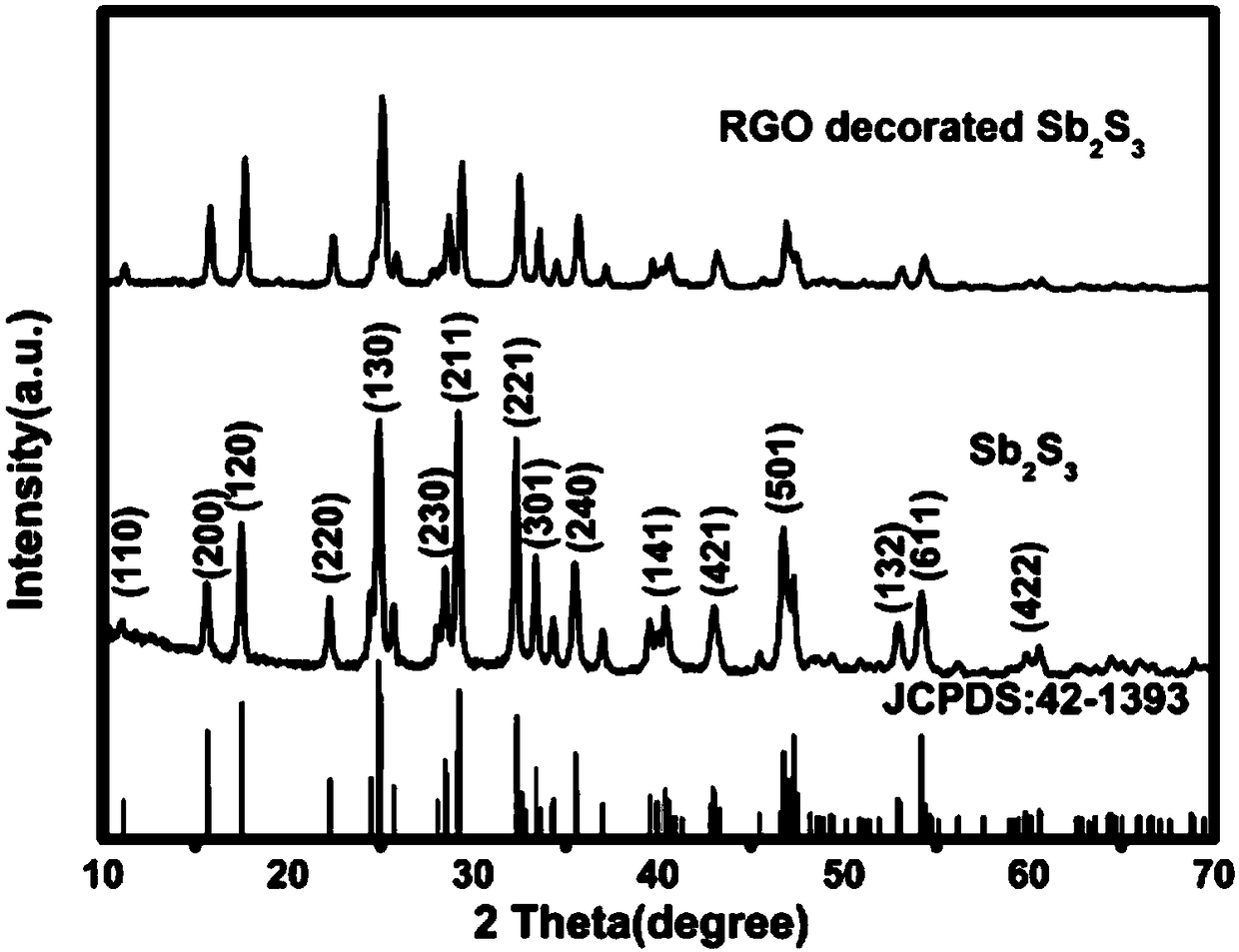

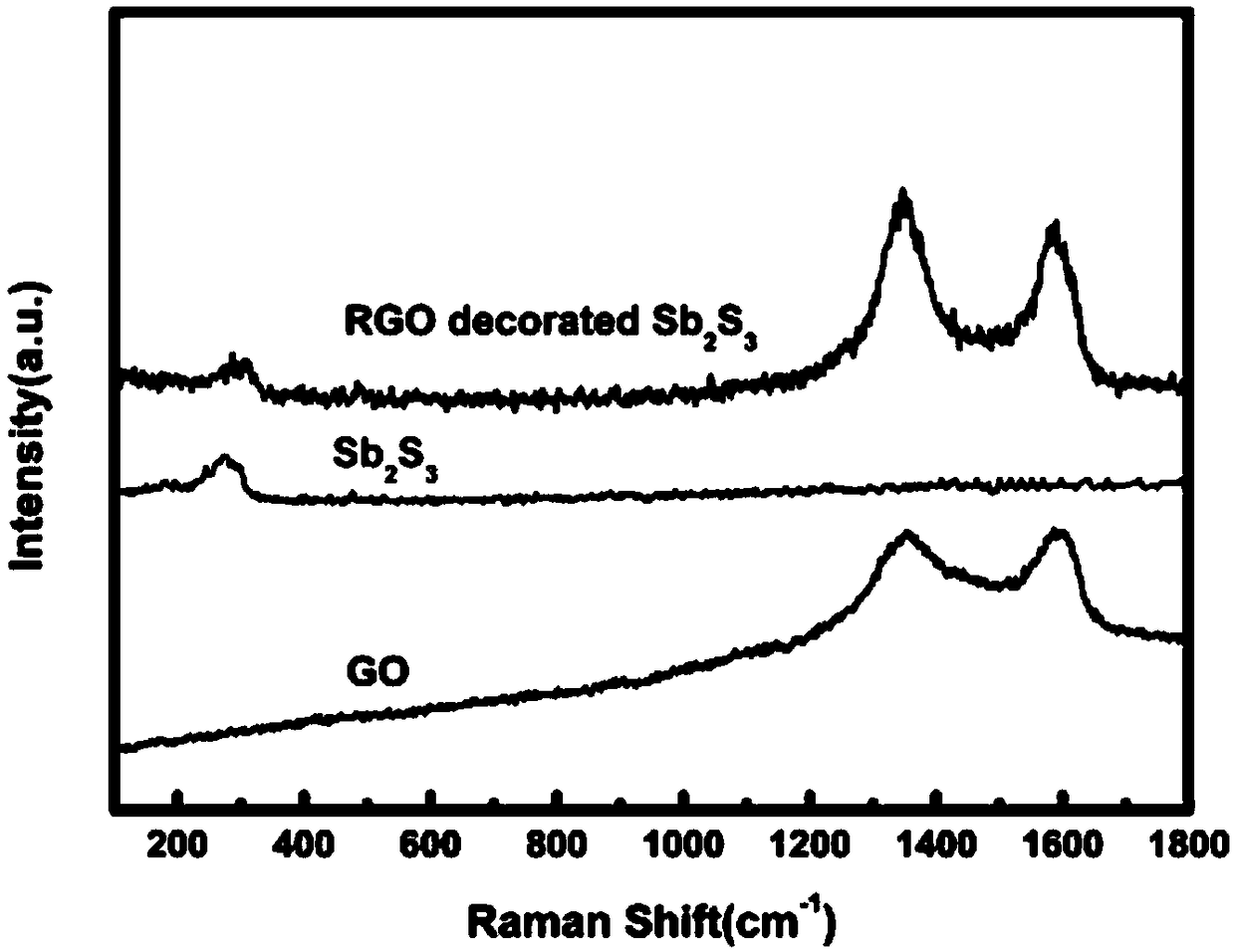

Reduced graphene oxide modified antimony trisulfide battery anode material

A technology of antimony trisulfide and battery negative electrode, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low stability of negative electrode materials, achieve high specific capacity, enhance conductivity and stability, and improve volume expansion effect and effect of agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0033] A kind of reduced graphene oxide modified Sb 2 S 3 A method for preparing a negative electrode material for a sodium ion battery, comprising the following steps:

[0034] Step 1. First, dissolve 1 mmol of antimony trichloride, 2 mmol of L-cysteine, and 2 mmol of sodium sulfide nonahydrate in 30 ml of deionized water, stir for 2 hours, and heat the reaction at 160 degrees Celsius 12 hours. Then wash with deionized and absolute ethanol, and finally dry at 60 degrees Celsius for 12 hours to obtain Sb 2 S 3 powder.

[0035] Take 1 mmol of Sb prepared above 2 S 3 The powder was added to 20 milliliters of absolute ethanol, and then 10 milliliters of graphene oxide solution (5 milligrams of graphene oxide was dissolved in 10 milliliters of deionized water, prepared by ultrasonic cleaning for 1 hour at a power of 200 watts), magnetic Stir for 1 hour to obtain a precursor solution;

[0036]Step 2. Then transfer the above precursor solution to a polytetrafluoroethylene-li...

Embodiment 1-2

