Patents

Literature

118results about "Electrode systems manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

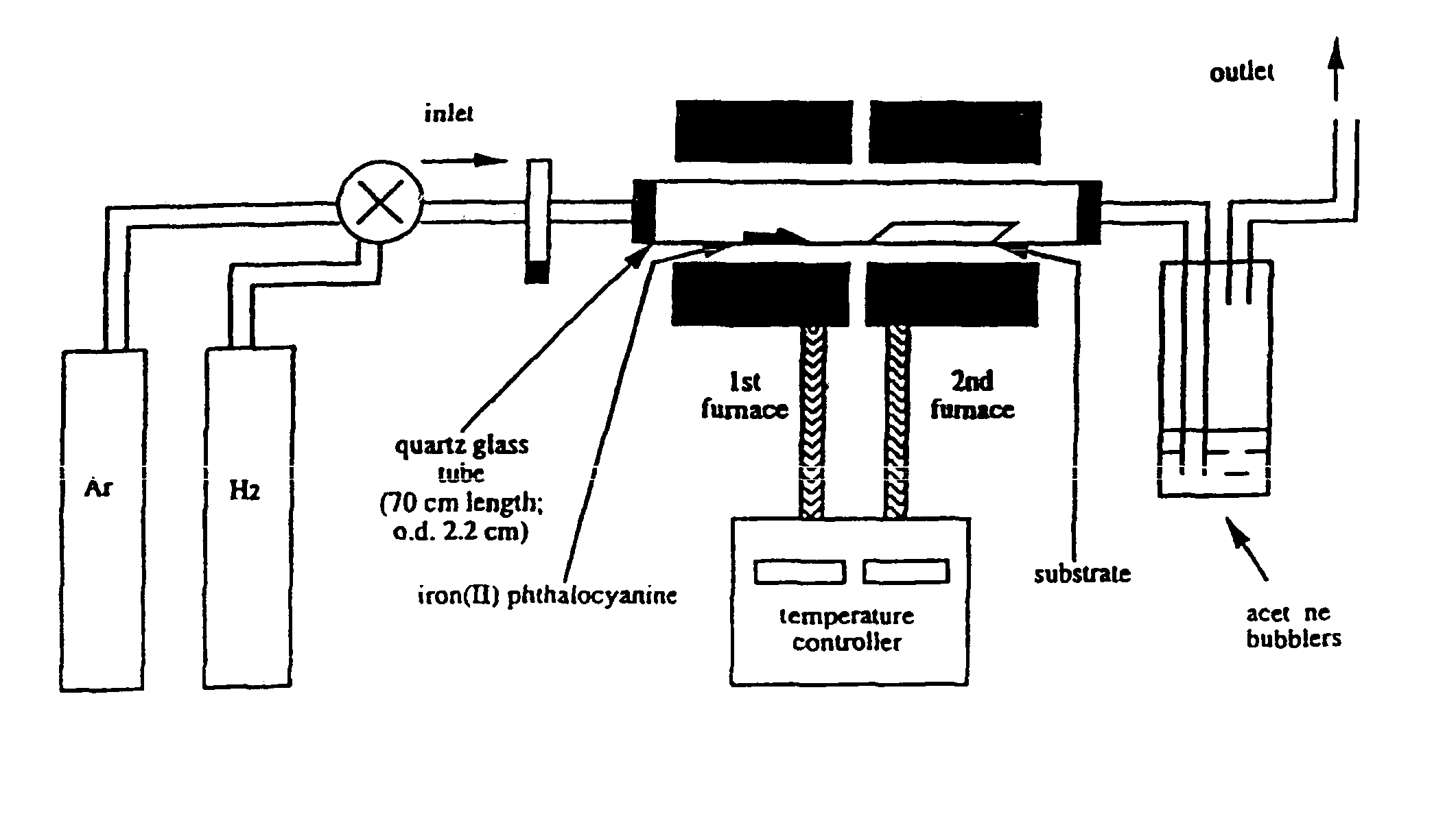

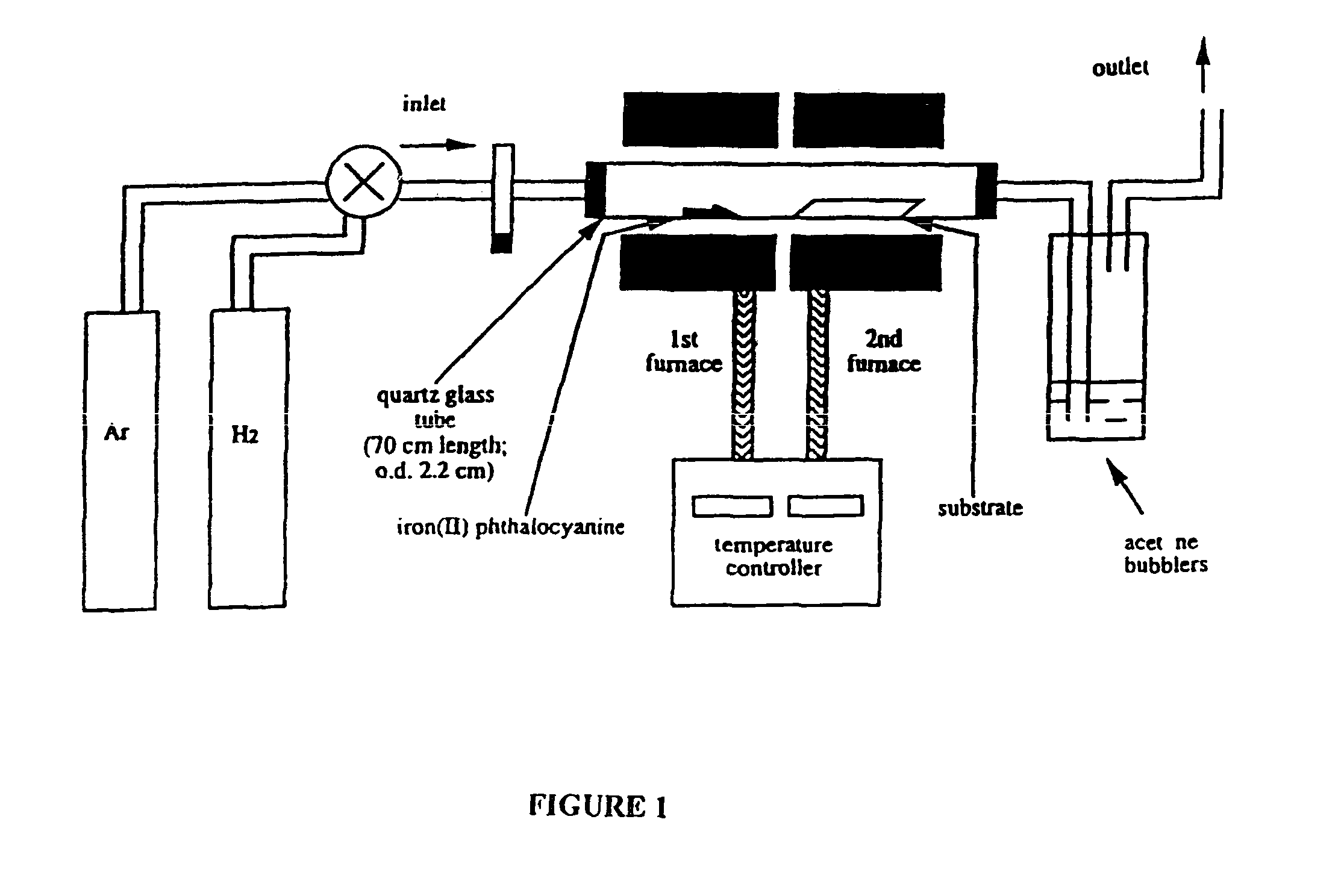

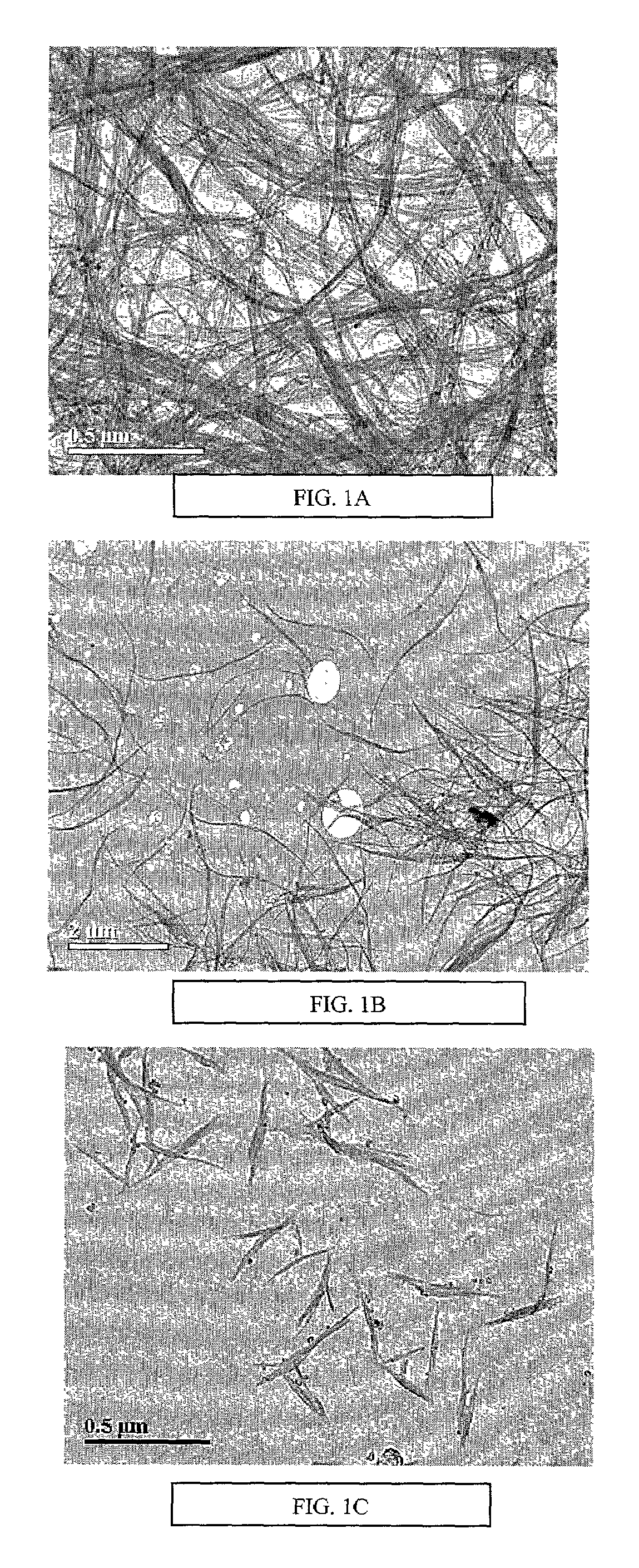

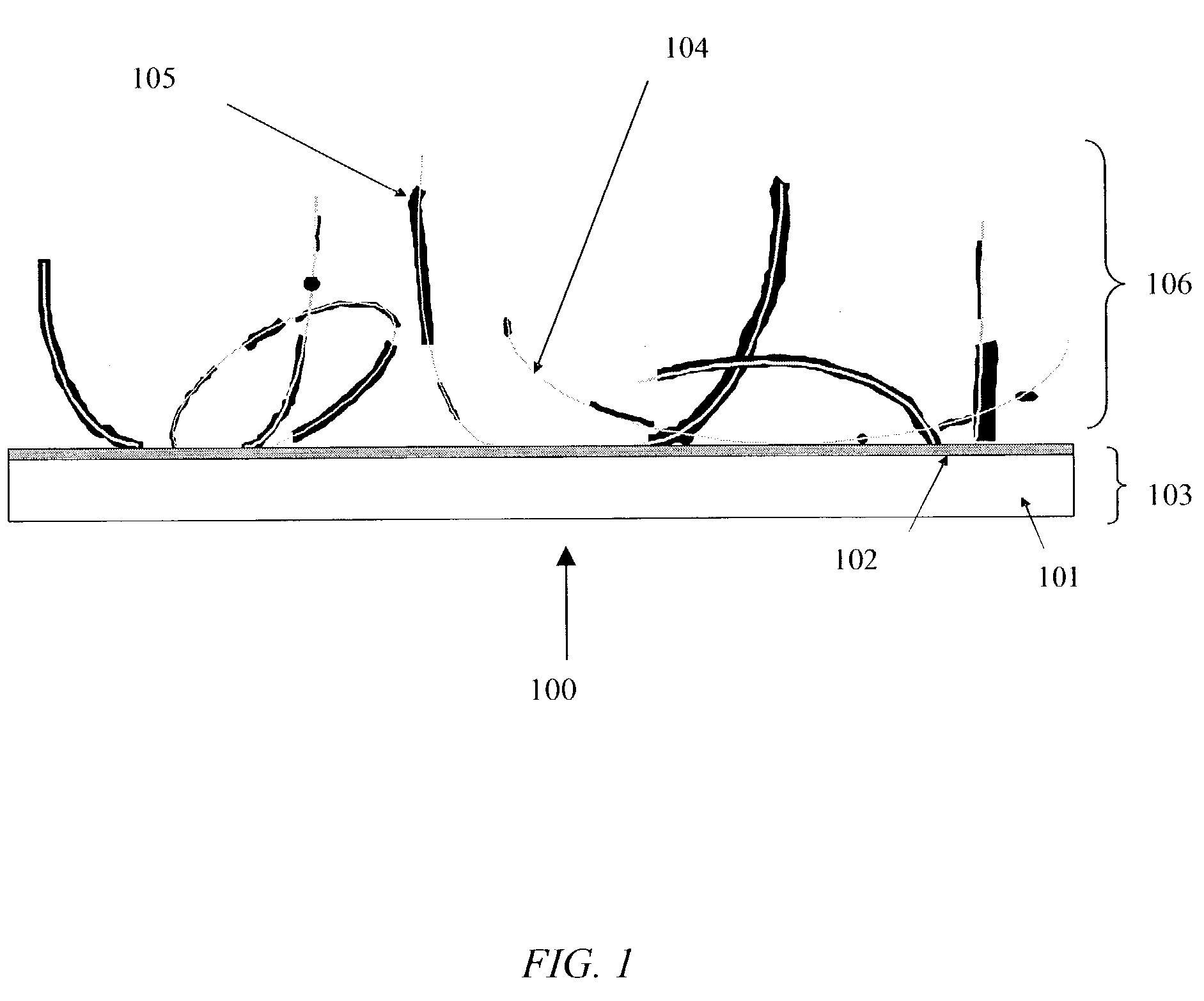

Free-standing and aligned carbon nanotubes and synthesis thereof

One or more highly-oriented, multi-walled carbon nanotubes are grown on an outer surface of a substrate initially disposed with a catalyst film or catalyst nano-dot by plasma enhanced hot filament chemical vapor deposition of a carbon source gas and a catalyst gas at temperatures between 300° C. and 3000° C. The carbon nanotubes range from 4 to 500 nm in diameter and 0.1 to 50 μm in length depending on growth conditions. Carbon nanotube density can exceed 104 nanotubes / mm2. Acetylene is used as the carbon source gas, and ammonia is used as the catalyst gas. Plasma intensity, carbon source gas to catalyst gas ratio and their flow rates, catalyst film thickness, and temperature of chemical vapor deposition affect the lengths, diameters, density, and uniformity of the carbon nanotubes. The carbon nanotubes of the present invention are useful in electrochemical applications as well as in electron emission, structural composite, material storage, and microelectrode applications.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

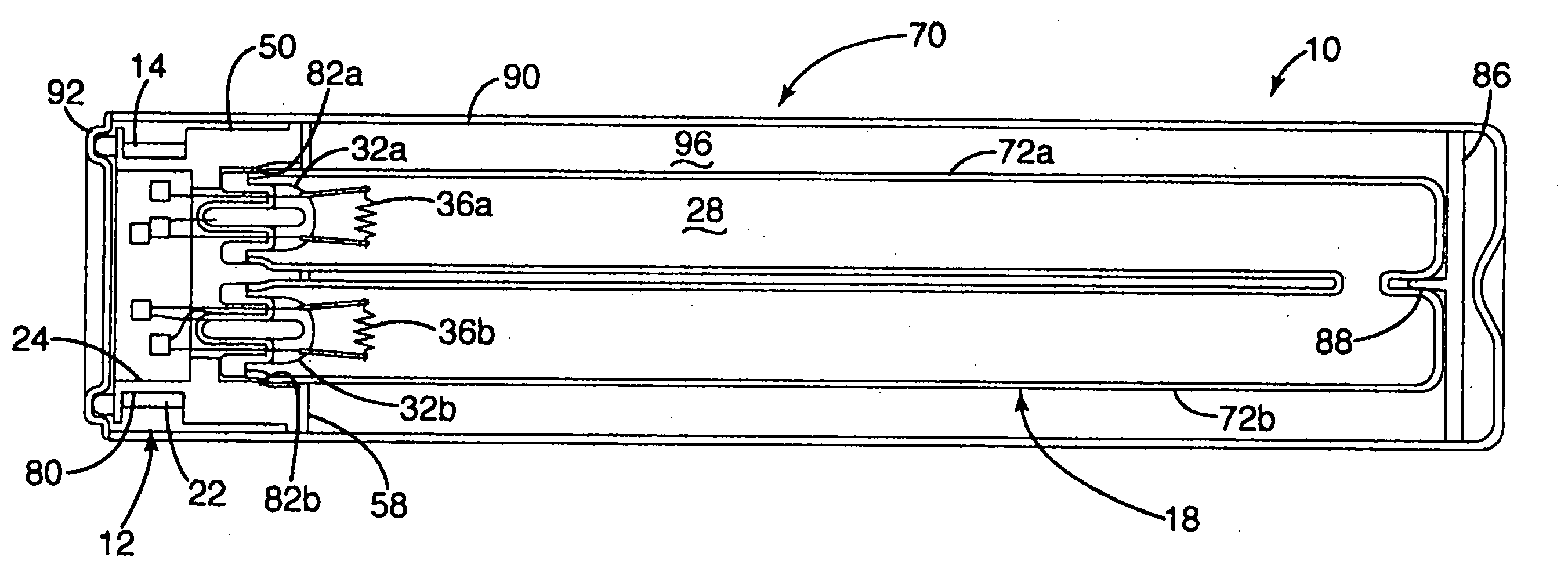

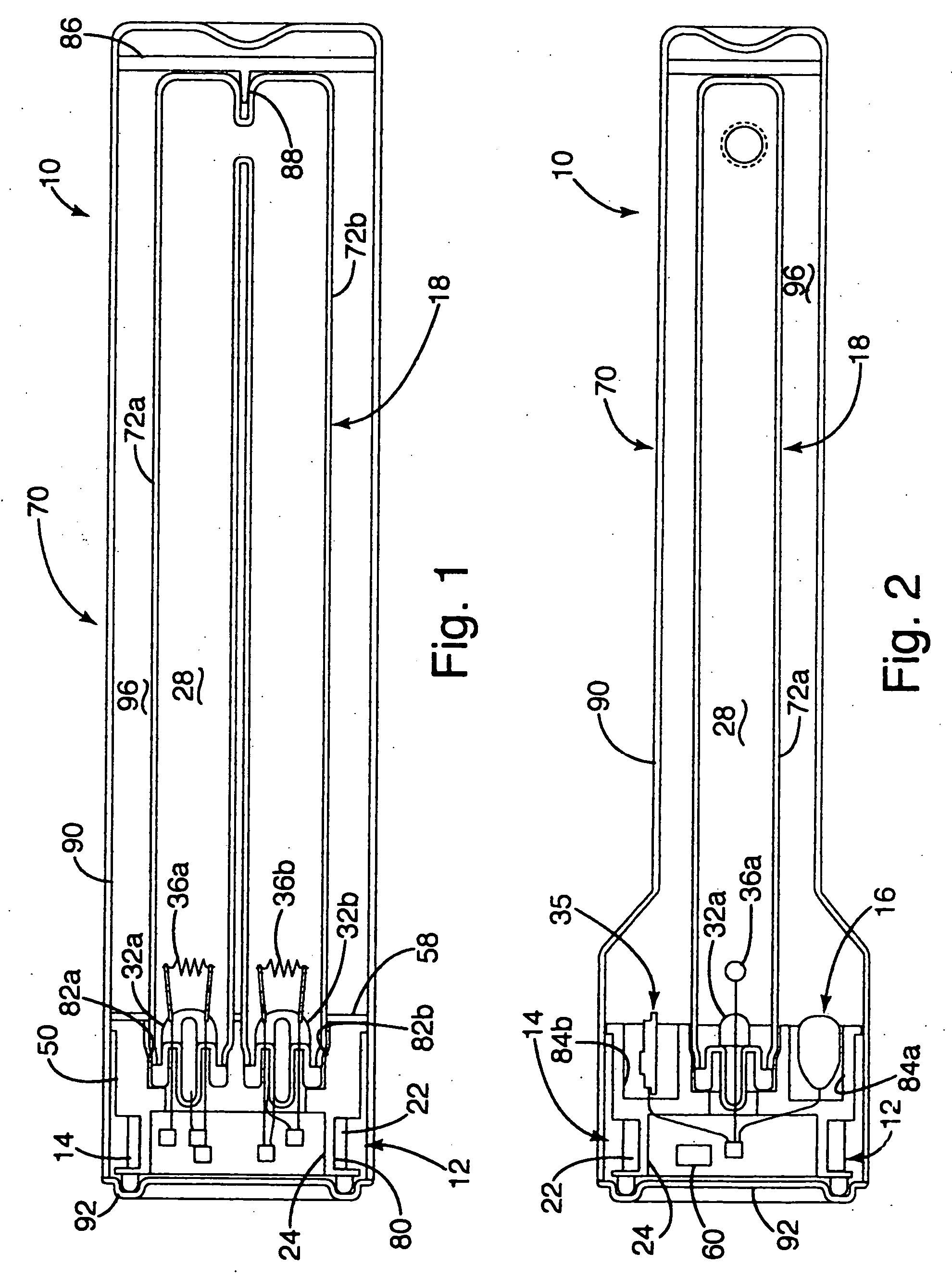

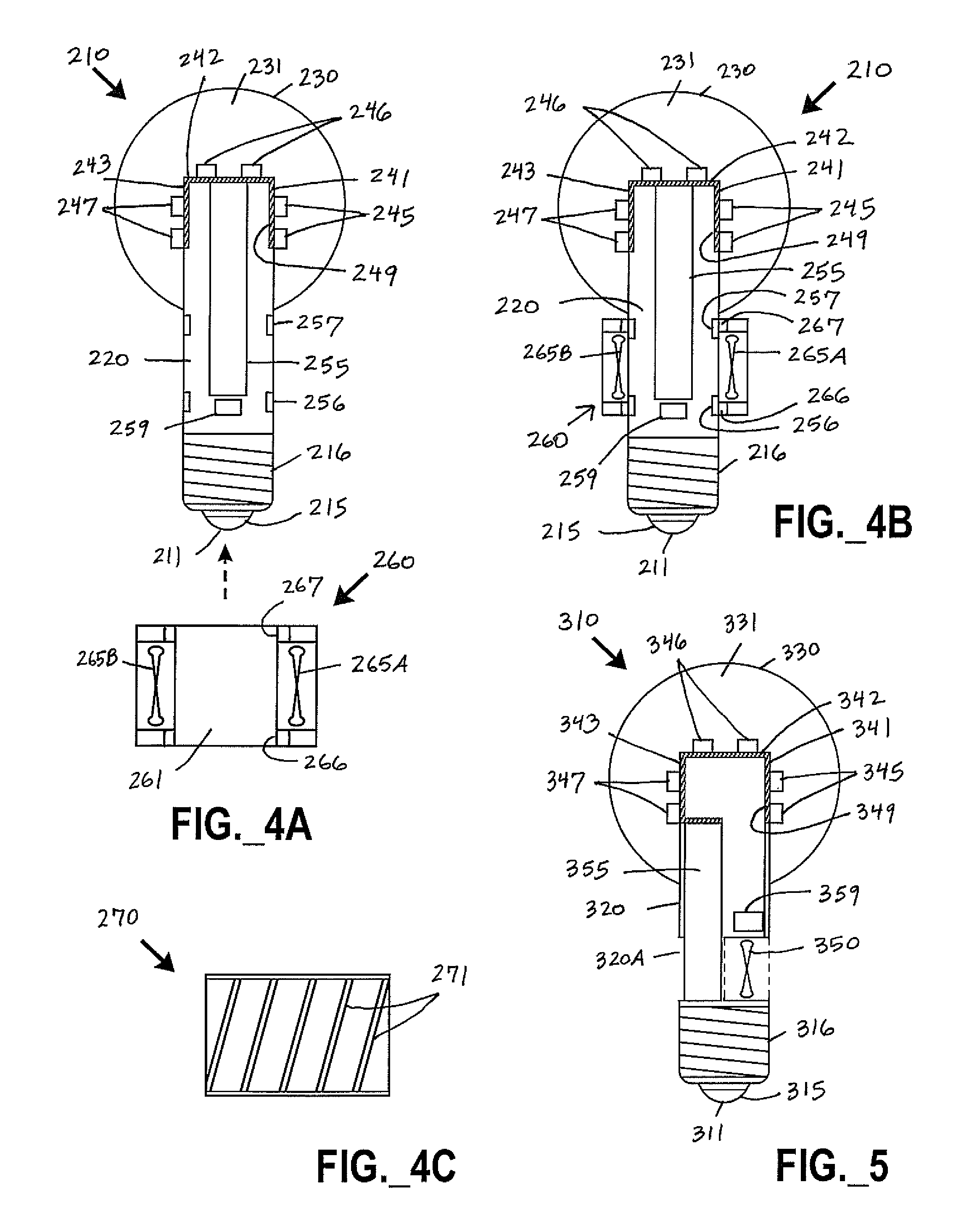

Method of manufacturing a lamp assembly

InactiveUS20050116650A1Improve power factorReduce power lossPoint-like light sourceElongate light sourcesElectric forceResonance

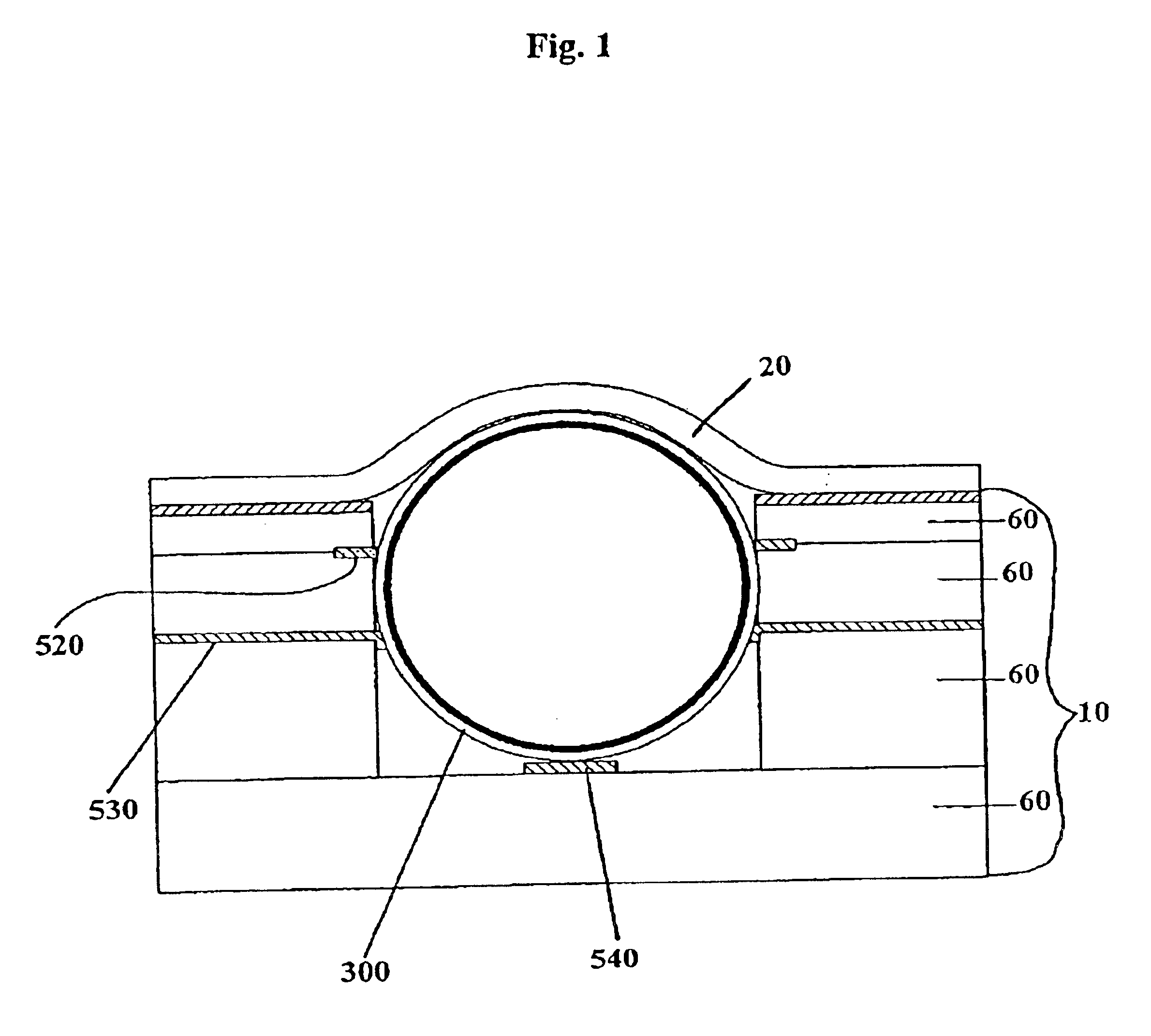

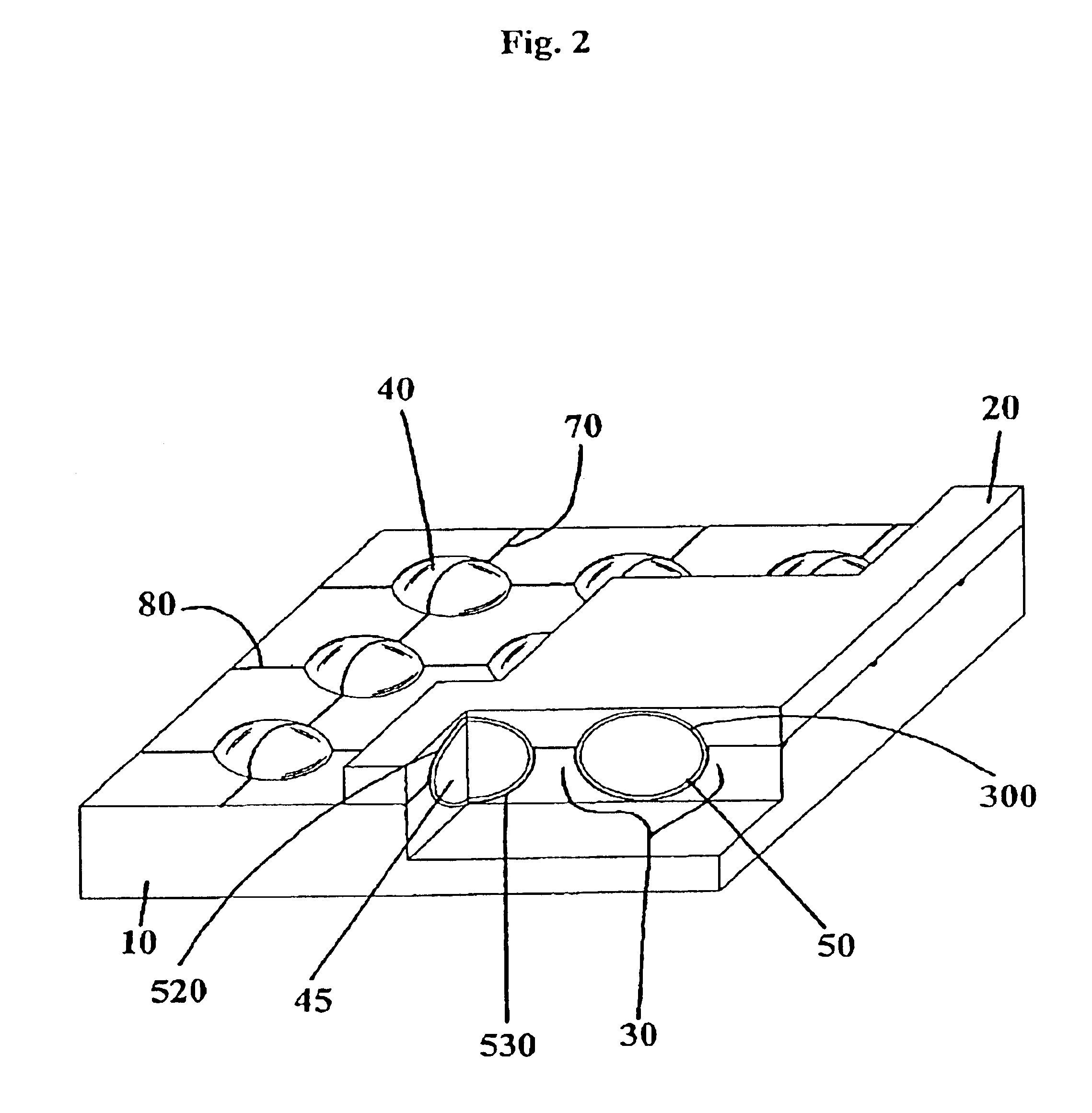

A lamp assembly configured to inductively receive power from a primary coil. The lamp assembly includes a lamp circuit including a secondary and a lamp connected in series. In a first aspect, the lamp circuit includes a capacitor connected in series with the lamp and the secondary to tune the circuit to resonance. The capacitor is preferably selected to have a reactance that is substantially equal to or slightly less than the reactance of the secondary and the impedance of the lamp. In a second aspect, the lamp assembly includes a sealed transparent sleeve that entirely encloses the lamp circuit so that the transparent sleeve is fully closed and unpenetrated. The transparent sleeve is preferably the lamp sleeve itself, with the secondary, capacitor and any desired starter mechanism disposed within its interior.

