Patents

Literature

116results about How to "Great abrasion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

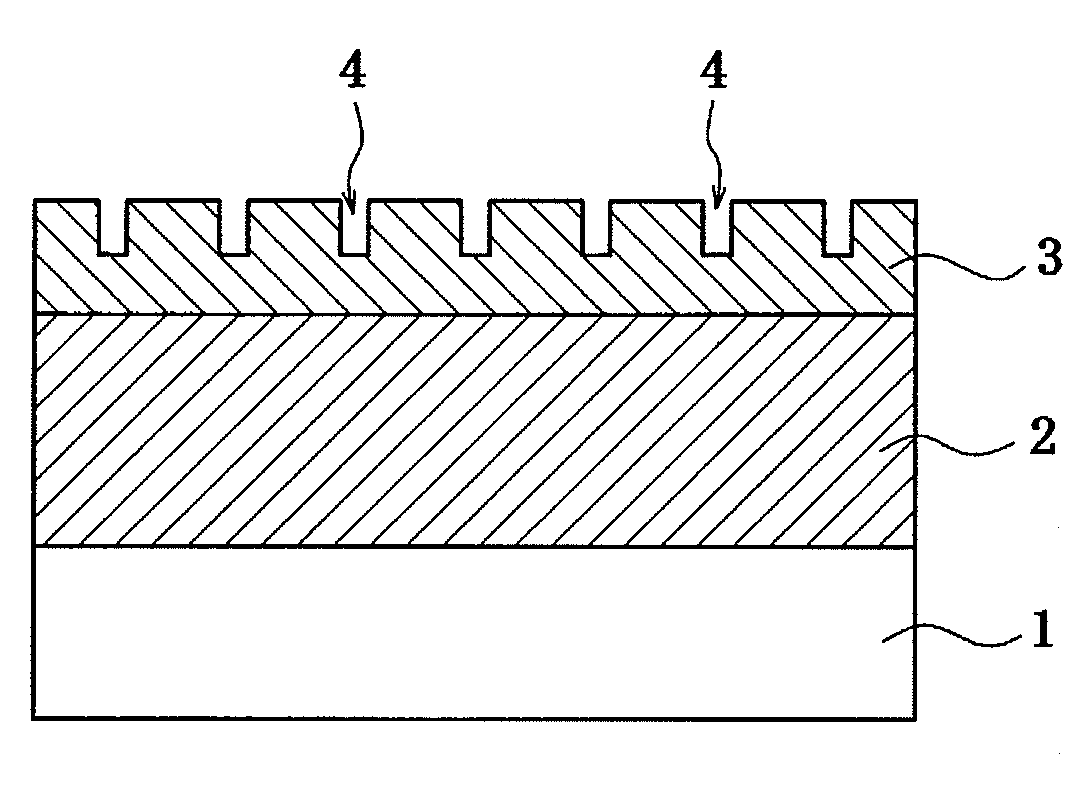

Image forming method, and image formed matter

InactiveUS20120128949A1Improve wear resistanceIncrease speedLayered productsDuplicating/marking methodsWater dispersibleEngineering

An image forming method including: applying a pre-treatment liquid onto a coating layer provided on at least one surface of a support of a recording medium, jetting an inkjet ink onto the coating layer, onto which the pre-treatment liquid has been applied, so as to form an image, and applying or jetting a post-treatment liquid onto the coating layer, onto which the inkjet ink has been jetted, so as to form a transparent protective layer on the coating layer, wherein the inkjet ink contains the water-dispersible colorant, a water-soluble organic solvent, a surfactant, a penetrant and water, and wherein an amount of pure water transferred into the recording medium, provided with the coating layer, measured at a contact time of 100 ms with a dynamic scanning liquid absorptometer is 1 ml / m2 to 10 ml / m2, and the pre-treatment liquid contains a water-soluble aliphatic organic acid.

Owner:RICOH KK

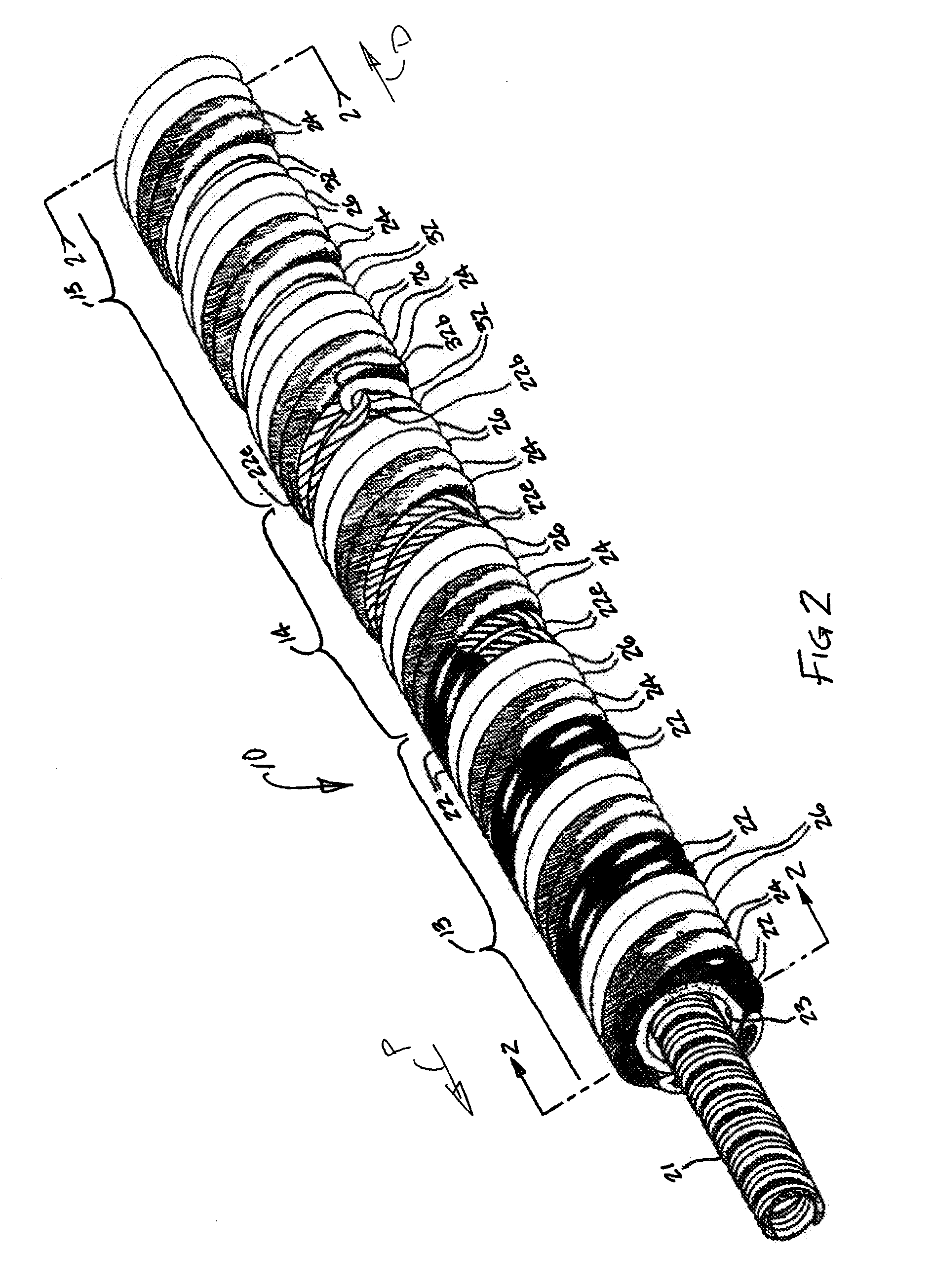

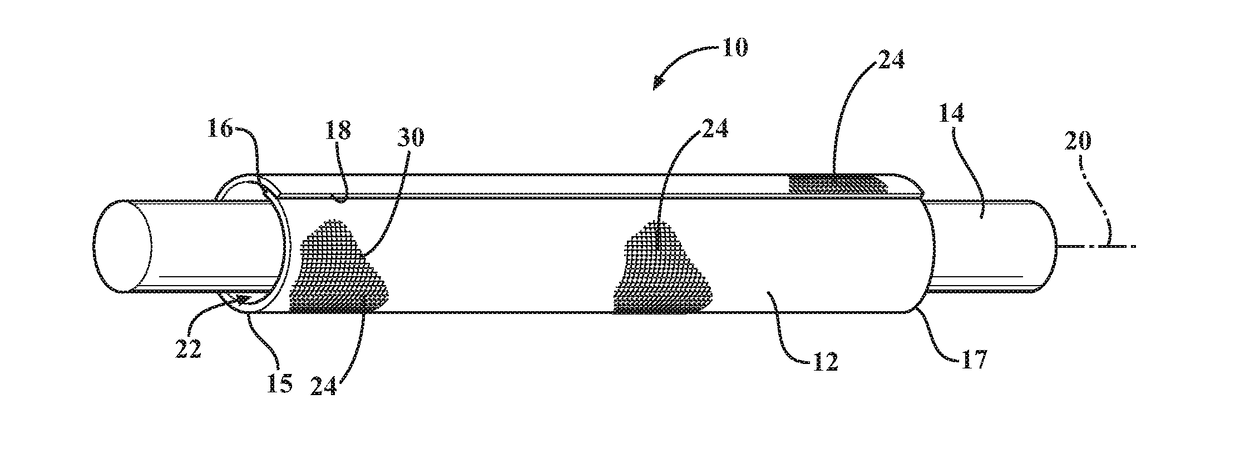

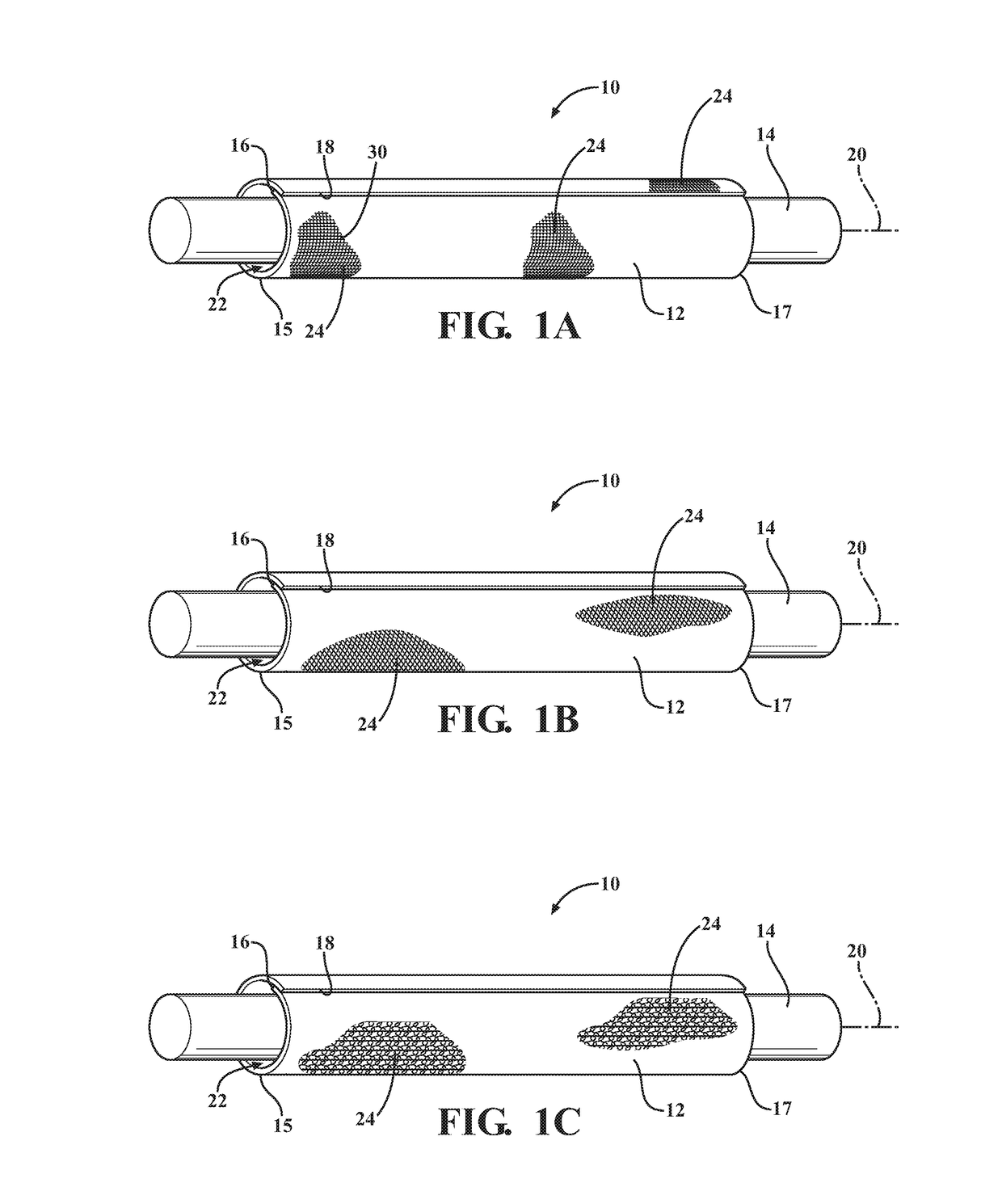

Implantable lead

ActiveUS20100137928A1Good flexibility , fatigue resistance and flex lifeImprove reliabilityContact member manufacturingInternal electrodesTissue damageDefibrillation

