Composite sulfide as well as preparation method and application thereof

A sulfide, sulfur source technology, applied in chemical instruments and methods, antimony sulfide, antimony compounds, etc., can solve the problems of limited sodium ion battery application, low sodium ion diffusion rate, complex preparation process, etc., to achieve excellent low-temperature electrochemical The effect of good performance, material morphology, and high product phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] In order to solve at least the above-mentioned problems, the embodiment part of the present invention provides a kind of preparation method of composite sulfide, and described preparation method comprises:

[0042] heat-treating the precursor and the sulfur source at 450°C to 650°C to obtain the composite sulfide,

[0043] Wherein, the precursor includes XSb, and X includes Ga and / or In.

[0044] The invention heat-treats the precursor GaSb and / or InSb and the sulfur source at a specific temperature, and through the gas-solid reaction, the sulfur atoms are diffused into the GaSb and / or InSb lattice under thermodynamic drive, and transformed into antimony gallium sulfide and / or antimony indium sulfide, the prepared composite sulfide has higher first-cycle specific capacity, better cycle stability and excellent low-temperature electrochemical performance.

[0045] In some embodiments, the molar ratio of the precursor to the sulfur source is 1:(10 to 30).

[0046] Furt...

Embodiment 1

[0058] This embodiment provides a method for preparing composite sulfides, the preparation method comprising: placing GaSb powder in a tube furnace, feeding H 2 S gas was heat-treated at 550°C for 9 hours, and the protective gas for heat treatment was argon, H 2 The flow rate of S gas is 120mL / min, the flow rate of argon gas is 250mL / min, and the heating rate of heat treatment is 5°C / min to obtain the composite sulfide; wherein, GaSb powder and H 2 The molar ratio of S gas is 1:20.

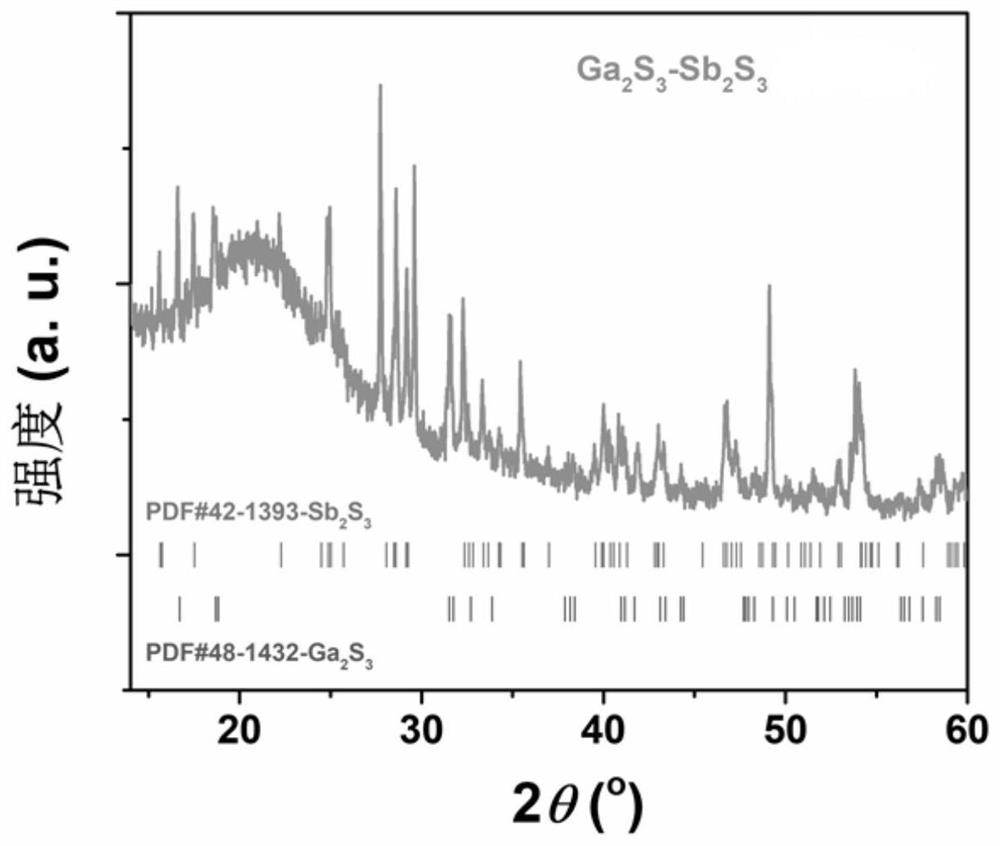

[0059] The composite sulfide prepared in this example includes Ga 2 S 3 and Sb 2 S 3 , denoted as Ga 2 S 3 -Sb 2 S 3 .

[0060] figure 1 For the XRD pattern of the composite sulfide prepared in this embodiment, the peak position in the figure corresponds well, indicating that the synthesized Ga 2 S 3 -Sb 2 S 3 Higher purity.

Embodiment 2

[0062] This embodiment provides a method for preparing a composite sulfide, the preparation method comprising: placing InSb powder and GaSb powder with a mass ratio of 1:1 in a tube furnace, feeding H 2 S gas was heat treated at 500°C for 10.5h, and the protective gas for heat treatment was nitrogen, H 2 The flow rate of the S gas was 120 mL / min, the flow rate of the nitrogen gas was 250 mL / min, and the heating rate of the heat treatment was 6° C. / min to obtain the composite sulfide. Among them, InSb powder and GaSb powder with H 2 The molar ratio of S gas is 1:15.

[0063] The composite sulfide prepared in this example includes Ga 2 S 3 、In 2 S 3 and Sb 2 S 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com