Owner:PHILIPS IP VENTURES BV

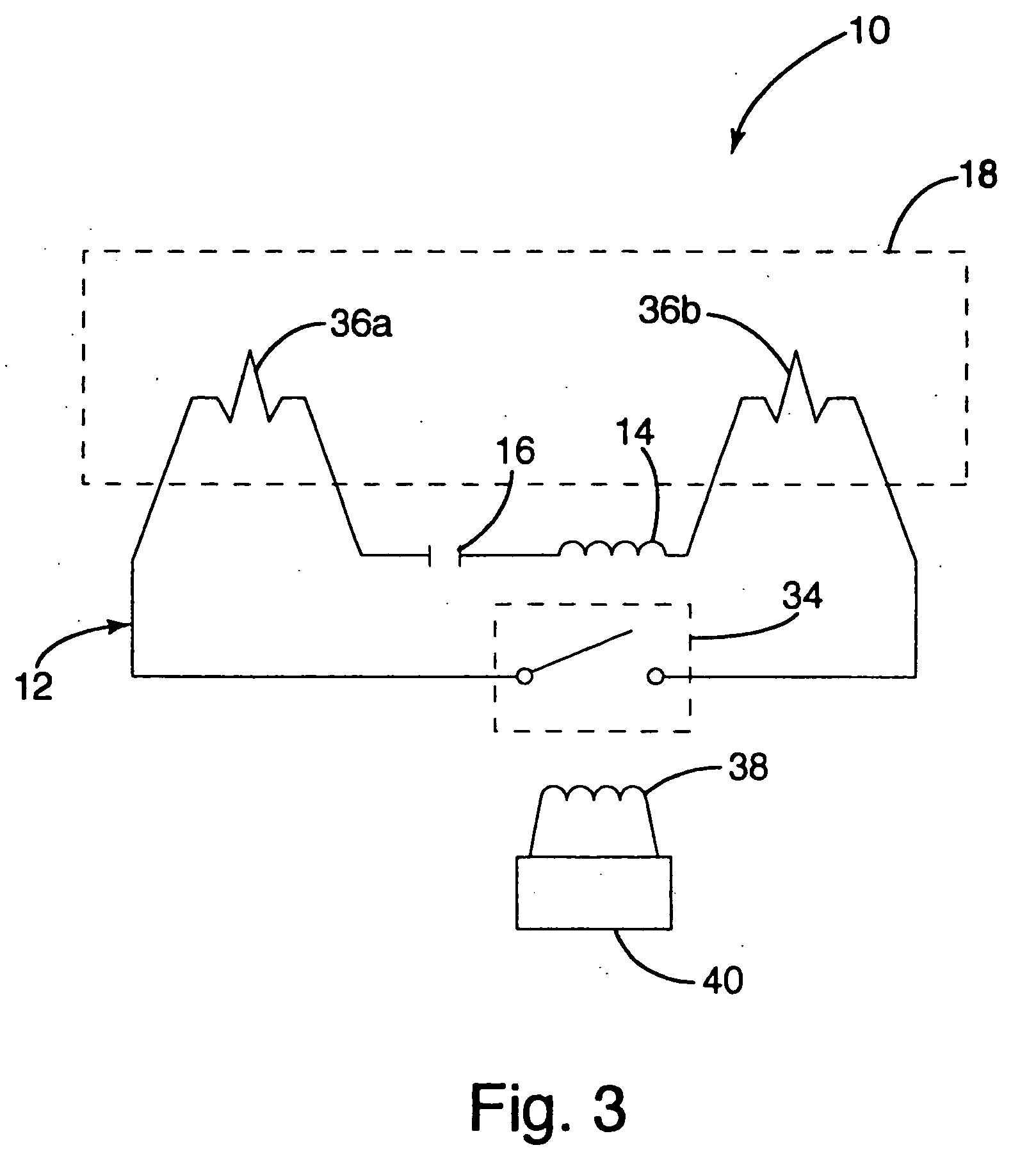

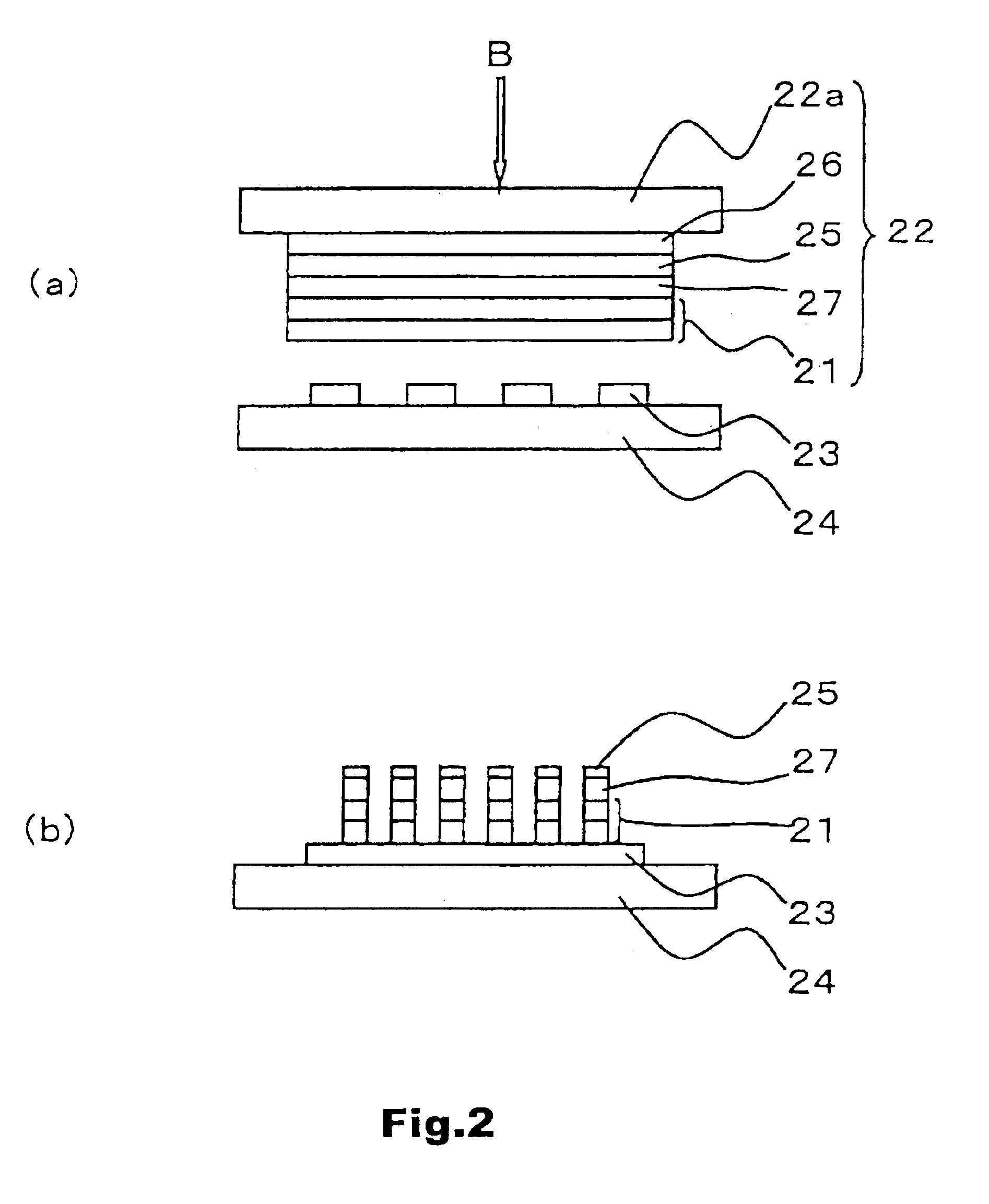

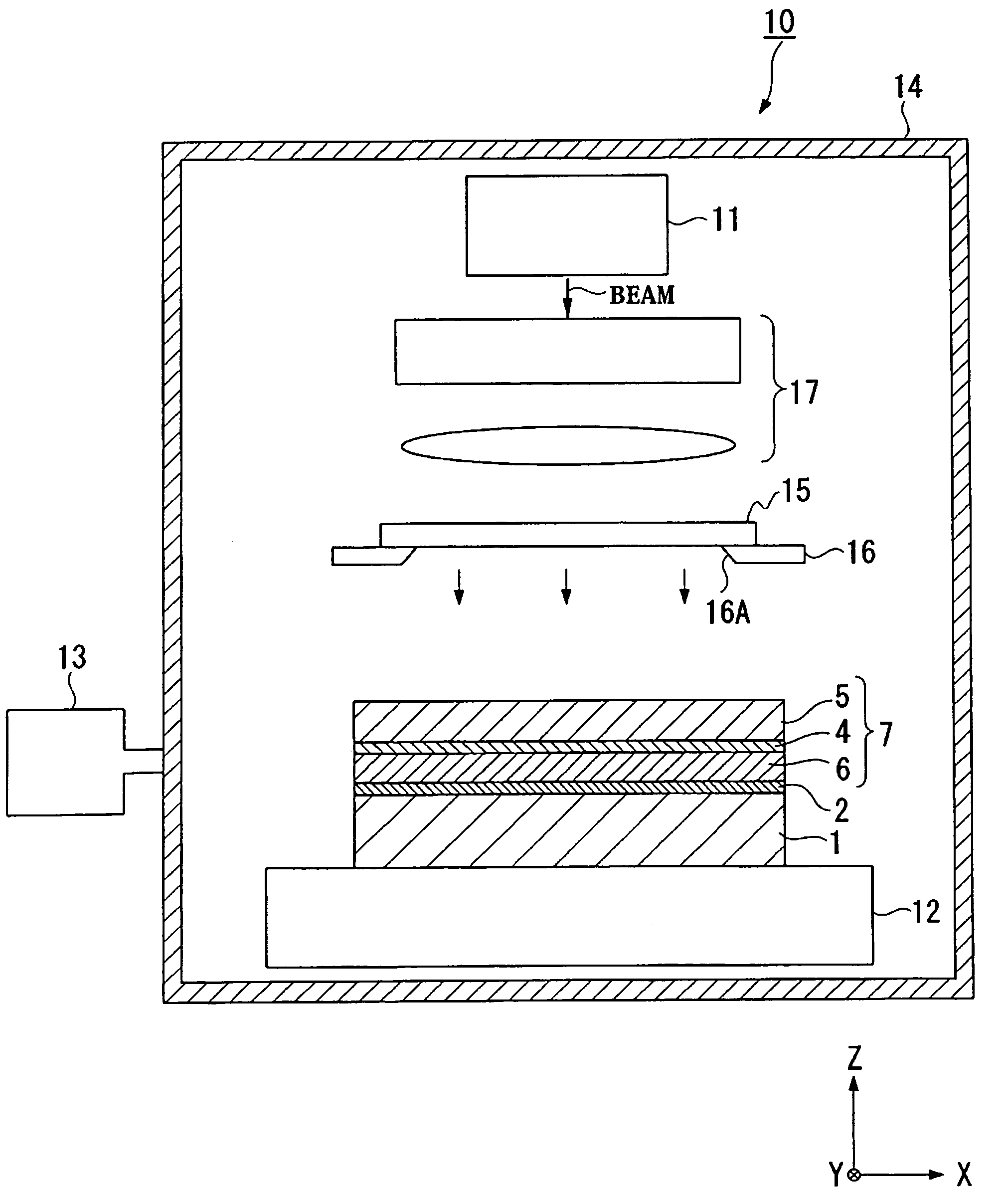

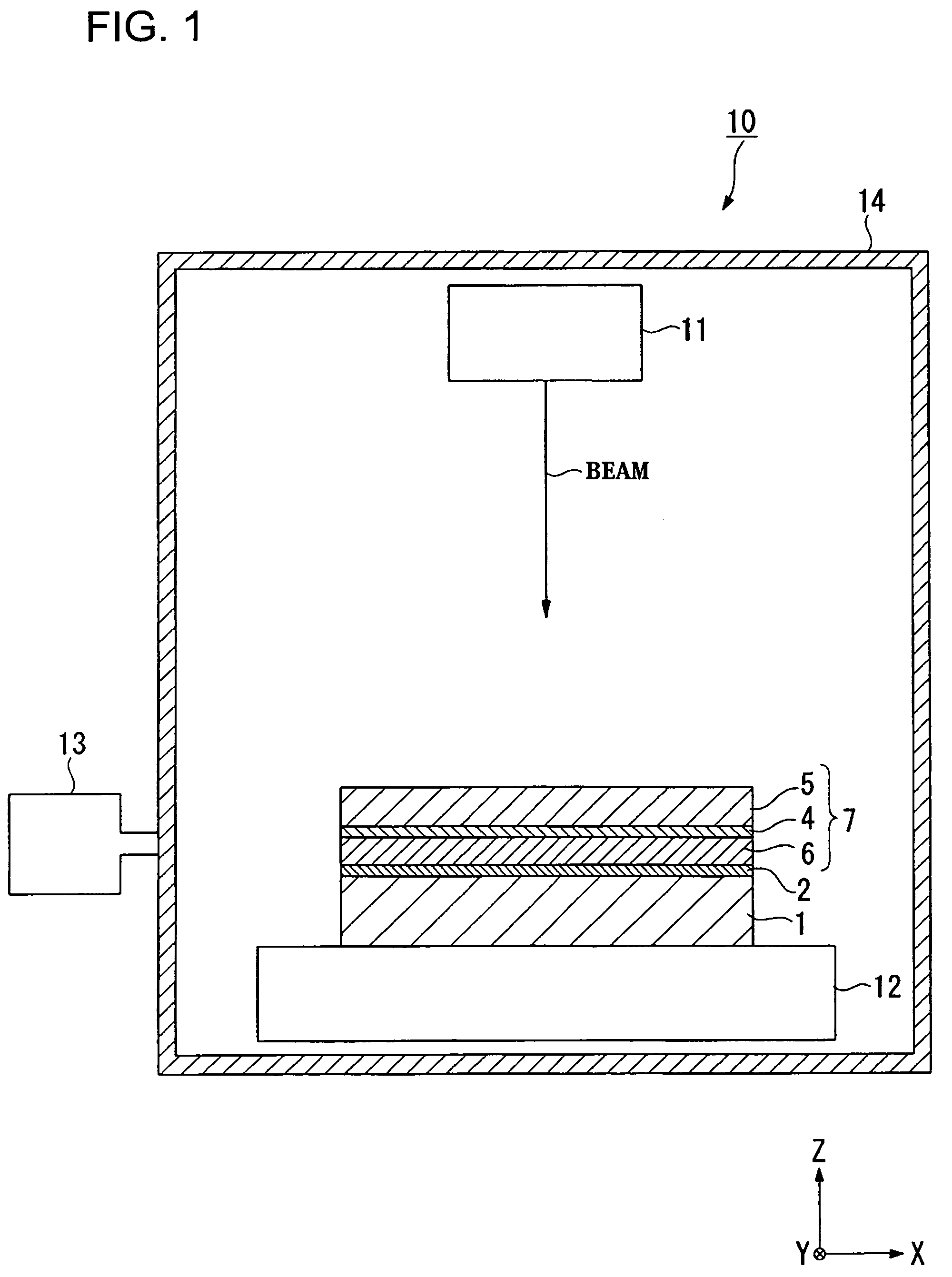

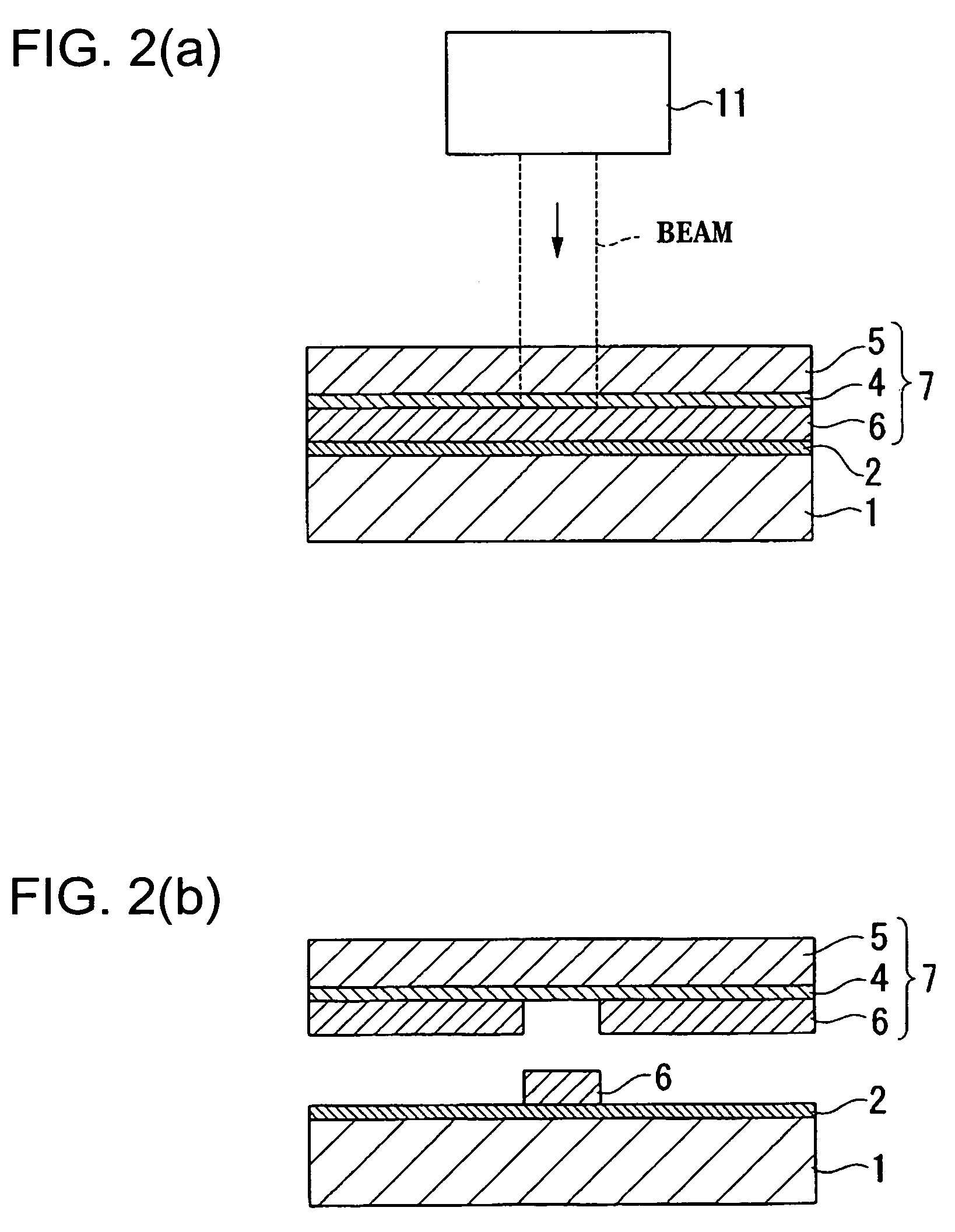

Transfer film and process for producing organic electroluminescent device using the same

InactiveUS6805979B2Decorative surface effectsCathode ray/electron stream lampsEngineeringOrganic electroluminescence

Owner:SHARP KK

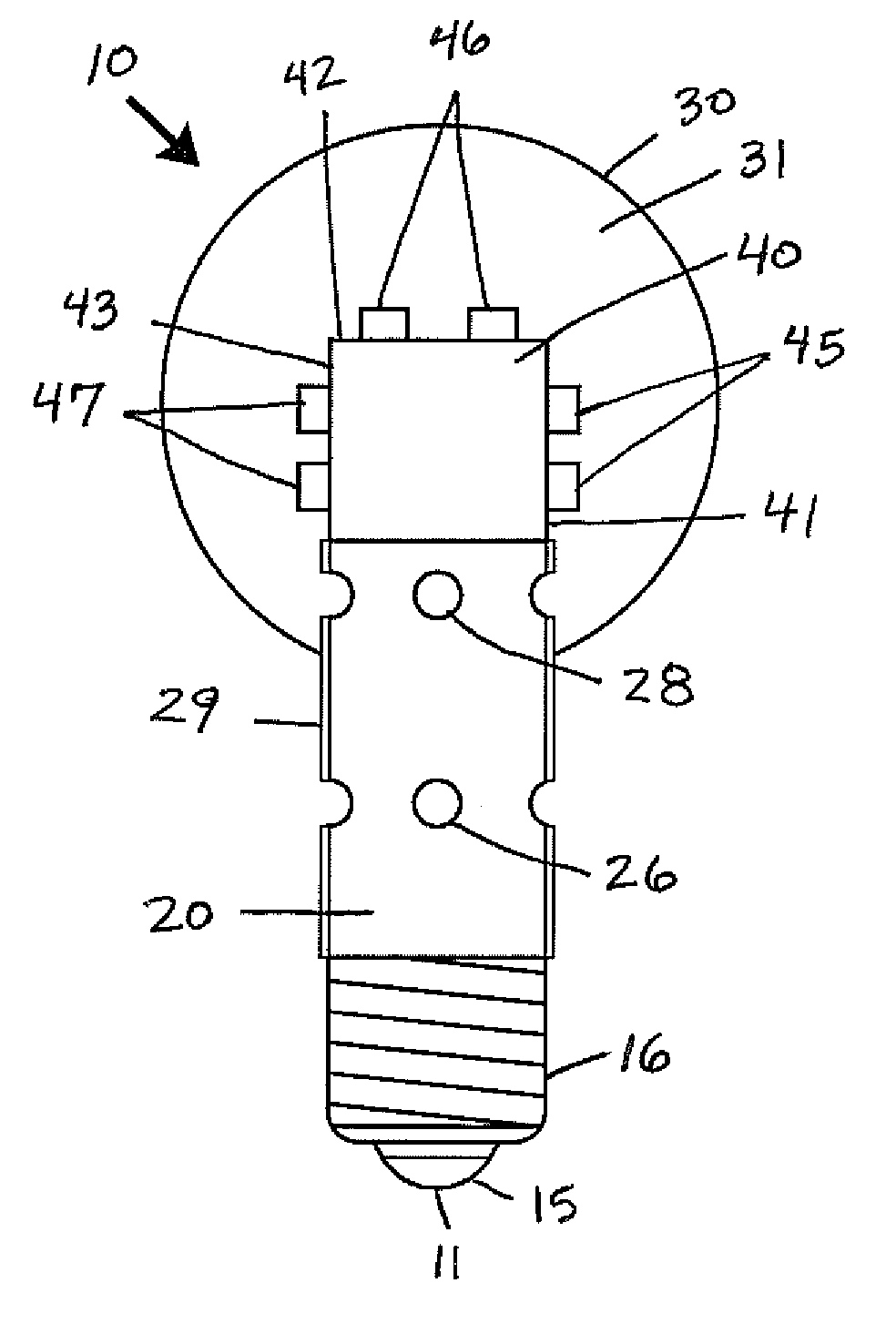

LED light bulbs

ActiveUS20110298371A1Address limitationsPlanar light sourcesPoint-like light sourceEngineeringLED lamp

LED light bulbs include openings in base or cover portions, and optional forced flow elements, for convective cooling. Thermally conductive optically transmissive material may be used for cooling, optionally including fins. A LED light engine may be fabricated from a substrate via planar fabrication techiques and shaped to form a substantially rigid upright support structure. Mechanical, electrical, and thermal connections may be made between a LED light engine and a LED light bulb.