Owner:WL GORE & ASSOC INC

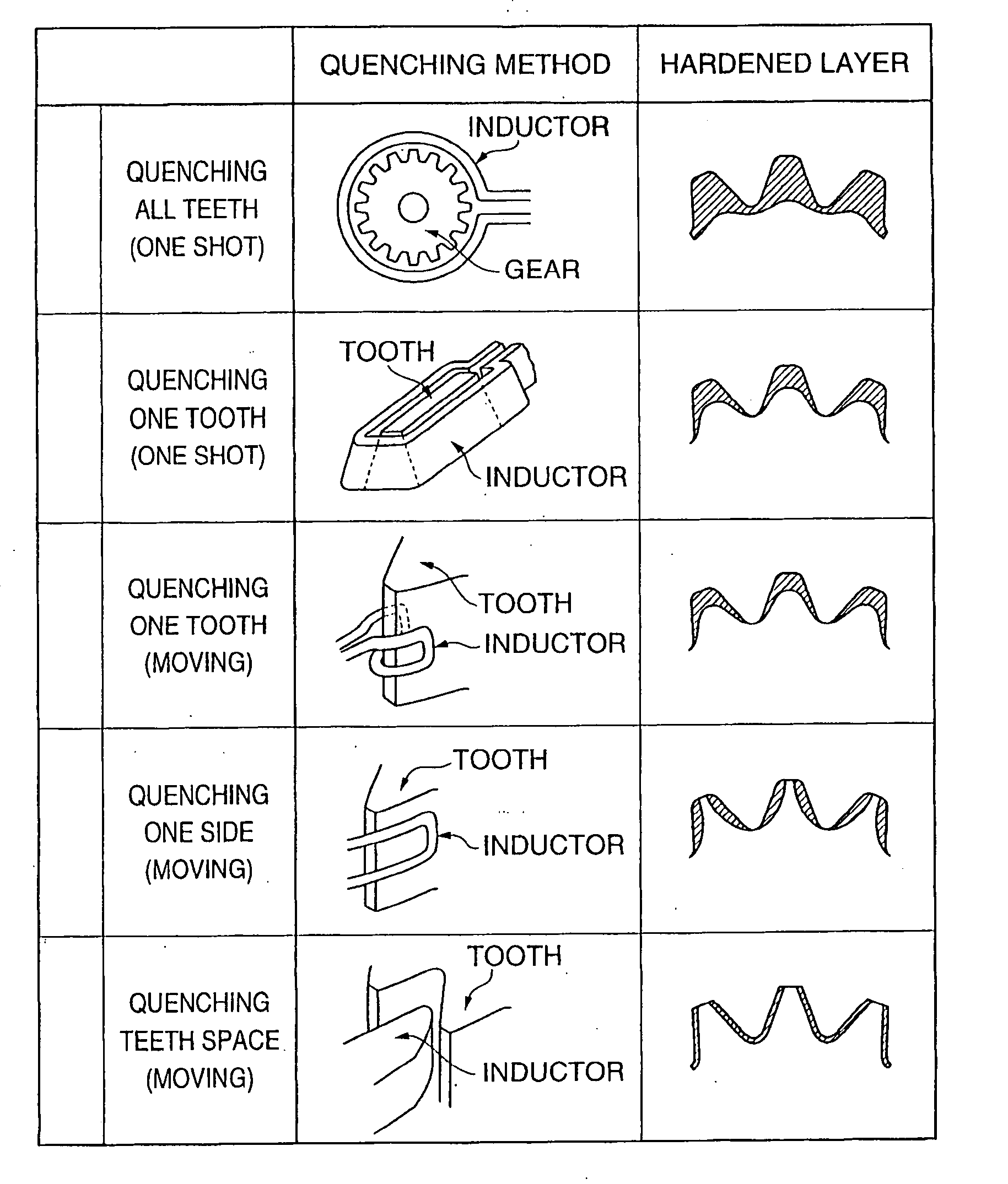

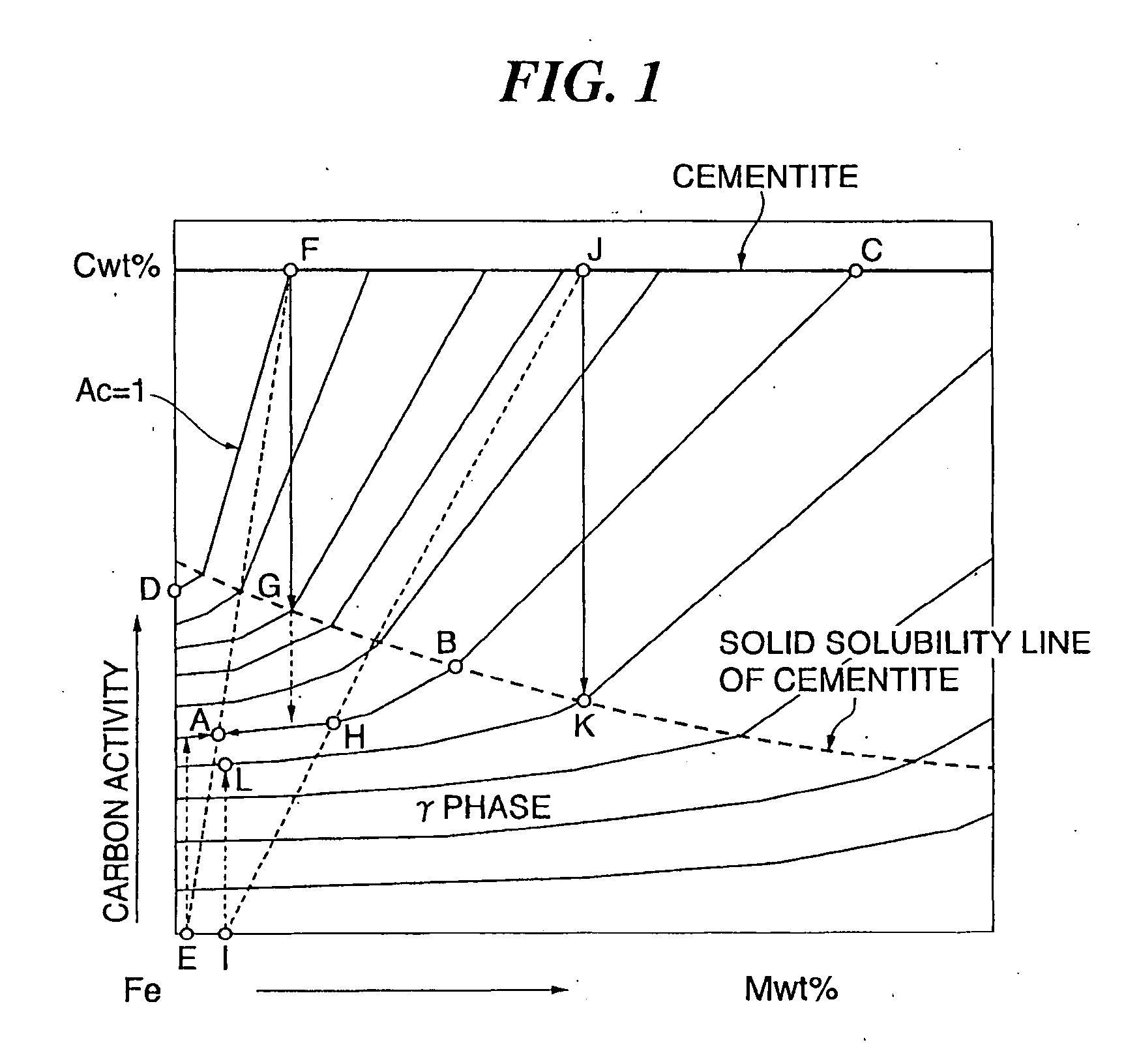

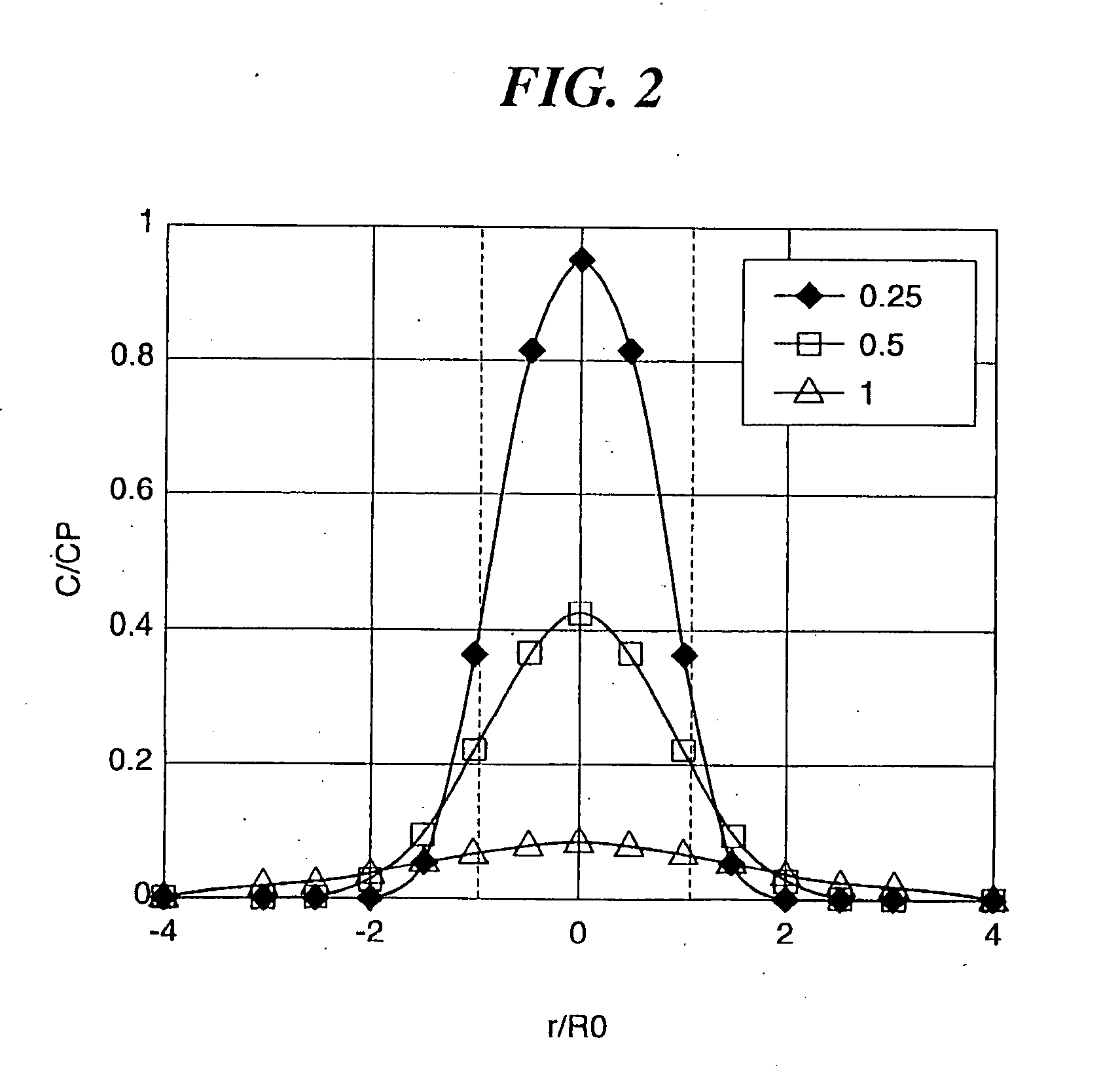

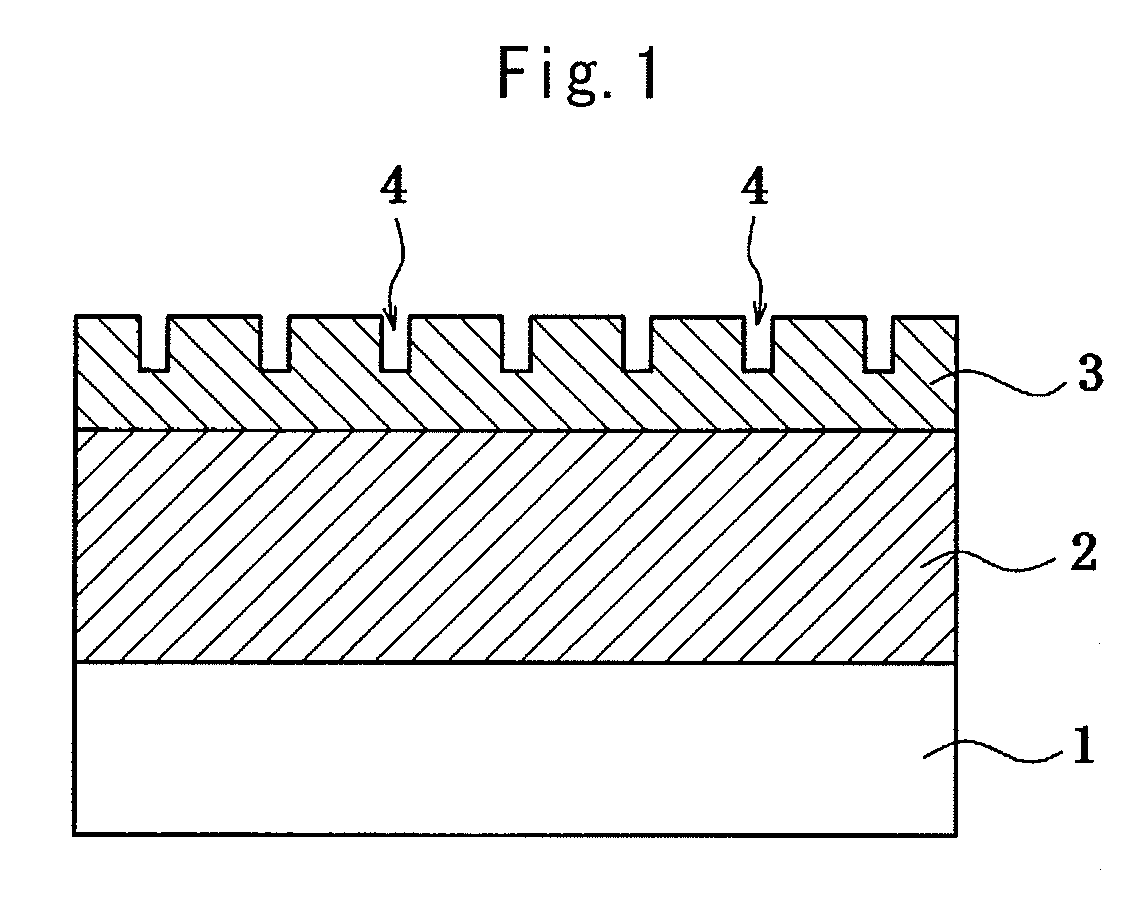

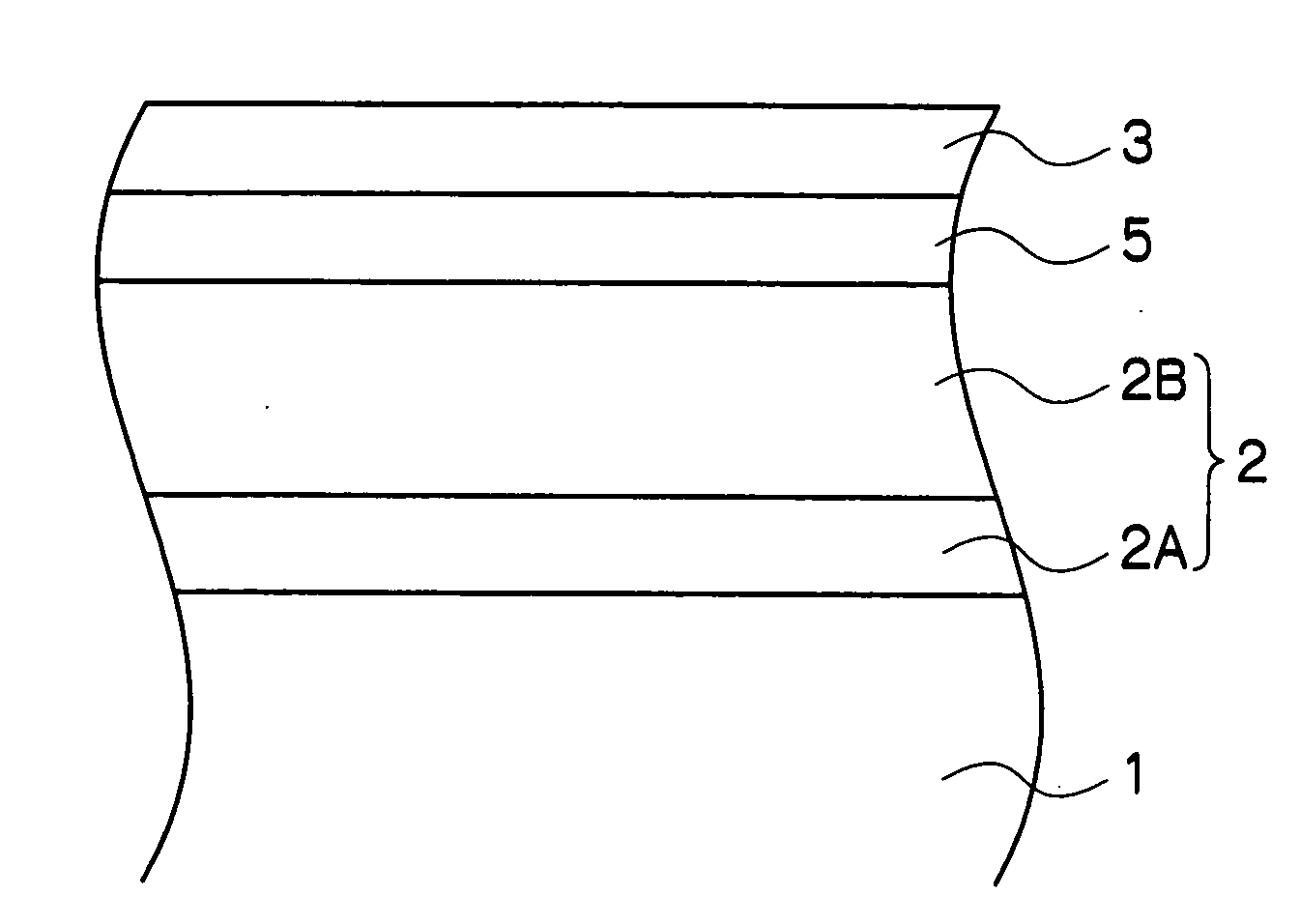

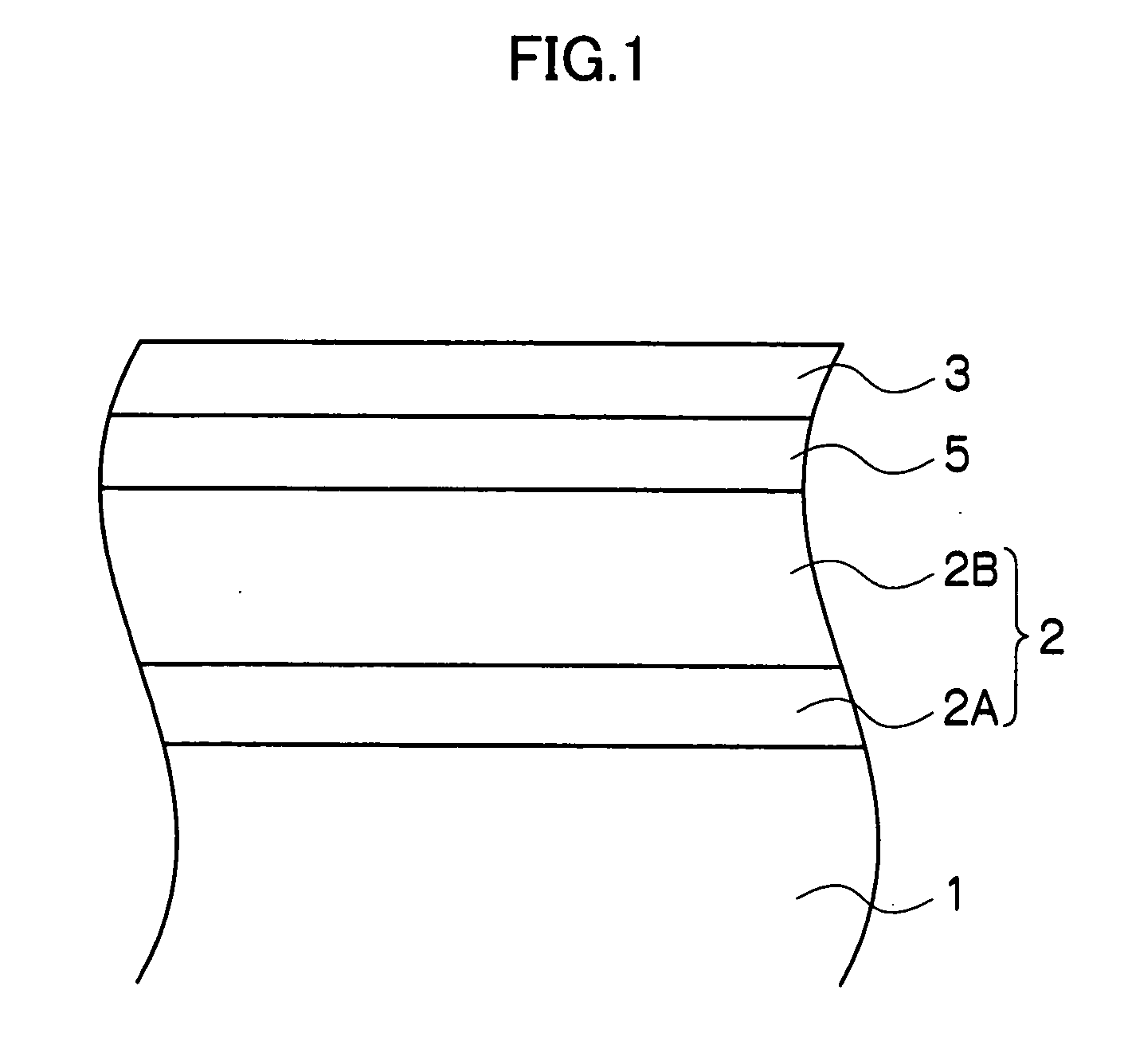

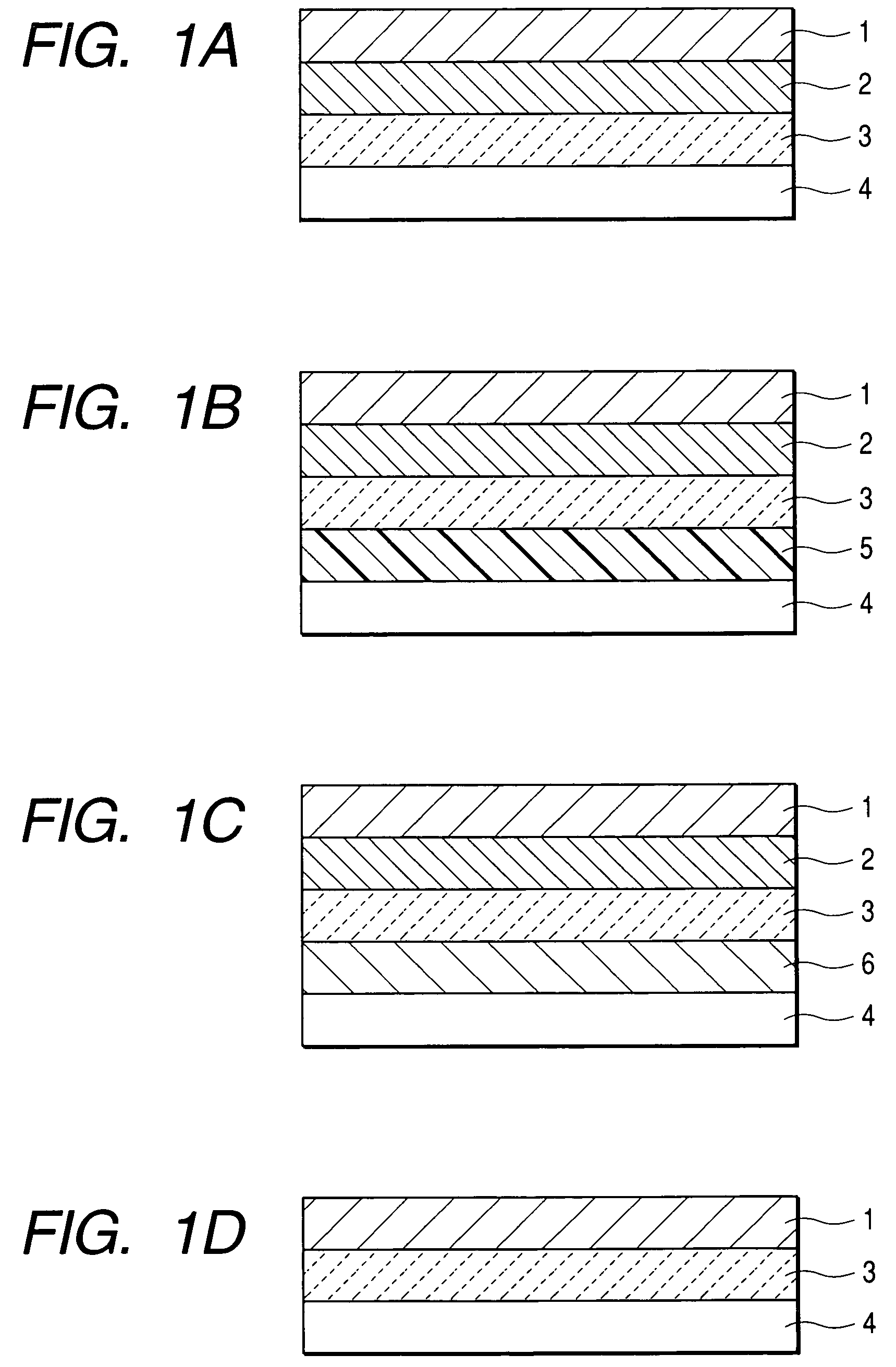

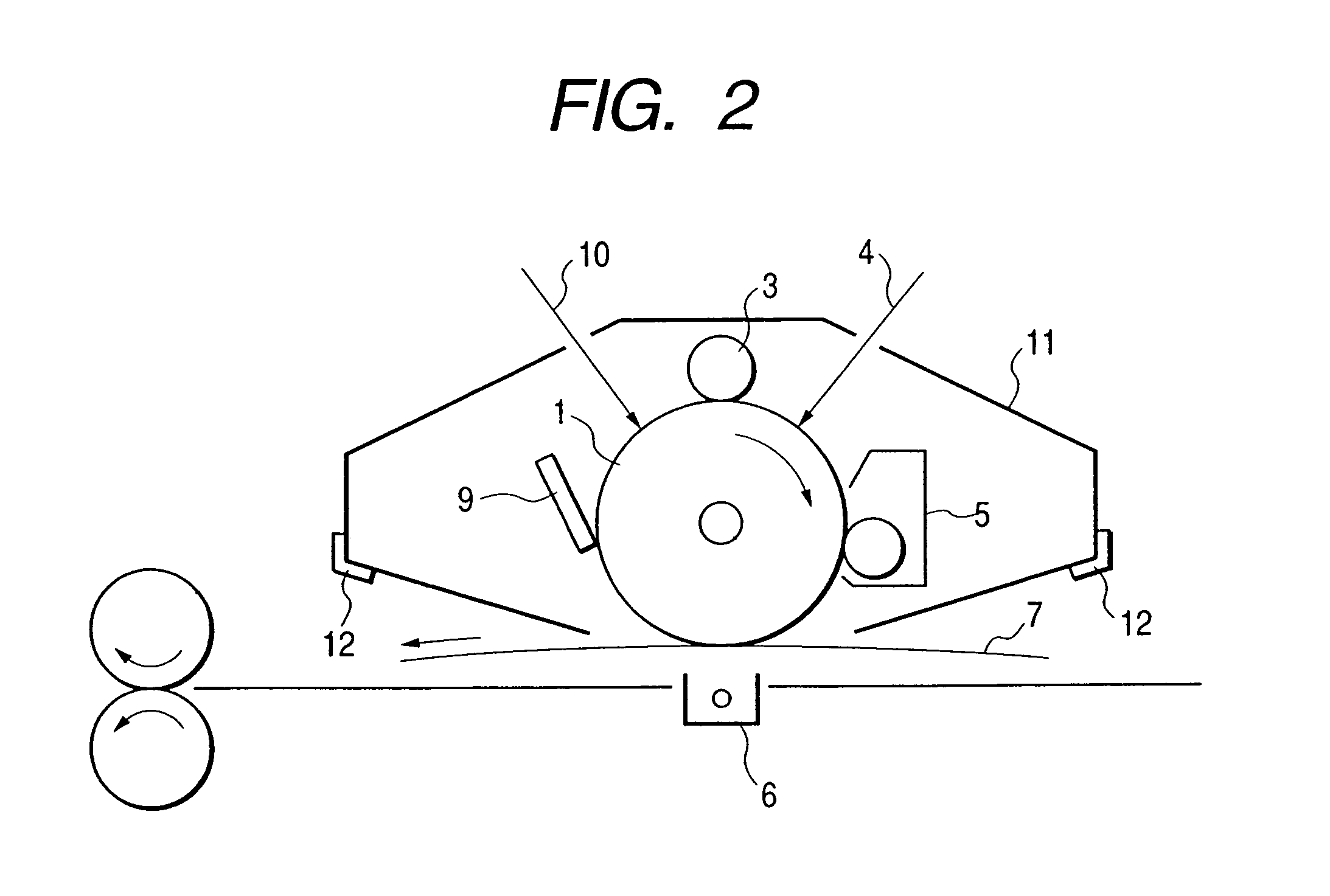

Rolling member and producing method thereof

InactiveUS20050257860A1Great abrasionHigh bearing stressFurnace typesIncreasing energy efficiencySurface layerSolid solution

A rolling member excellent in pitting strength, spalling strength and bending strength of dedendum has a first quench hardened layer 1 which is formed on a surface layer of the rolling member and has a parent phase taking the form of martensite phase which forms a solid solution with carbon of 0.35 to 0.8 wt %, and a second quench hardened layer 2 which is formed at a deeper layer under the first quench hardened layer and has a parent phase containing at least either one of martensite phase or bainite phase which forms a solid solution with carbon of 0.07 to 0.3 wt % and contains cementite dispersed therein in a content of 2 to 20% by volume.

