Preparation method of monodisperse antimony sulfide quantum dot

A technology of antimony sulfide and quantum dots, which is applied in antimony sulfide, chemical instruments and methods, inorganic chemistry, etc., can solve compatibility problems, achieve simple equipment, low synthesis cost, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

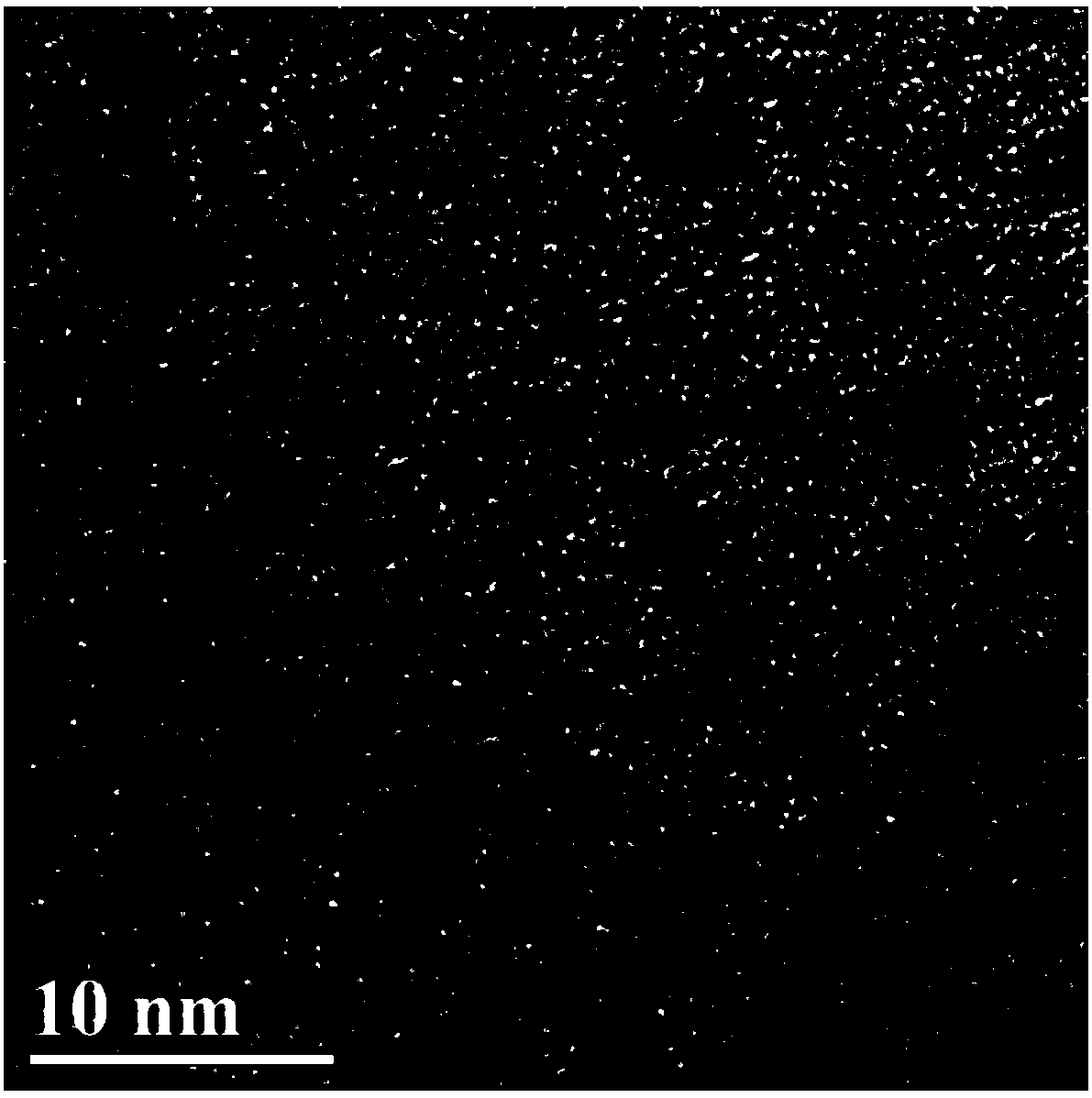

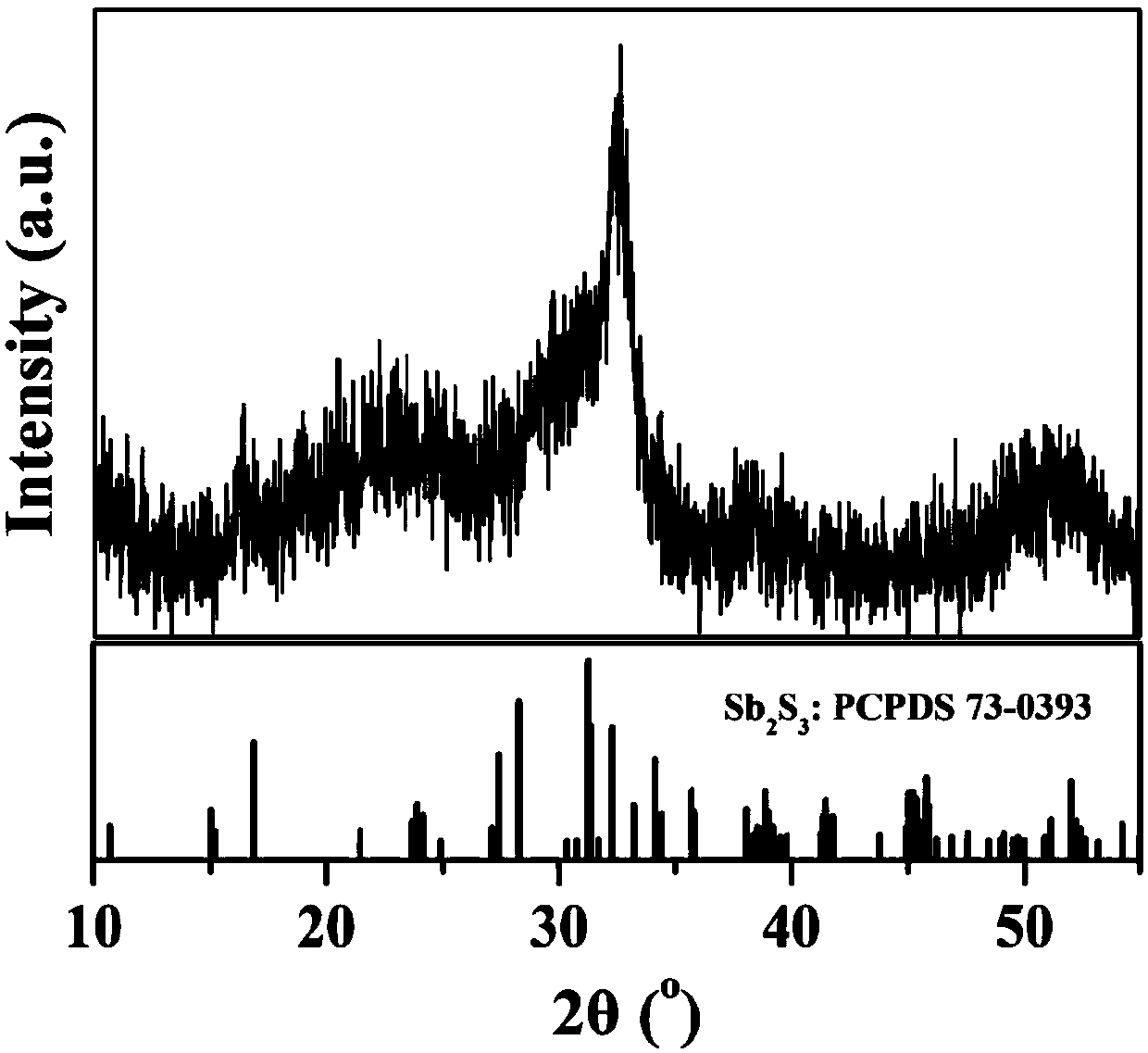

Image

Examples

Embodiment 1

[0028] A preparation method of monodisperse antimony sulfide quantum dots, comprising the following steps:

[0029] A, thioacetamide is dissolved in ethylene glycol methyl ether, is configured into the solution of 0.15mol / L;

[0030] B, antimony acetate is dissolved in glacial acetic acid, is configured into the solution of 0.25mol / L;

[0031] C. Heat the magnetic stirring constant temperature oil bath to 120°C and then keep it warm;

[0032] D. Take 30ml of the thioacetamide solution described in step A and transfer it to a round bottom flask, add 0.6ml diethanolamine, 0.6mmol ethylenediaminetetraacetic acid, 0.5mmol sodium lauryl sulfate and 0.5mmol cetyl tris Methyl ammonium bromide, the round bottom flask is placed in a magnetic stirring constant temperature oil bath;

[0033] E. Add a Ф6×25mm stirring bar to the mixture prepared in step D, seal the mouth of the round bottom flask with a rubber stopper, and perform magnetic stirring at a speed of 650r / min, and form a uni...

Embodiment 2

[0038] The difference between embodiment 2 and embodiment 1 is:

[0039] In step C, heat the magnetic stirring constant temperature oil bath to 60°C and then keep it warm;

[0040] After opening the rubber stopper on the mouth of the round-bottomed flask in step F, add 0.5ml of antimony acetate solution prepared according to the method in step B, and continue stirring for 15 minutes. After the solution is bright yellow, quickly take the round-bottomed flask out of the oil bath, Quickly cool in a pre-prepared ice-water bath.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is:

[0043] In step C, heat the magnetic stirring constant temperature oil bath to 150°C and then keep it warm;

[0044]After opening the rubber stopper on the mouth of the round-bottomed flask in step F, add 0.5ml of antimony acetate solution prepared according to the method in step B, and continue stirring for 25 minutes. After the solution is bright yellow, the round-bottomed flask is quickly taken out from the oil bath, Quickly cool in a pre-prepared ice-water bath.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com