Owner:IDEAL IND LIGHTING LLC

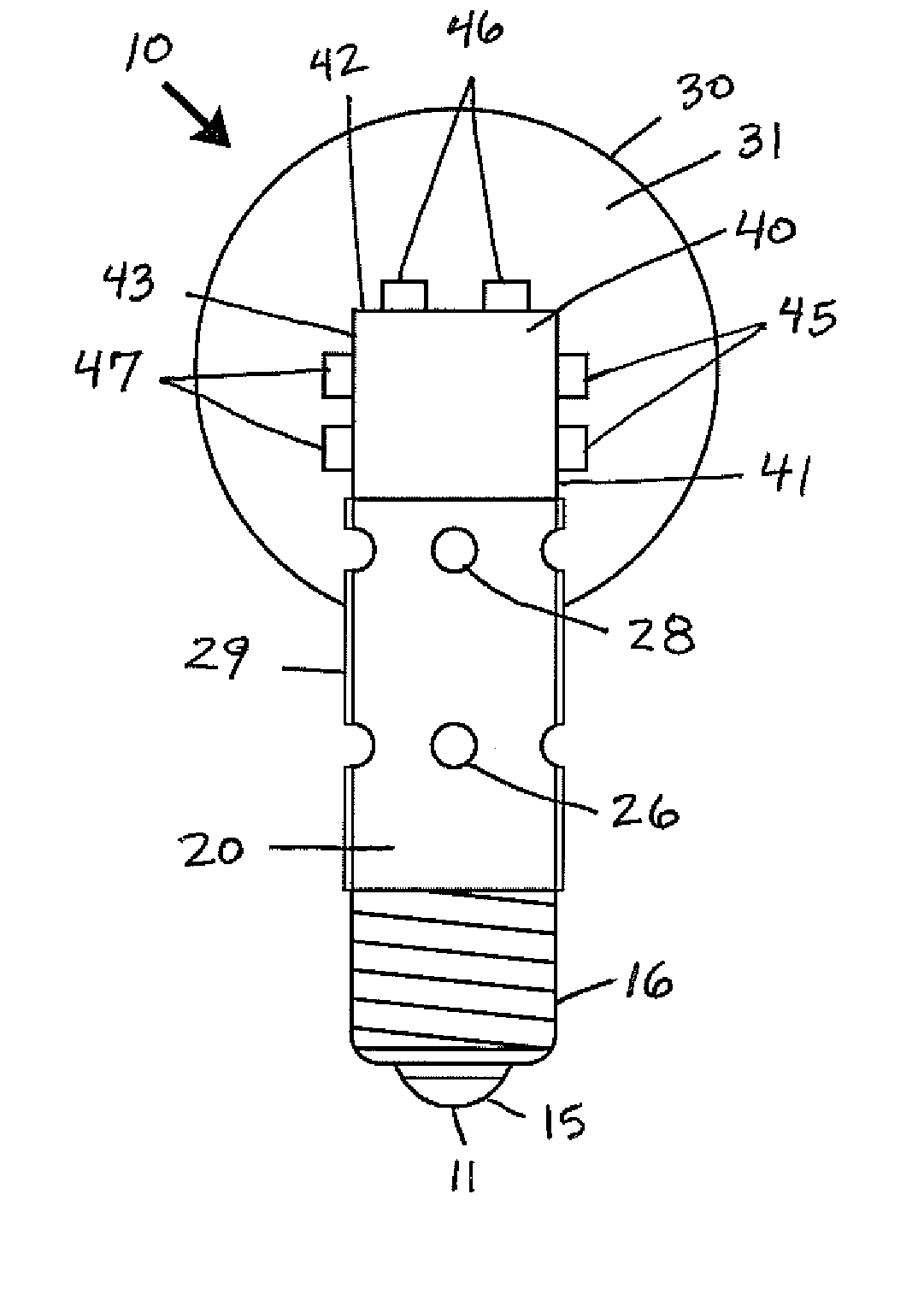

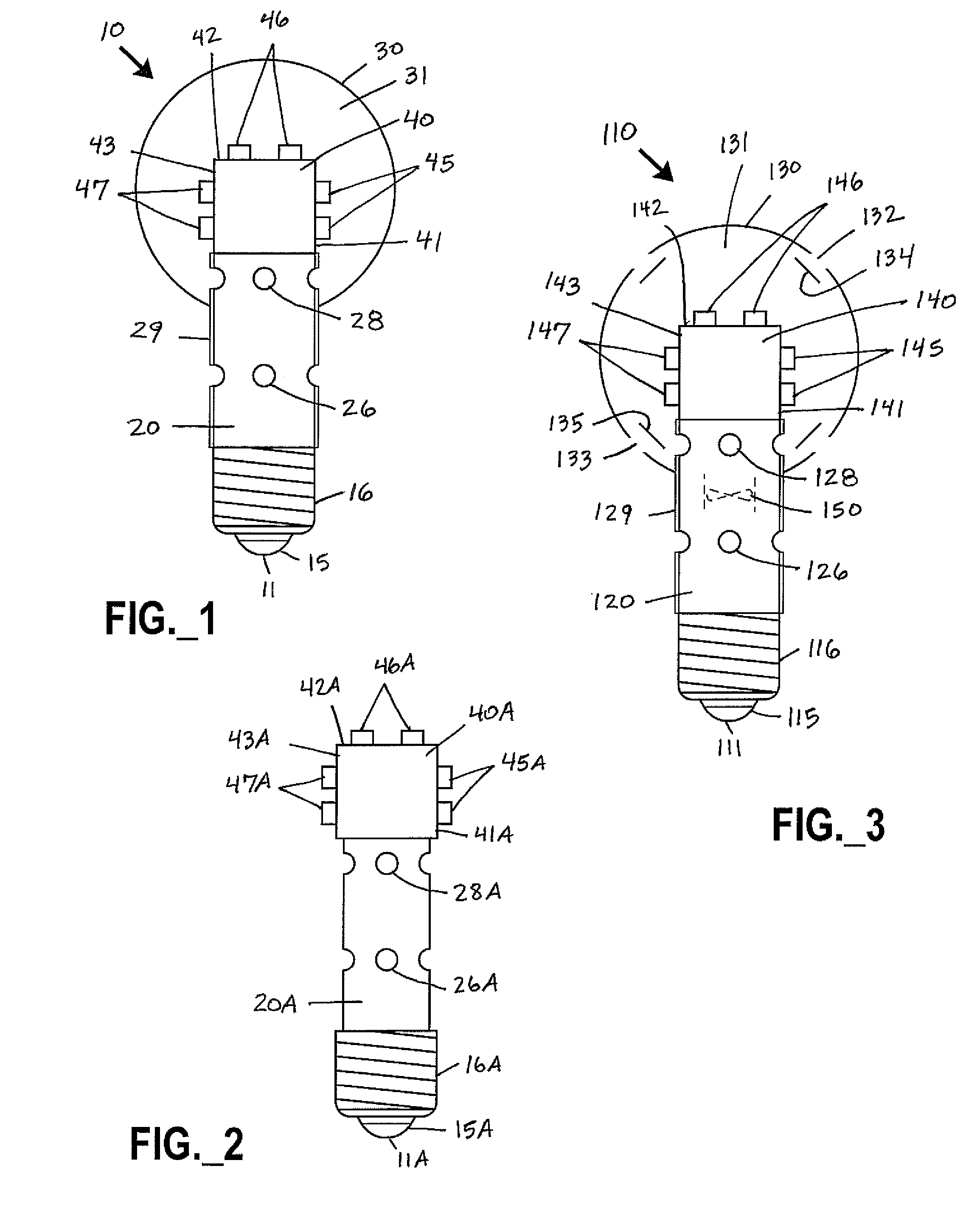

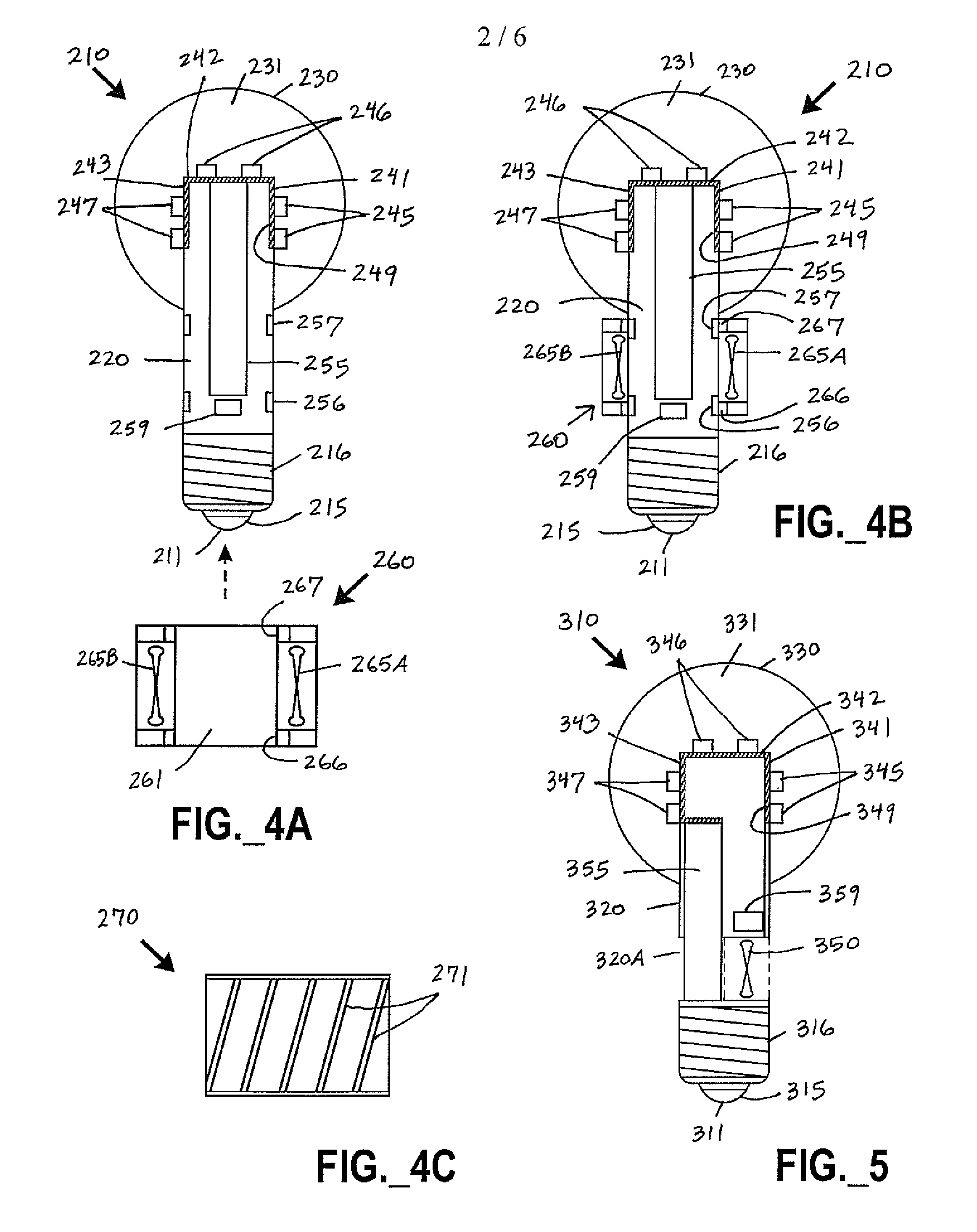

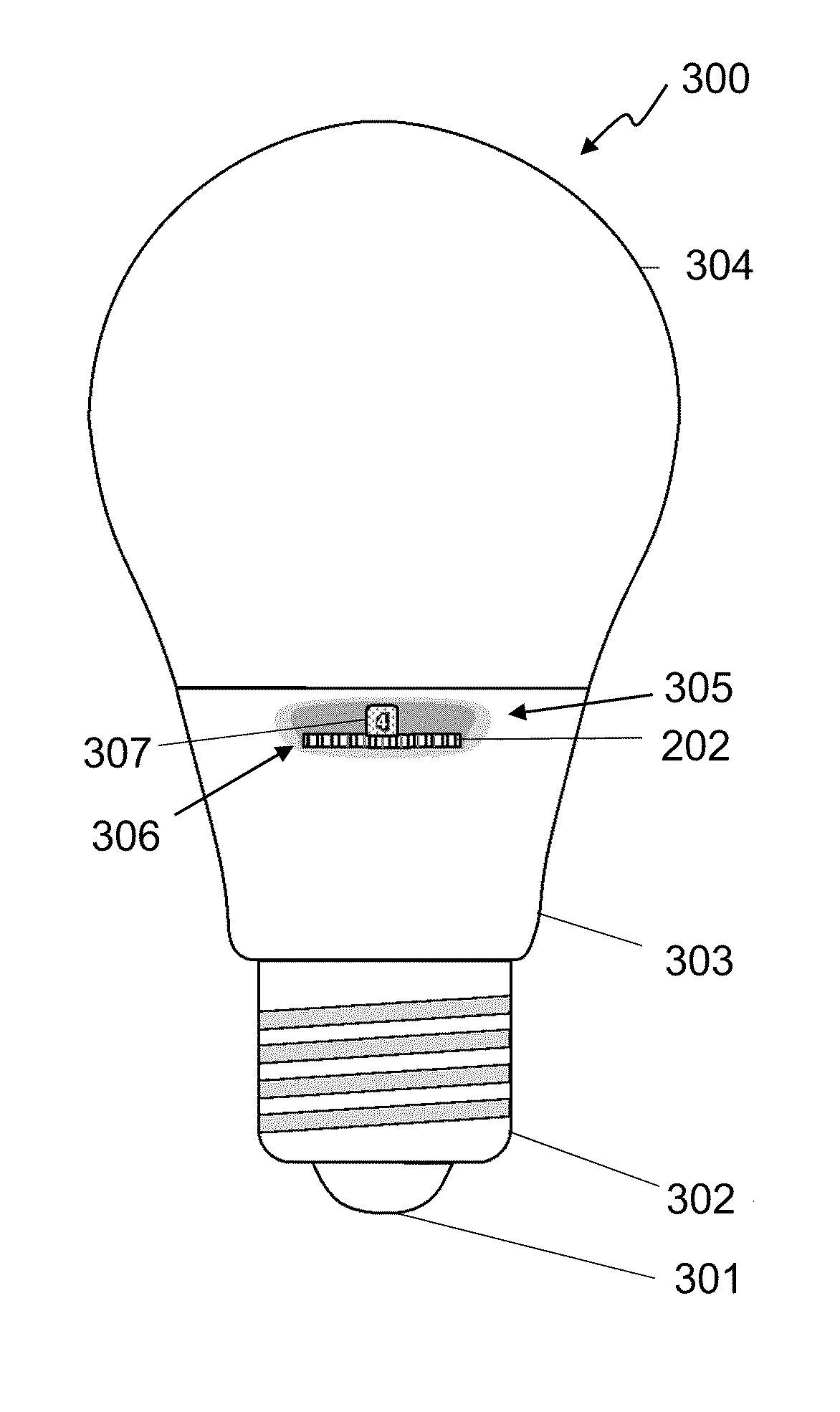

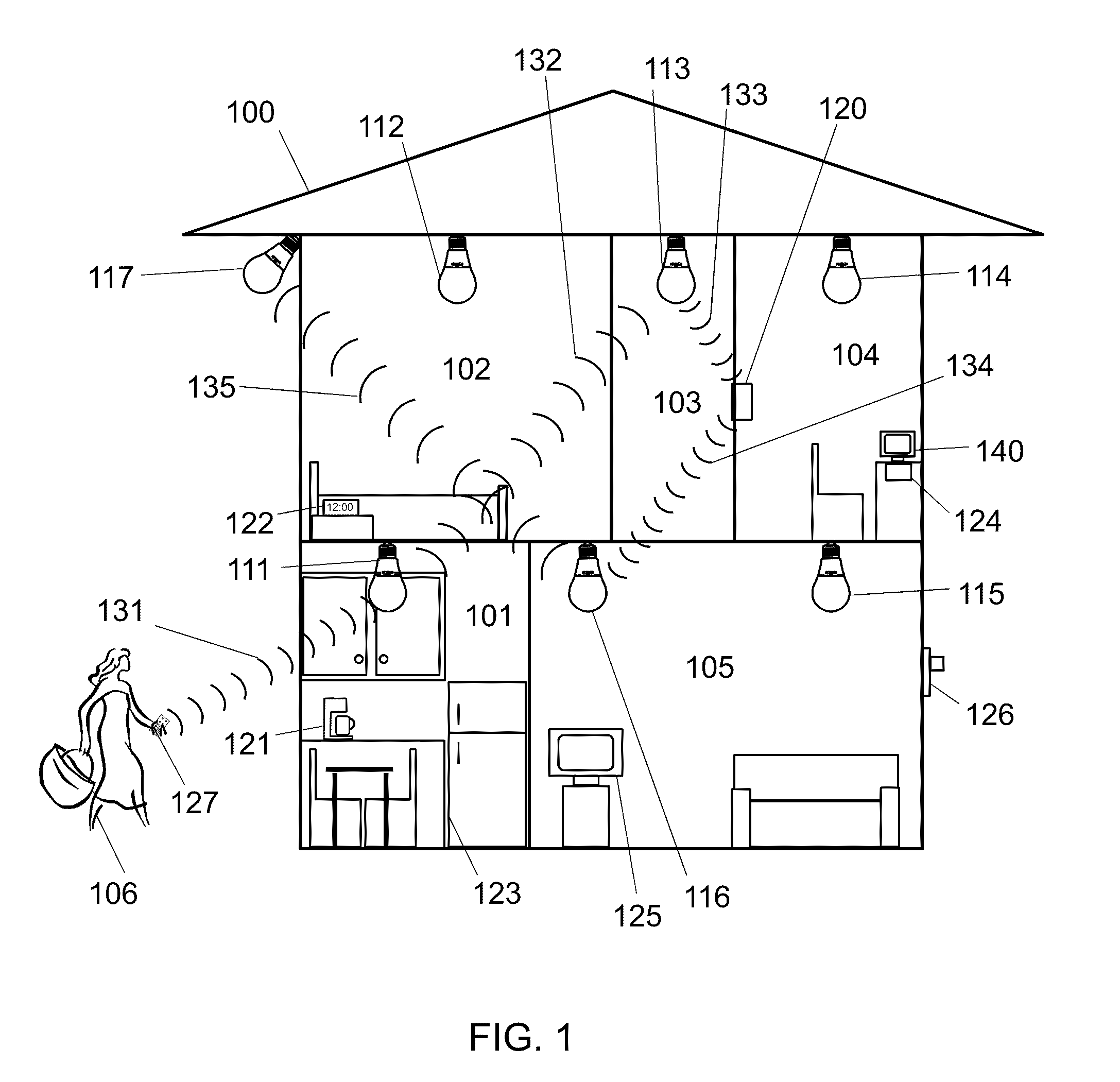

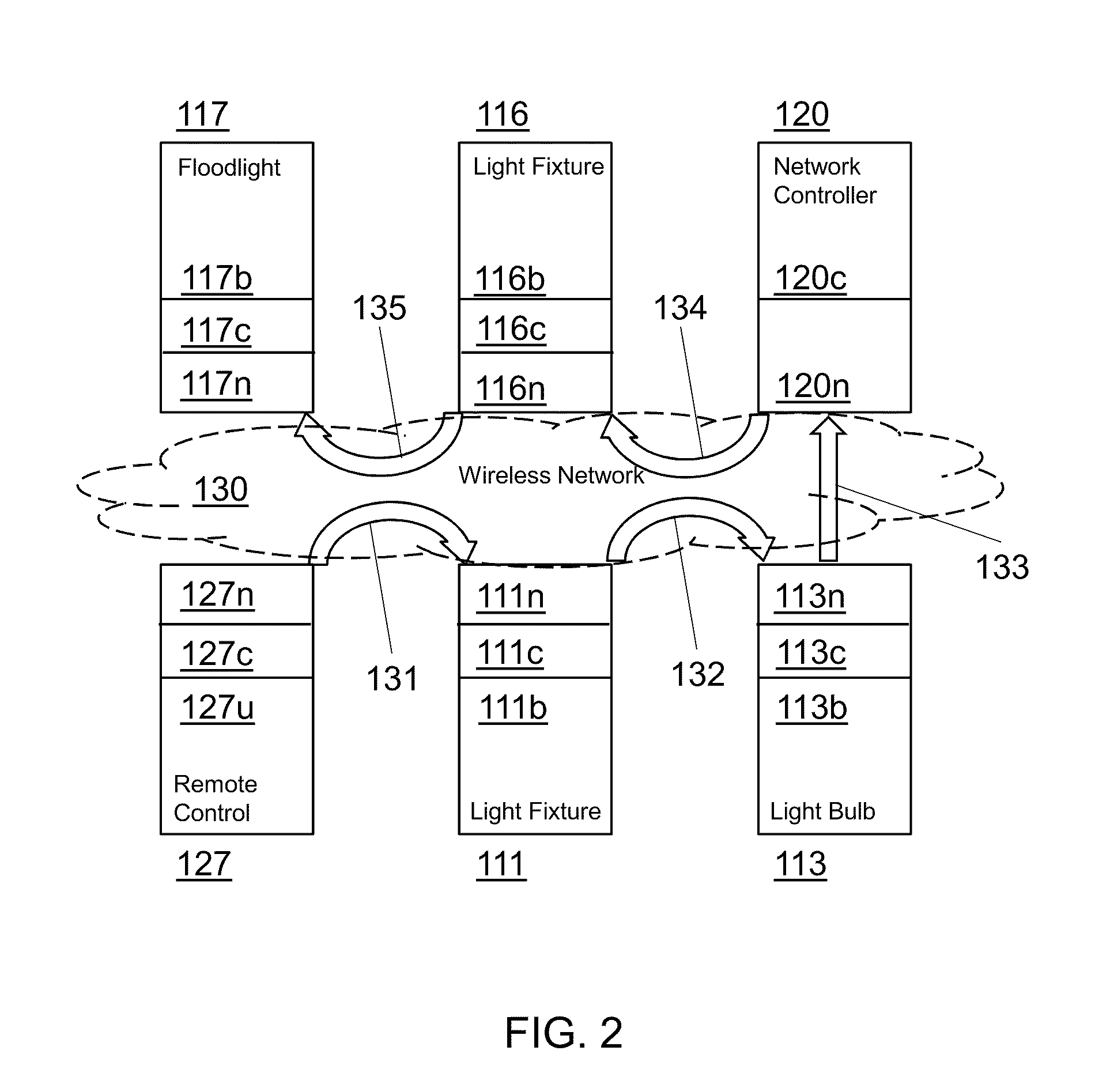

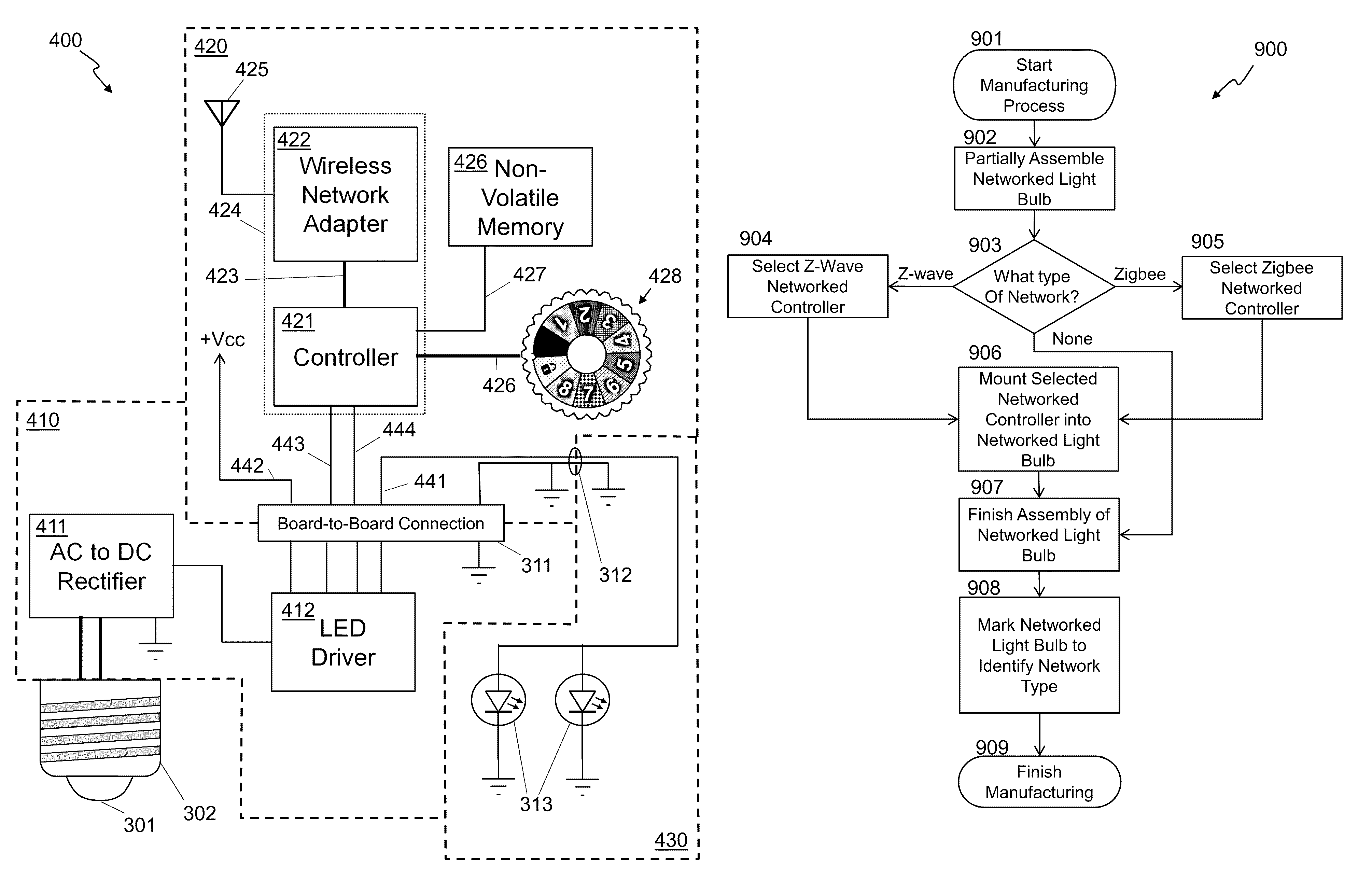

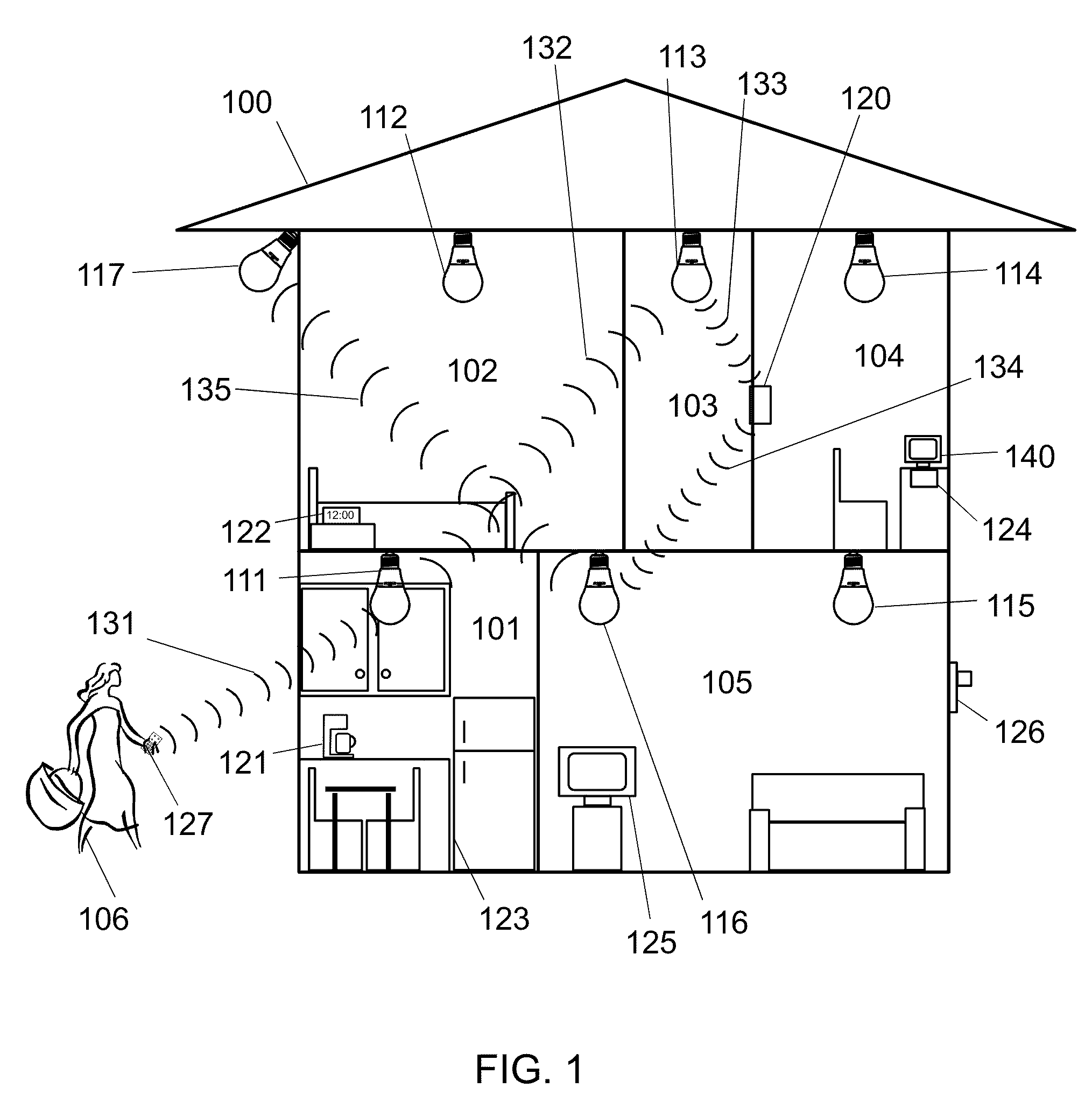

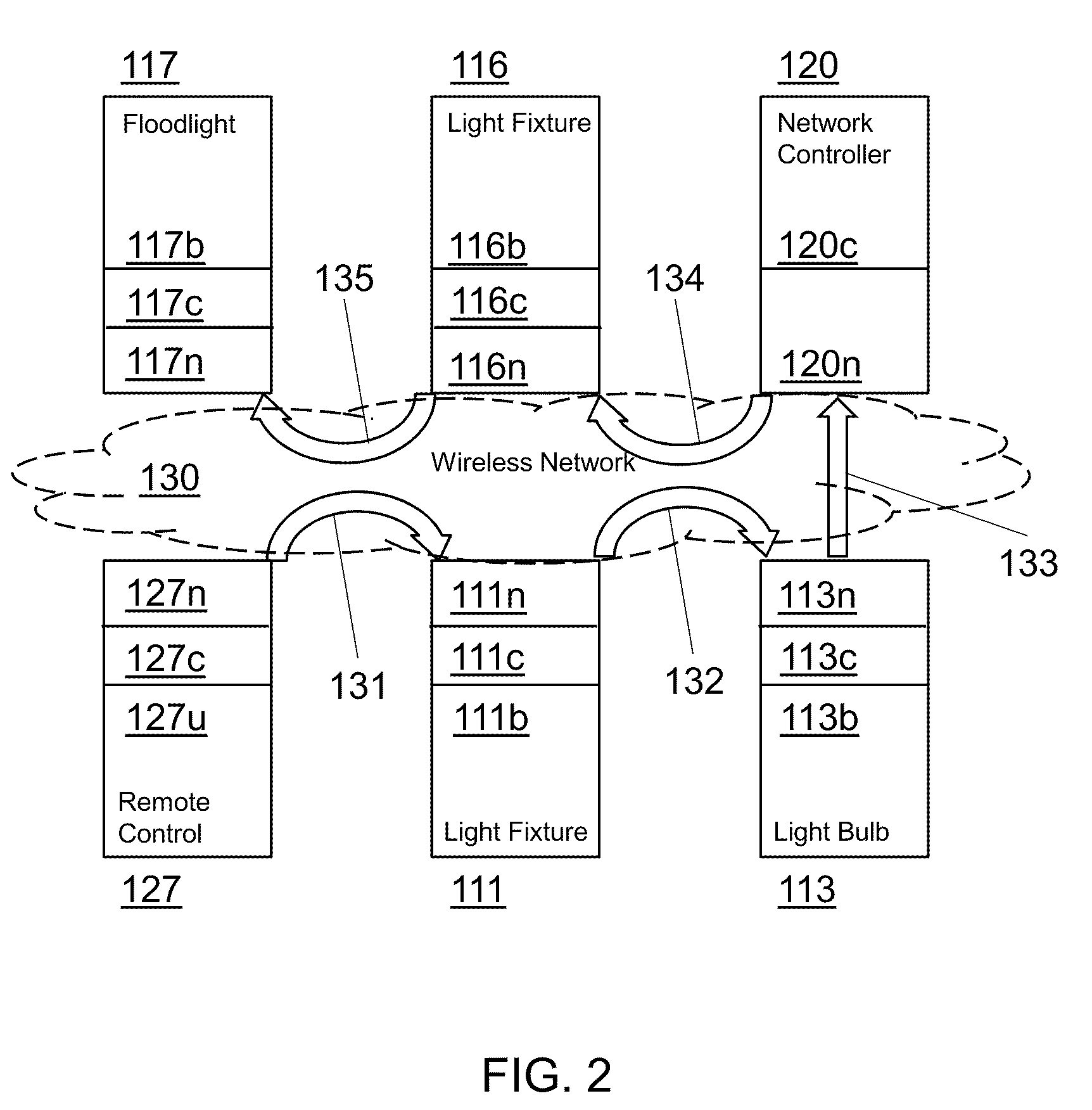

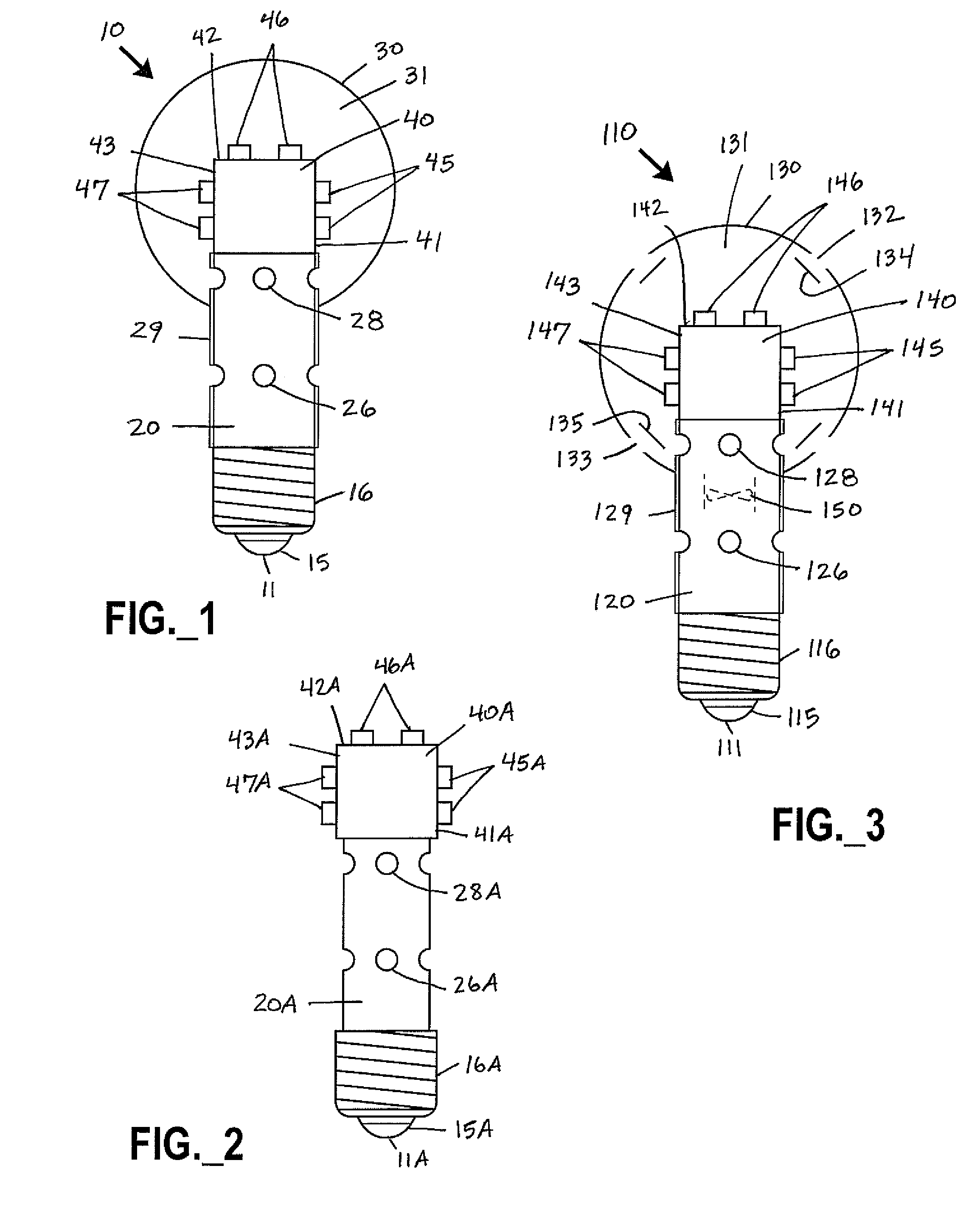

Modular Networked Light Bulb

ActiveUS20110095687A1Point-like light sourceElectric circuit arrangementsElectricityNetworking protocol

Various methods of manufacturing a lighting apparatus and embodiments of a modular networked lighting apparatus are disclosed. One method defines a mechanical form factor with a minimum set of electrical connections for a networking module, builds a subassembly of the networked lighting apparatus, the subassembly comprising attachment points compatible with the mechanical form factor for the networking module and contacts for the minimum set of electrical connections for the networking module, installs a networking module into the subassembly of the networked lighting apparatus, the networking module compatible with a selected networking protocol for the networked lighting apparatus, completes the final assembly of the networked lighting module, and marks the networked lighting apparatus to indicate the selected networking protocol for the networked lighting apparatus. In some embodiments, the lighting apparatus may function without the networking module installed. One embodiment of the modular, networked light bulb has means for supporting and holding an electronics module conforming with a predetermined form factor in place, and means for allowing the electronics module to control at least a brightness level of the at least one LED. The modular networked light bulb may have a networked controller conforming with the predetermined form factor used as the electronics module. The networked controller is able to connect to a network and may be positioned and held by the means for supporting and holding an electronics module.

Owner:SIGNIFY HLDG BV

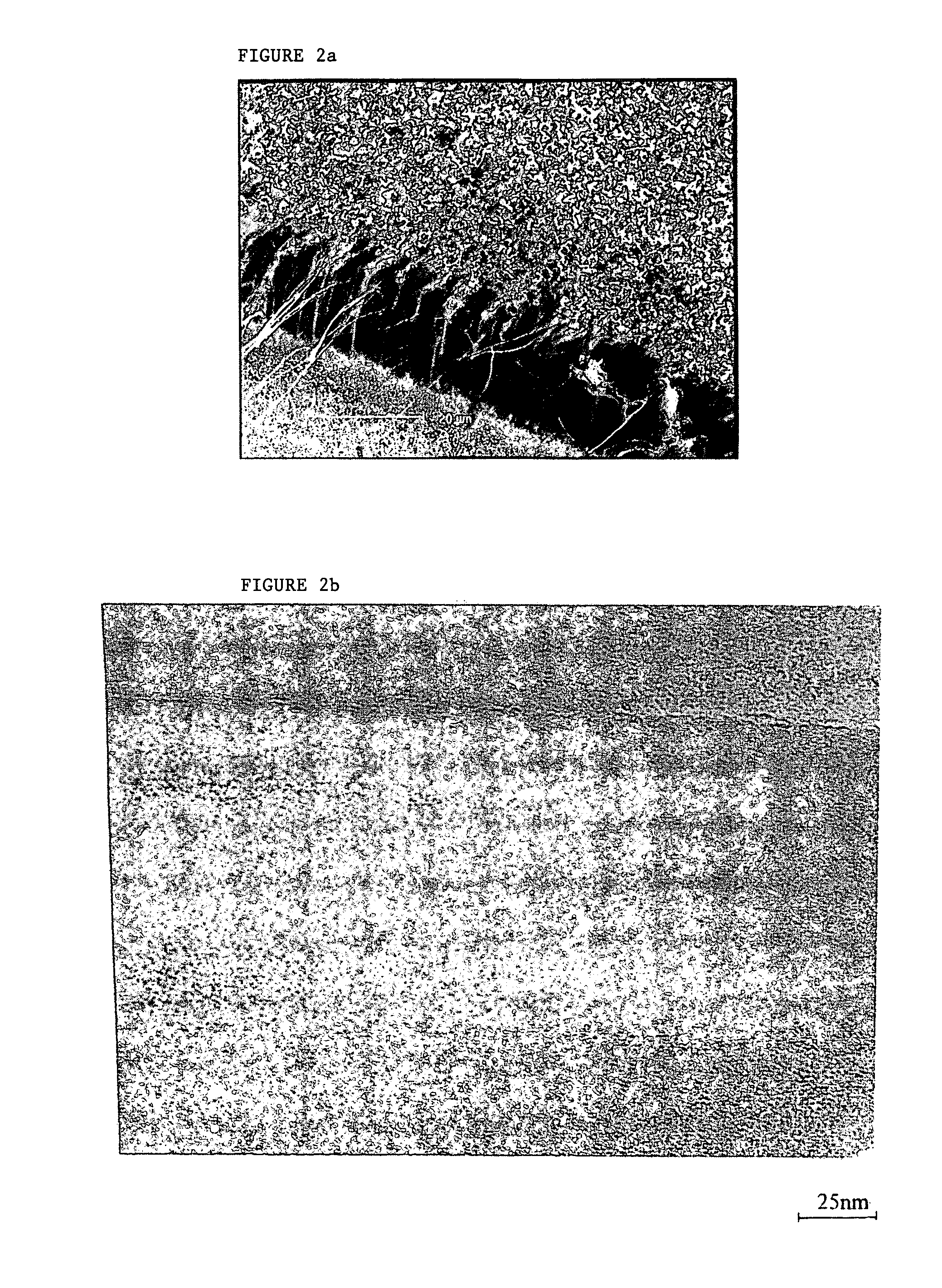

Substrate-supported aligned carbon nanotube films

InactiveUS7799163B1Conveniently routedIncreases potential applicationMaterial nanotechnologyCarbon compoundsNanotube

This invention relates to a process for preparing a substrate-supported aligned carbon nanotube film including: synthesizing a layer of aligned carbon nanotubes on the substrate capable of supporting nanotube growth, applying a layer of a second substrate to a top surface of aligned carbon nanotube layer, removing said substrate capable of supporting nanotube growth to provide an aligned carbon nanotube film supported on said second substrate.

Owner:UNIV OF DAYTON THE

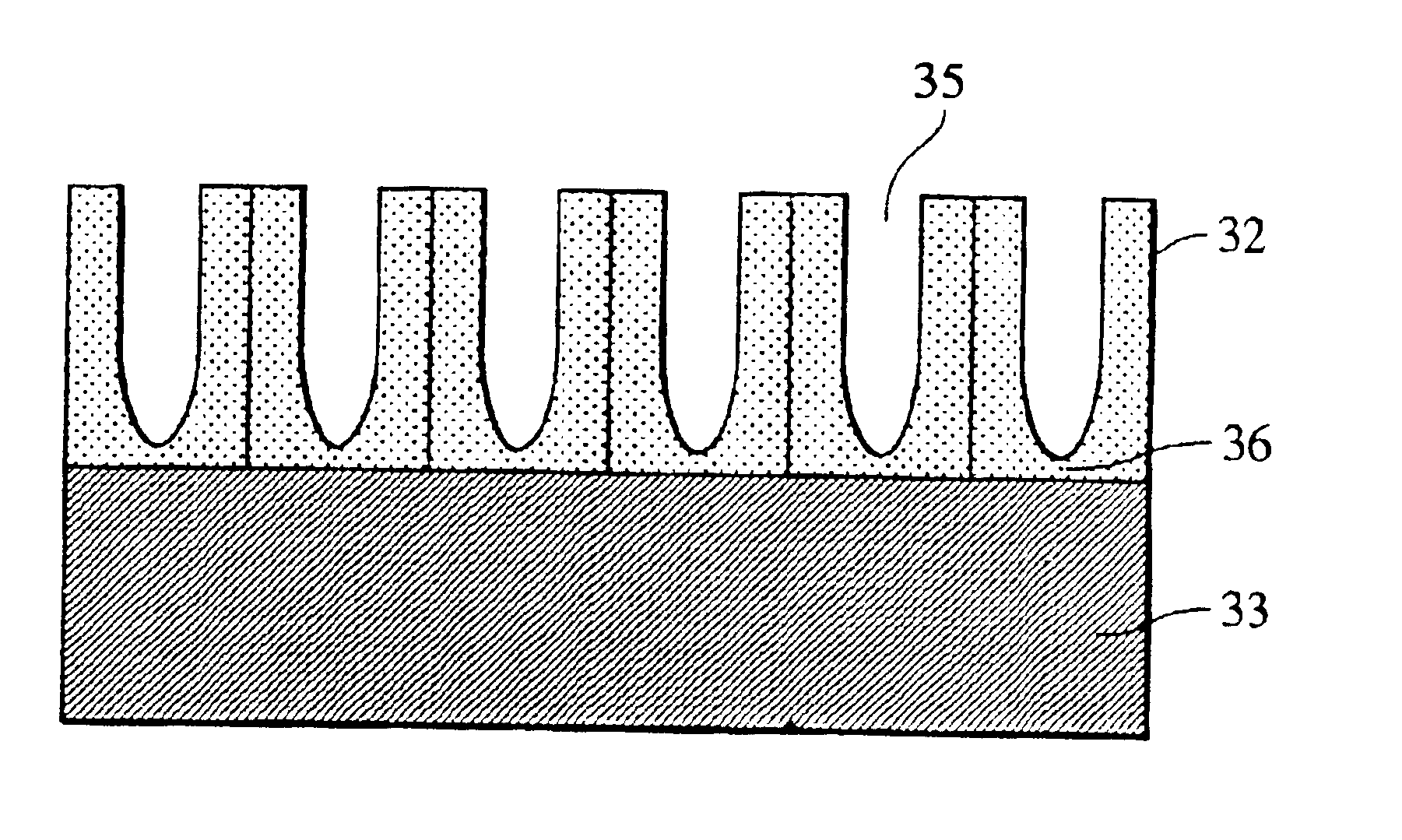

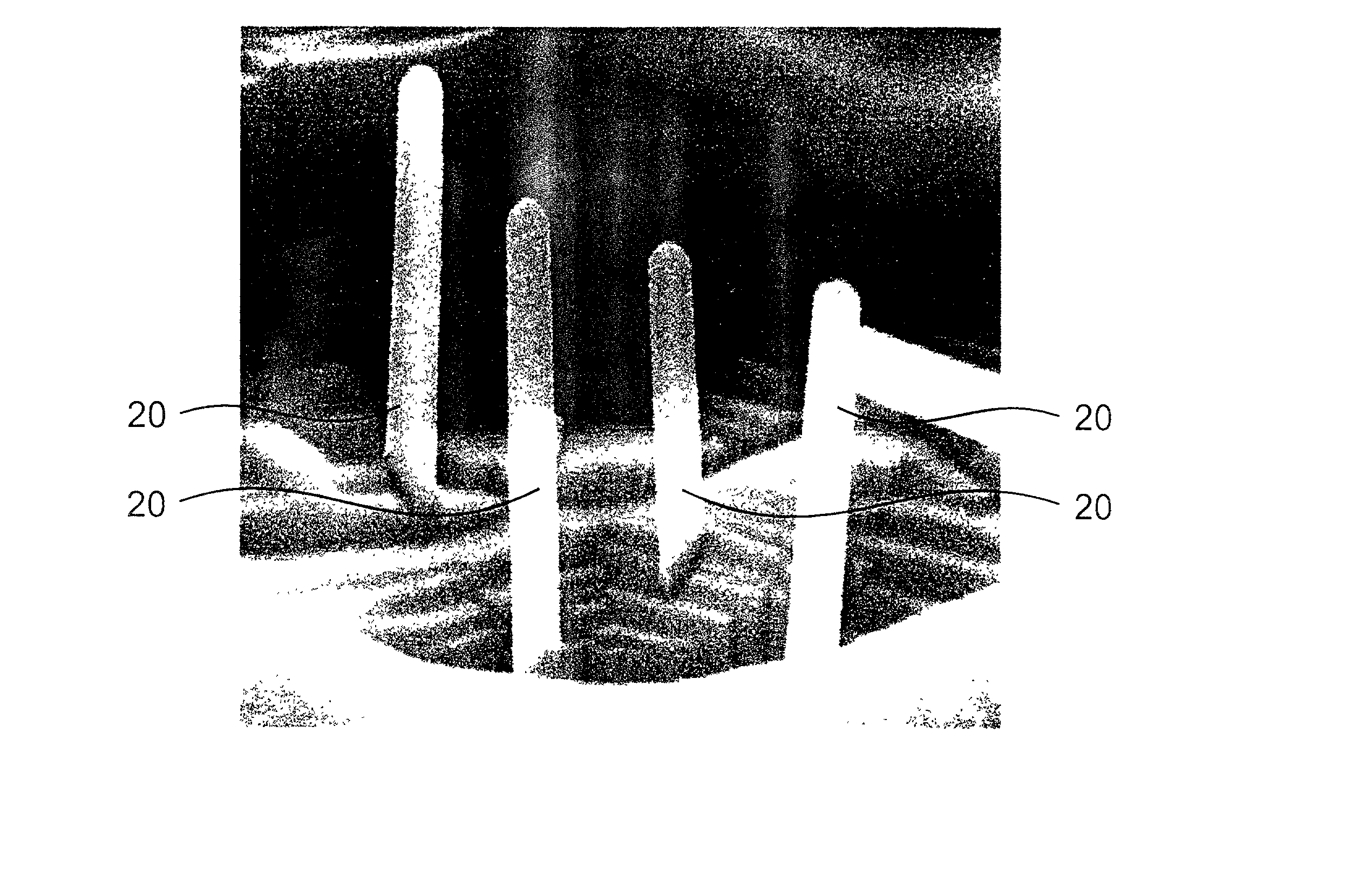

Nanostructure, electron emitting device, carbon nanotube device, and method of producing the same

InactiveUS6838297B2Good shape uniformityReliably producedNanostructure manufactureNanomagnetismNanoholeCarbon nanotube

Owner:CANON KK

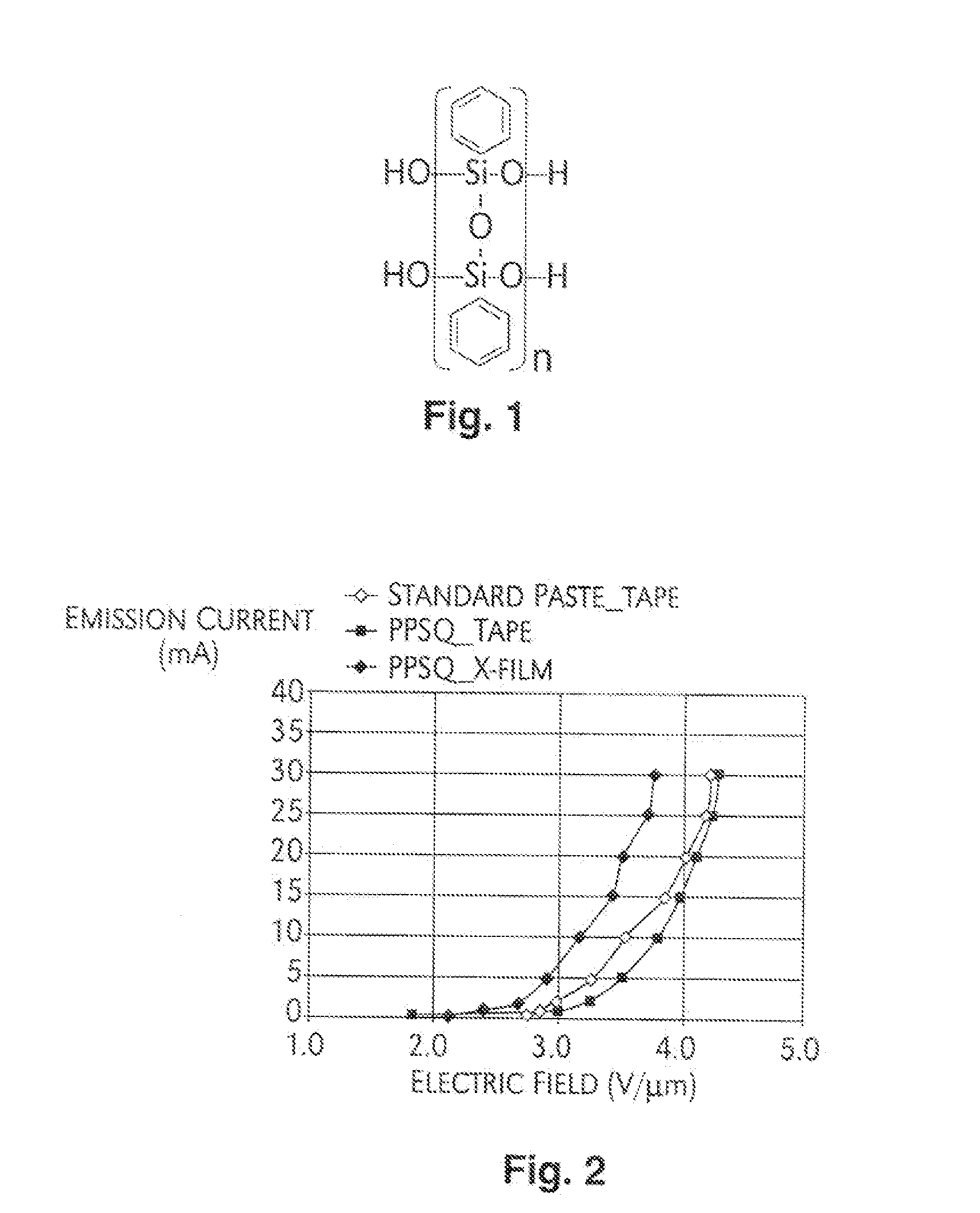

Curing binder material for carbon nanotube electron emission cathodes

InactiveUS20070262687A1Improve adhesionReduce exhaustMaterial nanotechnologyCathode ray/electron stream lampsField emission deviceBiological activation

A binder material, inorganic polymer, is used to formulate carbon nanotube pastes. This material can be cured at 200° C. and has a thermal-stability up to 500° C. Low-out gassing of this binder material makes it a good candidate for long life field emission devices. Due to better adhesion with this binder material, a strong adhesive peelable polymer from liquid form can be applied on the CNT cathode to achieve a uniform activation with even contact and pressure on the surface. The peelable polymer films may be used both as an activation layer and a mask layer to fabricate high-resolution patterned carbon nanotube cathodes for field emission devices using lithographic processes.