Owner:KOMATSU LTD

Ink composition and ink jet recording method

An ink composition contains a pigment, first wax particles, second wax particles, and a resin emulsion, in which the first wax particles have a melting point of 120° C. or higher and 170° C. or lower, the second wax particles have a melting point of 70° C. or higher and less than 120° C., the resin emulsion has a glass transition point of 50° C. or higher and 150° C. or lower, the first wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles or polypropylene wax particles, and the second wax particles contain one or more kinds of wax particles selected from the group consisting of polyethylene wax particles.

Owner:SEIKO EPSON CORP

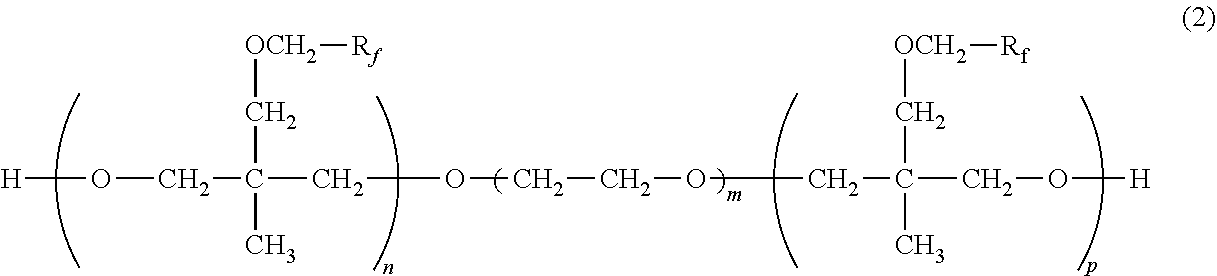

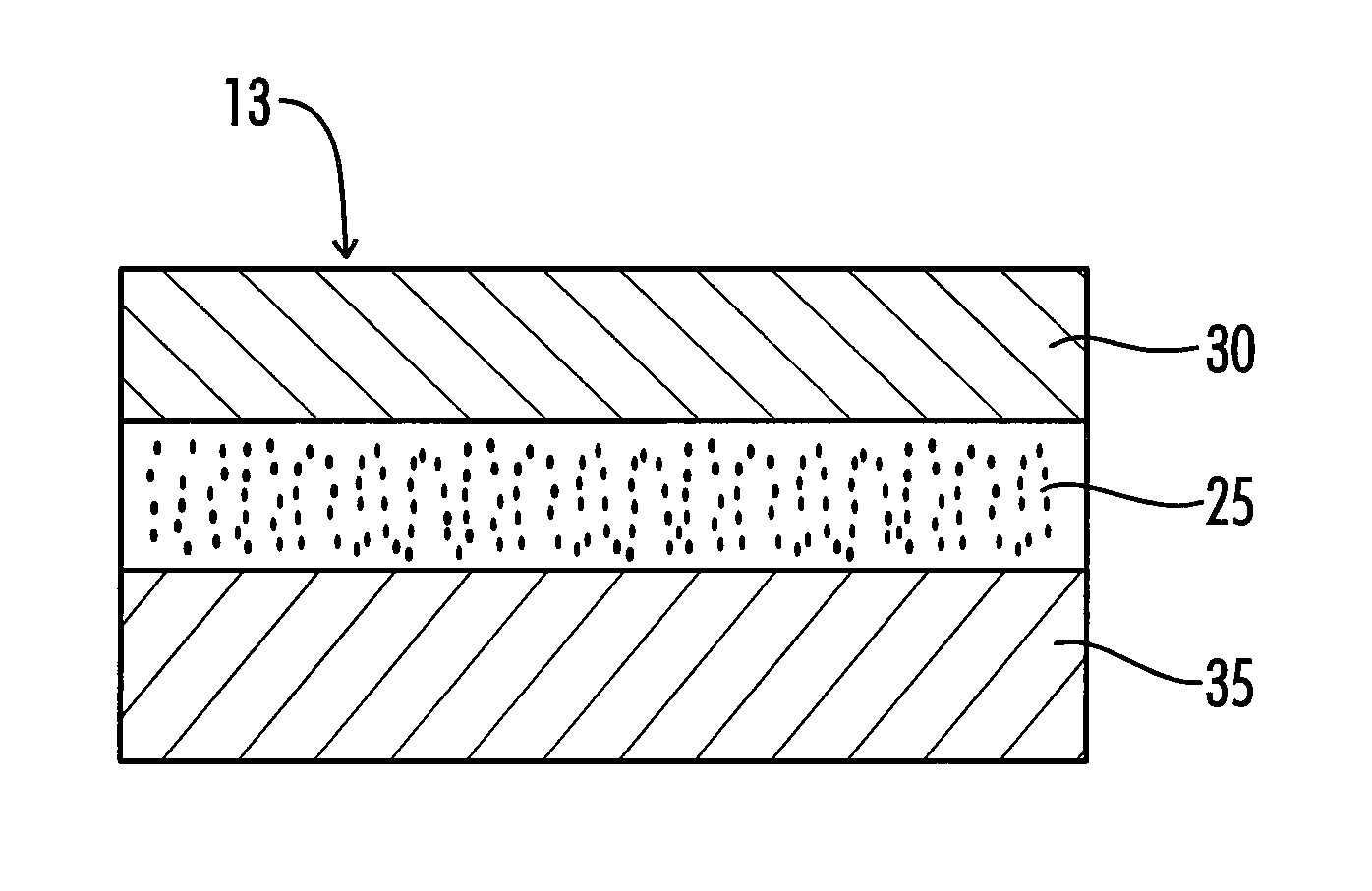

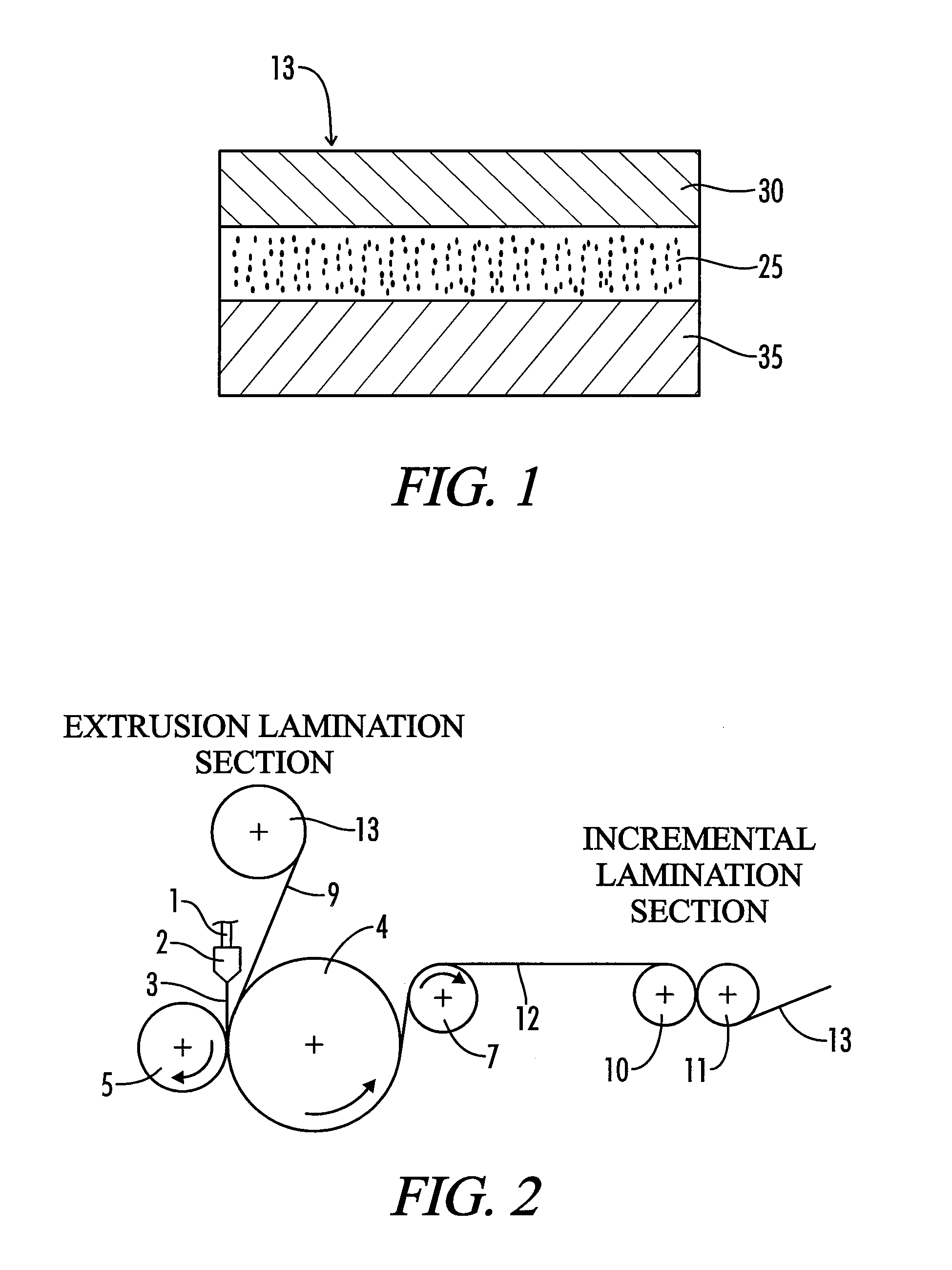

Vapor permeable, liquid impermeable composite fabric and fabrication process

InactiveUS7501357B2Improve stabilityGreat abrasionLamination ancillary operationsSynthetic resin layered productsEnvironmental resistancePolyolefin

A flexible, vapor permeable, liquid impermeable composite fabric comprising a ultraviolet light stabilized and thermally stabilized microporous-formable polyolefin barrier layer extrusion laminated to an ultra-violet light stabilized and thermally stabilized polyolefin nonwoven fabric, the composite of which has been incrementally stretched to induce sufficient moisture vapor transmission characteristics while maintaining adequate resistance to water penetration, and methods of making the composite. This composite may be further laminated to one or more layers of either woven or nonwoven materials offering strength and environmental resistance characteristics sufficient for various outdoor applications including covers and building construction products. Embodiments of the above mentioned components have been shown to offer improved liquid resistance, environmental stability, and abrasion resistance as compared to existing commercially available materials.

