Preparation method of antimony sulfide/graphene composite micro-nano material

A graphene composite, micro-nano technology, applied in graphene, antimony sulfide, chemical instruments and methods, etc., can solve the problems of good electrochemical performance, unstable electrochemical performance, high degree of composite micro-nano materials, and achieve electrical The effect of stable chemical properties, excellent compounding rate and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

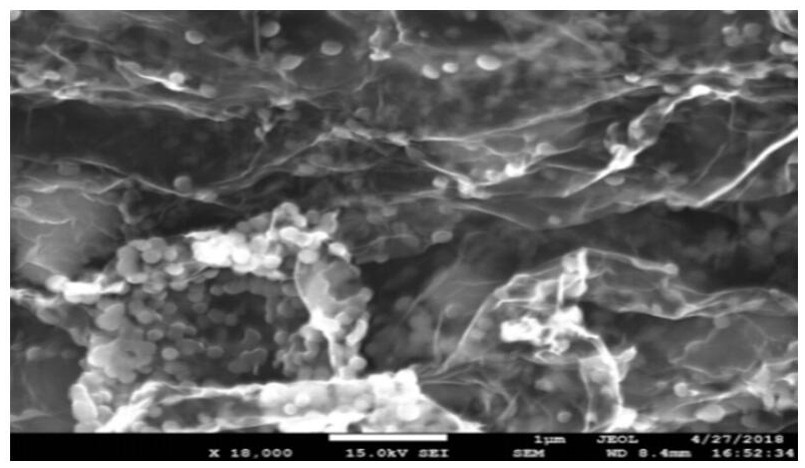

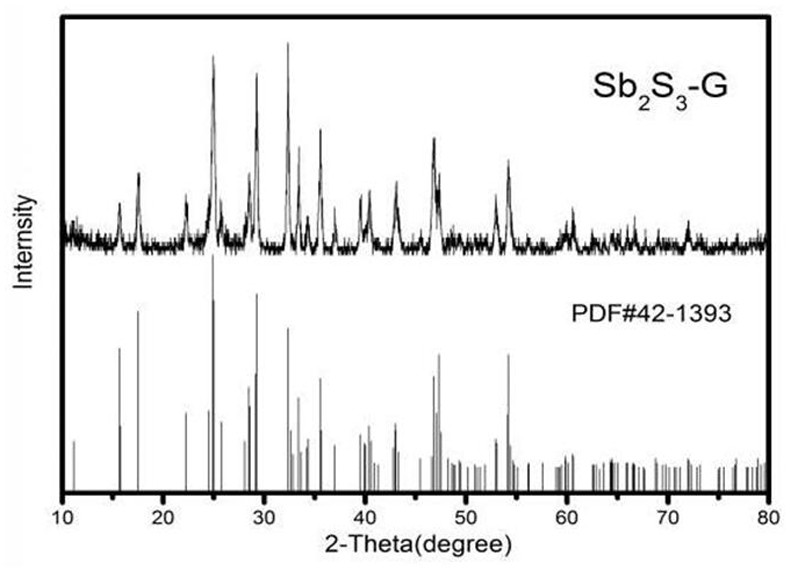

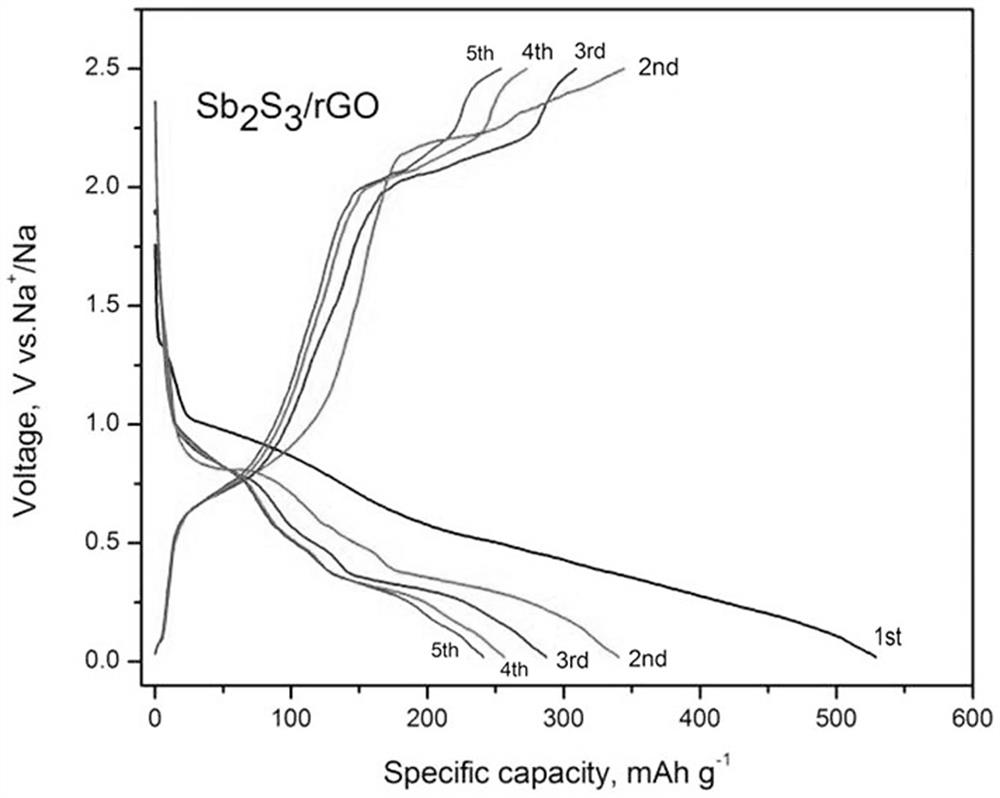

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0033] A kind of preparation method of antimony sulfide / graphene composite micro-nano material proposed by the present invention comprises the following steps:

[0034] Step 1: According to the formula ratio of the antimony sulfide / graphene composite micro-nano material, weigh the raw material graphene oxide dispersion, antimony potassium tartrate, thioacetamide and absolute ethanol. The composite micro-nano material is prepared by the weight ratio of the following raw materials: graphene oxide dispersion: antimony potassium tartrate: thioacetamide: absolute ethanol = 2:65:15:80.

[0035] Wherein, the concentration of the graphene oxide dispersion is 0.5mg / mL.

[0036] The weight proportions of the selected raw materials in this embodiment are: 0.4 kg of graphene oxide dispersion, 13 kg of antimony potassium tartrate, 3 kg of thioacetamide and 16 kg of absol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com