A transition metal chalcogenide carbon-based heterostructure composite material with regular morphology and its preparation method and application

A transition metal and heterostructure technology, which is applied in the preparation/purification of carbon, structural parts, chemical instruments and methods, etc., can solve the complex preparation process, poor controllability, irregular morphology of transition metal chalcogenides, etc. problem, to achieve the effect of simple and fast method and controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

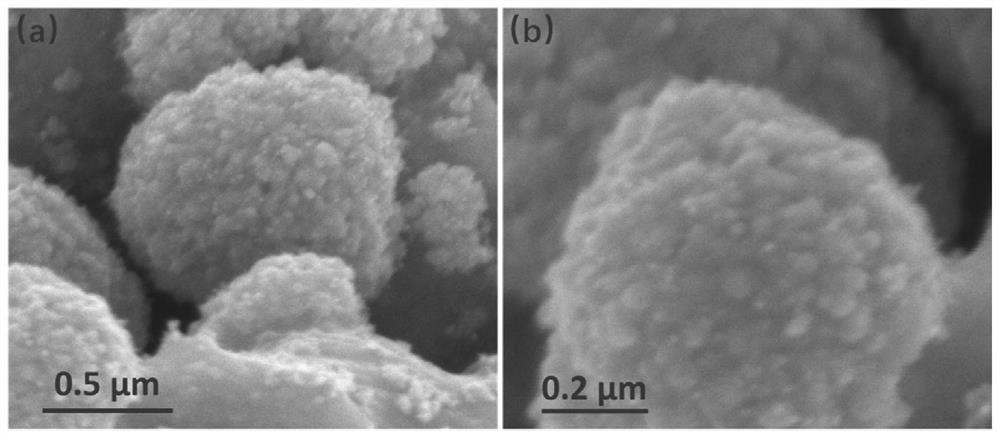

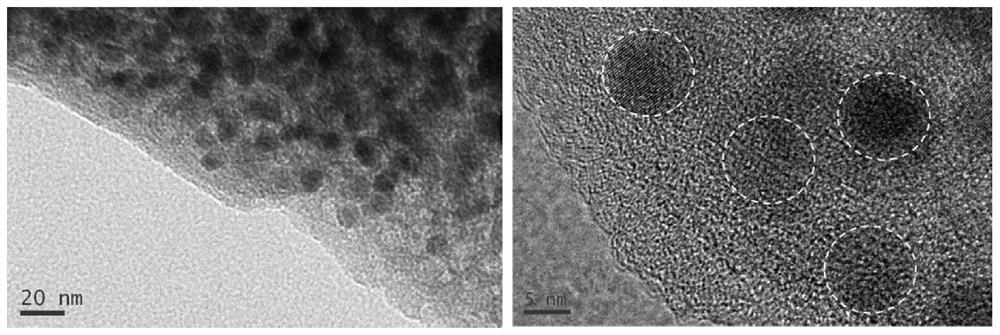

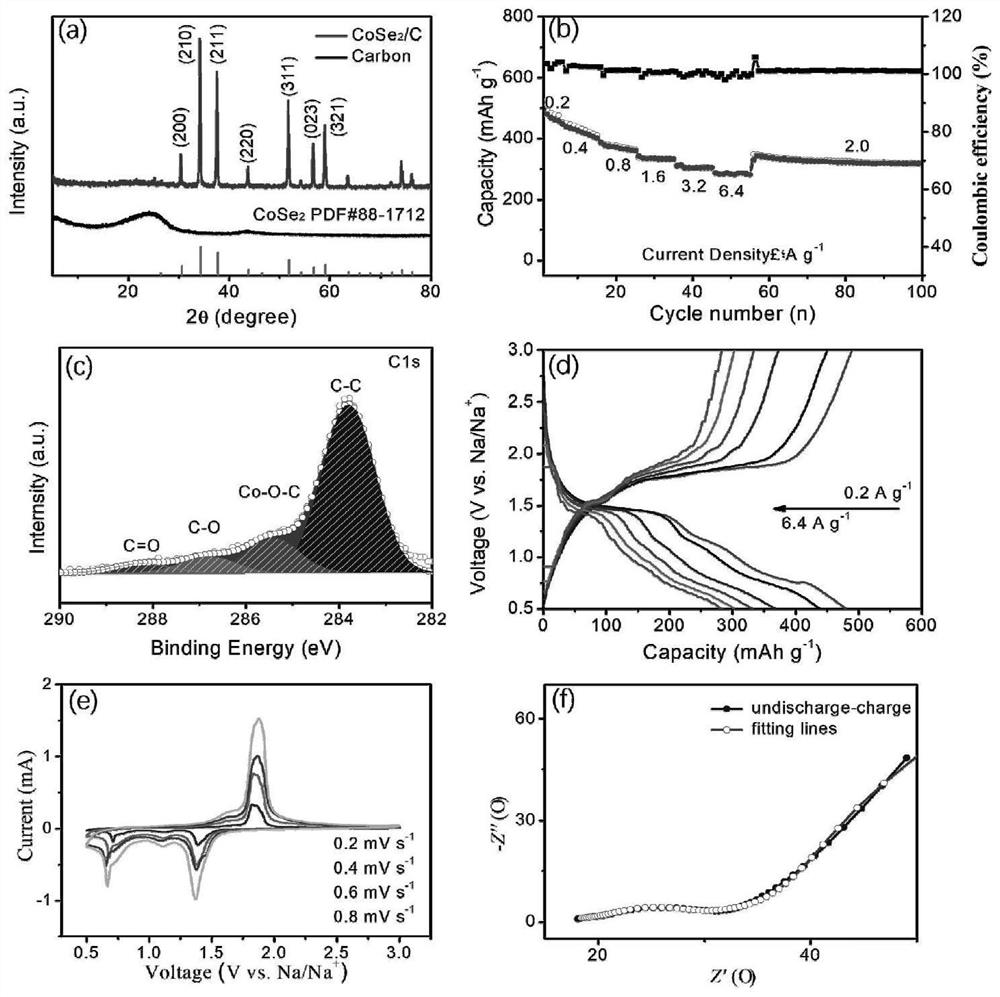

[0043] Mix 1.0 g of commercial cobalt acetylacetonate with 2.0 g of selenium powder and 3.0 g of sodium sulfate, and then calcinate it at 500 ° C for 2 h under the protection of inert gas argon, with a heating rate of 3 ° C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder That is, nanodot-like cobalt diselenide carbon-based heterostructure (CoSe 2 / C). figure 1 Based on the scanning electron microscope picture of the nano-dot-like cobalt diselenide carbon-based heterostructure, it can be observed that the carbon matrix is completely covered with the cobalt diselenide material. figure 2 The worthwhile nano-dot-like cobalt diselenide carbon-based heterostructure transmission electron microscope pictures, it ca...

Embodiment 2