Owner:CLOPAY PLASTIC

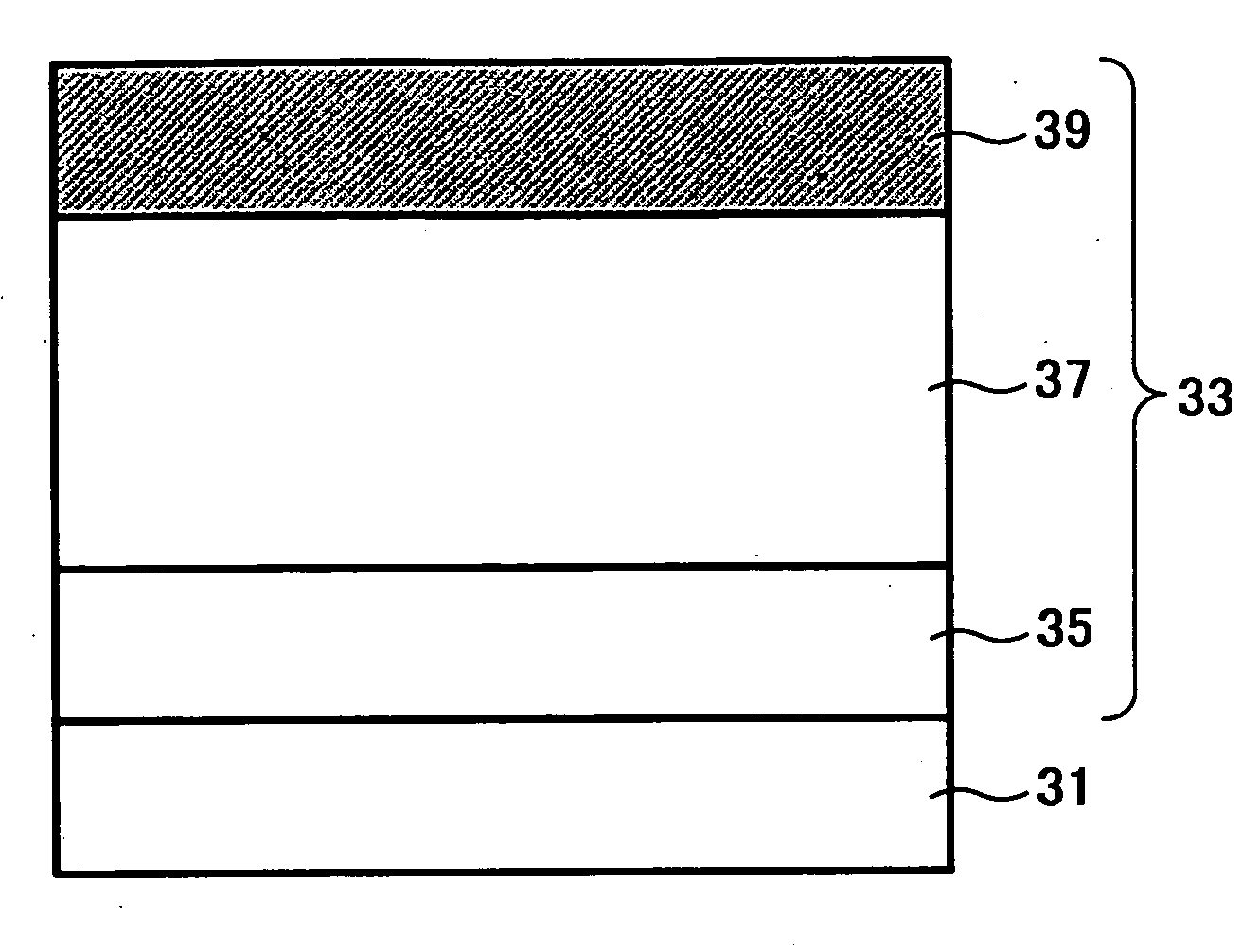

Non-asbestos friction material composition

ActiveUS20140202805A1Suppress generationAbrasion resistance be excellentFriction liningActuatorsAsbestosZinc

Provided by the present invention are: a non-asbestos frictional material composition containing a binder, an organic filler, an inorganic filler, and a fiber substrate, wherein, in the non-asbestos frictional material composition, content of a copper is 5% or less by mass as a copper element, content of a metal fiber other than a copper fiber and a copper alloy fiber is 0.5% or less by mass, and a titanate salt is contained therein with antimony trisulfide or zinc powders, with content of the titanate salt being in the range of 10 to 35% by mass; and a frictional material and a friction member that use the said non-asbestos frictional material composition.