Owner:SAMSUNG ELECTRONICS CO LTD

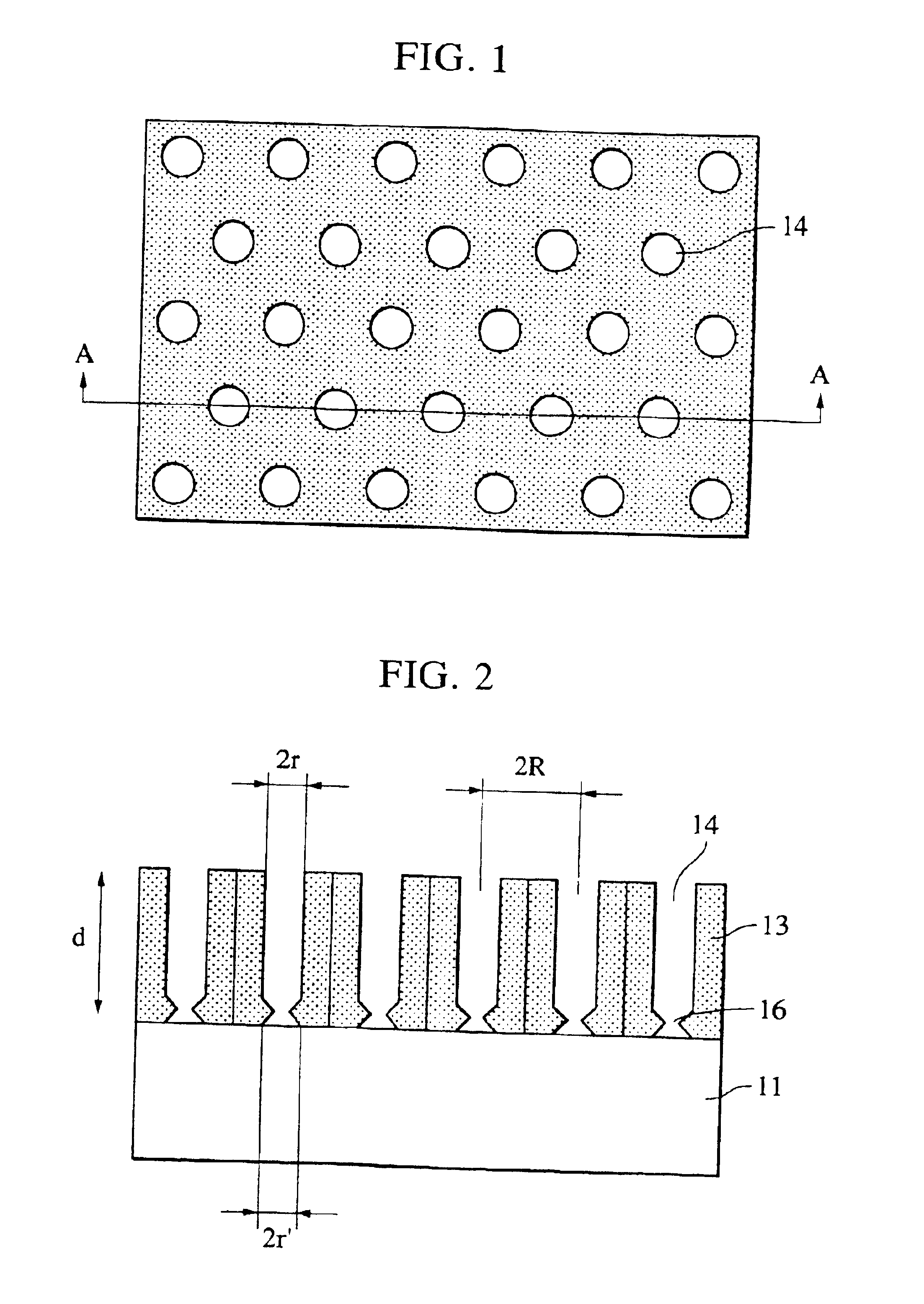

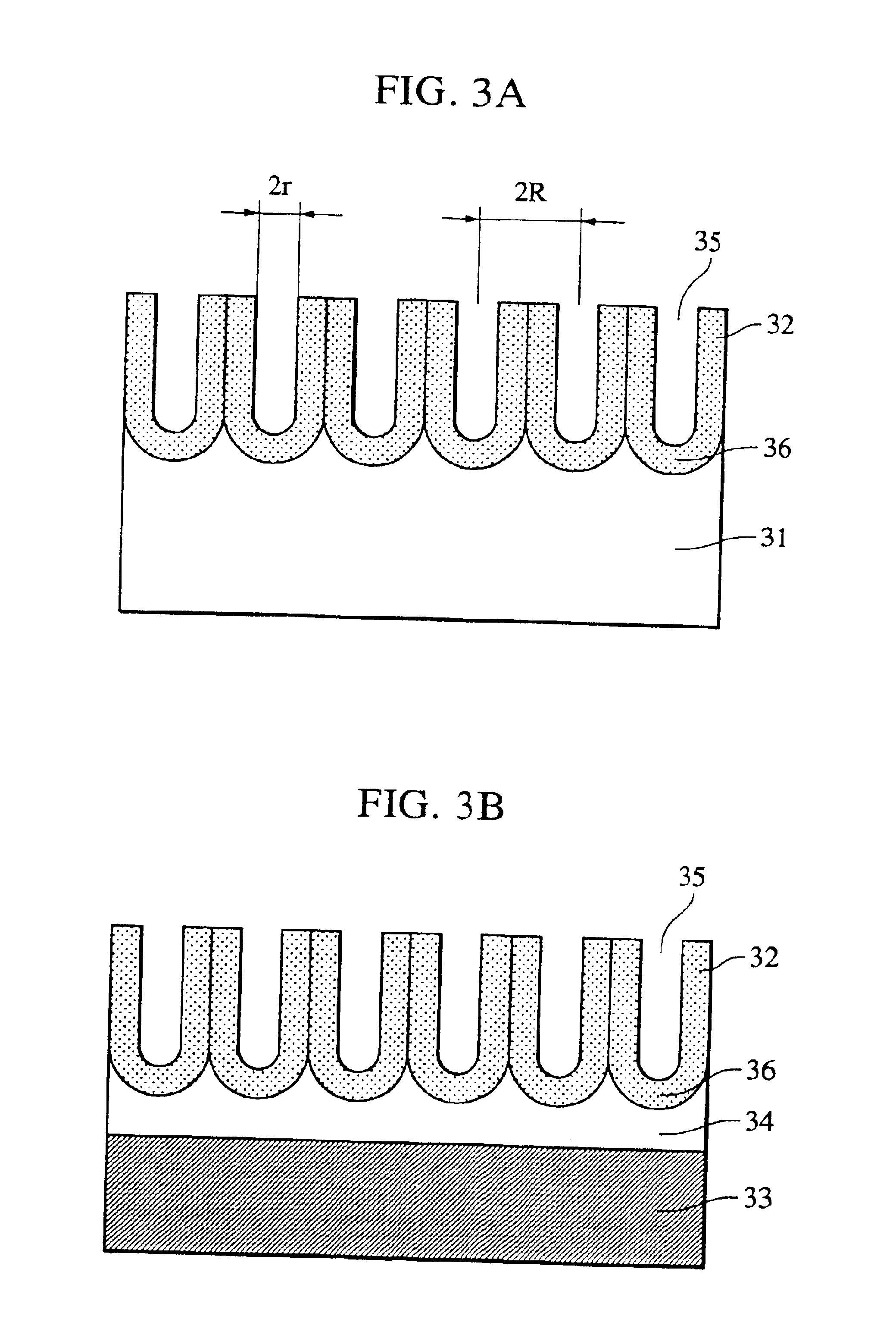

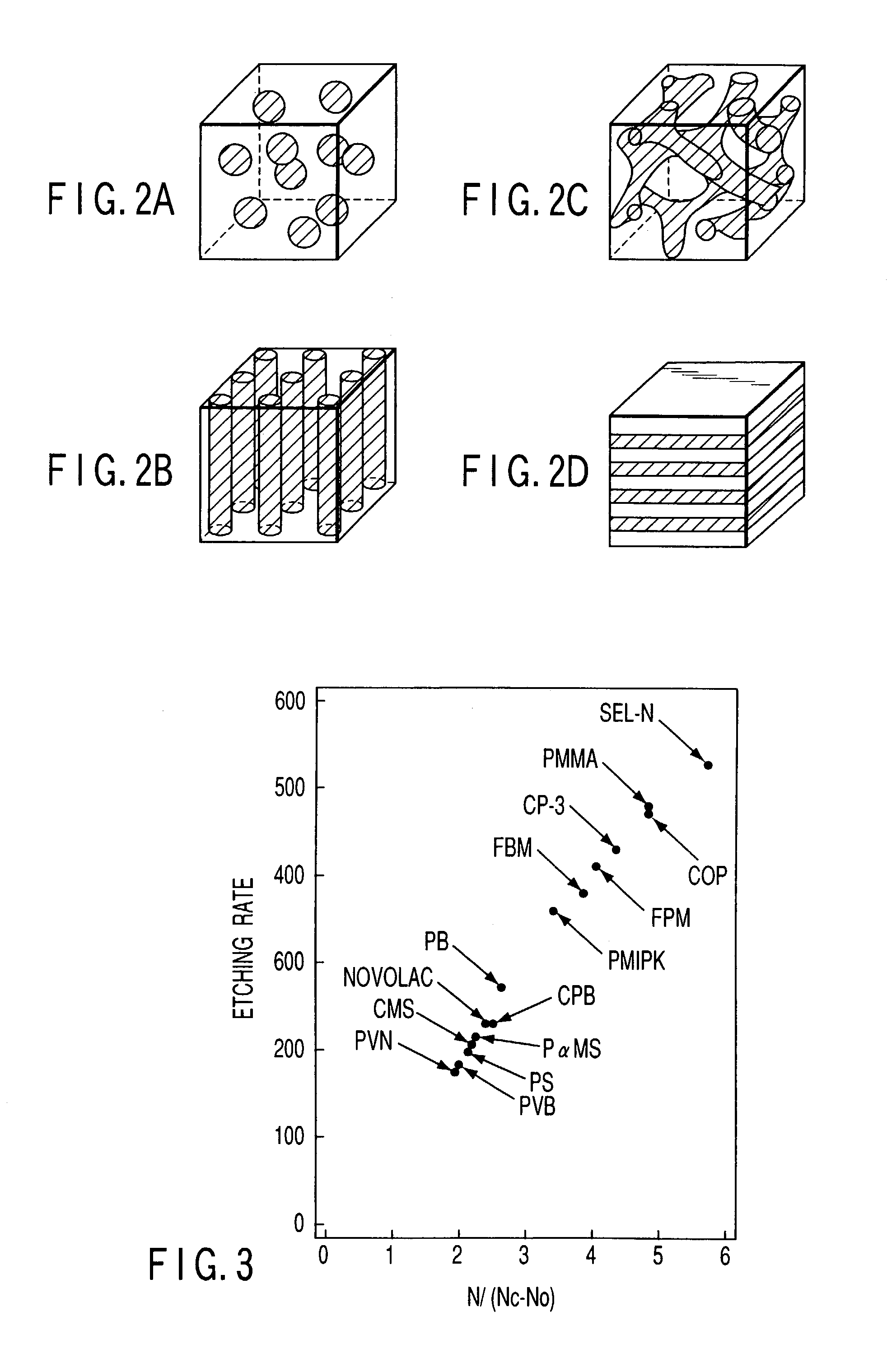

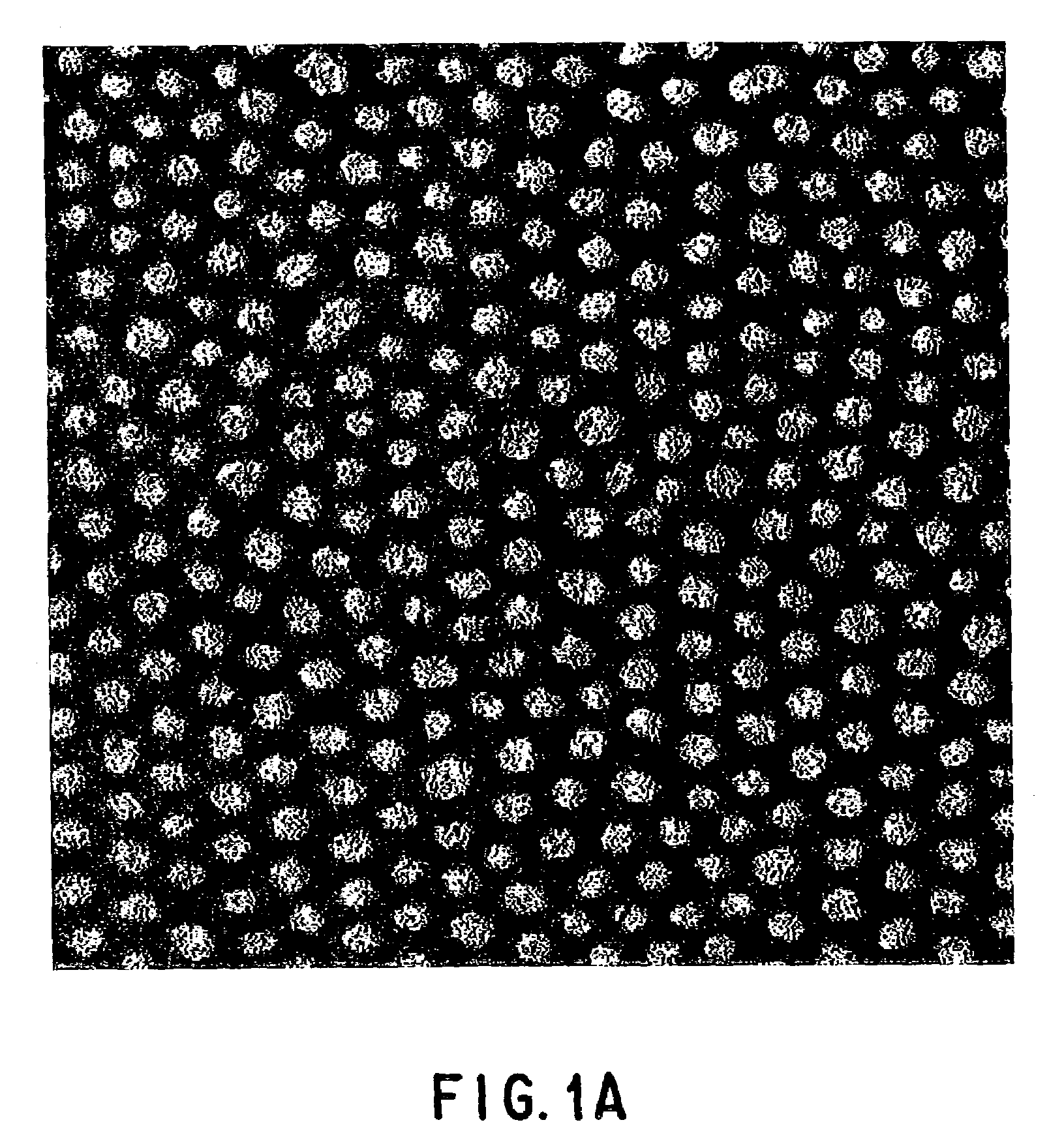

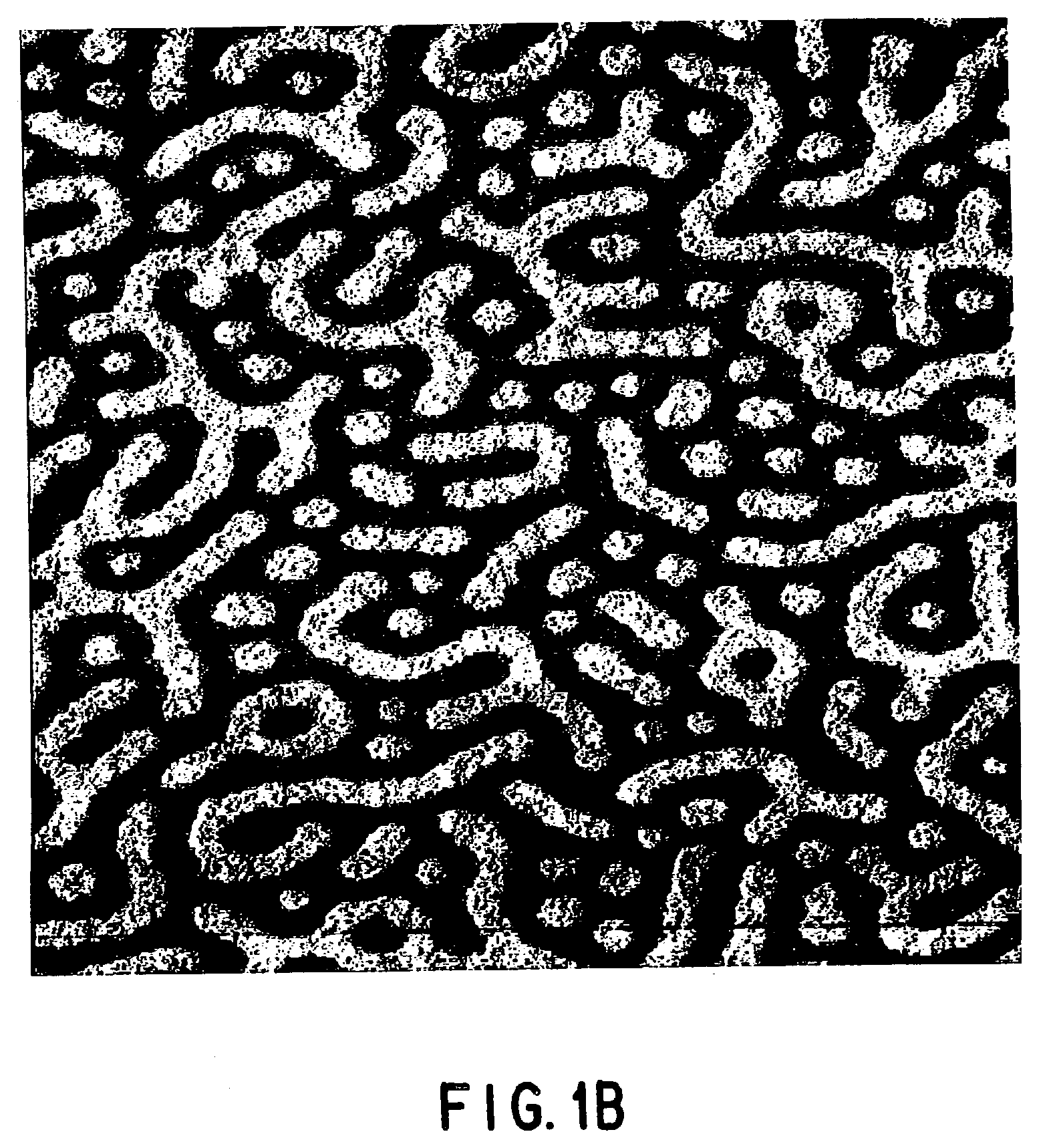

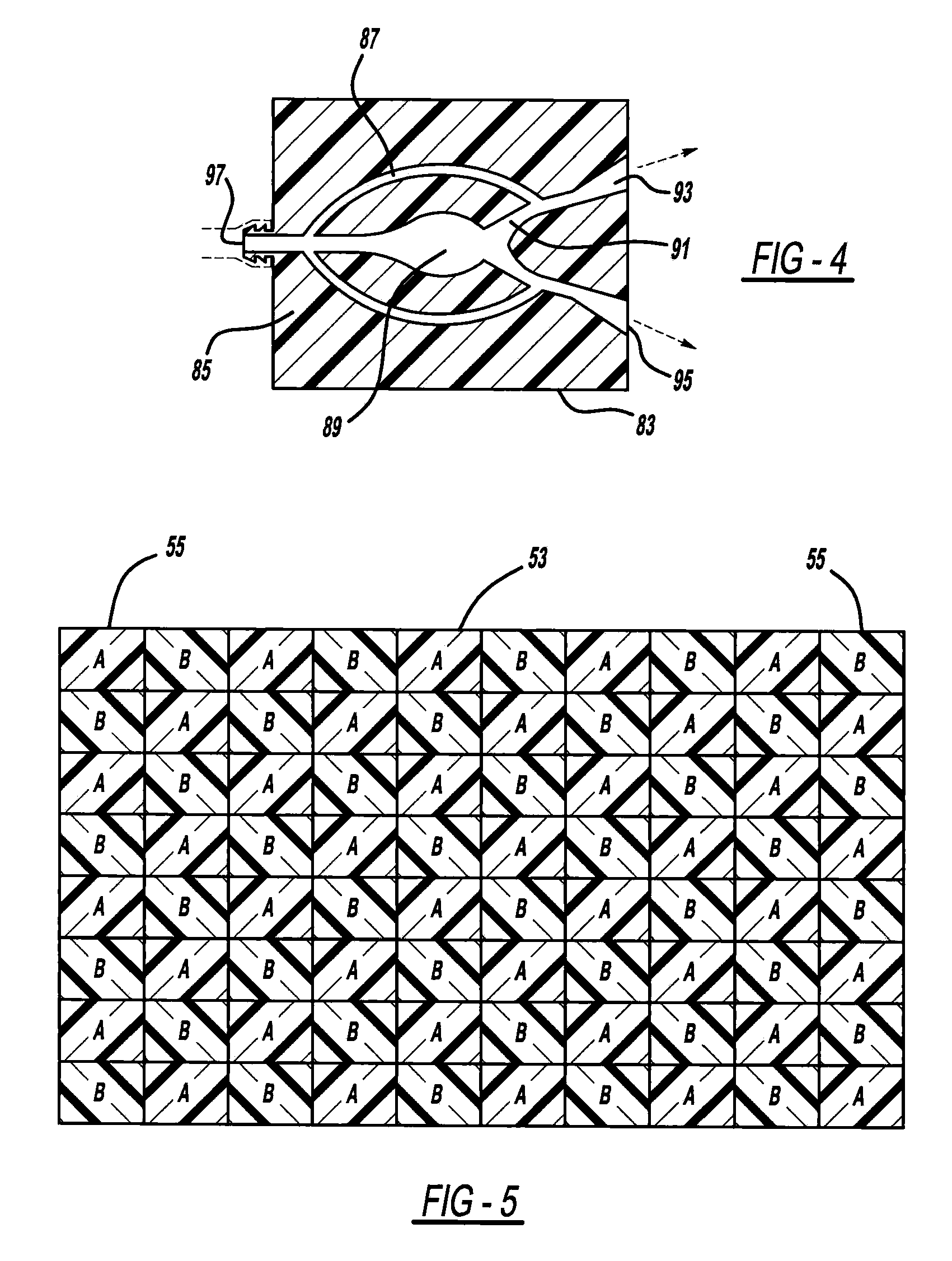

Method for manufacturing porous structure and method for forming pattern

InactiveUS7090784B2Increase throughputConsiderable regularityMaterial nanotechnologyCell electrodesPolymer scienceOxygen

A pattern forming material contains a block copolymer or graft copolymer and forms a structure having micro polymer phases, in which, with respect to at least two polymer chains among polymer chains constituting the block copolymer or graft copolymer, the ratio between N / (Nc-No) values of monomer units constituting respective polymer chains is 1.4 or more, where N represents total number of atoms in the monomer unit, Nc represents the number of carbon atoms in the monomer unit, No represents the number of oxygen atoms in the monomer unit.

Owner:KK TOSHIBA

Modular networked light bulb

Various methods of manufacturing a lighting apparatus and embodiments of a modular networked lighting apparatus are disclosed. One method defines a mechanical form factor with a minimum set of electrical connections for a networking module, builds a subassembly of the networked lighting apparatus, the subassembly comprising attachment points compatible with the mechanical form factor for the networking module and contacts for the minimum set of electrical connections for the networking module, installs a networking module into the subassembly of the networked lighting apparatus, the networking module compatible with a selected networking protocol for the networked lighting apparatus, completes the final assembly of the networked lighting module, and marks the networked lighting apparatus to indicate the selected networking protocol for the networked lighting apparatus. In some embodiments, the lighting apparatus may function without the networking module installed. One embodiment of the modular, networked light bulb has means for supporting and holding an electronics module conforming with a predetermined form factor in place, and means for allowing the electronics module to control at least a brightness level of the at least one LED. The modular networked light bulb may have a networked controller conforming with the predetermined form factor used as the electronics module. The networked controller is able to connect to a network and may be positioned and held by the means for supporting and holding an electronics module.

Owner:SIGNIFY HLDG BV

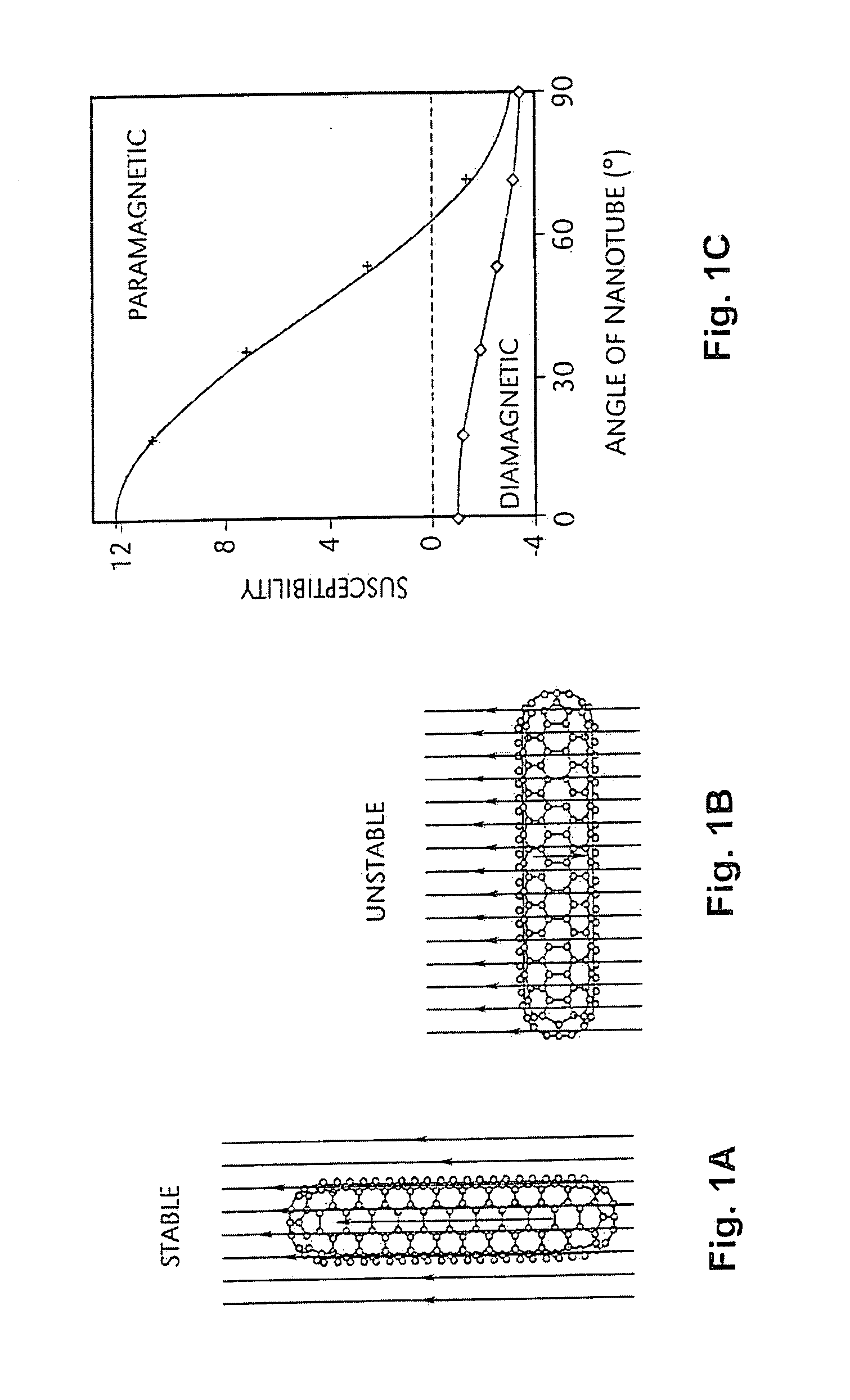

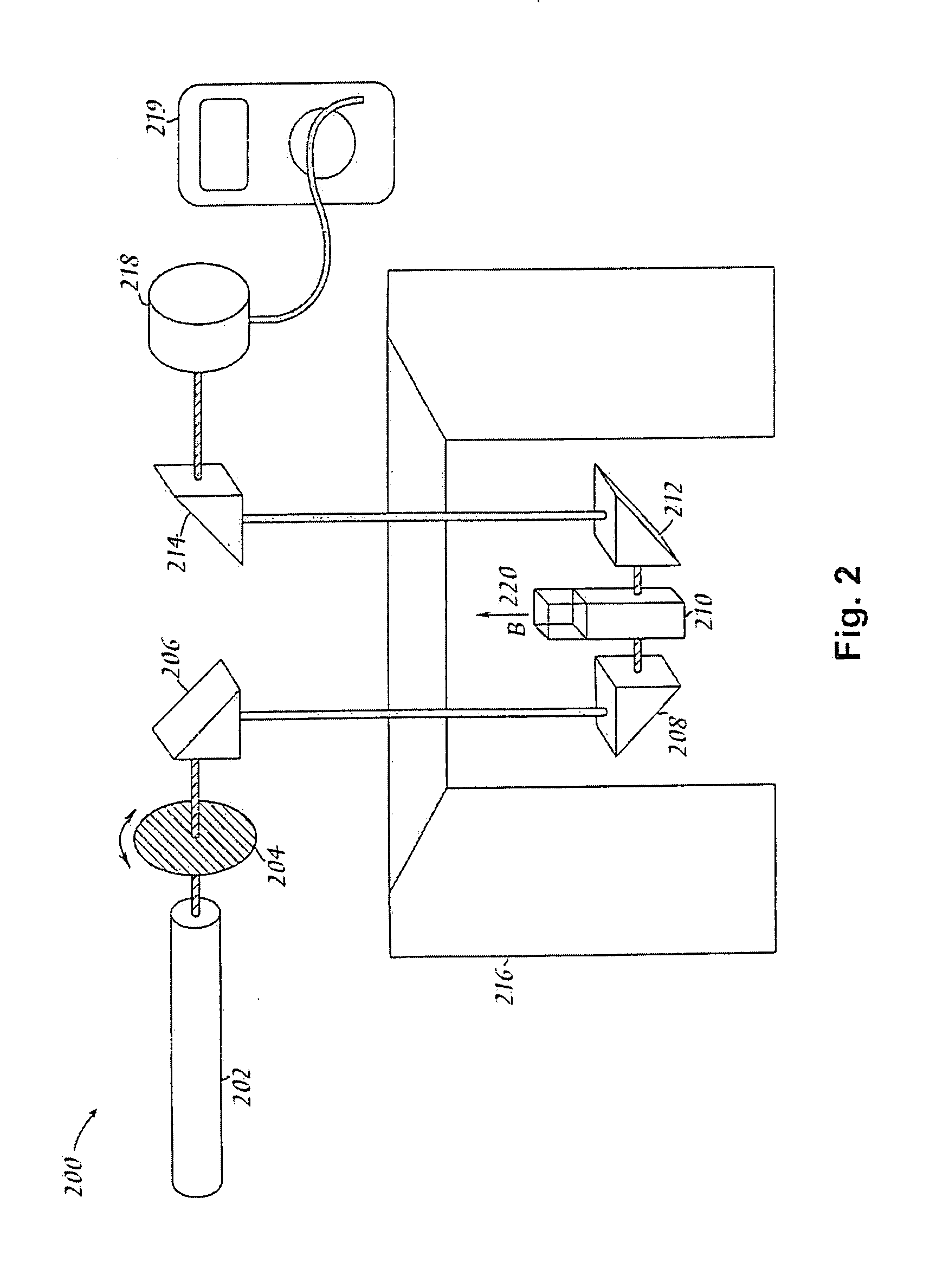

Metallization of carbon nanotubes for field emission applications

The present invention is directed towards metallized carbon nanotubes, methods for making metallized carbon nanotubes using an electroless plating technique, methods for dispensing metallized carbon nanotubes onto a substrate, and methods for aligning magnetically-active metallized carbon nanotubes. The present invention is also directed towards cold cathode field emitting materials comprising metallized carbon nanotubes, and methods of using metallized carbon nanotubes as cold cathode field emitters.

Owner:NANO

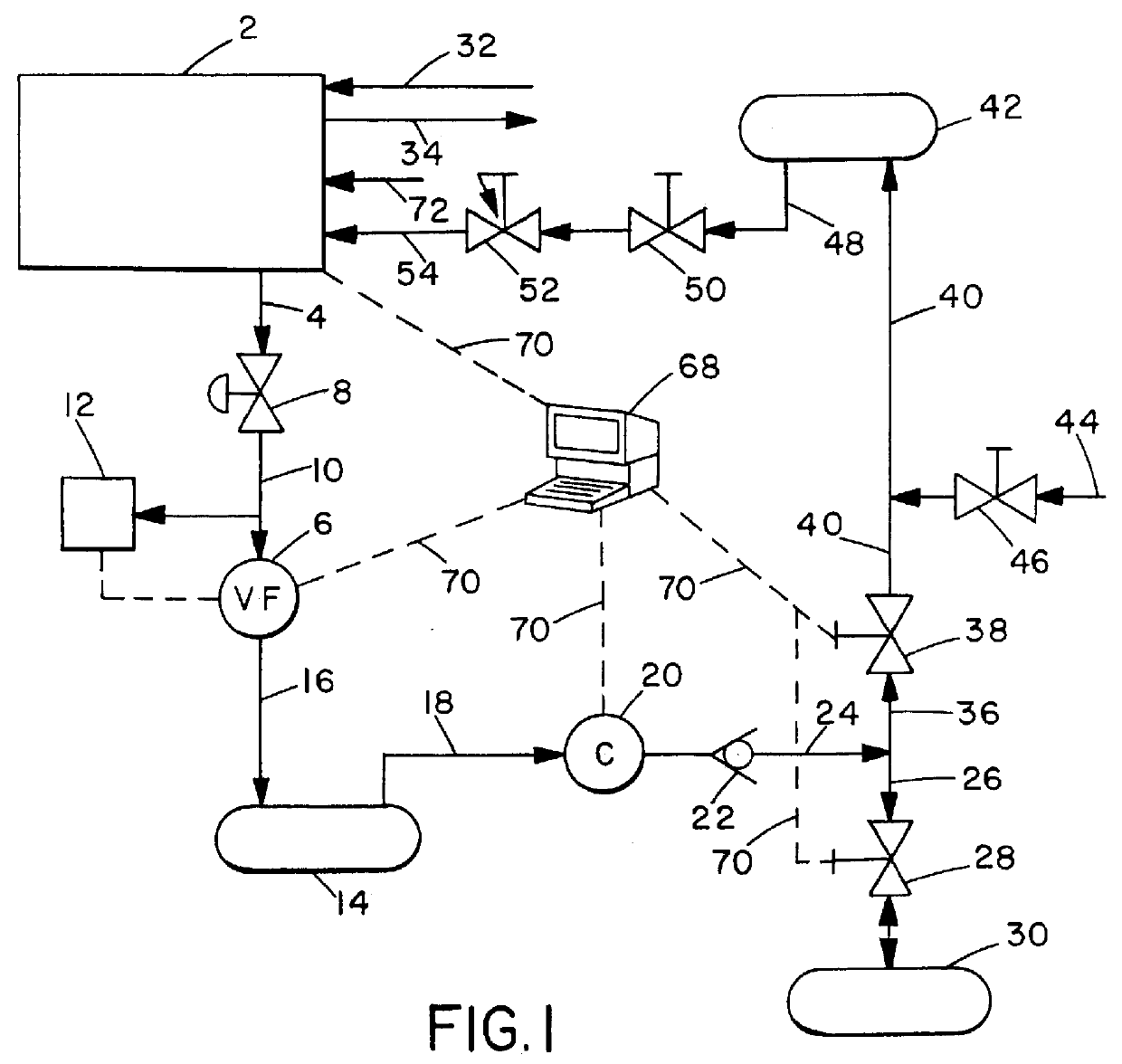

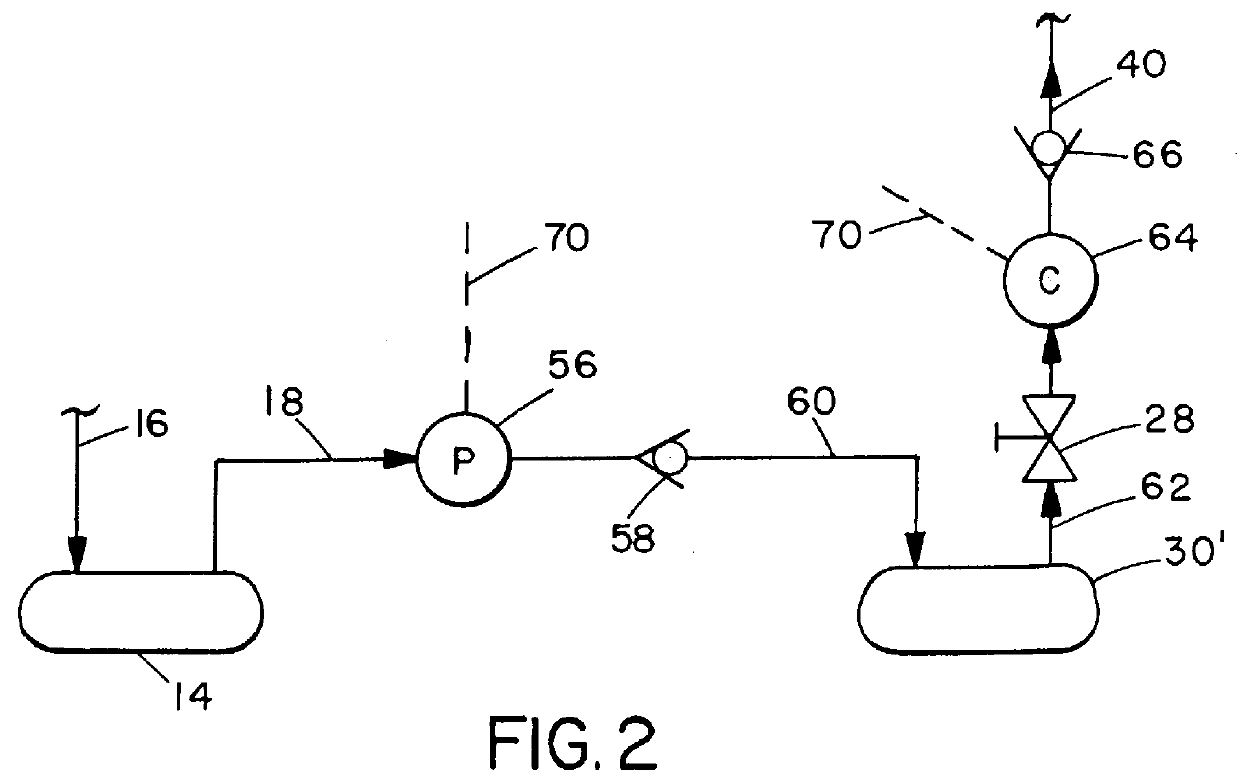

Method for recovery and reuse of gas

A gas recovery and reuse / recycle method is disclosed which can readily and economically recover valuable and / or environmentally hazardous gases from a manufacturing or chemical process and then return the gas to the process for reuse, and repeat this many times without significant contamination or degradation of the gas or the produced products. All gas transport, compression and storage equipment is designed and maintained so that it is non-contaminating to the process gas. Commonly the process gas will be a Group VIII gas, preferably He, Ne, Kr or Xe, or a gas which comprises a hazard to the ambient environment or beings therein, such as a carbon oxide gas, a halocarbon gas, an acid-precursor gas, a biologically hazardous gas, or a radioactive gas.