[0046] Mix 1.0g of commercial cobalt acetylacetonate, 2.0g of selenium powder and 3.0g of sodium sulfate evenly, and then calcinate it at 500°C for 2h under the protection of reducing gas 5% hydrogen-argon mixed gas, and the heating rate is 3°C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder Nano-microsphere cobalt diselenide nanotube carbon-based heterostructure (CoSe 2 / C). Figure 4 It is a scanning electron microscope picture of the carbon-based heterogeneous structure of the nano-microsphere cobalt diselenide nanotube, and the particles wrapped by the carbon nanotube can be seen. Electrochemical test results show that at 5.0A g -1 Under the current density, after 5000 cycles, the sodium capacitance can ...

Embodiment 3

[0050] Mix 1.0g of commercial cobalt acetylacetonate, 2.0g of selenium powder and 3.0g of sodium sulfate evenly, and then calcinate it at 800°C for 5h under the protection of reducing gas 5% hydrogen-argon mixed gas, and the heating rate is 10°C min -1 , natural cooling. Grind the calcined black product into powder, add an appropriate amount of water, perform ultrasonication for 30 minutes, magnetically stir for 3 hours, and then perform suction filtration. After repeated operations for 5 times, dry it in vacuum at 80°C for 12 hours to obtain a black powder That is grape microspherical cobalt selenide carbon-based heterostructure (CoSe / C). Figure 5 This is the scanning electron microscope picture of the grape microspherical cobalt selenide carbon-based heterostructure, and the nanoparticles wrapped by the carbon matrix can be seen. Electrochemical test results show that at 5.0A g -1 Under the current density, after 8000 cycles, the sodium capacitance can maintain 297mAh g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com