Owner:RESONAC CORP

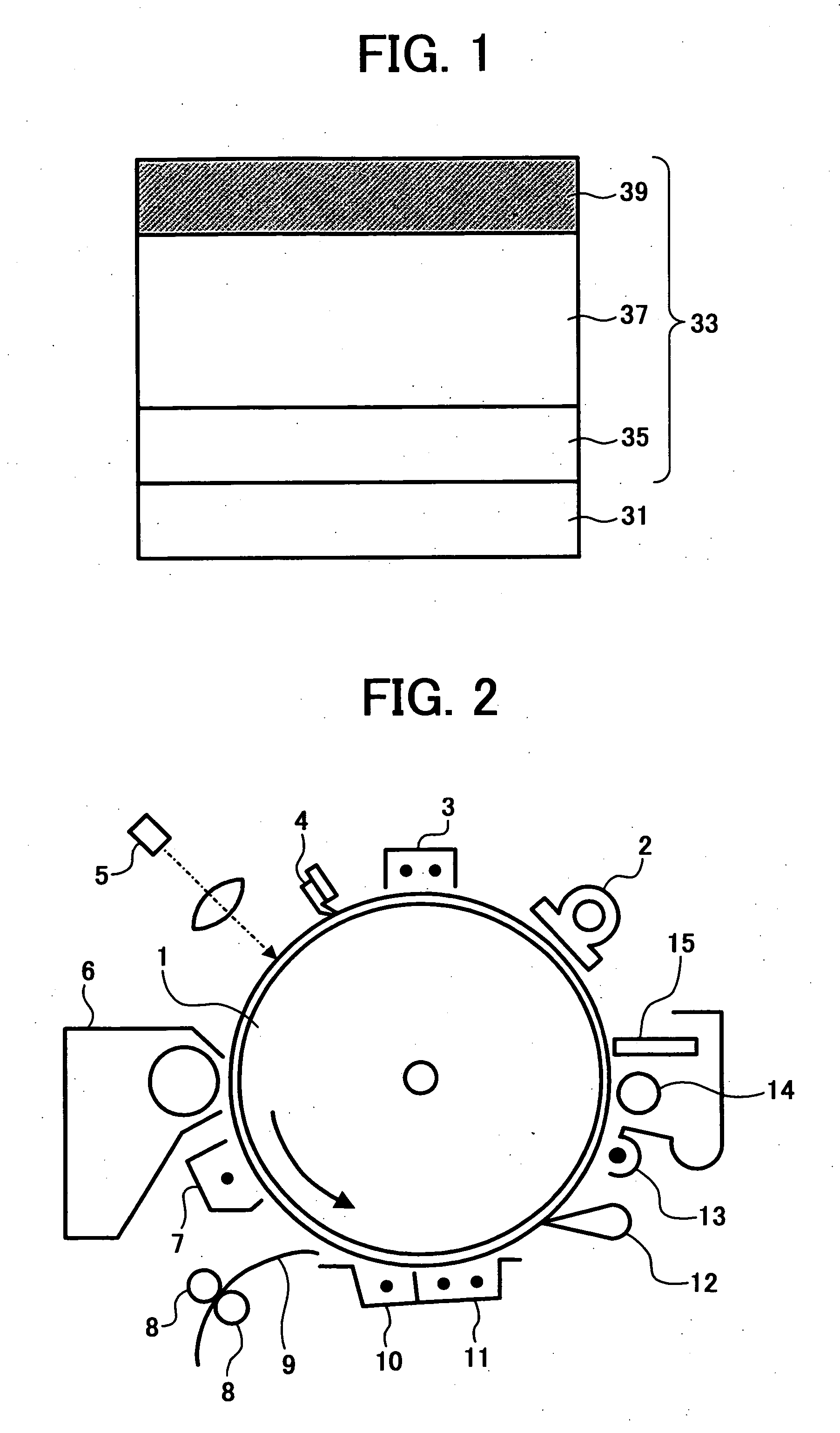

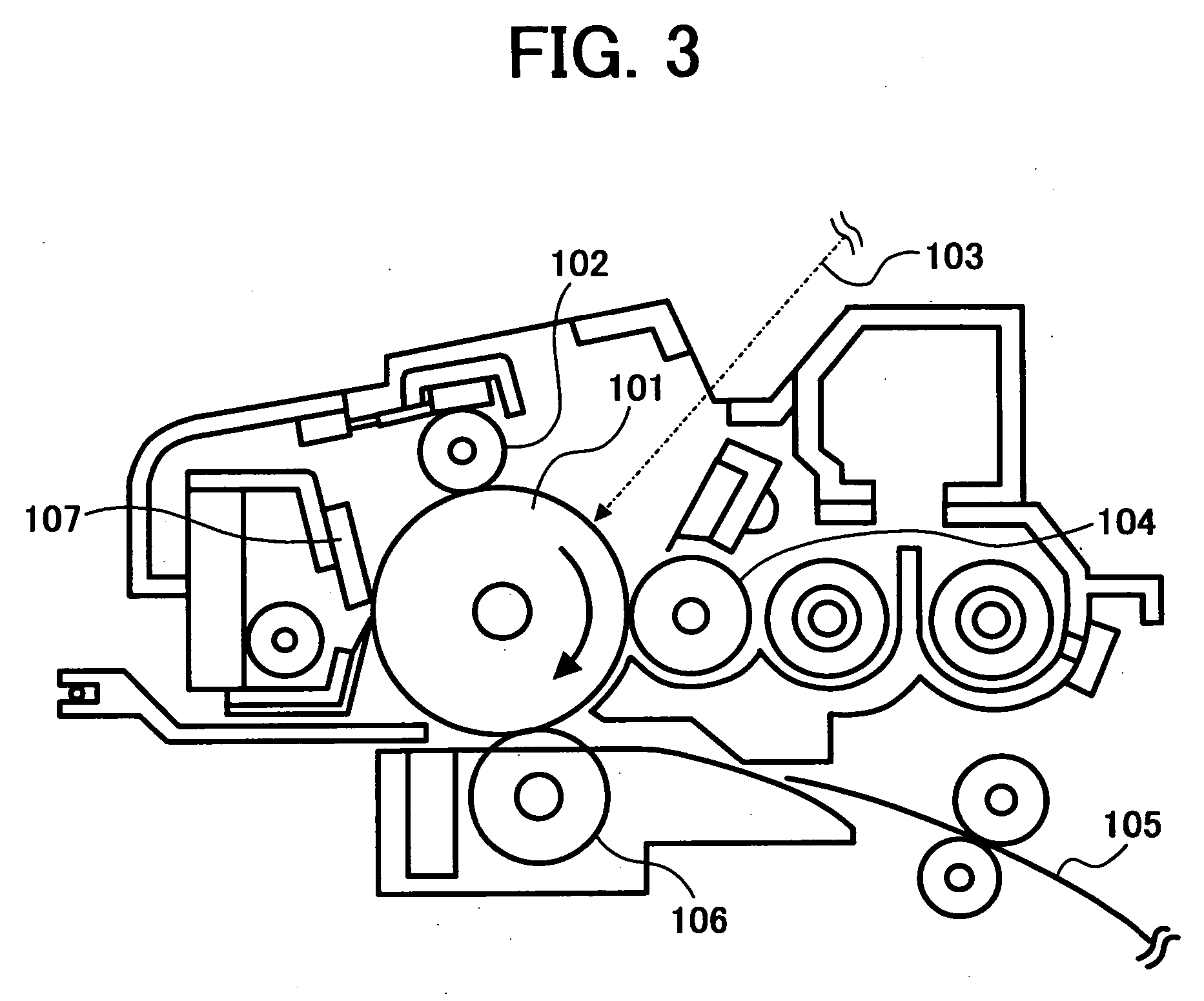

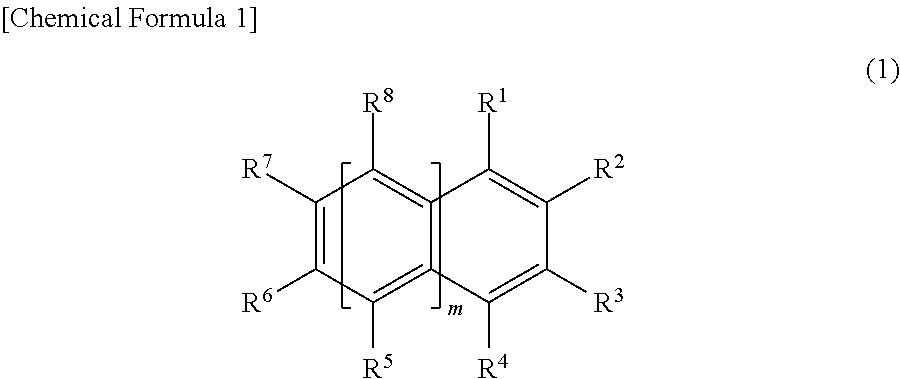

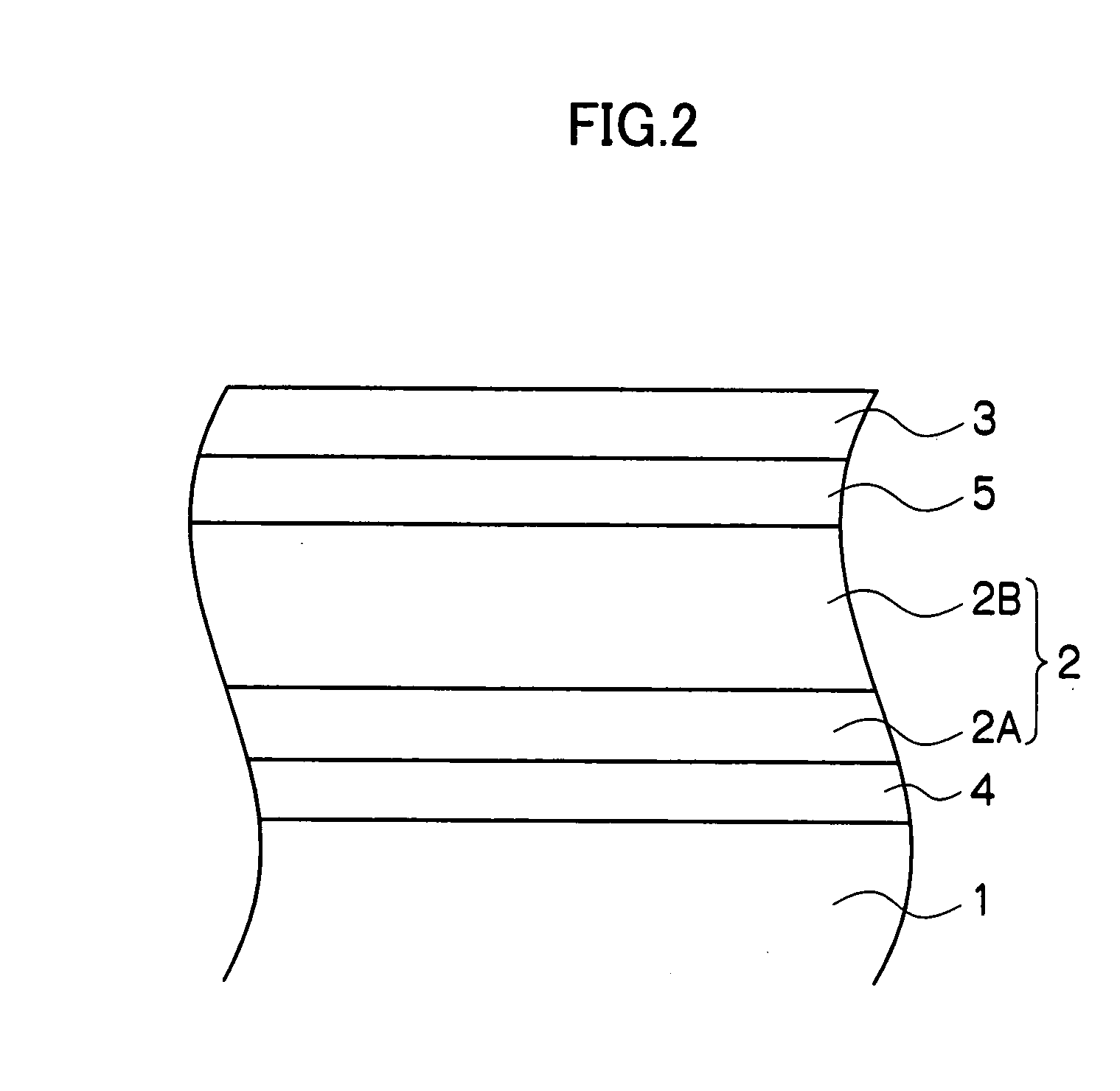

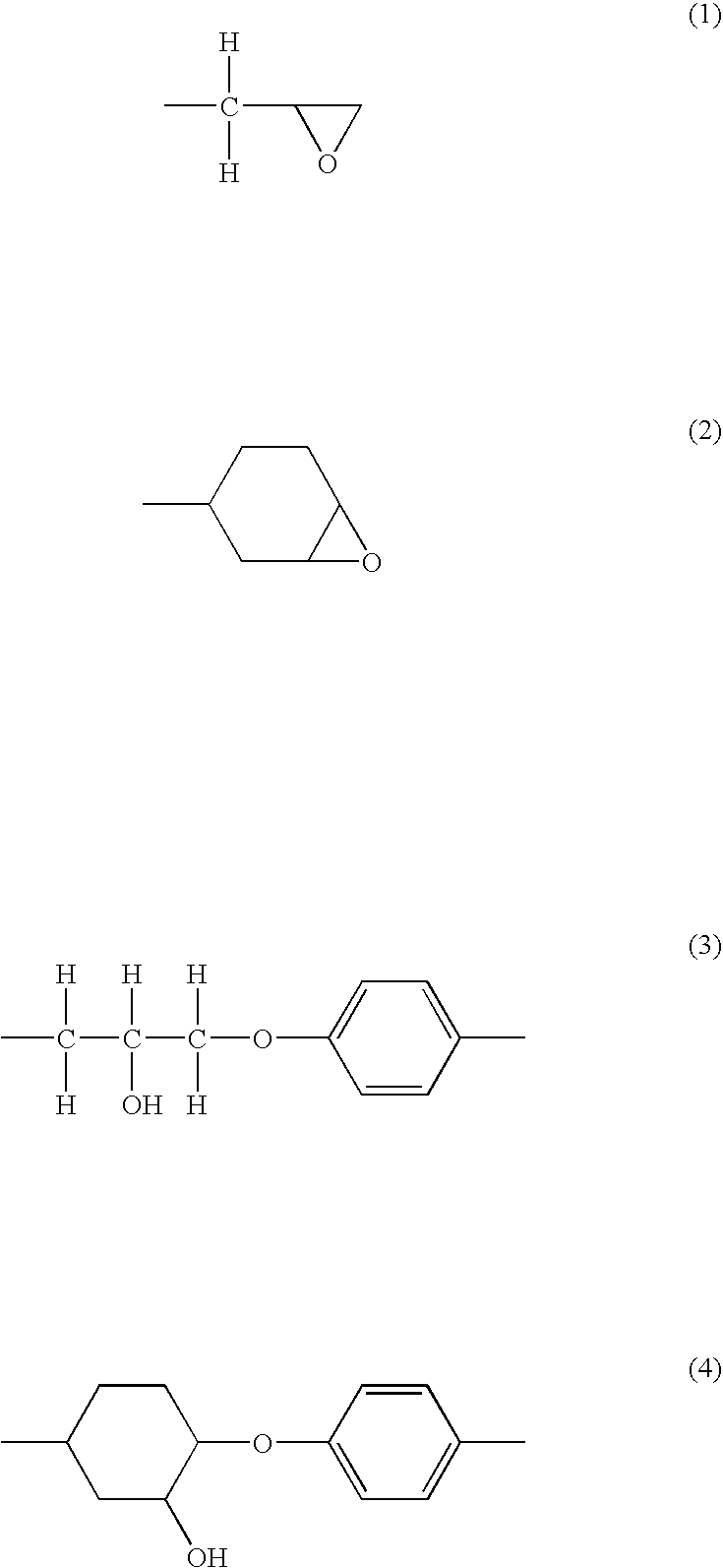

Electrophotographic photoreceptor, and image forming method, image forming apparatus and process cartridge therefor using the electrophotographic photoreceptor

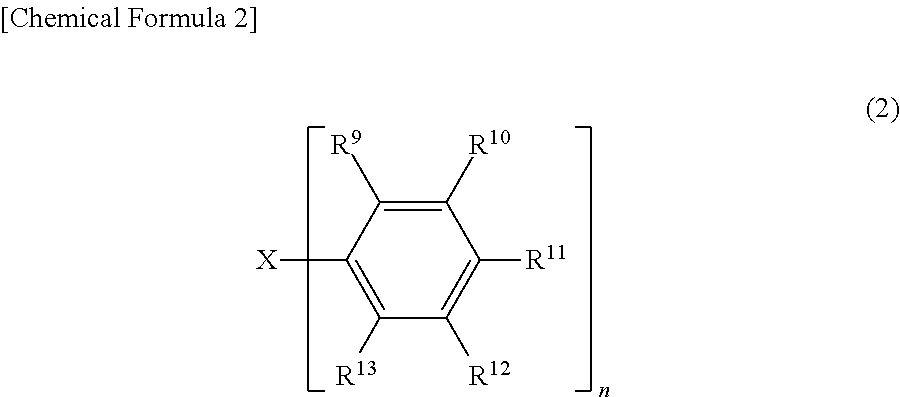

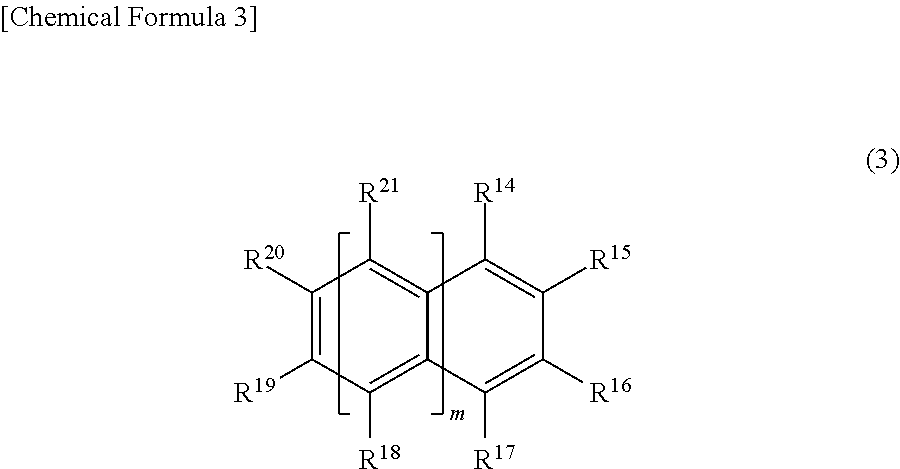

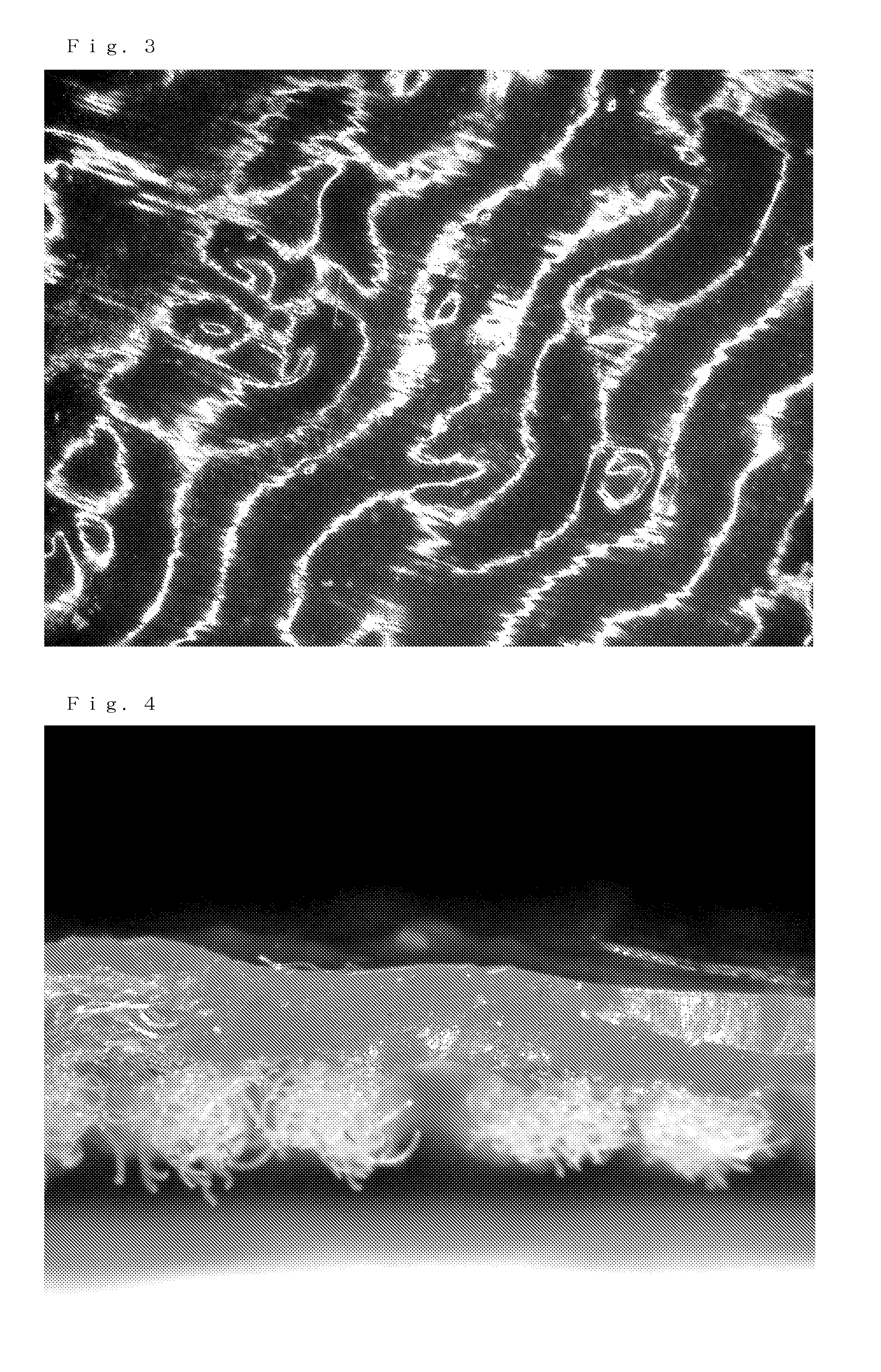

InactiveUS20060160003A1Great abrasionLess white-spotted defective imagesElectrographic process apparatusCorona dischargeImage formationSingle bond

An electrophotographic photoreceptor including an electroconductive substrate and a photosensitive layer located overlying the electroconductive substrate, wherein the photosensitive layer comprises units obtained from a radical polymerizing monomer, in which an aliphatic group having two radical polymerizing groups and a charge transporting group including no radical polymerizing group are connected to each other in a single bond, at the surface thereof.

Owner:RICOH KK

Ink jet recording process

ActiveUS20110234728A1Quick drying effect is goodHigh-quality and abrasion resistanceMeasurement apparatus componentsDuplicating/marking methods2-PyrrolidoneSolvent

Recording onto a non-ink-absorbing recording medium is performed using an aqueous ink composition containing a first solvent composed of at least one selected from 2-pyrrolidone, 1,3-dimethyl-imidazolidinone, and N,N′-dimethylpropylene urea, a second solvent composed of at least one selected from 1,2-hexanediol and 1,2-pentanediol, and a third solvent composed of at least one selected from glycol diethers and heating the non-ink-absorbing recording medium at 40 to 60° C.

