Preparation method and application of antimony sulfide nanorod

A technology of nanorods and antimony sulfide, applied in antimony sulfide, chemical instruments and methods, nanotechnology, etc., can solve the problems of low reversible capacity and limitations, and achieve good industrialization prospects, improved volume expansion, and good electrochemical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Add 0.23g (1mmoL) antimony trichloride (SbCl 3 ) was dissolved in 10mL of absolute ethanol, ultrasonically stirred to dissolve, and the volume of absolute ethanol was 10 times the amount of the antimony source substance;

[0027] 2) Add 0.076g (1mmoL) thiourea (CH 4 N 2 S), stir 0.5h to dissolve evenly, the amount of the substance of thiourea is 1 times of antimony source;

[0028] 3) Add oleylamine solution with a volume of 10 mL to the above solution and stir for 0.5 h to fully dissolve it;

[0029] 4) Put the above-mentioned mixed solution into a 50mL polytetrafluoroethylene substrate, install the shell of a stainless steel reaction kettle, and conduct a hydrothermal reaction at 180°C for 12 hours;

[0030] 5) Collect the solution after the hydrothermal reaction, centrifuge three times with cyclohexane and then centrifuge three times with glacial acetic acid, then obtain a black precipitate, and dry the precipitate to obtain the black sulfurized ladder nanorod;...

Embodiment 2

[0033] 1) Add 0.23g (1mmoL) antimony trichloride (SbCl 3 ) was dissolved in 20mL oleylamine, and dissolved by ultrasonic stirring for 0.5h;

[0034] 2) Add 0.076g (1mmoL) thiourea (CH 4 N 2 S), stir 0.5h to dissolve evenly, the amount of the substance of thiourea is 1 times of antimony source;

[0035] 3) Put the above-mentioned mixed solution into a 50mL polytetrafluoroethylene substrate, and put it on the shell of a stainless steel reaction kettle for hydrothermal reaction at 180°C for 12 h;

[0036] 4) Collect the solution after the hydrothermal reaction, first centrifuge three times with cyclohexane and then centrifuge three times with glacial acetic acid, then obtain a black precipitate, and dry the precipitate to obtain the black vulcanized ladder nanorod material;

[0037] 5) Fully grind the dried black vulcanized ladder nanorods as the negative electrode material of the sodium ion electrode, and mix them with carbon black and carboxymethyl cellulose according to the r...