Owner:ENTEGRIS INC

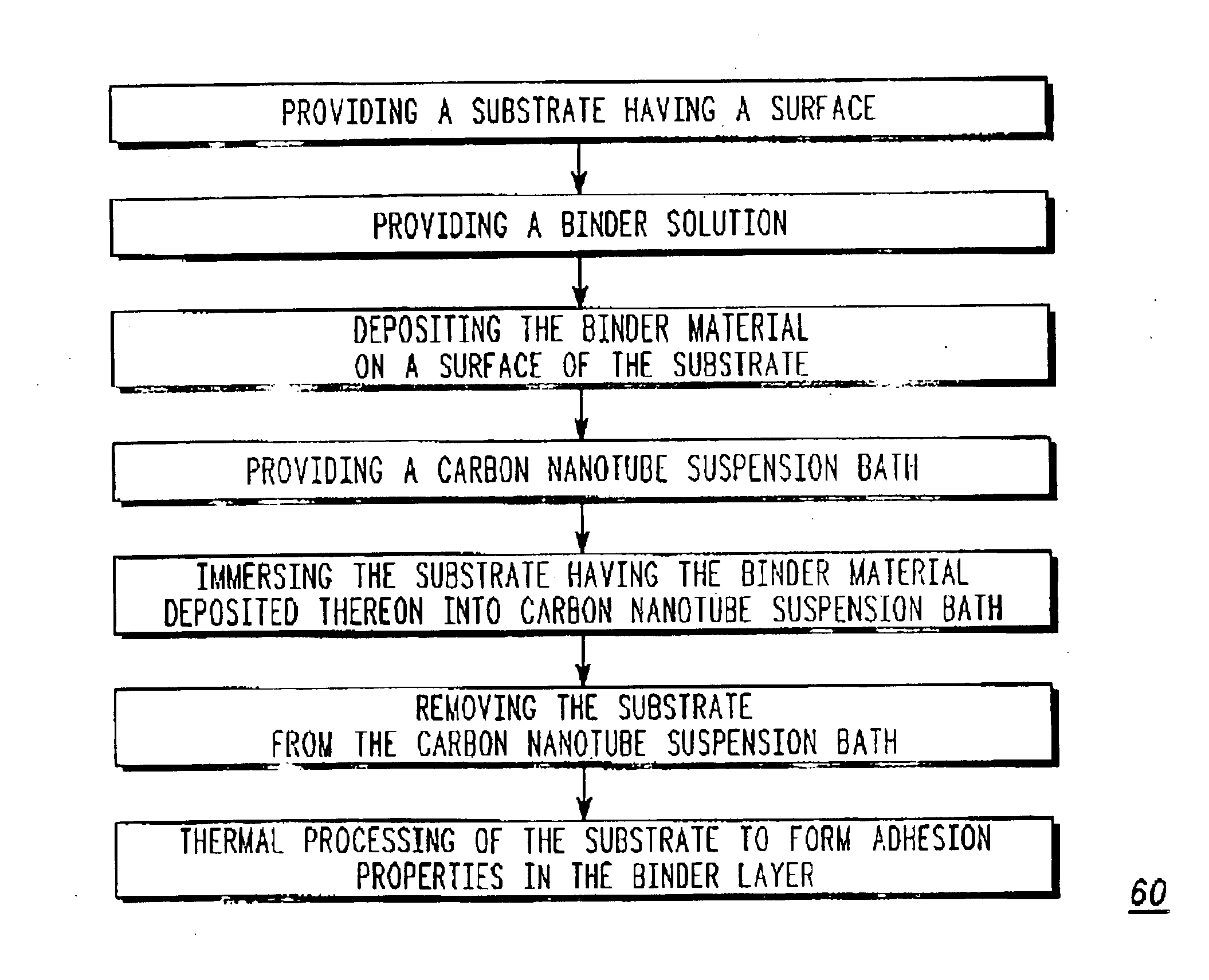

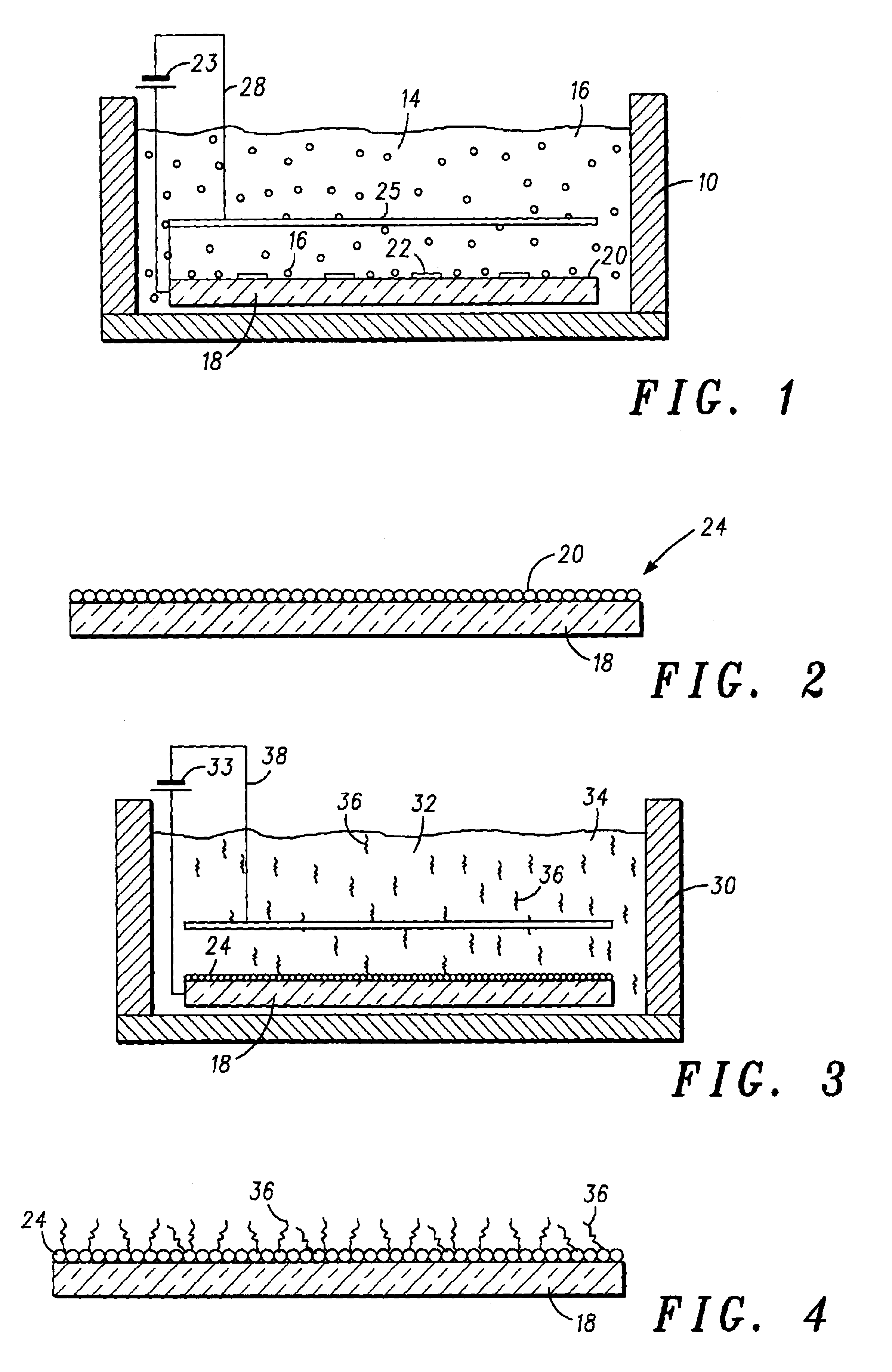

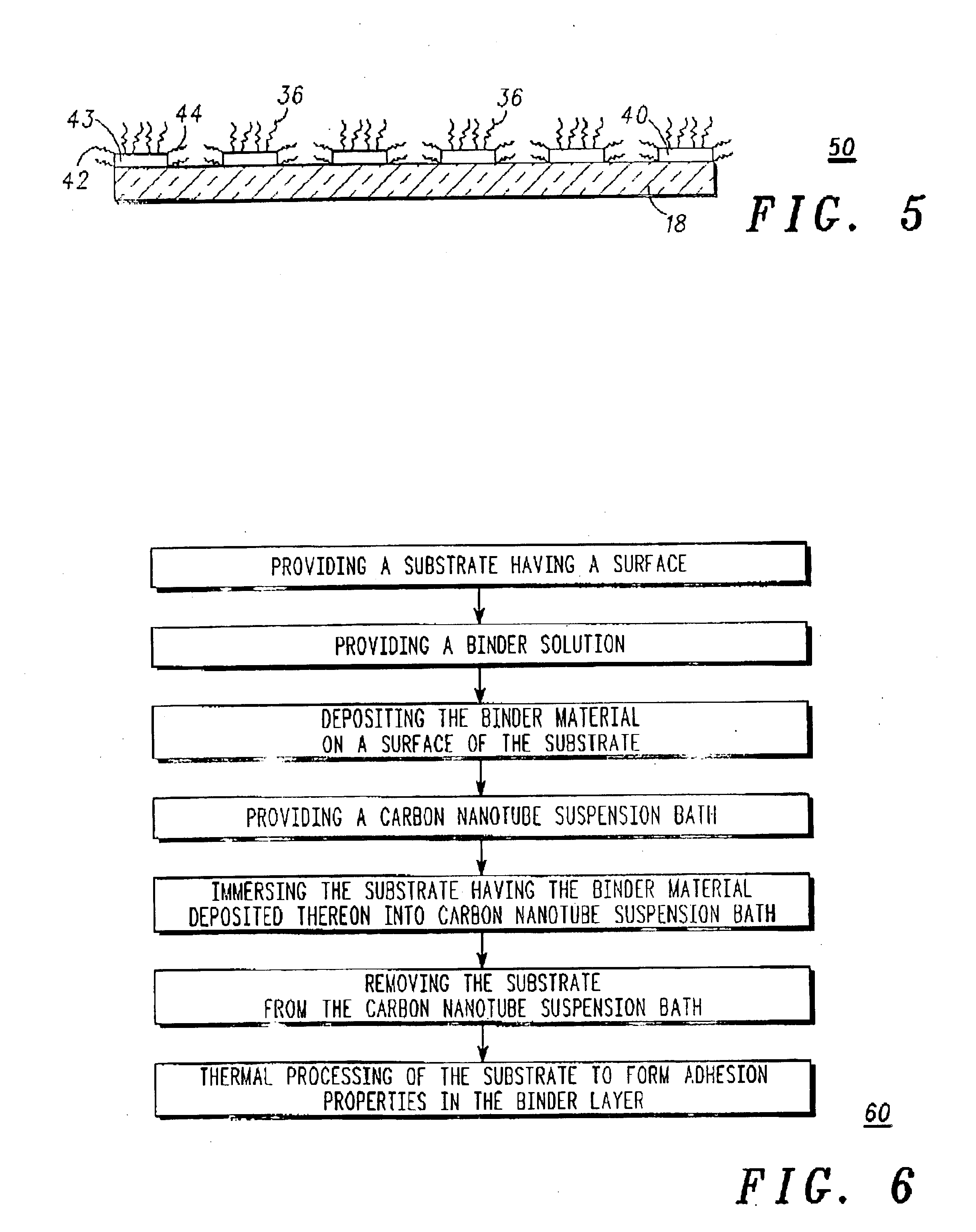

FED cathode structure using electrophoretic deposition and method of fabrication

InactiveUS6902658B2High densityVolume/mass flow measurementNanoinformaticsField emission deviceElectrophoresis

A method of fabricating a field emission device cathode using electrophoretic deposition of carbon nanotubes in which a separate step of depositing a binder material onto a substrate, is performed prior to carbon nanotube particle deposition. First, a binder layer is deposited on a substrate from a solution containing a binder material. The substrate having the binder material deposited thereon is then transferred into a carbon nanotube suspension bath allowing for coating of the carbon nanotube particles onto the substrate. Thermal processing of the coating transforms the binder layer properties which provides for the adhesion of the carbon nanotube particles to the binder material.

Owner:MOTOROLA SOLUTIONS INC

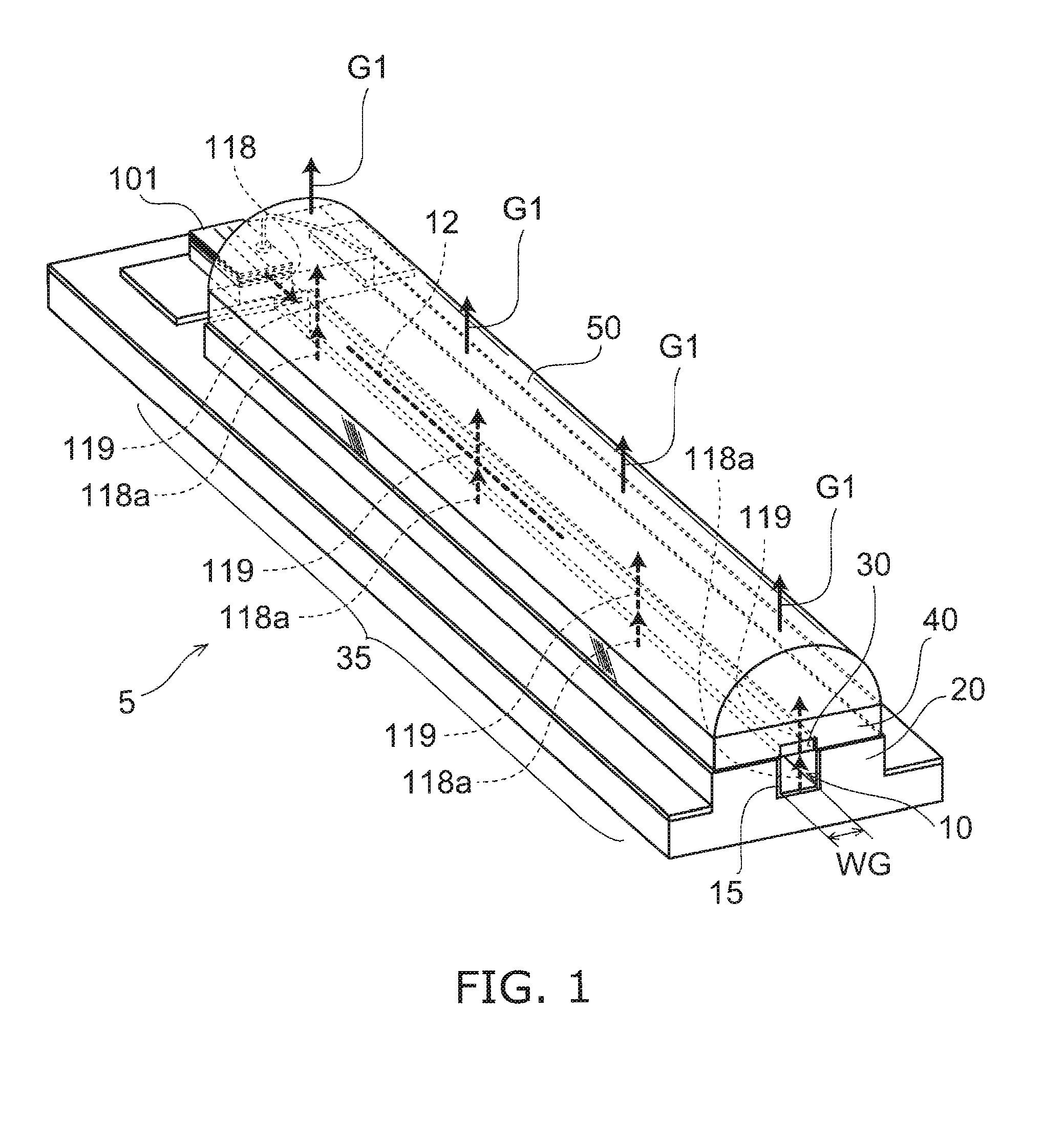

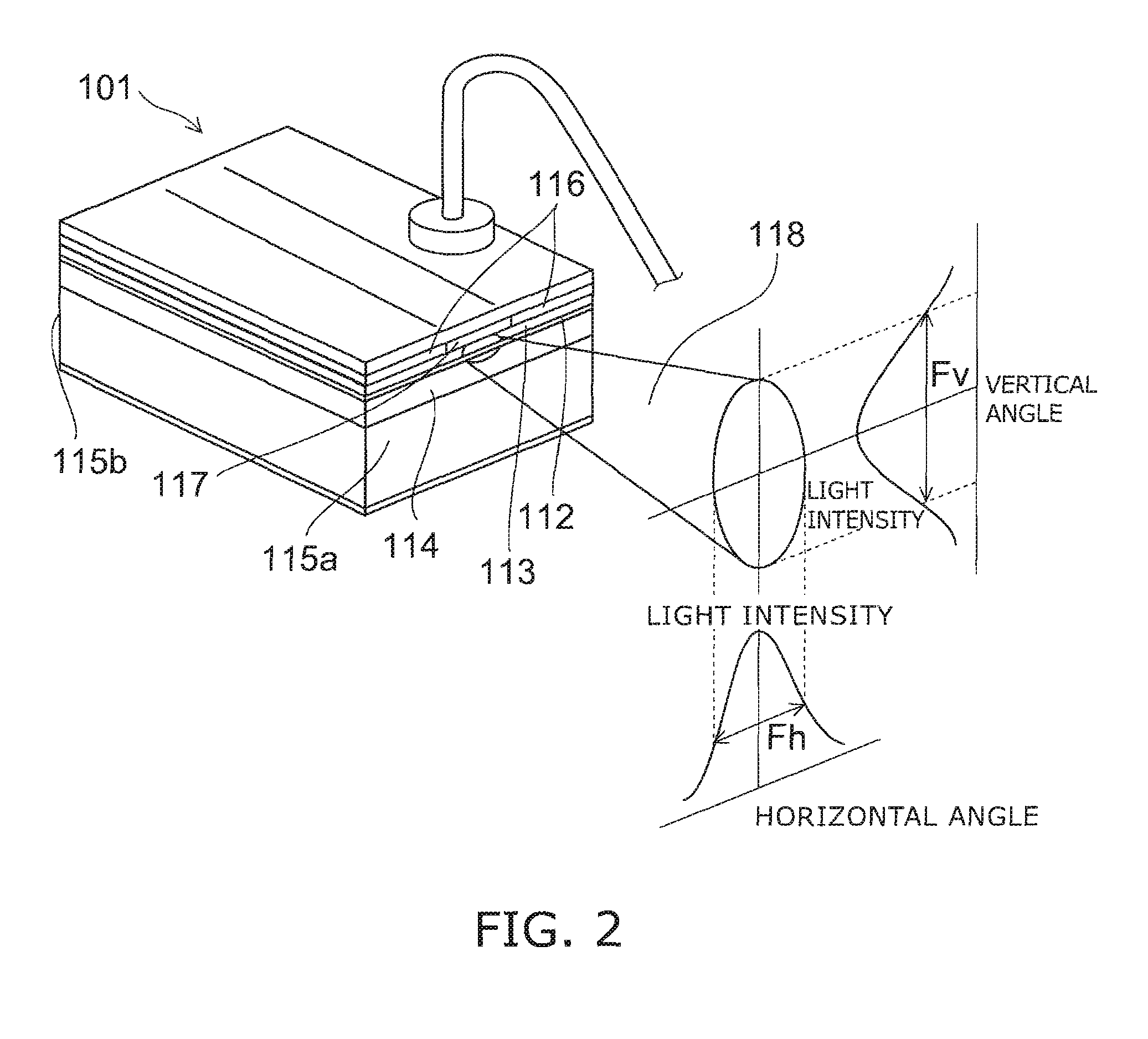

Light emitting device and method for manufacturing same, lighting fixture, and lighting system

InactiveUS20110032724A1Point-like light sourceLighting support devicesLight guideDistribution characteristic

A light emitting device includes: a light emitting element; a substrate including a groove-like light guide extending along a first direction, emission light emitted from the light emitting element and introduced into the light guide being reflected by an inner wall surface of the light guide, spreading along the first direction, and being turned into upward light directed upward above the substrate; and a lens provided above the light guide and configured to collect the upward light and control light distribution characteristic in a plane generally perpendicular to the first direction.

Owner:HARISON TOSHIBA LIGHTING CORP +1

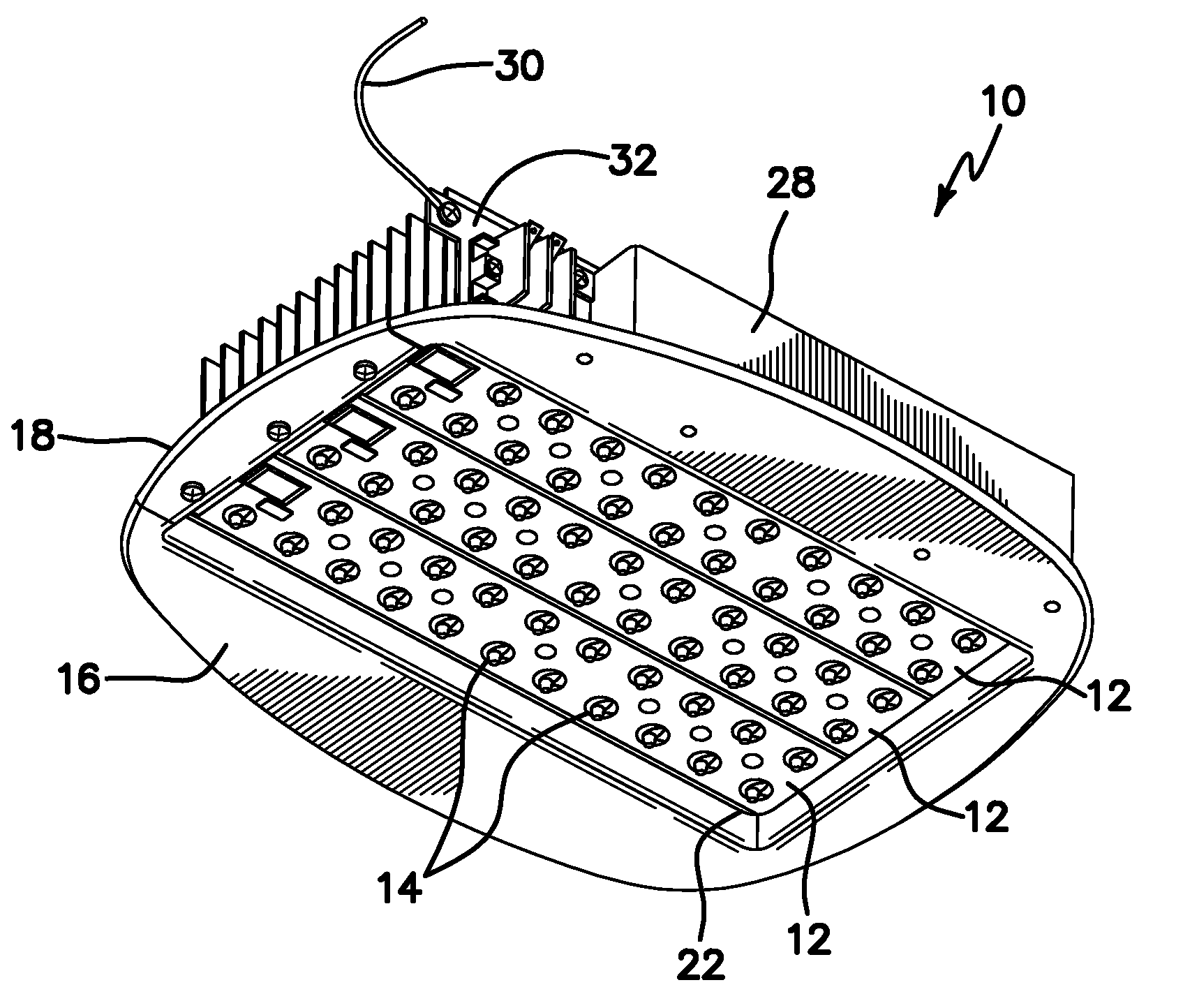

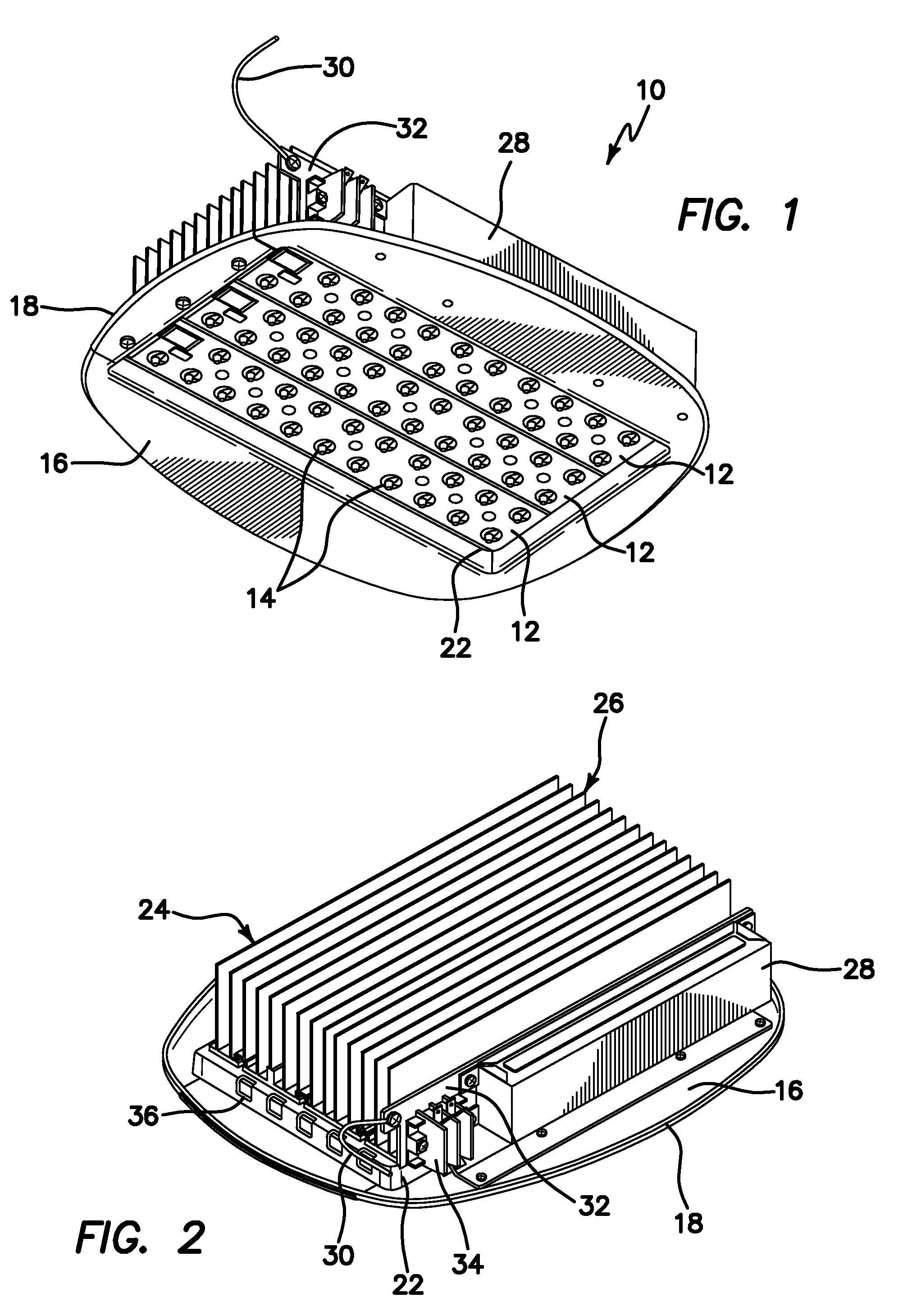

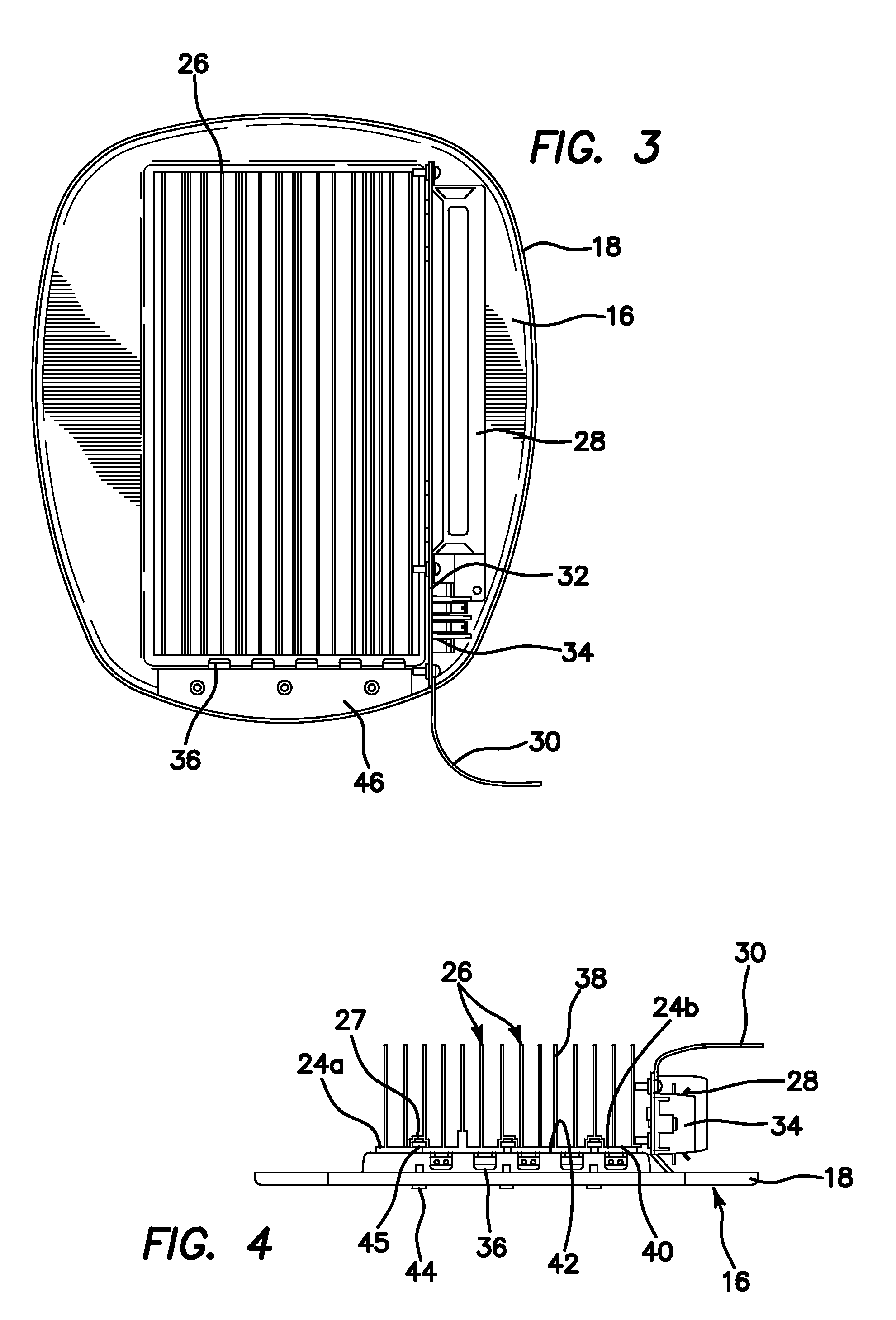

LED replacement lamp and a method of replacing preexisting luminaires with LED lighting assemblies

ActiveUS20100134046A1Reduce light pollutionImprove visibilityPlanar light sourcesLight source combinationsEffect lightEngineering

A lighting apparatus for retrofitting an existing luminaire includes a plurality of light emitting diodes (LED) of similar or differing wavelengths arranged and configured in at least one light bar array, a heat sink module thermally coupled to the at least one light bar array, an electronic power module electrically coupled to the at least one light bar array, and a plate coupled to the at least one light bar array, electronic power module and the heat sink module, the plate arranged and configured for coupling to the luminaire to provide quick and easy installation and replacement of the at least one light bar array, heat sink module and electronic power module into and from the luminaire.

Owner:SIGNIFY HLDG BV

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS20050087289A1Efficiently converted into thermal energySmall diameterElectric lighting sourcesSolid-state devicesDevice materialEngineering