Owner:SEIKO EPSON CORP

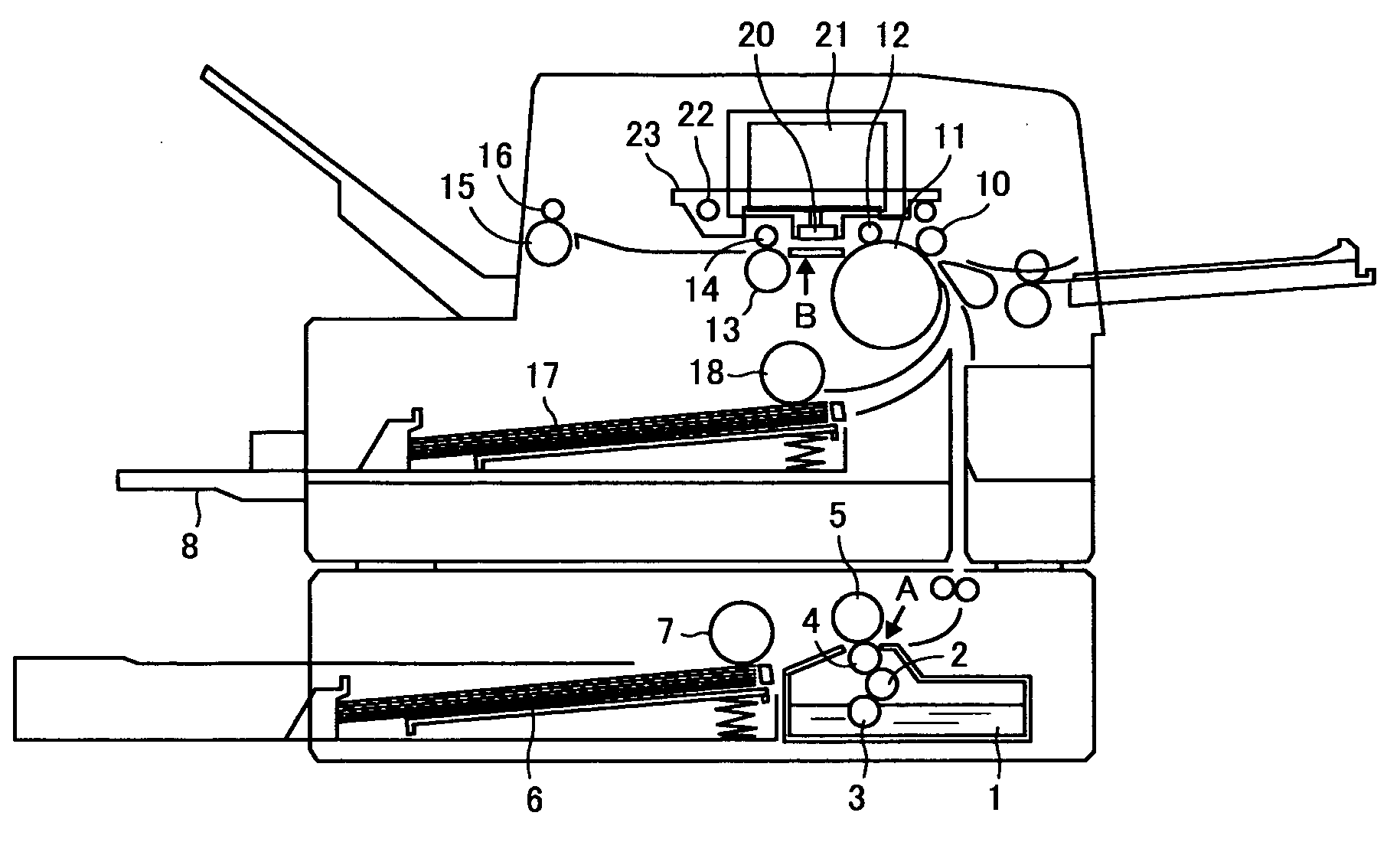

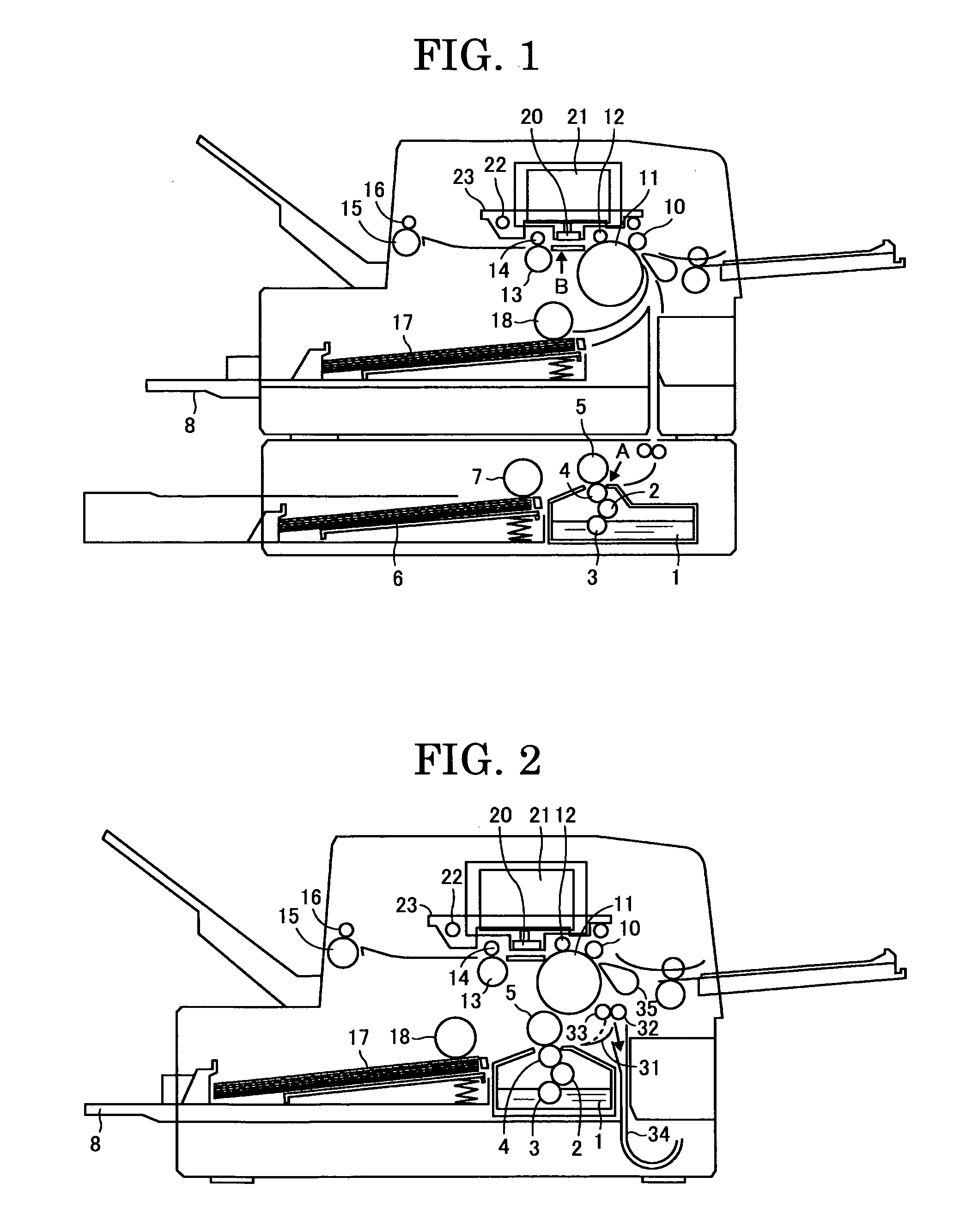

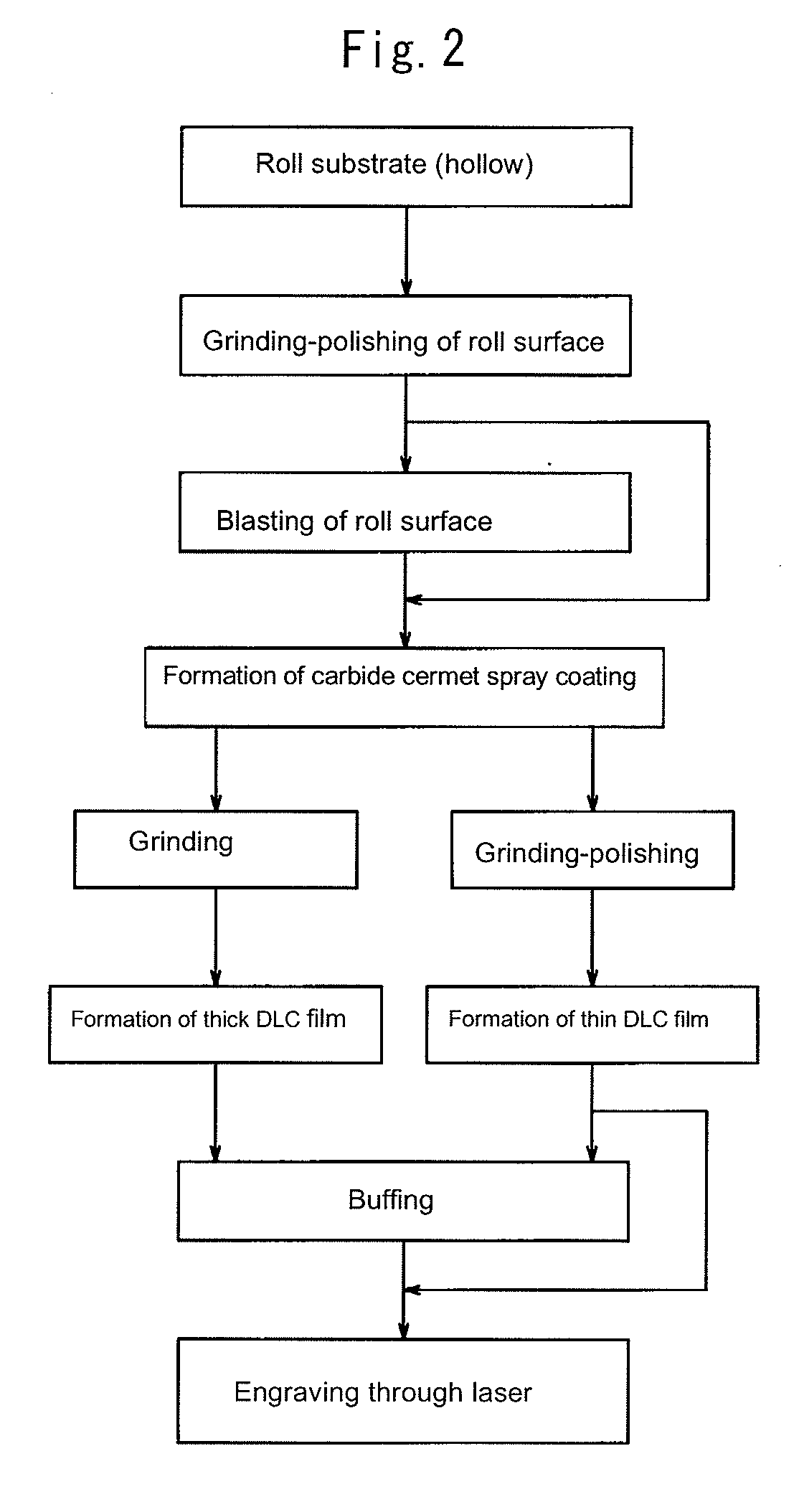

Printing roll and method of producing the same

InactiveUS20110203468A1Improve wear resistanceSmall contact resistanceMounting boardsPlate printingCermetEngineering

In order to propose a dry process technique of producing a printing roll having safe and beauty concave portions for printing image area without discharging environmental contaminating substance and a new technique for improving quality of printed matters, this invention is to provide a printing roll with DLC film layer in which laser beam-engraved grooves as concave portions for printing image area are formed on a carbide cermet spray coating formed on a surface of a roll substrate, and a method wherein a carbide cermet spray coating is formed on a surface of a roll substrate roughened by a blast treatment, the surface of the carbide cermet spray coating is ground or ground-polished, then a DLC film is formed on the ground or ground-polished surface and thereafter laser beam-engraved grooves are formed on the surface of the DLC film as a concave portion for printing image area.

Owner:TOCALO CO LTD

Aqueous ink composition and printing process by ink jet recording system using the composition

ActiveUS20110234682A1Excellent in abrasionImprove printing qualityInksPrintingPolymer chemistryRecording system

The aqueous ink composition according to the invention includes at least a water-insoluble coloring agent, a glycol ether having an HLB value calculated by a Davies' method in the range of 4.2 to 8.0, a 1,2-alkyldiol having 4 to 8 carbon atoms, resin particles, and water.

