten salt is 15wt%, the mass proportion of antimony sulfide is 27%, and the mass proportion of elemental sulfur is 58%. First, adjust the thickness of soot on the conveyor belt to be 4 cm, the running speed to be 0.4 cm / s, the distillation temperature to be 580°C, and the flow rate of nitrogen gas to be 0.2 cm / s. The condensing temperature of the first condensing tower was controlled to be 500°C and the gas flow rate was 0.1 cm / s, and the temperature of the second condensing tower w...

Embodiment 3

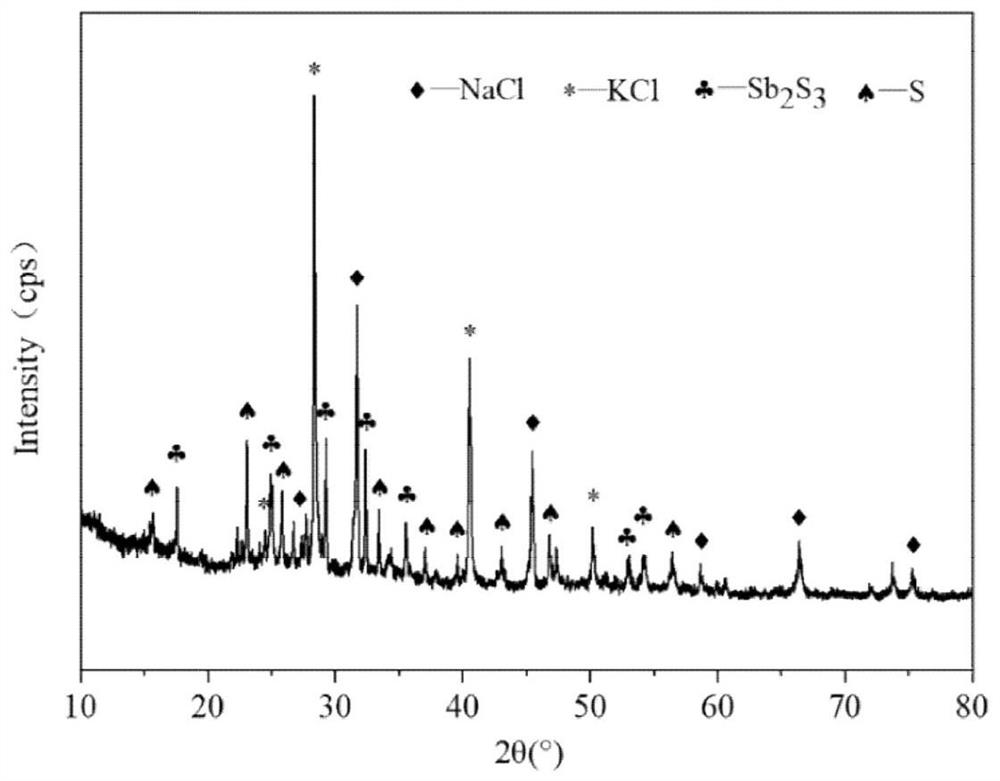

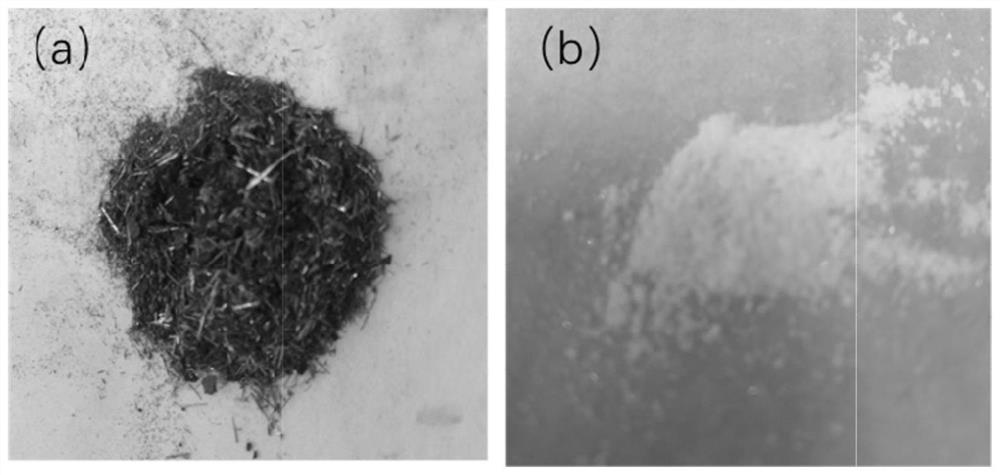

[0074] The continuous purification and desulfurization process test of smoke and dust was carried out with the same raw materials and parameters in the above-mentioned Example 2. After the process runs for 3 hours, the intermediate temperature condensation tower product is collected, and the proportion of antimony sulfide is 98.4wt%, the proportion of molten salt is 1.2wt%, and the proportion of elemental sulfur is 0.4wt%. The product of the second condensing tower is collected, and the proportion of antimony sulfide is 0.1 wt %, the proportion of molten salt is 0.2 wt %, and the sulfur grade is 99.7 wt %. The molten salt composition at the end of the conveyor belt is: 0.2 wt% of antimony sulfide, 0.1 wt% of sulfur, and 99.7% of molten salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com