[0039] A preparation method for a negative electrode sheet of a sodium ion battery, specifically, the reduced graphene oxide modified Sb prepared in the above-mentioned embodiment 1-1 of 0.08 grams 2 S 3 The negative electrode material of the battery is evenly mixed with 0.01 gram of binder sodium carboxymethyl cellulose and 0.01 gram of conductive agent Super-P, and water is used as a solvent to make a slurry, which is coated on copper foil (the thickness of the coating is 150 microns), and vacuum dried at 110 degrees centigrade for 12 hours, and rolled (the thickness of the rolled is 130 microns), to prepare a negative electrode sheet for a sodium ion battery.

[0040] The sodium ion battery negative plate, metal sodium sheet, and electrolyte prepared in this example were assembled into a sodium ion battery for constant current charge and discharge tests. The electrolyte used contained 1.0M NaClO 4 EC / DEC / FEC (1:1:2Vol%).

Embodiment 2-1

[0042] A kind of reduced graphene oxide modified Sb 2 S 3 A method for preparing a negative electrode material for a sodium ion battery, comprising the following steps:

[0043] Step 1. First, dissolve 1 mmol of antimony trichloride, 2 mmol of L-cysteine, and 2 mmol of sodium sulfide nonahydrate in 30 ml of deionized water, stir for 2 hours, and heat the reaction at 180 degrees Celsius 12 hours. Then washed with deionized and absolute ethanol, and finally dried at 60 °C for 12 hours to obtain Sb 2 S 3 powder.

[0044] The above prepared 0.5 mmol Sb 2 S 3 The powder was added to 20 milliliters of absolute ethanol, and then 10 milliliters of graphene oxide solution was added (10 milligrams of graphene oxide was dissolved in 10 milliliters of deionized water, and the power was 200 watts, and ultrasonic cleaning was performed for 2 hours), magnetically stirred for 1 Hour, obtain precursor solution;

[0045] Step 2. Next, the precursor solution was transferred to a polytetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com