Embodiment 3

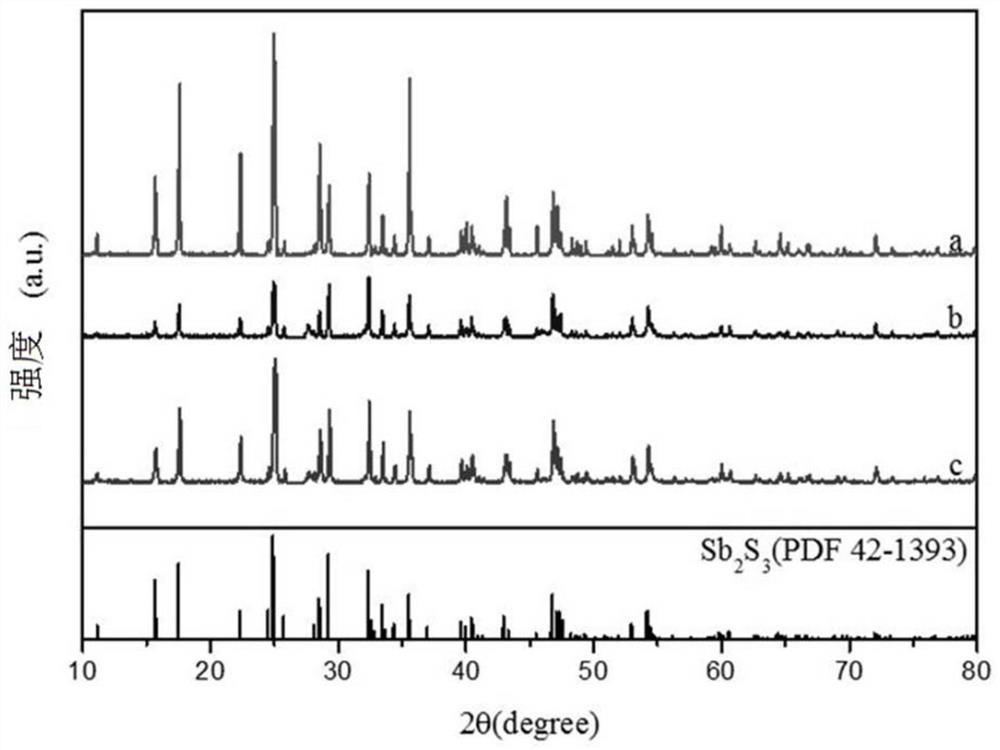

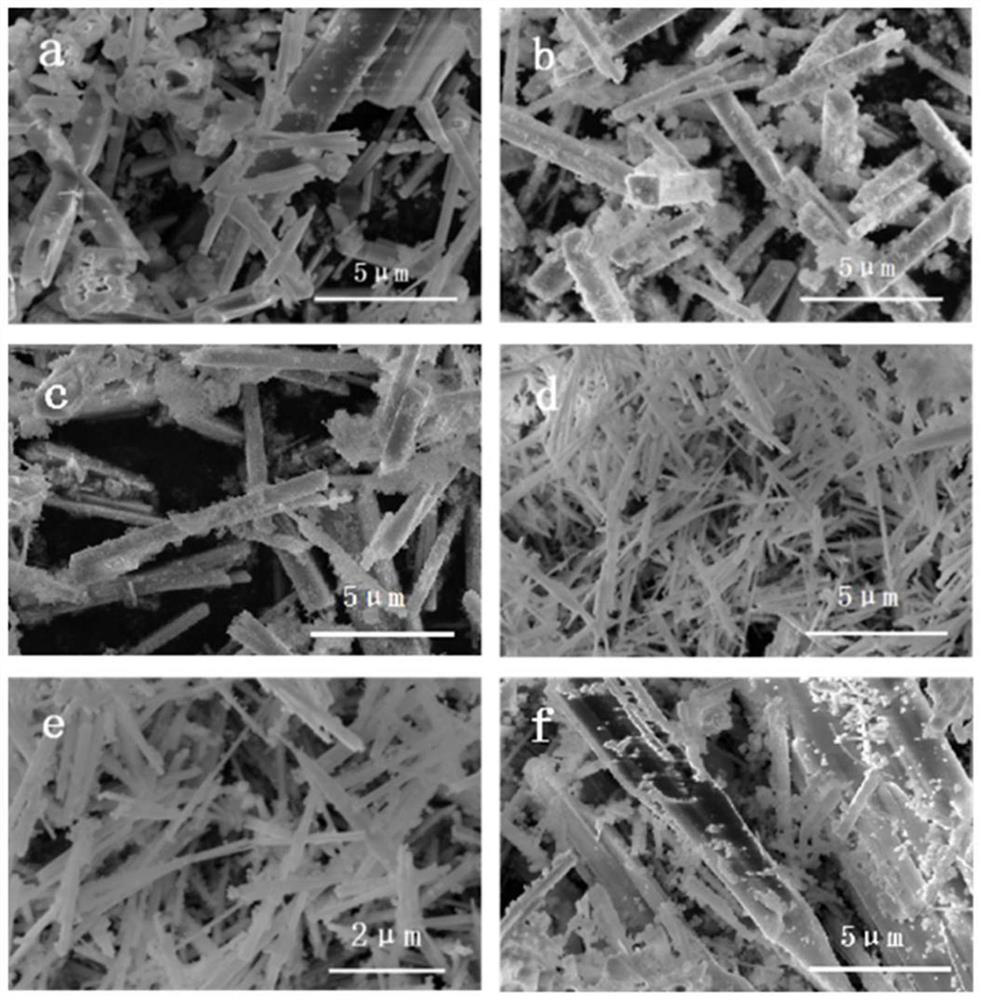

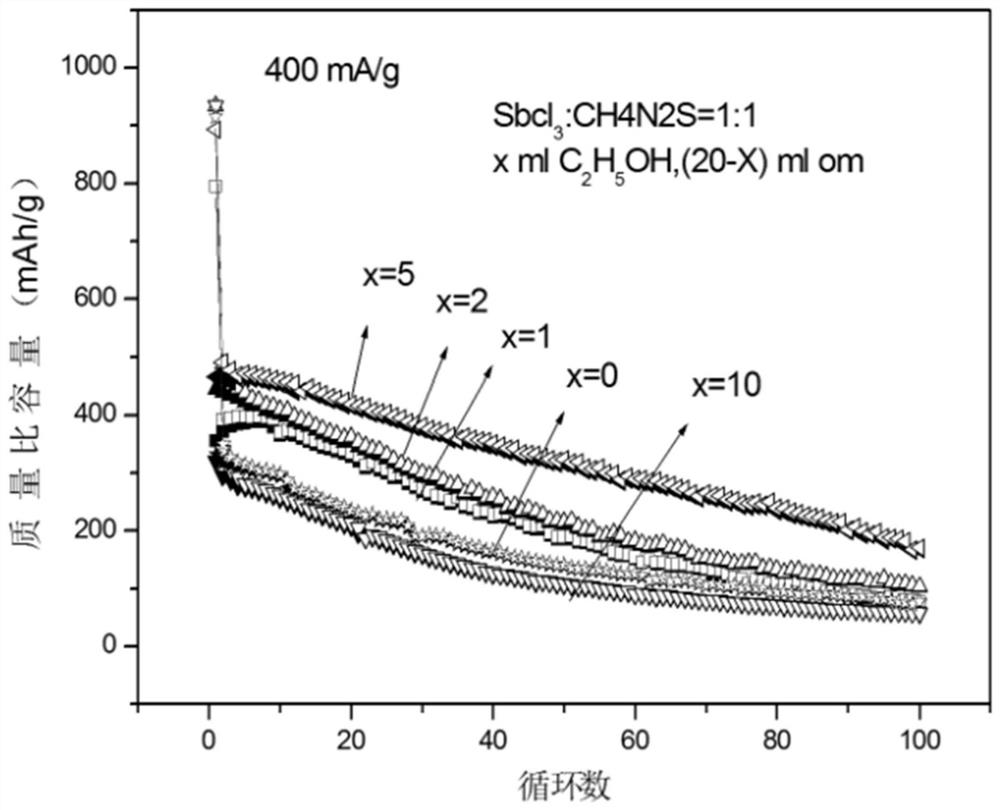

[0039] The operation is the same as in Example 1, except that the volume ratio of absolute ethanol and oleylamine is 1mL ethanol / 19mL oleylamine. Scanning electron microscopy (SEM) (e.g. figure 2 (b)) Observe that the obvious agglomeration phenomenon of the obtained product has disappeared, but the shape of the rod is still irregular, the size is not uniform, and there are still many particles in it. Cycle performance curve ( image 3 ) analysis, the charge-discharge cycle performance drops sharply after 50 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com