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

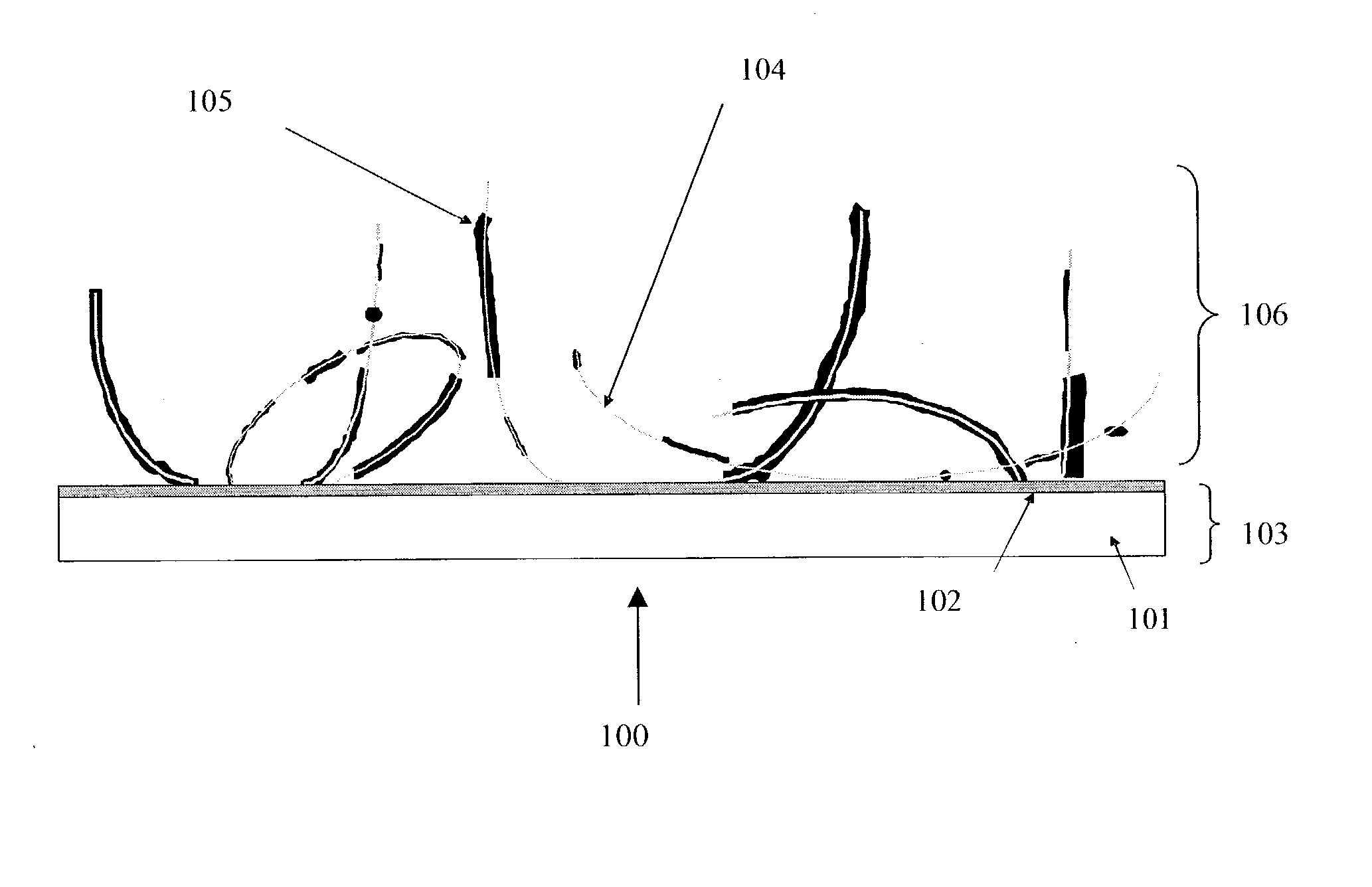

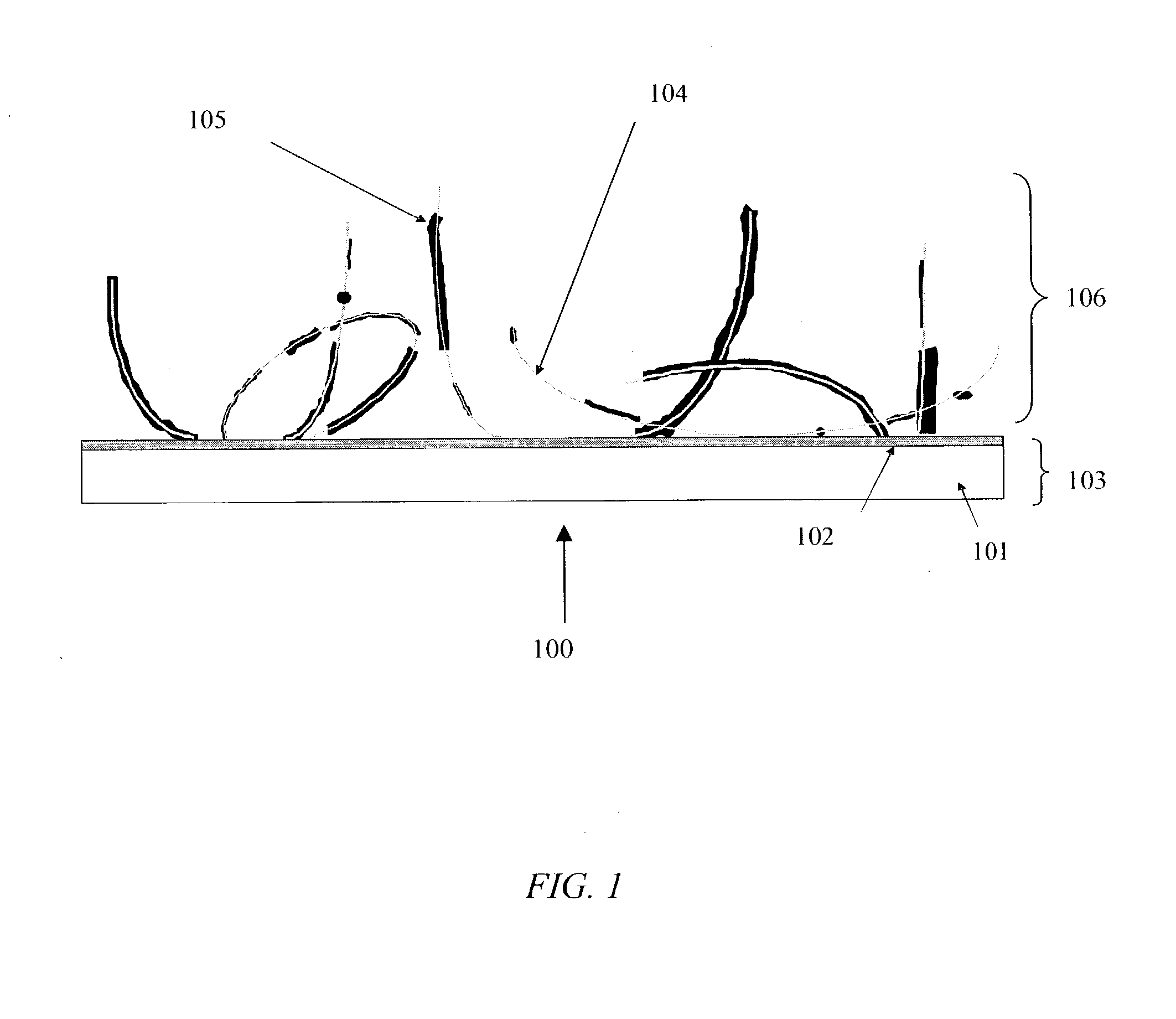

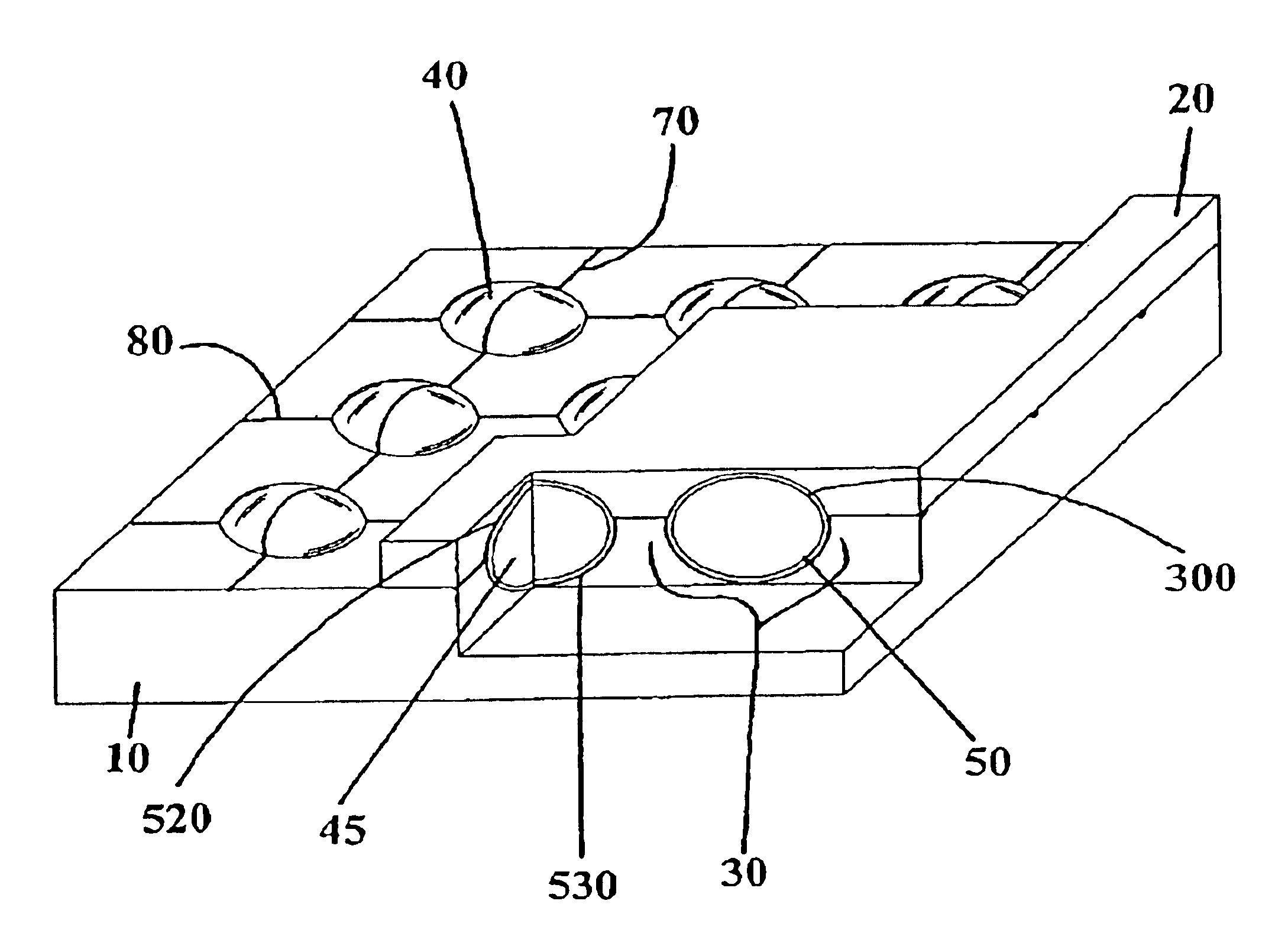

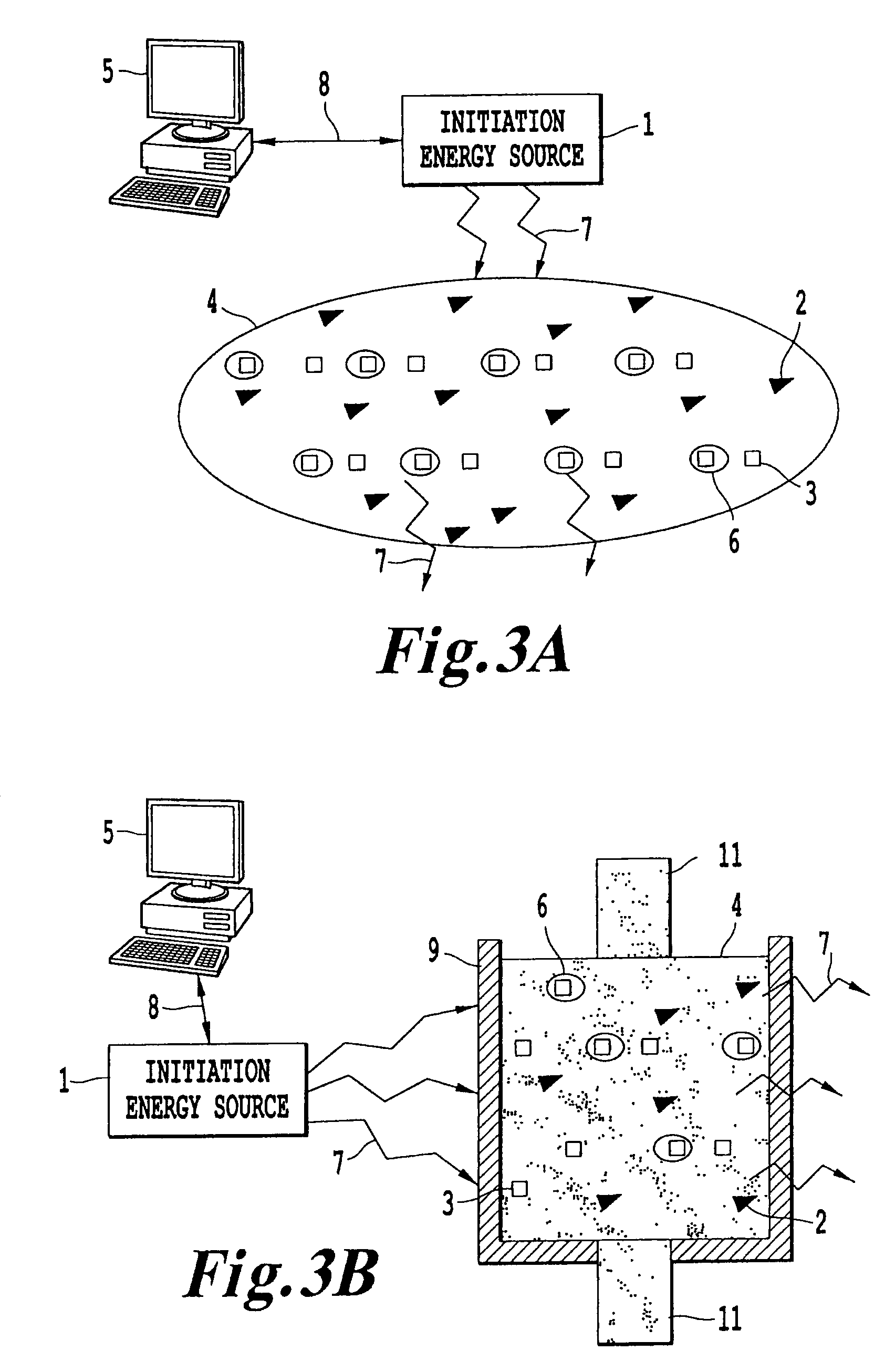

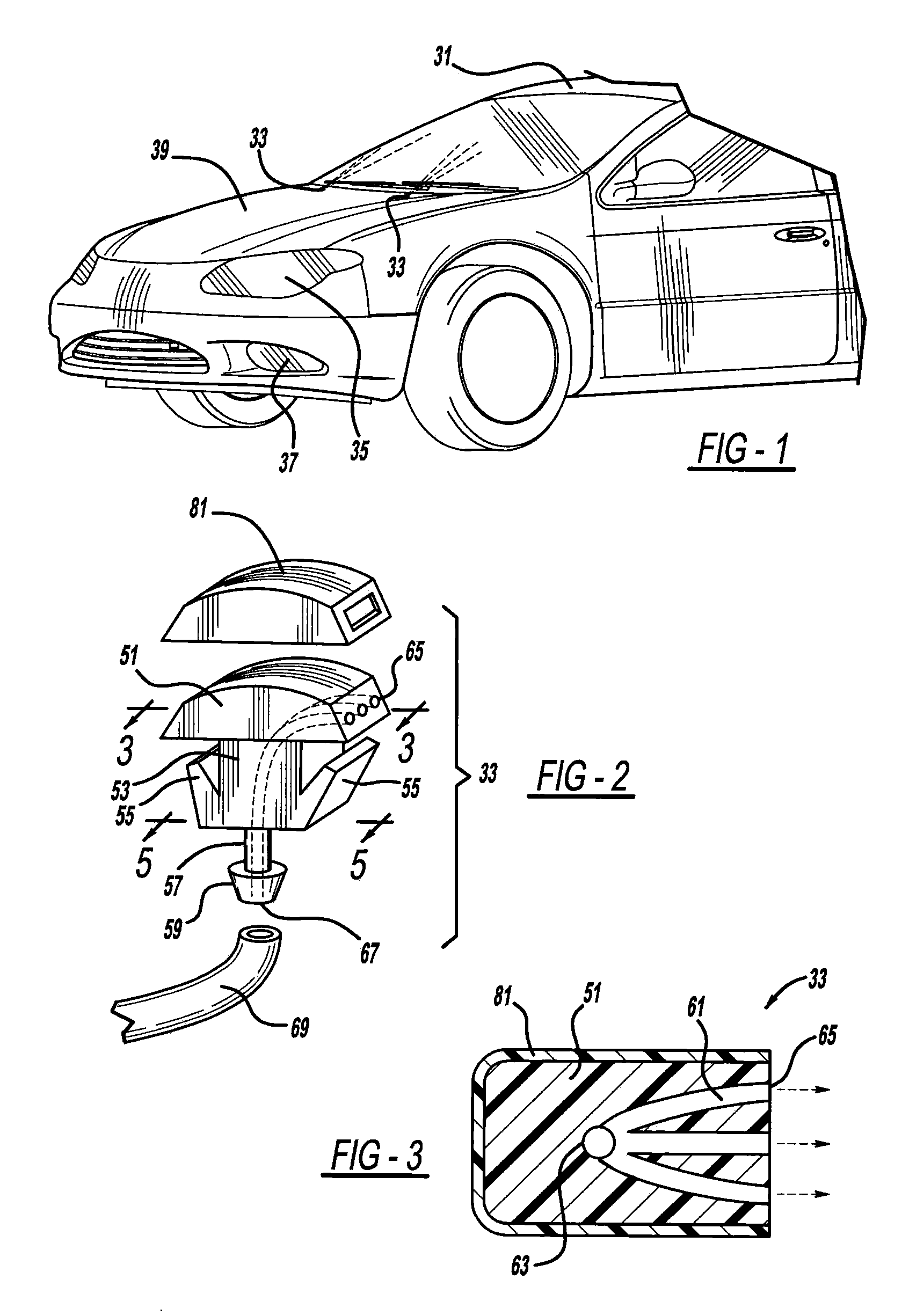

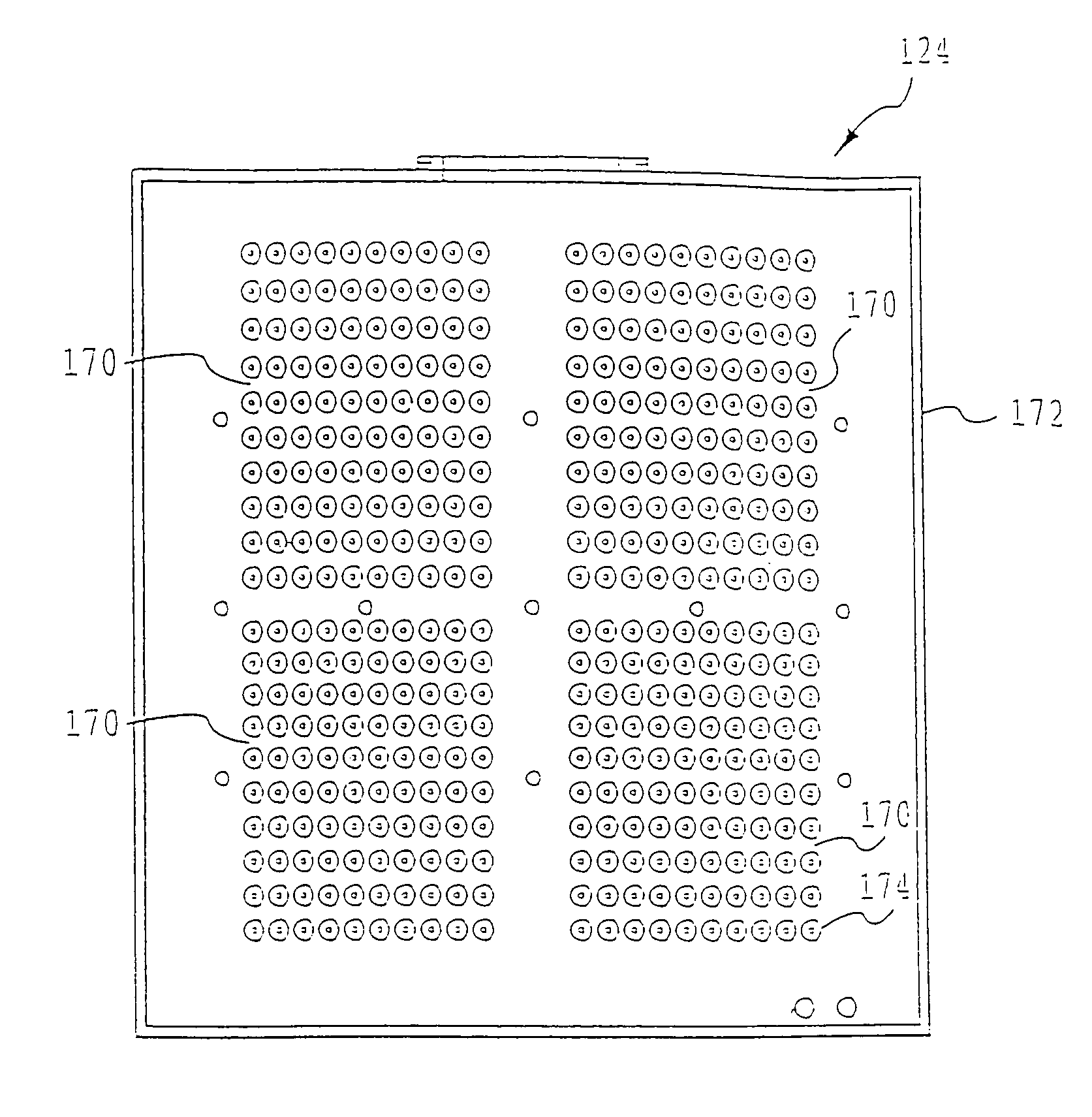

Design, fabrication, testing, and conditioning of micro-components for use in a light-emitting panel

InactiveUS6822626B2Sufficient resolutionManufactured very thinFixed microstructural devicesVolume/mass flow measurementEngineeringPre testing

Owner:LEIDOS

LED light bulbs

Owner:IDEAL IND LIGHTING LLC

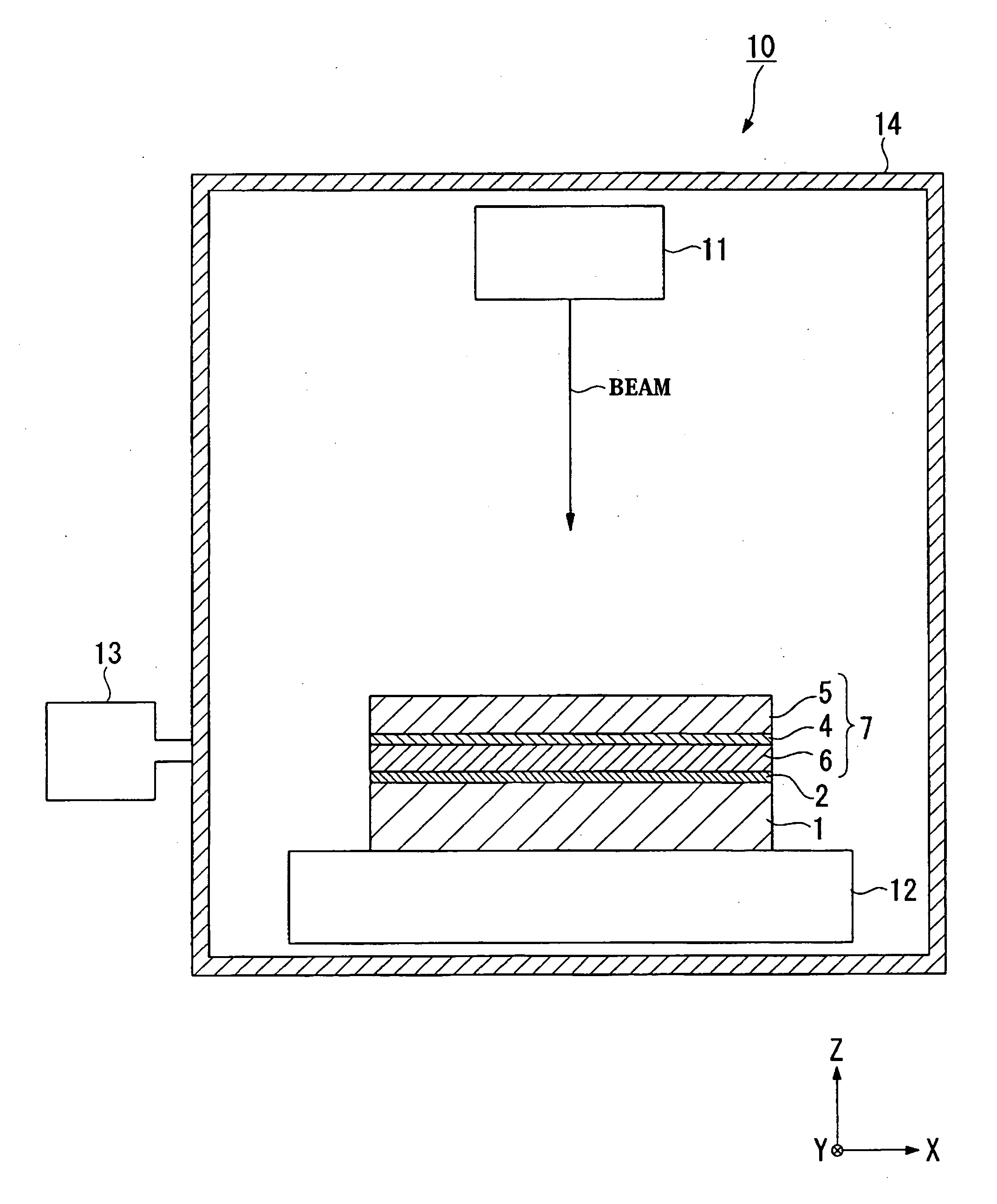

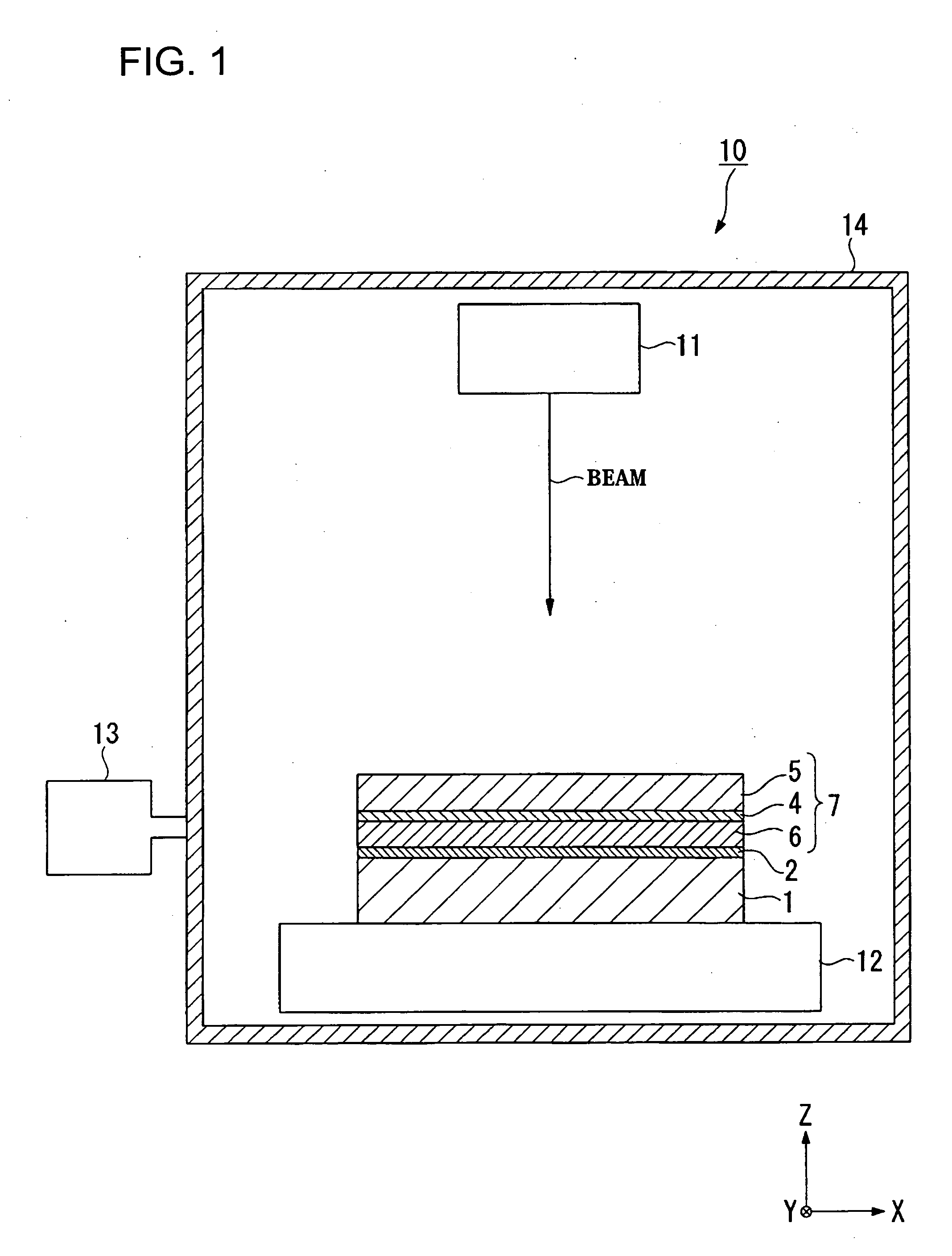

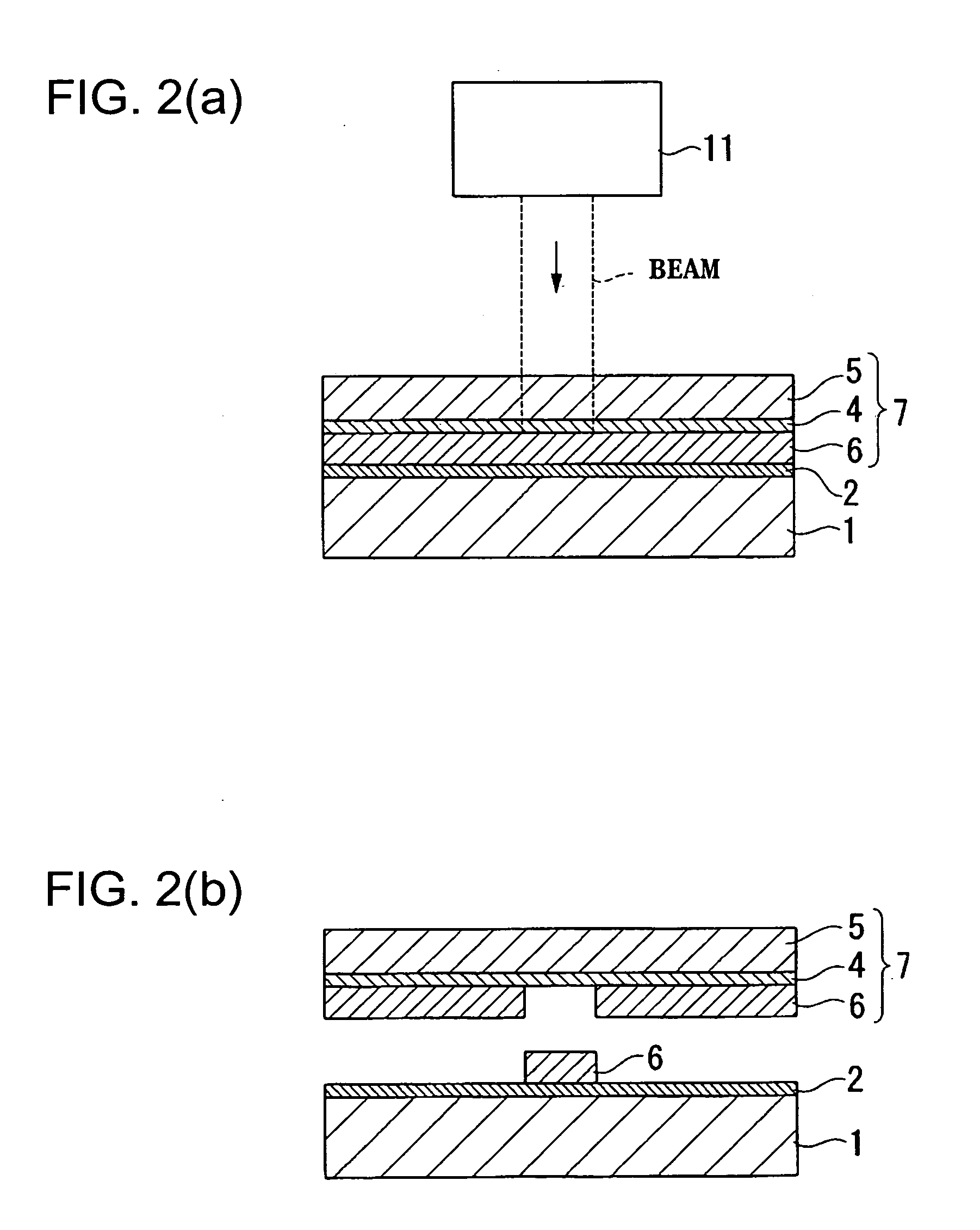

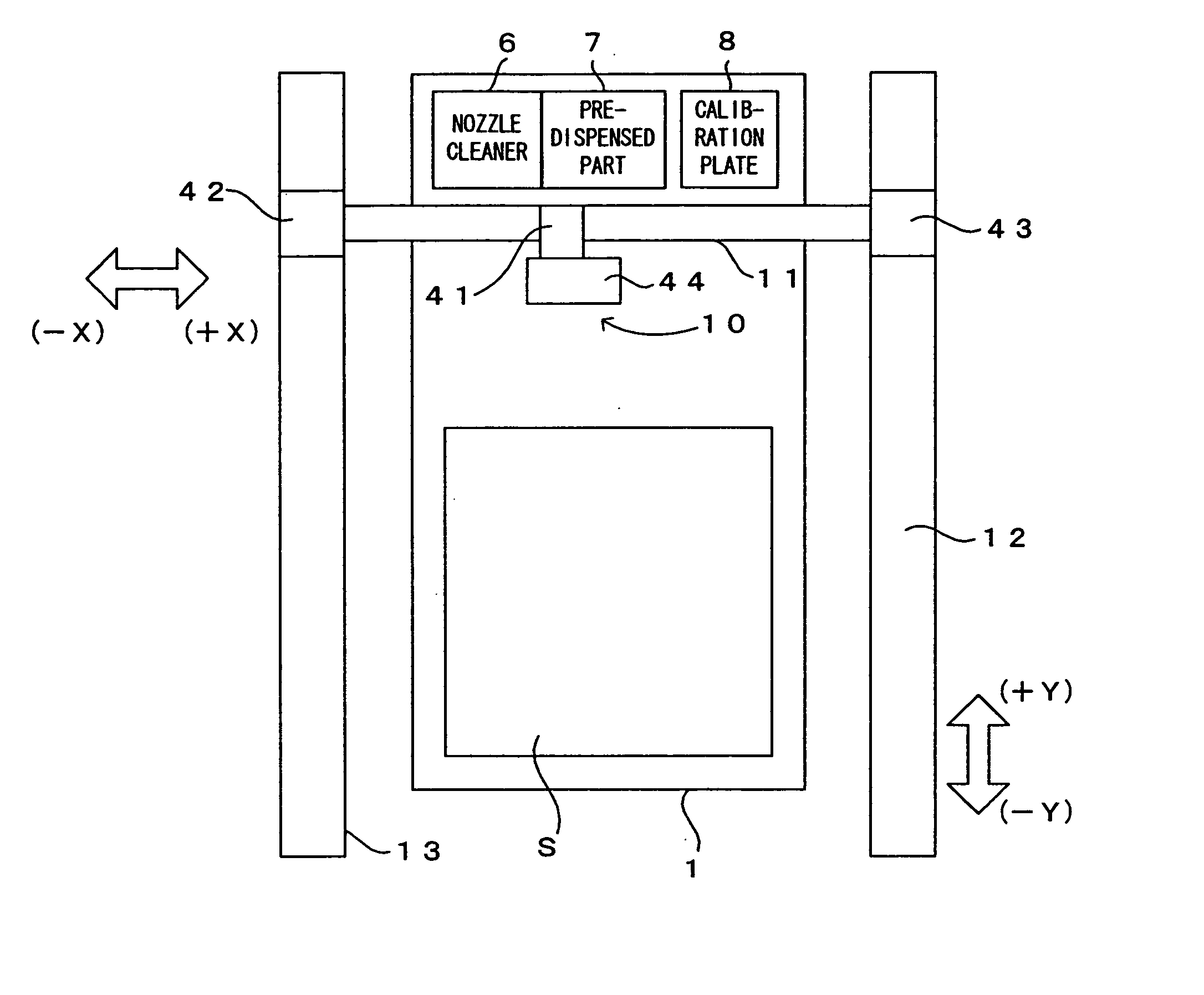

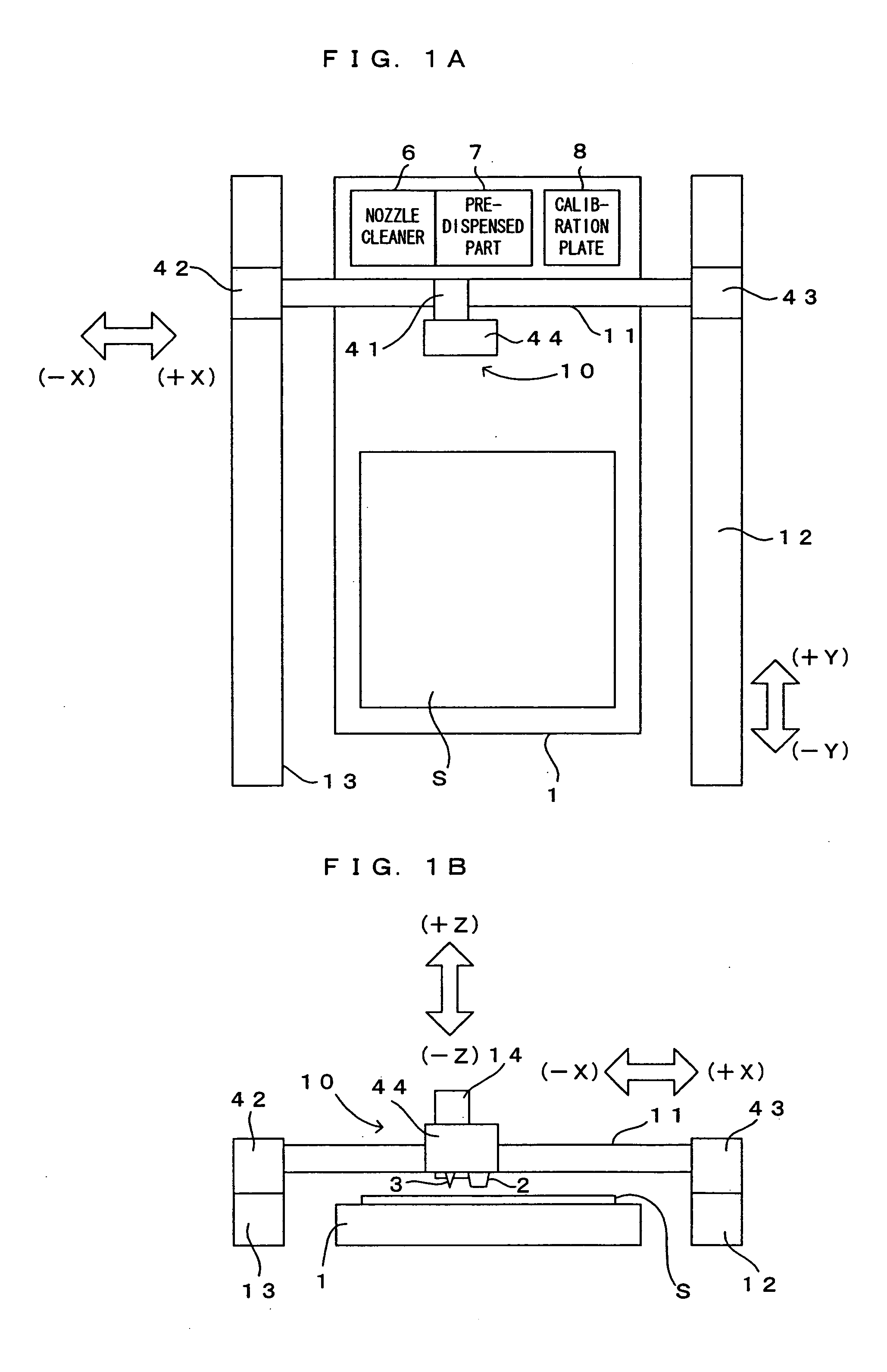

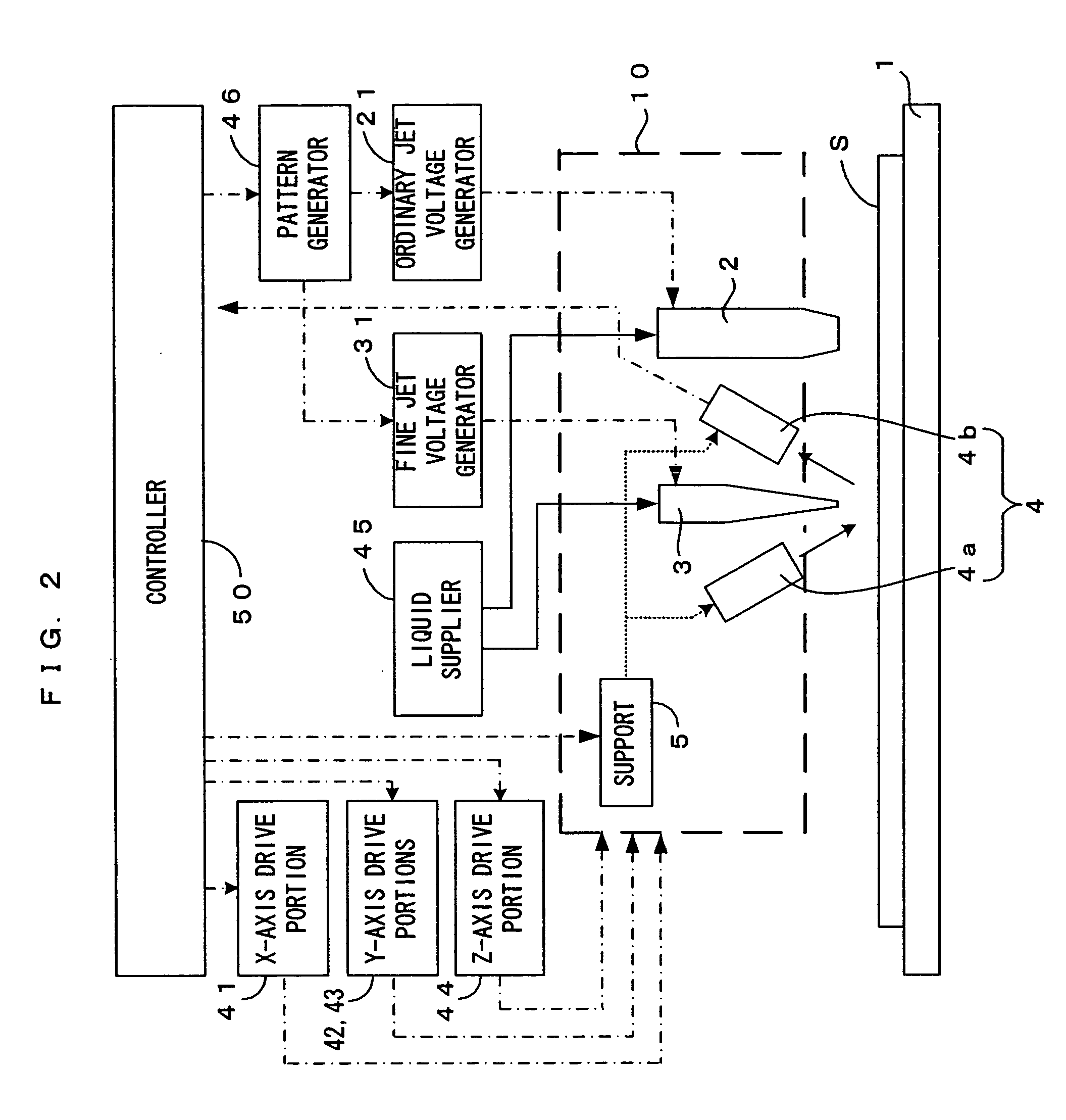

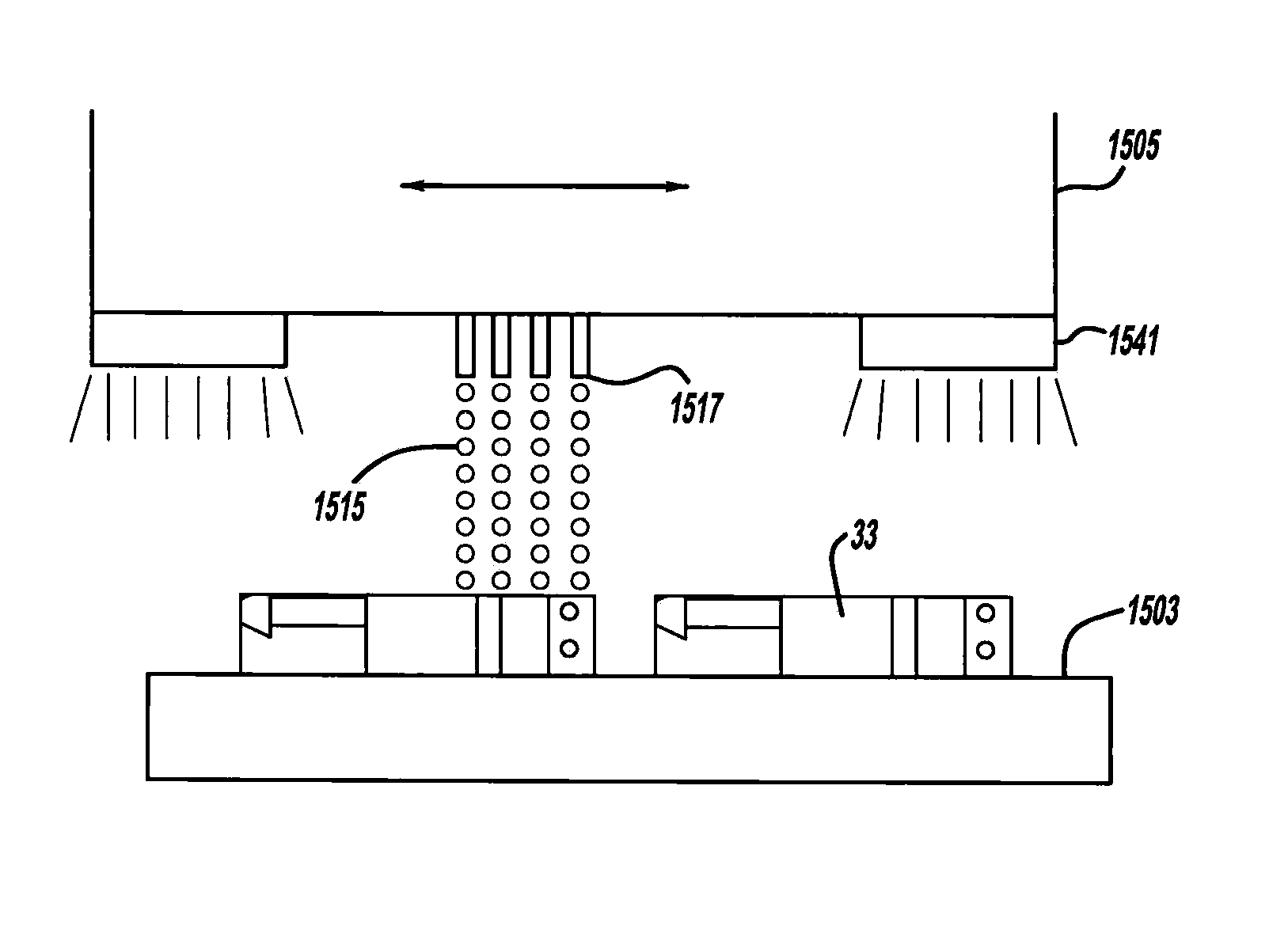

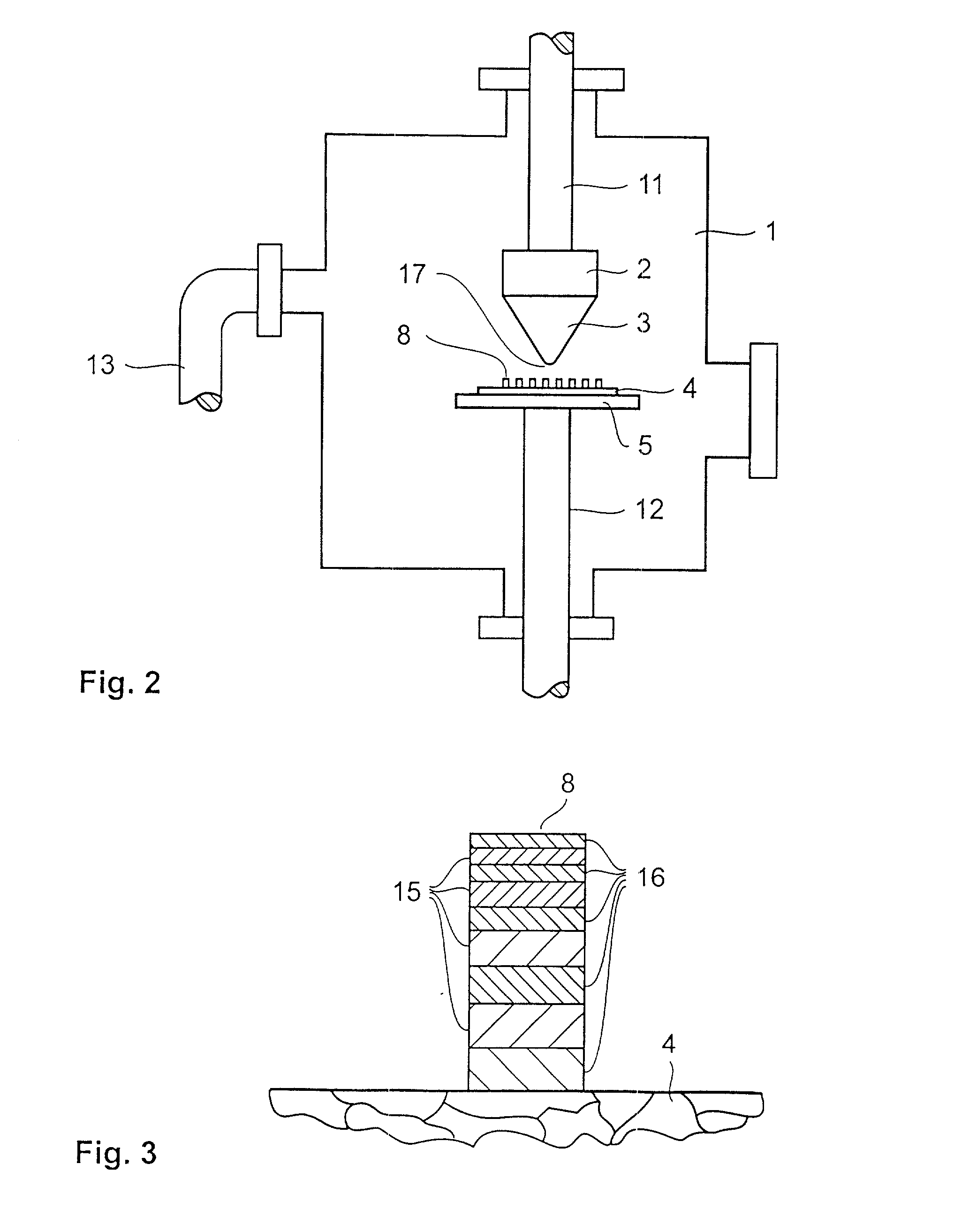

Processing apparatus which performs predetermined processing while supplying a processing liquid to a substrate

InactiveUS20050212837A1Efficiently formedLower capability requirementsBioreactor/fermenter combinationsBurnersEngineeringLaser

Above a substrate holder 1, an ordinary fluid jet nozzle 2 which is capable of injecting drops of a solution having ordinary particle diameters, a fine fluid jet nozzle 3 which is capable of injecting drops of a solution having fine particle diameters which are smaller than the ordinary particle diameters, and a regular reflection laser displacement gauge 4 are disposed. These are attached on the same plate, thereby forming a head 10. The head 10 freely moves in directions X, Y and Z, as an X-axis drive portion 41, Y-axis drive portions 42 and 43 and a Z-axis drive portion 44 operate in accordance with operation commands received from a controller 50 which controls the apparatus as a whole. It is therefore possible to set the head 10 to a predetermined position on a substrate S which is held by the substrate holder 1. Thus, the respective nozzles supply the solutions to any desired positions the substrate S.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for manufacturing porous structure and method for forming pattern

InactiveUS7097781B2Increase throughputConsiderable regularityMaterial nanotechnologyFinal product manufacturePolymer scienceOxygen

Owner:KK TOSHIBA

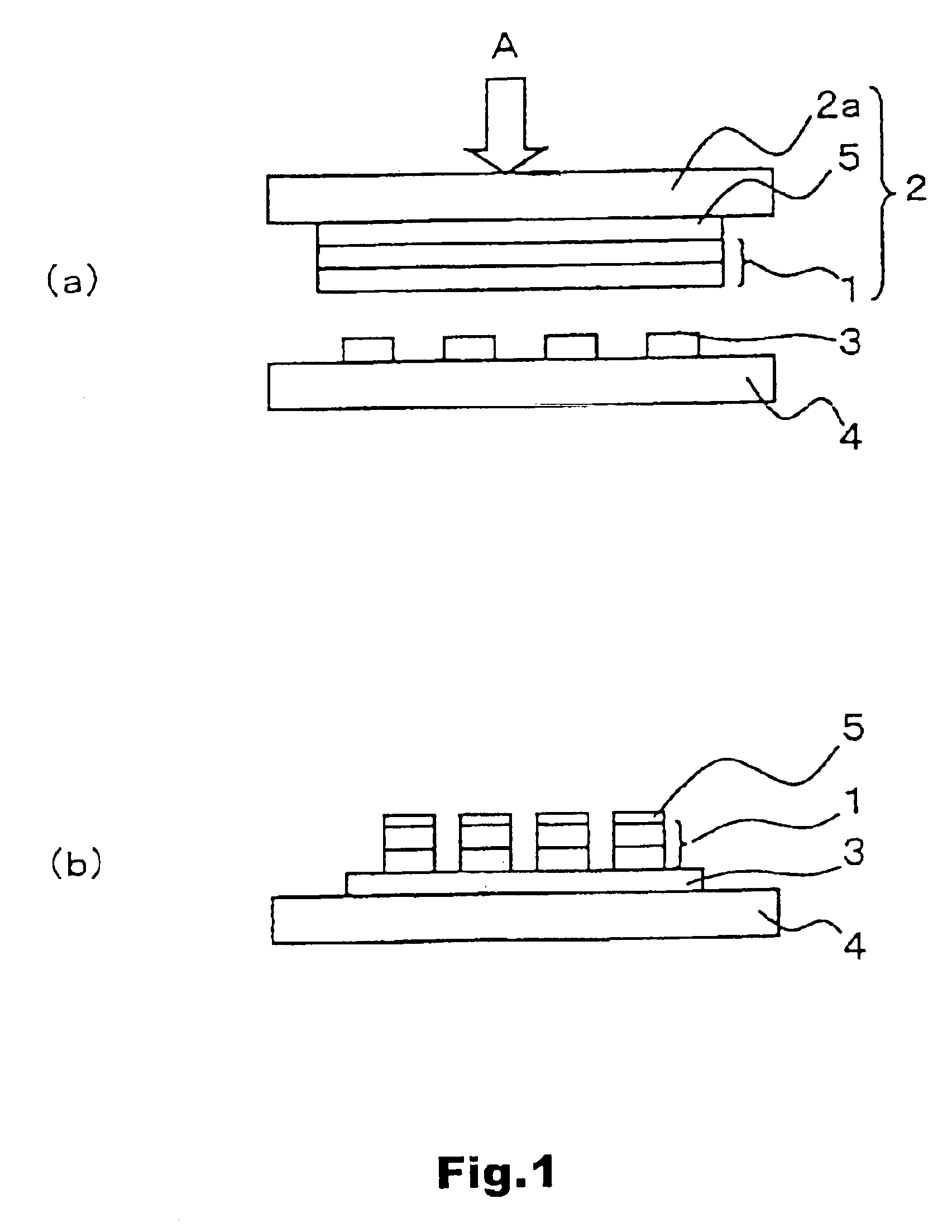

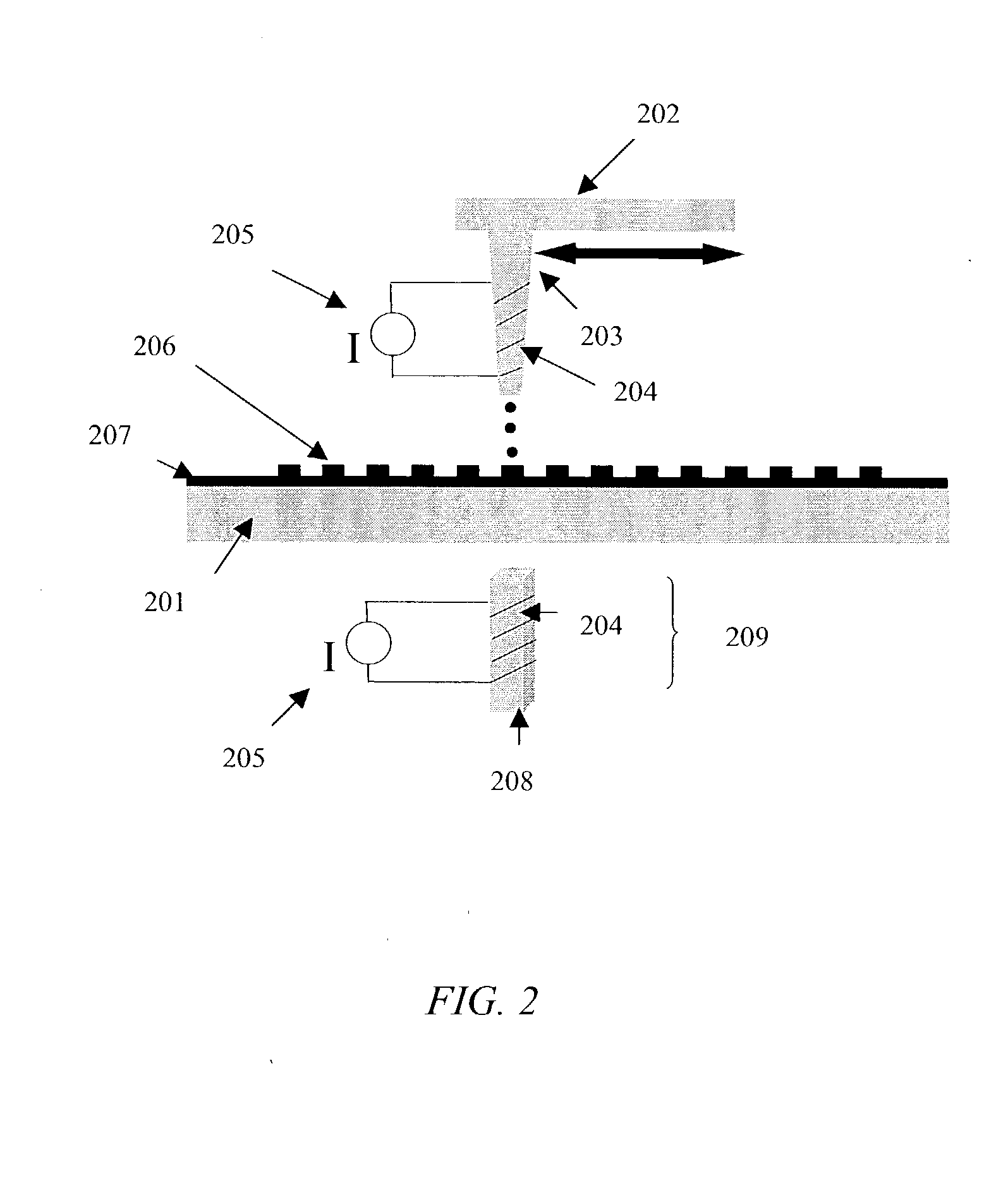

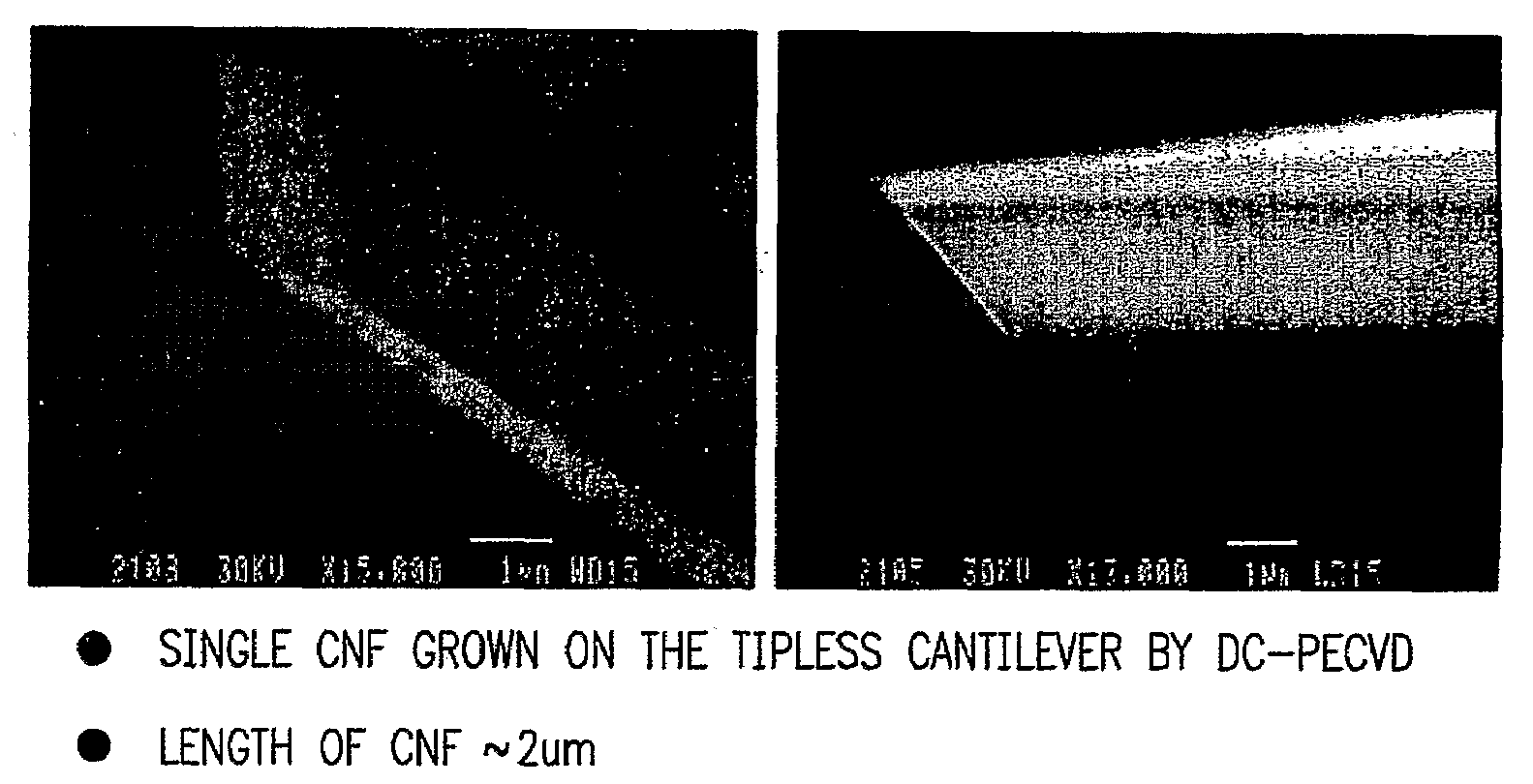

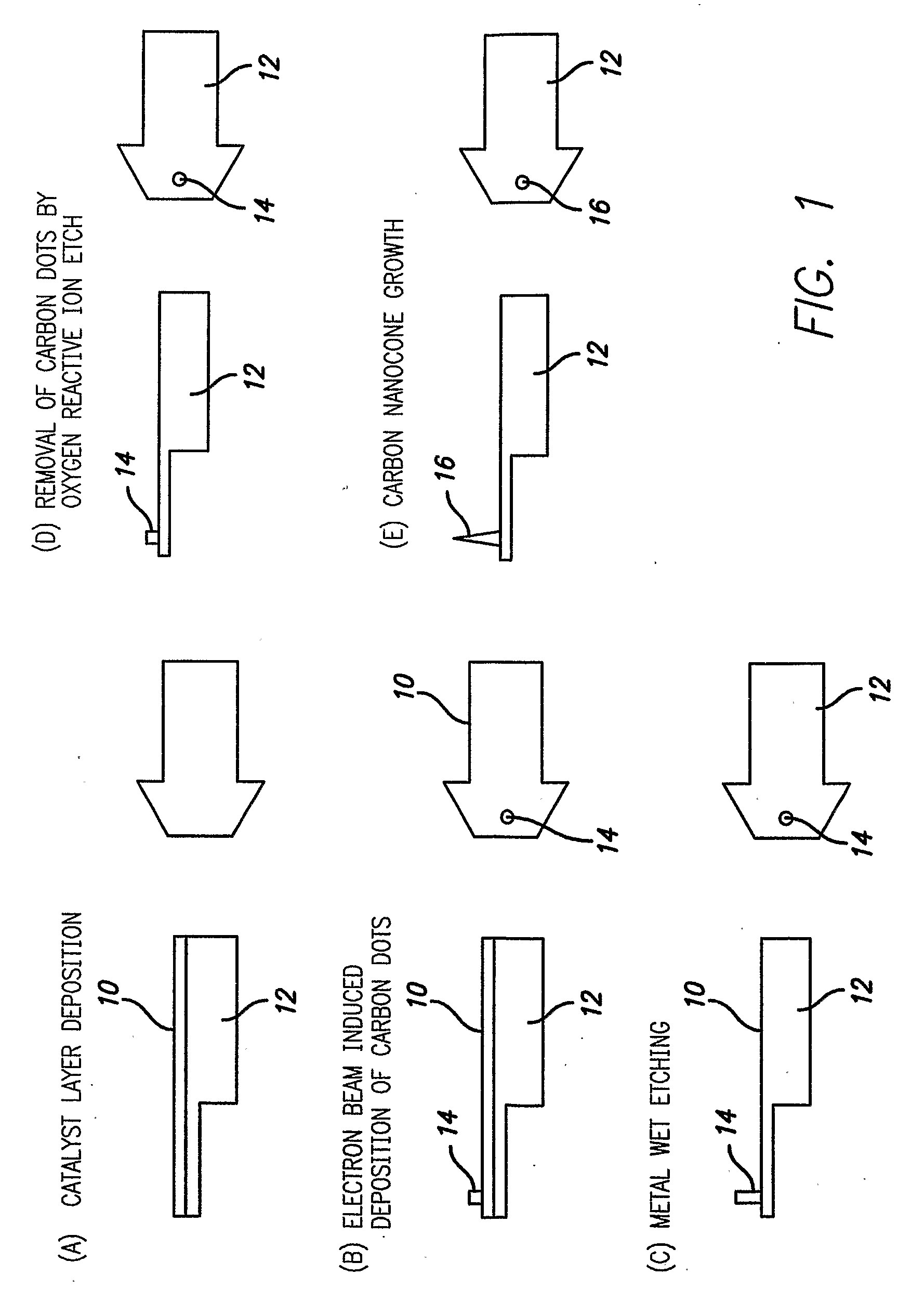

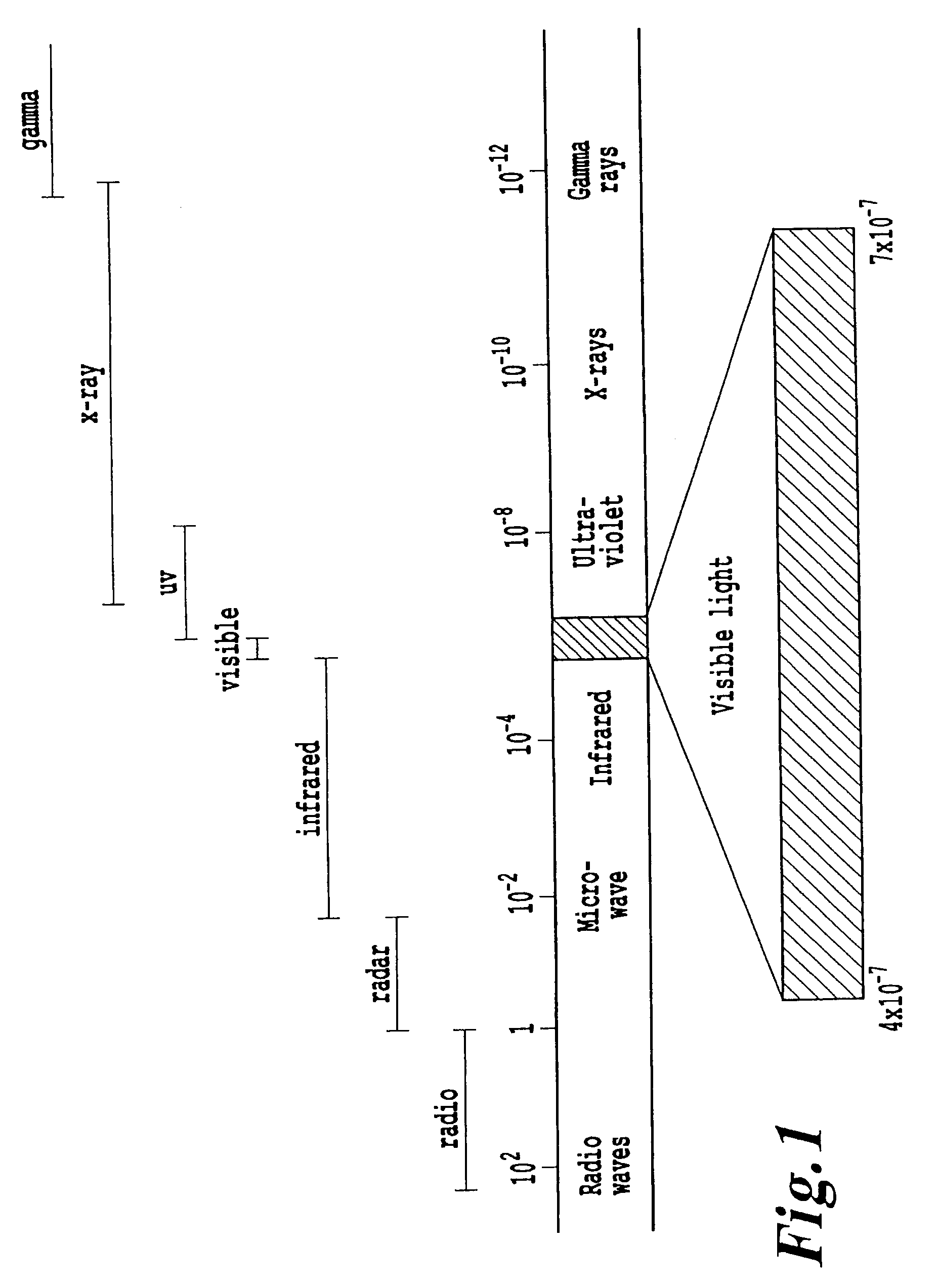

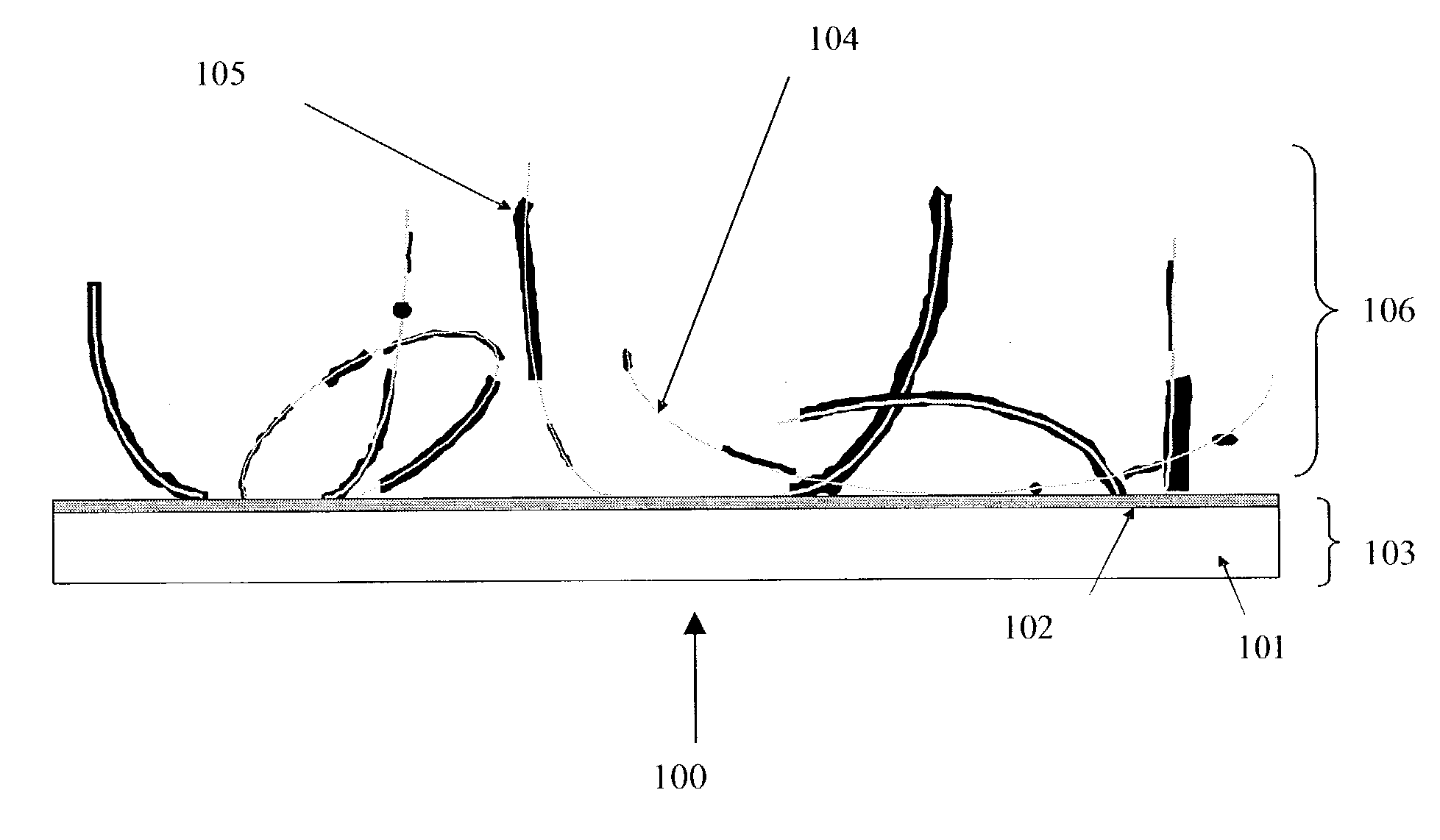

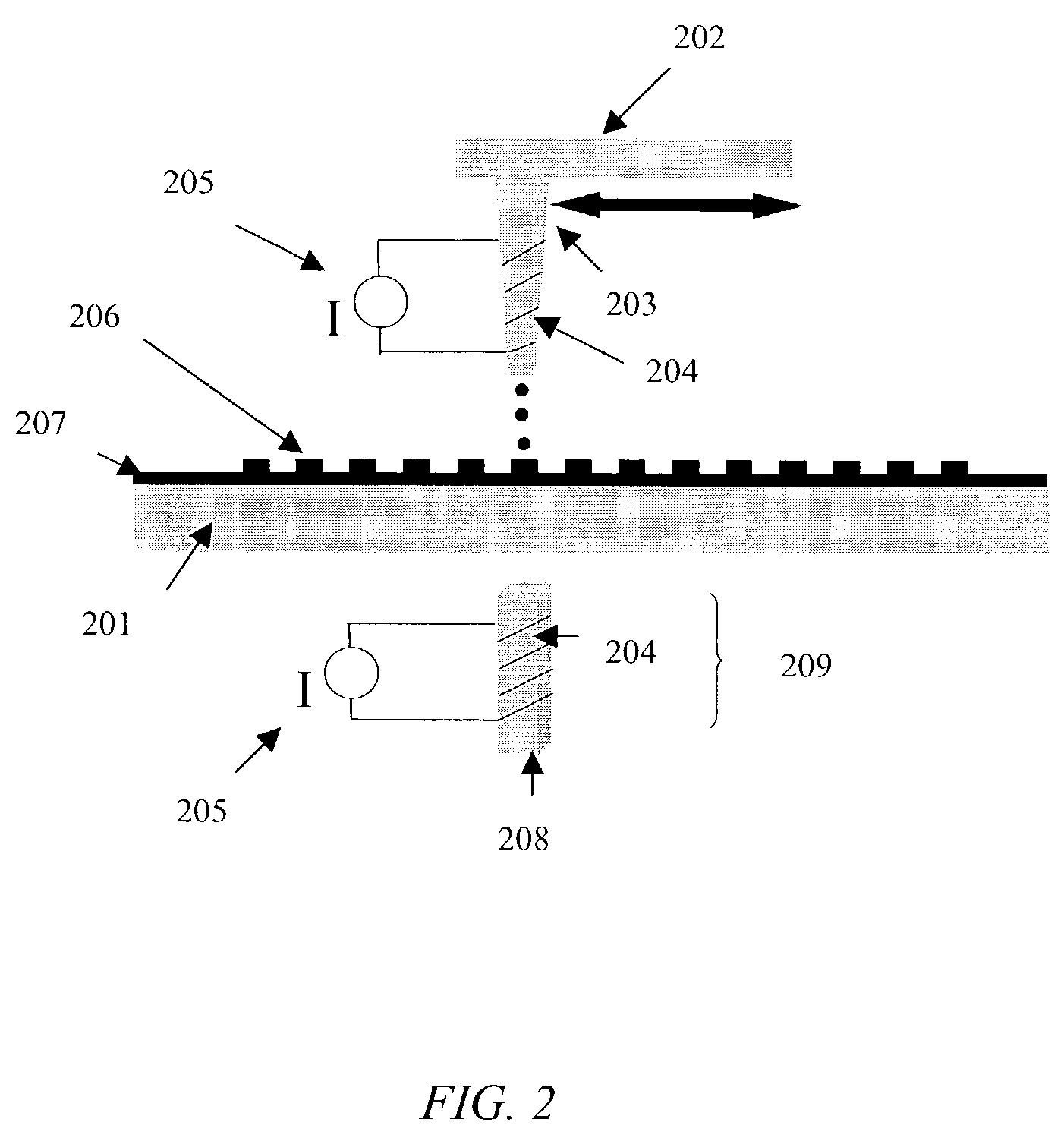

Probe System Comprising an Electric-Field-Aligned Probe Tip and Method for Fabricating the Same

A mechanically stable and oriented scanning probe tip comprising a carbon nanotube having a base with gradually decreasing diameter, with a sharp tip at the probe tip. Such a tip or an array of tips is produced by depositing a catalyst metal film on a substrate (10 & 12 in FIG. 1(a)), depositing a carbon dot (14 in FIG. 1(b)) on the catalyst metal film, etching away the catalyst metal film (FIG. 1(c)) not masked by the carbon dot, removing the carbon dot from the catalyst metal film to expose the catalyst metal film (FIG. 1(d)), and growing a carbon nanotube probe tip on the catalyst film (16 in FIG. 1(e)). The carbon probe tips can be straight, angled, or sharply bent and have various technical applications.

Owner:RGT UNIV OF CALIFORNIA

Plasmonic assisted systems and methods for interior energy-activation from an exterior source

Owner:DUKE UNIV +1

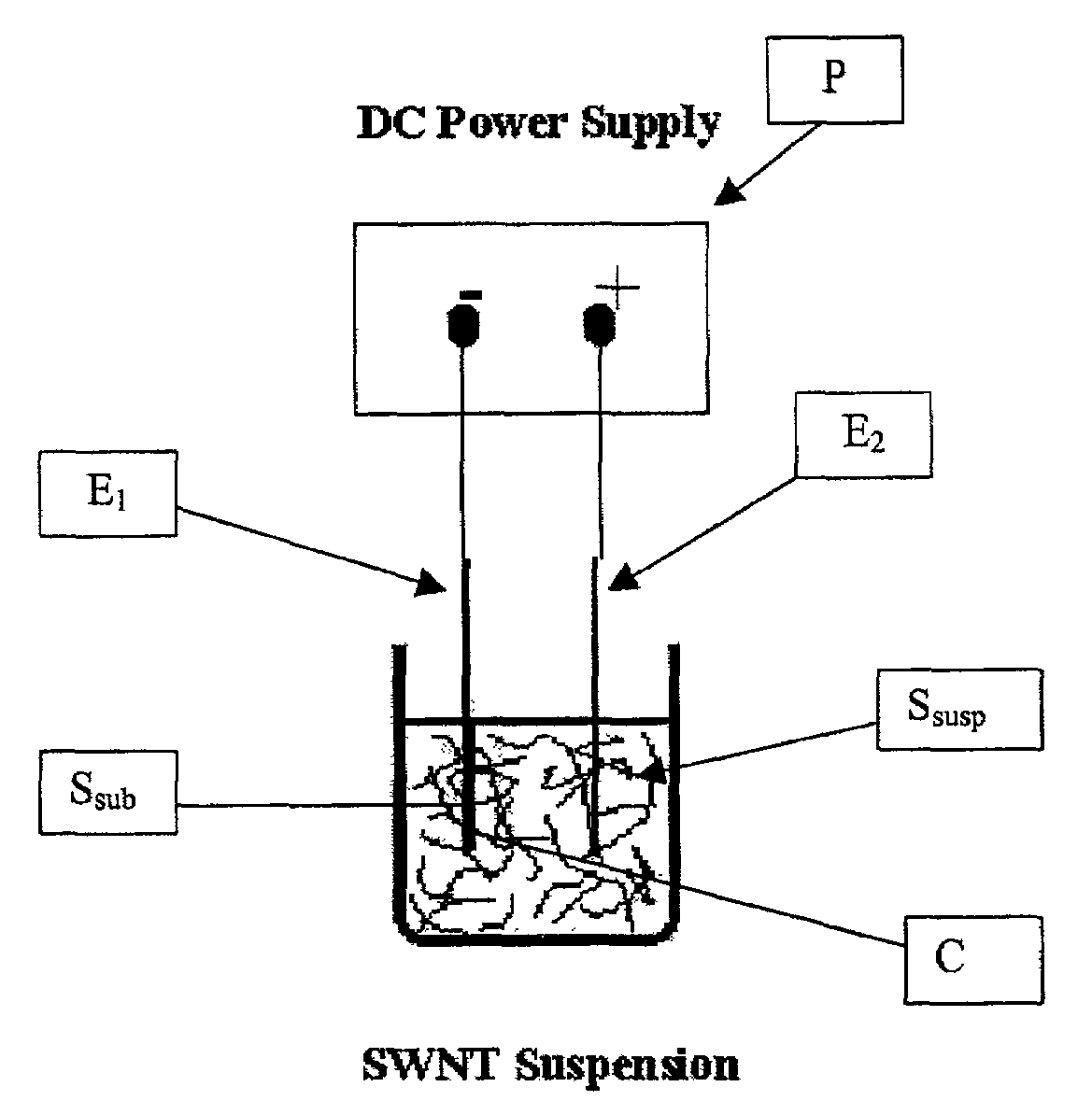

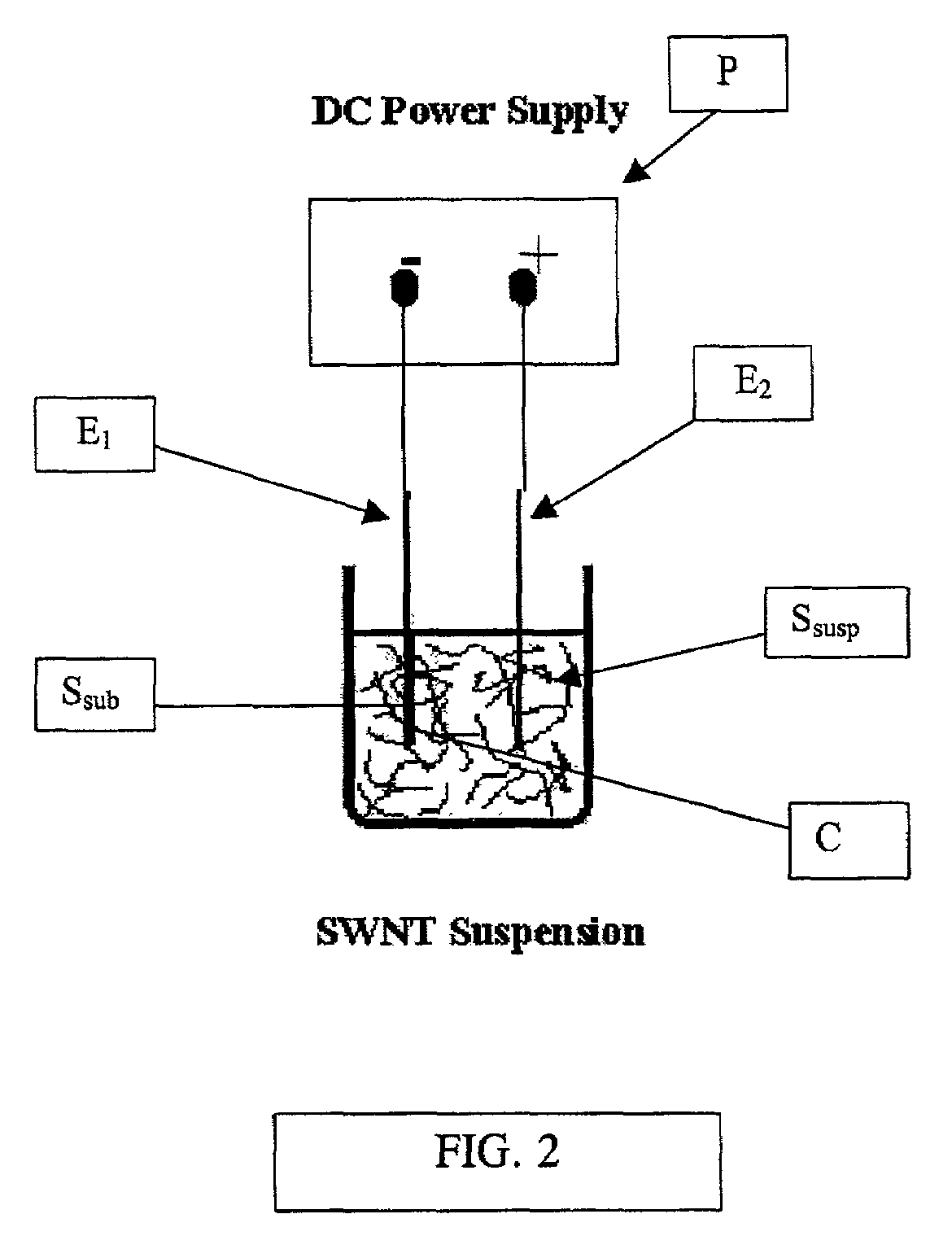

Deposition method for nanostructure materials

InactiveUS7252749B2Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsNanostructured materialsNanostructure

A method for depositing a coating of a nanostructure material onto a substrate includes: (1) forming a solution or suspension of containing the nanostructure material; (2) selectively adding “chargers” to the solution; (3) immersing electrodes in the solution, the substrate upon which the nanostructure material is to be deposited acting as one of the electrodes; (4) applying a direct and / or alternating current electrical field between the two electrodes for a certain period of time thereby causing the nanostructure materials in the solution to migrate toward and attach themselves to the substrate electrode; and (5) subsequent optional processing of the coated substrate.

Owner:NURAY TECH +1

Process of making a component with a passageway

A component is provided that includes at least one passageway. In another aspect, a component, such as a lamp or a vehicular washer jet, is made of layers of material, a light curable material and / or multiple built-up materials. Another aspect uses a three-dimensional printing machine to emit material from an ink jet printing head to build up a component.

Owner:A RAYMOND & CO

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS7217334B2Enhance and improve adhesionHigh quality transmissionElectric lighting sourcesSolid-state devicesEngineeringSemiconductor

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

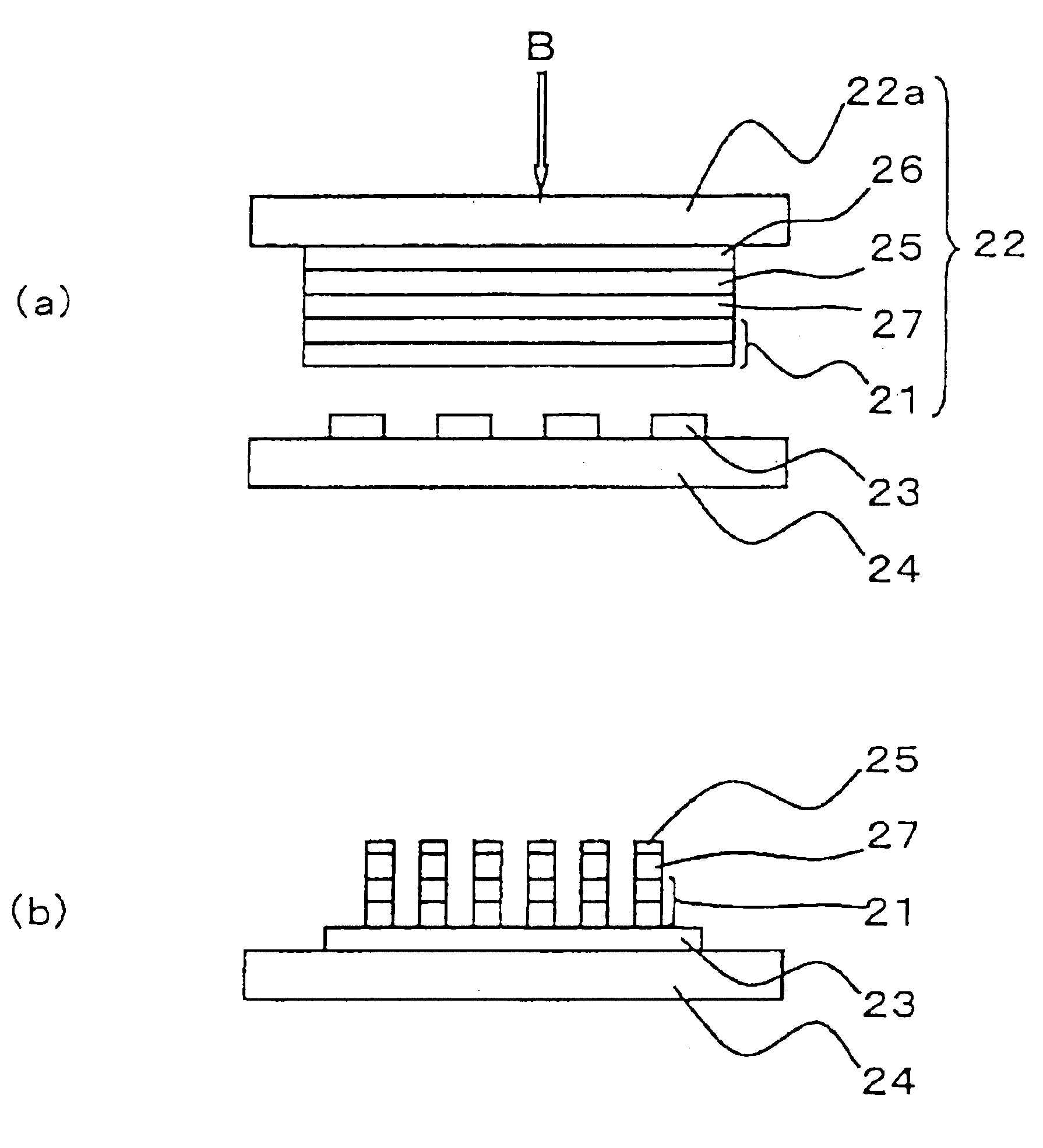

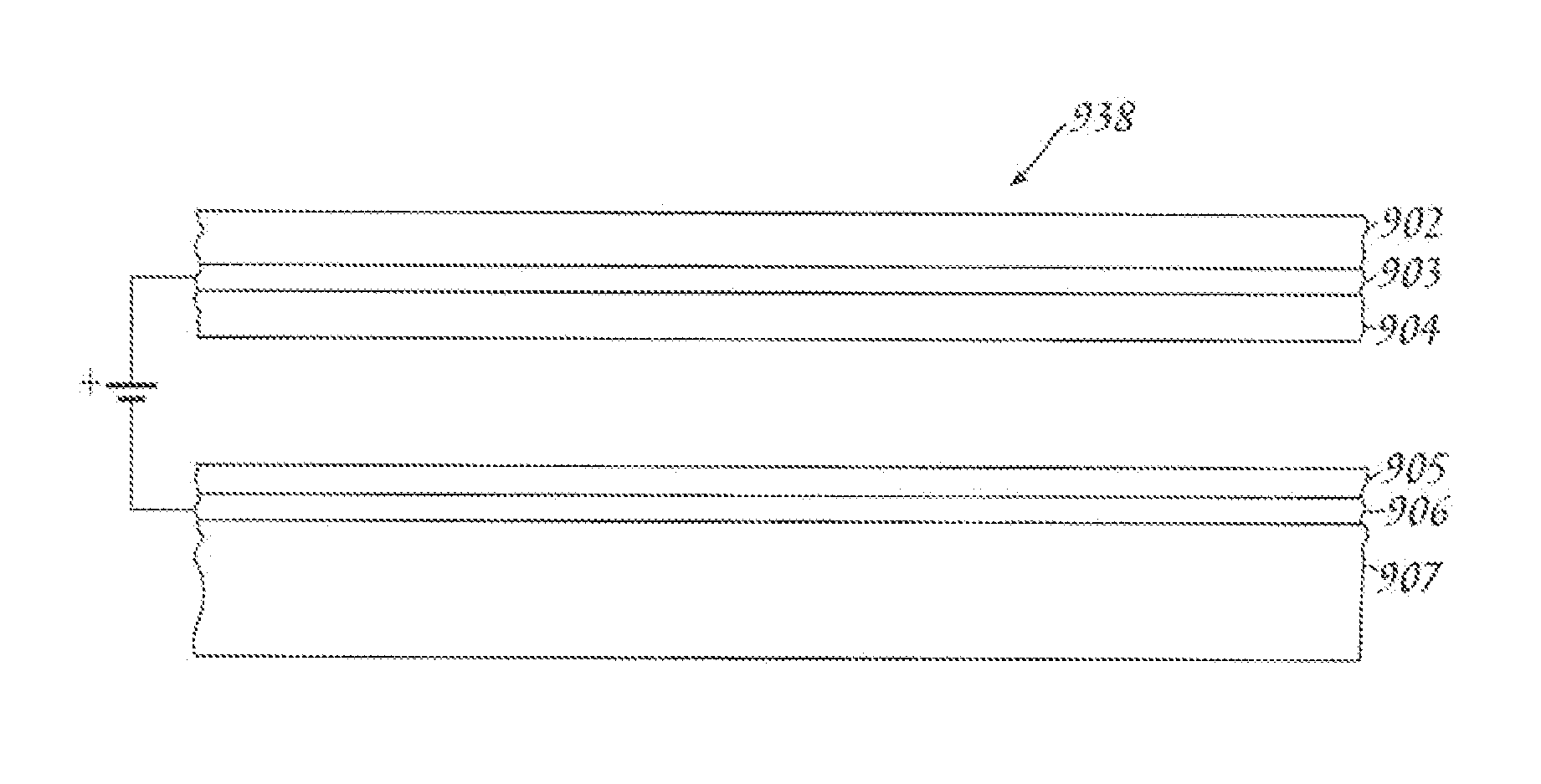

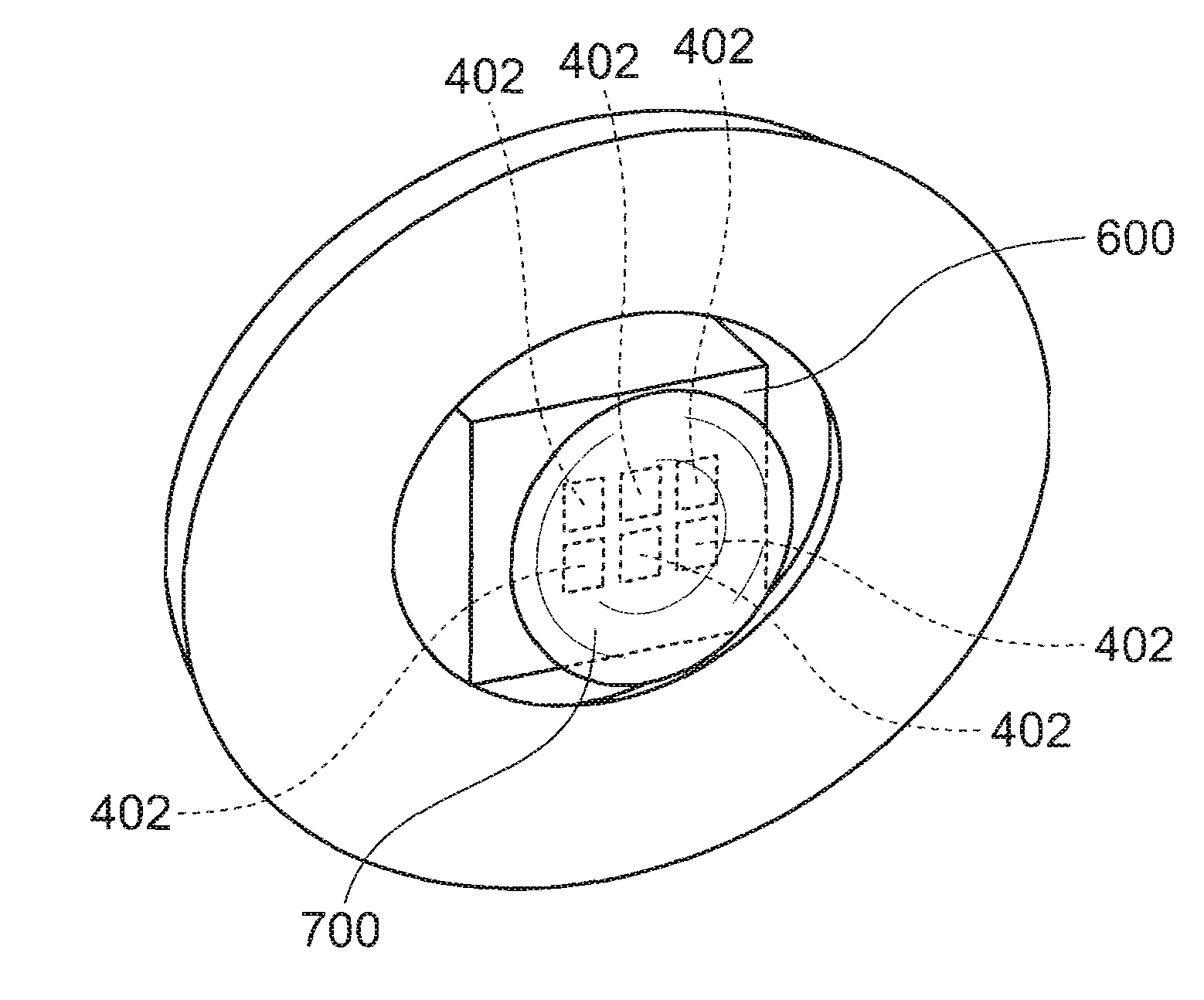

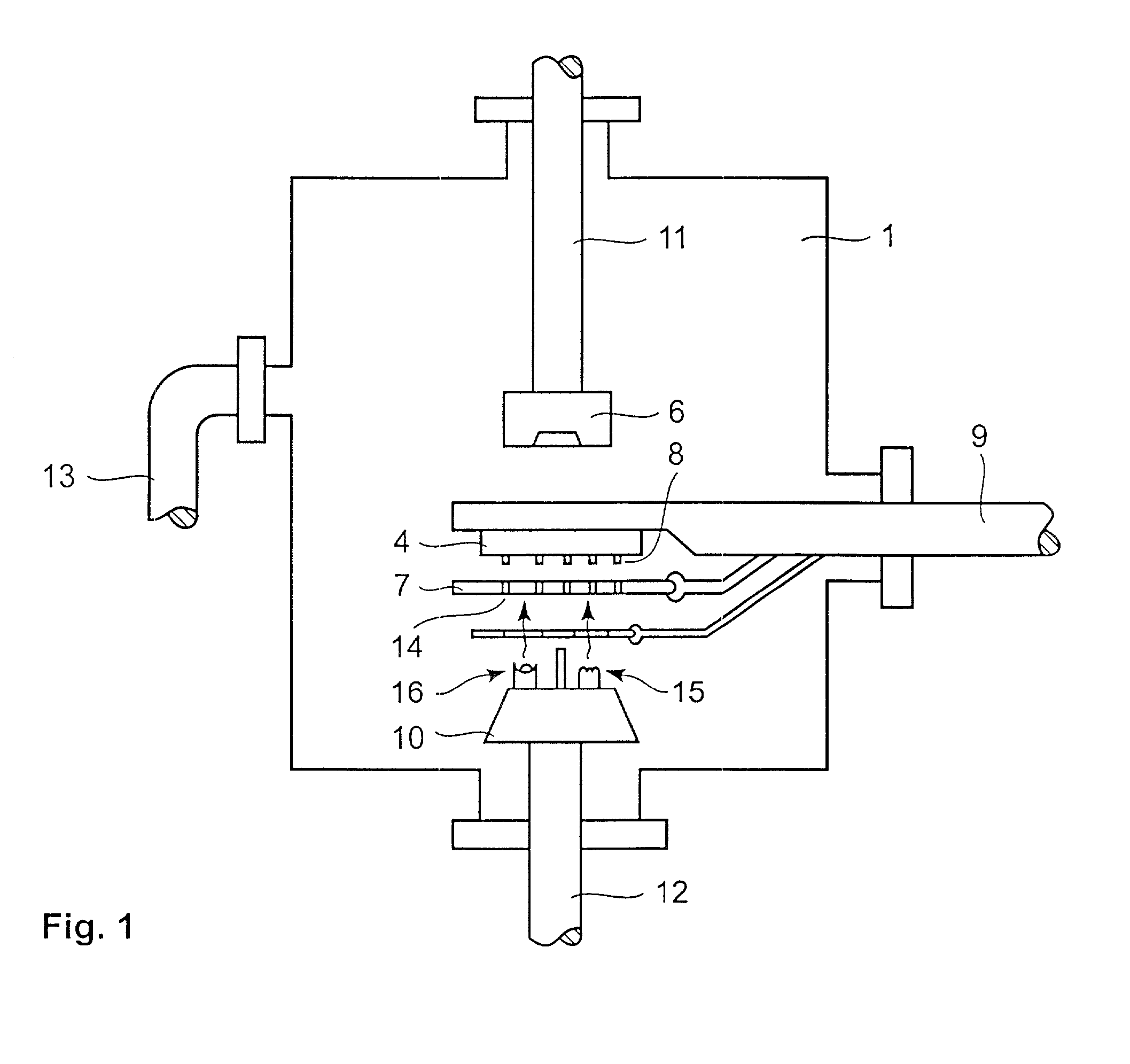

Crystals comprising single-walled carbon nanotubes

InactiveUS20020130610A1High yieldStay efficientMaterial nanotechnologyCarbon compoundsFullerene moleculeNanotube

The invention is directed to a method of manufacturing single-walled carbon nanotubes comprising the steps of providing on a substrate at least one pillar comprising alternate layers of a first precursor material comprising fullerene molecules and a second precursor material comprising a catalyst, and heating the at least one pillar in the presence of a first magnetic or electric field. It further is directed to a precursor arrangement for manufacturing single-walled carbon nanotubes comprising on a substrate at least one pillar comprising alternate layers of a first precursor material comprising fullerene molecules and a second precursor material comprising a catalyst. A third aspect is a nanotube arrangement comprising a substrate and thereupon at least one crystal comprising a bundle of single-walled carbon nanotubes with essentially identical orientation and structure.

Owner:IBM CORP

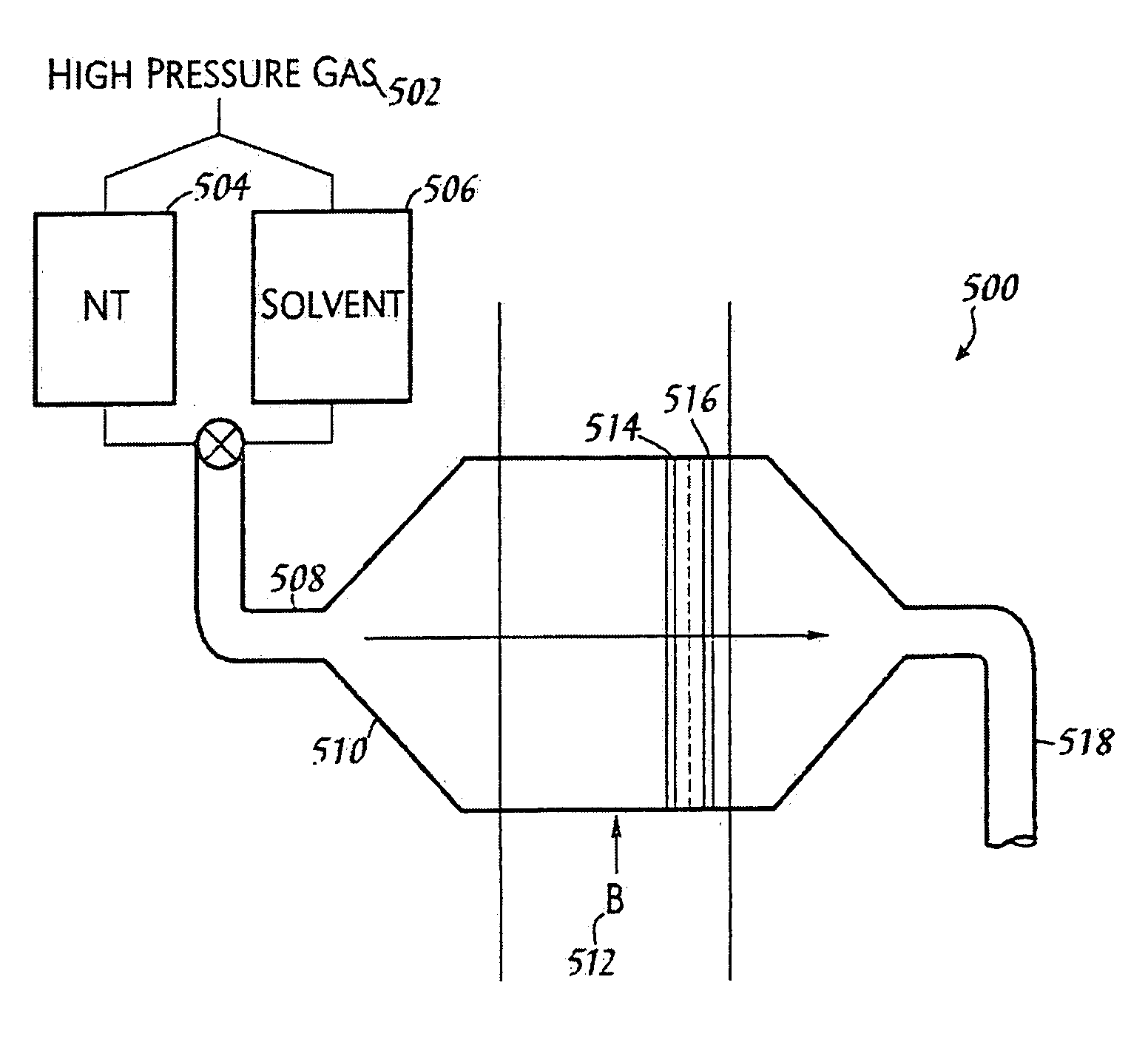

Macroscopic ordered assembly of carbon nanotubes

InactiveUS20080210370A1Firmly assembledMaterial nanotechnologyNanostructure manufactureNear neighborMicroscopic scale

The present invention is directed to the creation of macroscopic materials and objects comprising aligned nanotube segments. The invention entails aligning single-wall carbon nanotube (SWNT) segments that are suspended in a fluid medium and then removing the aligned segments from suspension in a way that macroscopic, ordered assemblies of SWNT are formed. The invention is further directed to controlling the natural proclivity or nanotube segments to self assemble into or ordered structures by modifying the environment of the nanotubes and the history of that environment prior to and during the process. The materials and objects are “macroscopic” in that they are large enough to be seen without the aid of a microscope or of the dimensions of such objects. These macroscopic ordered SWNT materials and objects have the remarkable physical, electrical, and chemical properties that SWNT exhibit on the microscopic scale because they are comprised of nanotubes, each of which is aligned in the same direction and in contact with its nearest neighbors. An ordered assembly of closest SWNT also serves as a template for growth of more and larger ordered assemblies. An ordered assembly further serves as a foundation for post processing treatments that modify the assembly internally to specifically enhance selected material properties such as shear strength, tensile strength, compressive strength, toughness, electrical conductivity, and thermal conductivity.

Owner:RICE UNIV

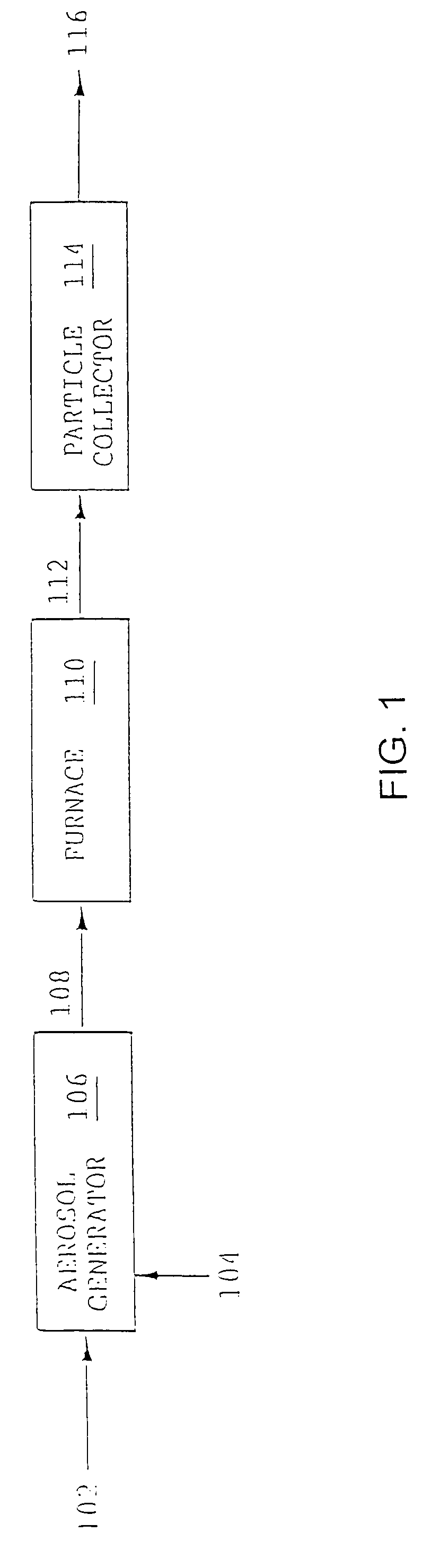

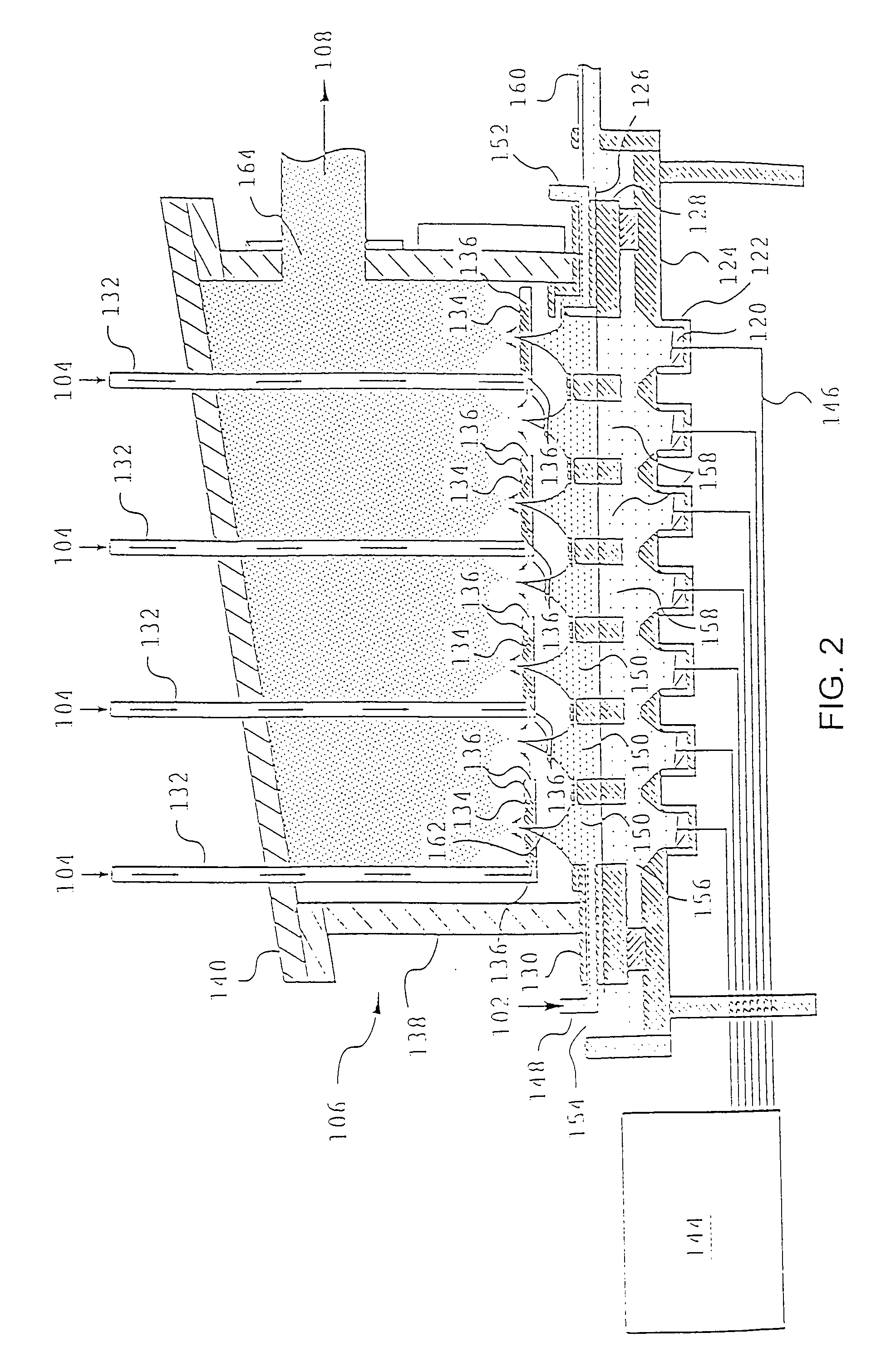

Direct-write deposition of phosphor powders

InactiveUS7476411B1Improve automationHigh resolution displayRare earth metal oxides/hydroxidesMaterial granulation and coatingApparent densityPhosphor

A liquid suspension of phosphor particles and method for depositing the liquid suspension. The suspension advantageously has a low viscosity with a high solids-loading of phosphor particles. The apparent density of the phosphor particles is well-controlled to enable the particles to be dispersed in the liquid vehicle. The suspension is useful in direct-write tools such as ink-jet devices.

Owner:SICPA HLDG SA

Metallization of carbon nanotubes for field emission applications

The present invention is directed towards metallized carbon nanotubes, methods for making metallized carbon nanotubes using an electroless plating technique, methods for dispensing metallized carbon nanotubes onto a substrate, and methods for aligning magnetically-active metallized carbon nanotubes. The present invention is also directed towards cold cathode field emitting materials comprising metallized carbon nanotubes, and methods of using metallized carbon nanotubes as cold cathode field emitters.

Owner:NANO

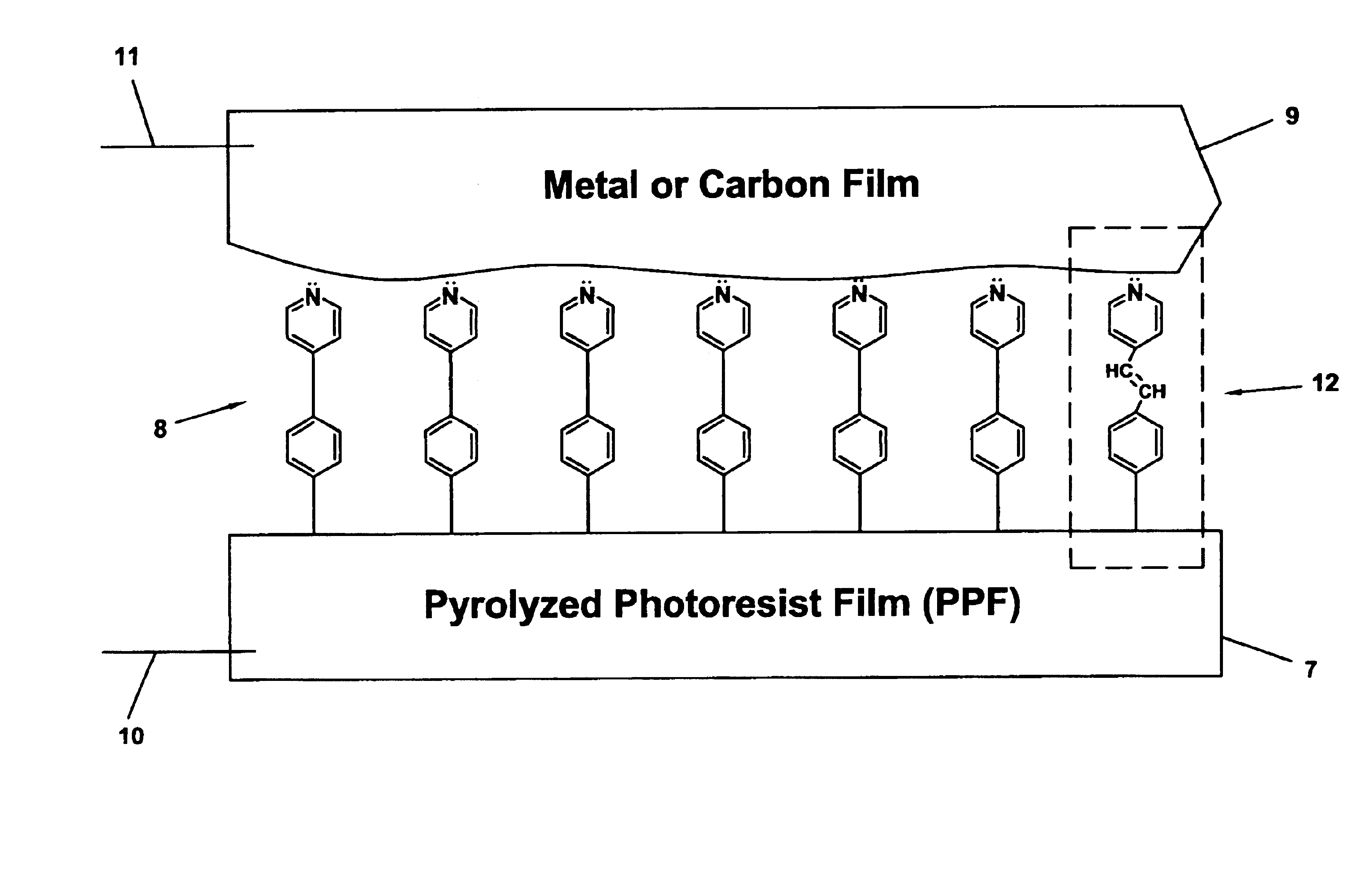

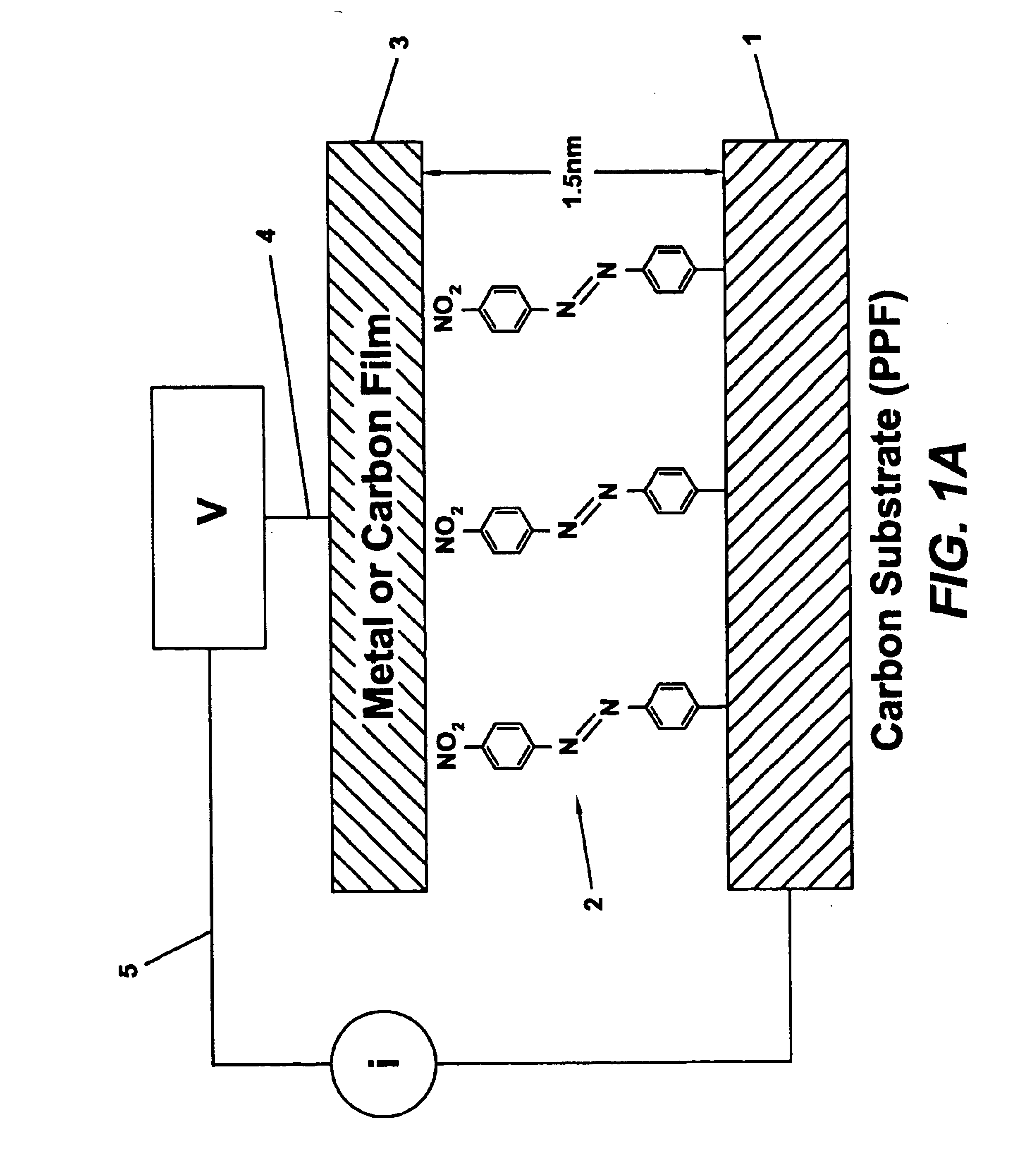

Pixel array

InactiveUS6919128B2Improve electron emission efficiencyOptical radiation measurementNanoinformaticsElectronMolecular physics

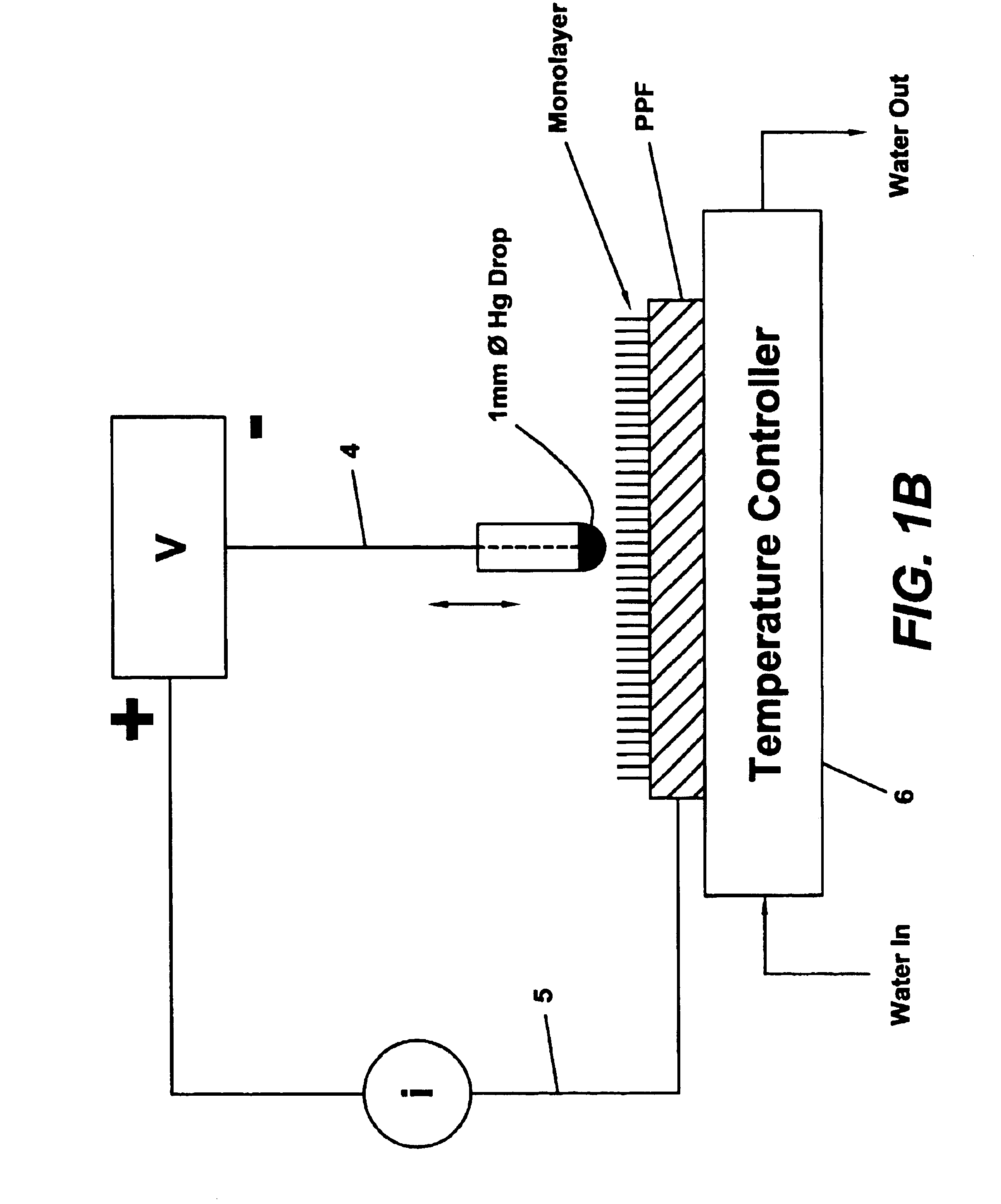

The present invention includes a chemical monolayer construction that comprises: (a) a substrate having a contact surface; and (b) a plurality of substantially parallel molecular units, wherein said molecular units are attached to said substrate so as to be strongly coupled electronically to said substrate, such as through a conjugated bond. The present invention also includes electronic circuit components and devices including a chemical monolayer construction of the present invention.

Owner:THE OHIO STATE UNIV RES FOUND

Popular searches

Fuel cells Tubular articles Discharge tube screens Cathode ray tubes/electron beam tubes Alkali metal halides From chemically reactive gases Superconductor device manufacture/treatment Energy based chemical/physical/physico-chemical processes Chemical vapor deposition coating Single crystal growth details

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com