Owner:SEIKO EPSON CORP

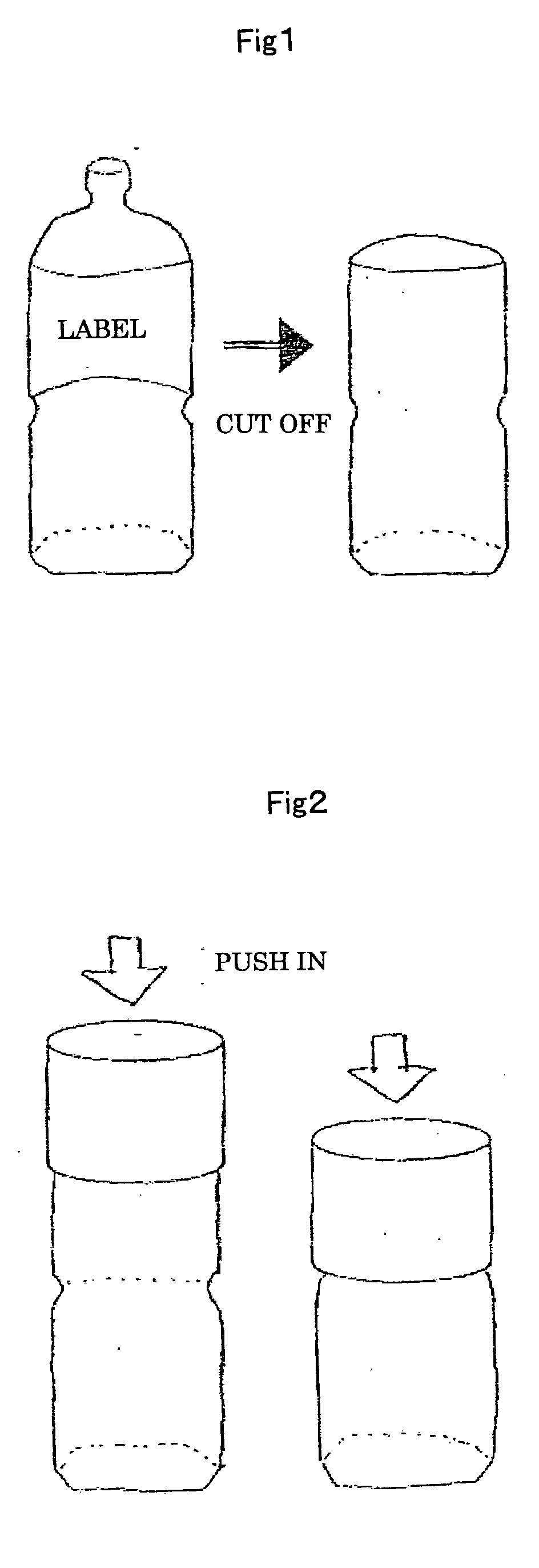

Heat shrinking polyester film

InactiveUS20060063008A1Good printabilityHigh transparencySynthetic resin layered productsFlat articlesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

Method of production of radial conjugated diene polymer

An alkali metal-reacted aromatic compound which has three or more carbon atoms which are directly bonded to alkali metal atoms and aromatic rings in one molecule is used as a polymerization initiator to polymerize a monomer mixture which is contains at least one conjugated diene compound to thereby produce a radial conjugated diene polymer. Further, active ends of the polymer having active ends which is obtained by this method is made to react with a modifier which can react with the active ends to thereby produce an end-modified radial conjugated diene polymer. According to the present invention, it is possible to provide a method of production of the radial conjugated diene polymer which gives a high degree of freedom of polymer design and easy control of the polymer structure.

Owner:ZEON CORP

Electrophotographic photoreceptor, and process cartridge and image-forming apparatus using the same

ActiveUS20080070138A1Good effectAvoid image blurElectrographic process apparatusCoatingsSurface layerInter layer

An electrophotographic photoreceptor including a conductive substrate, and a photosensitive layer, an intermediate layer, and a surface layer formed thereon in this order, wherein the surface layer contains a Group 13 element and at least one of nitrogen or oxygen.

Owner:FUJIFILM BUSINESS INNOVATION CORP

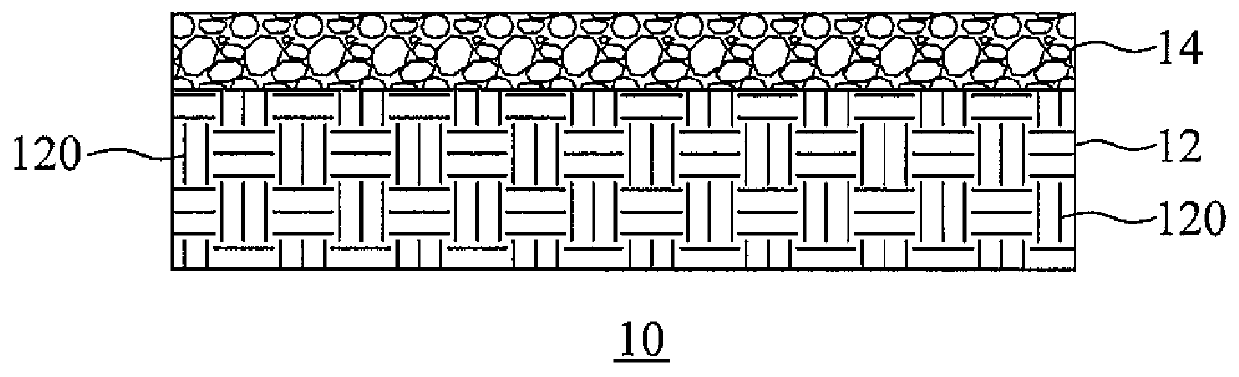

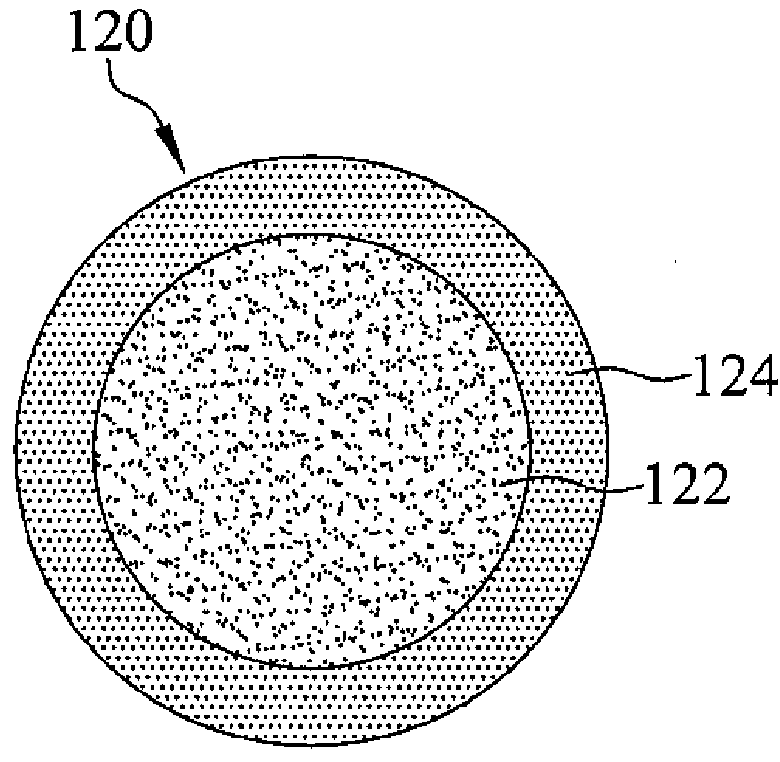

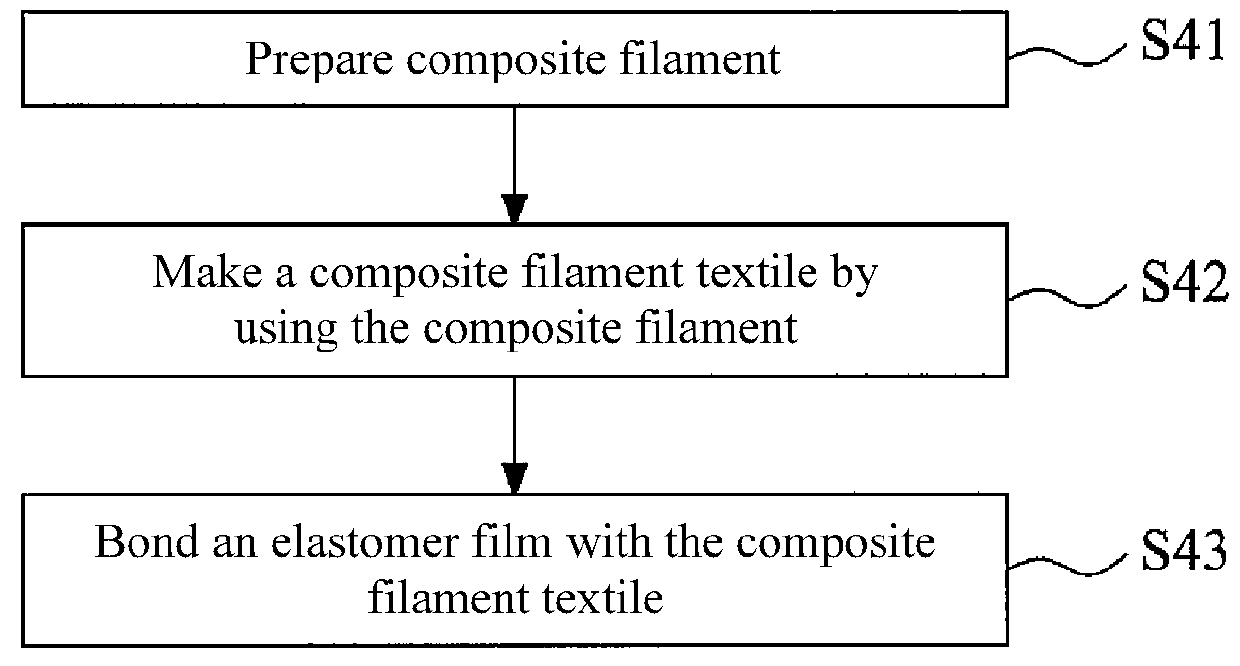

Composite filament textile and environment-friendly composite filament artificial leather manufactured using the same

InactiveUS20160053434A1Great abrasionGood dimensional stabilitySynthetic resin layered productsFilament/thread formingPolyesterPolyolefin

An environmental-friendly composite filament artificial leather includes a composite filament textile and an elastomer film. The composite filament textile is made of composite filament. The composite filament includes at least one core portion and a sheath portion. The at least one core portion is a polyester-type polymer, a polyamide polymer or a polypropylene polymer. The sheath portion sheathes the at least one core portion, and the sheath portion is a thermoplastic elastomer. The elastomer film is bonded with the composite filament textile. The elastomer film is made of one selected from the following materials: thermoplastic polyurethane (TPU), thermoplastic polyester elastomer (TPEE) and thermoplastic polyolefin (TPO). By this way, an environment-friendly artificial leather of lightweight, good abrasion, good touch feeling and well dimentional stability can be manufactured. Furthermore, the artificial leather can be manufactured without use of any solvent, so as to conform to the environment protection requirement.

Owner:SAN FANG CHEM IND

Thermoplastic resin composition having high durability

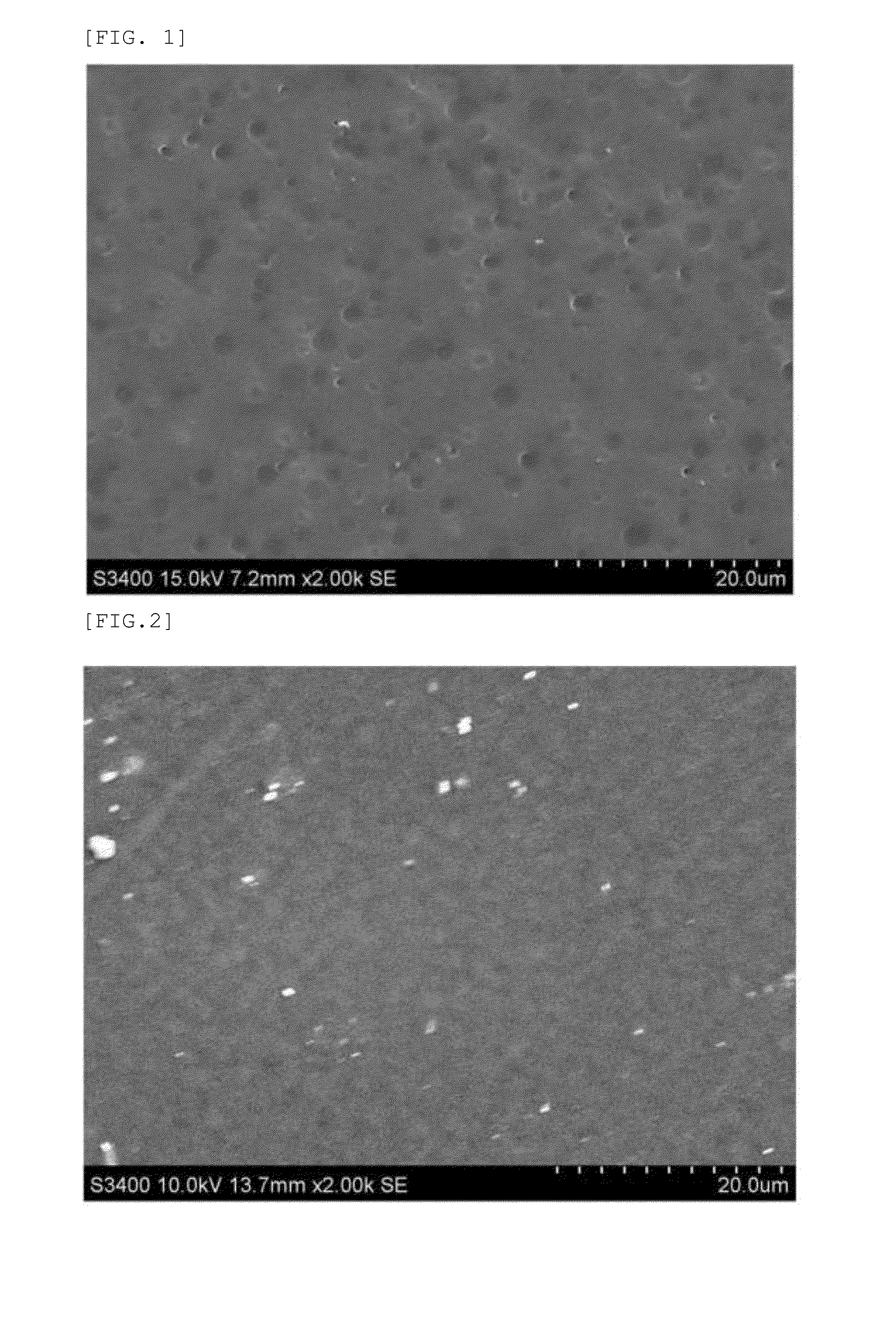

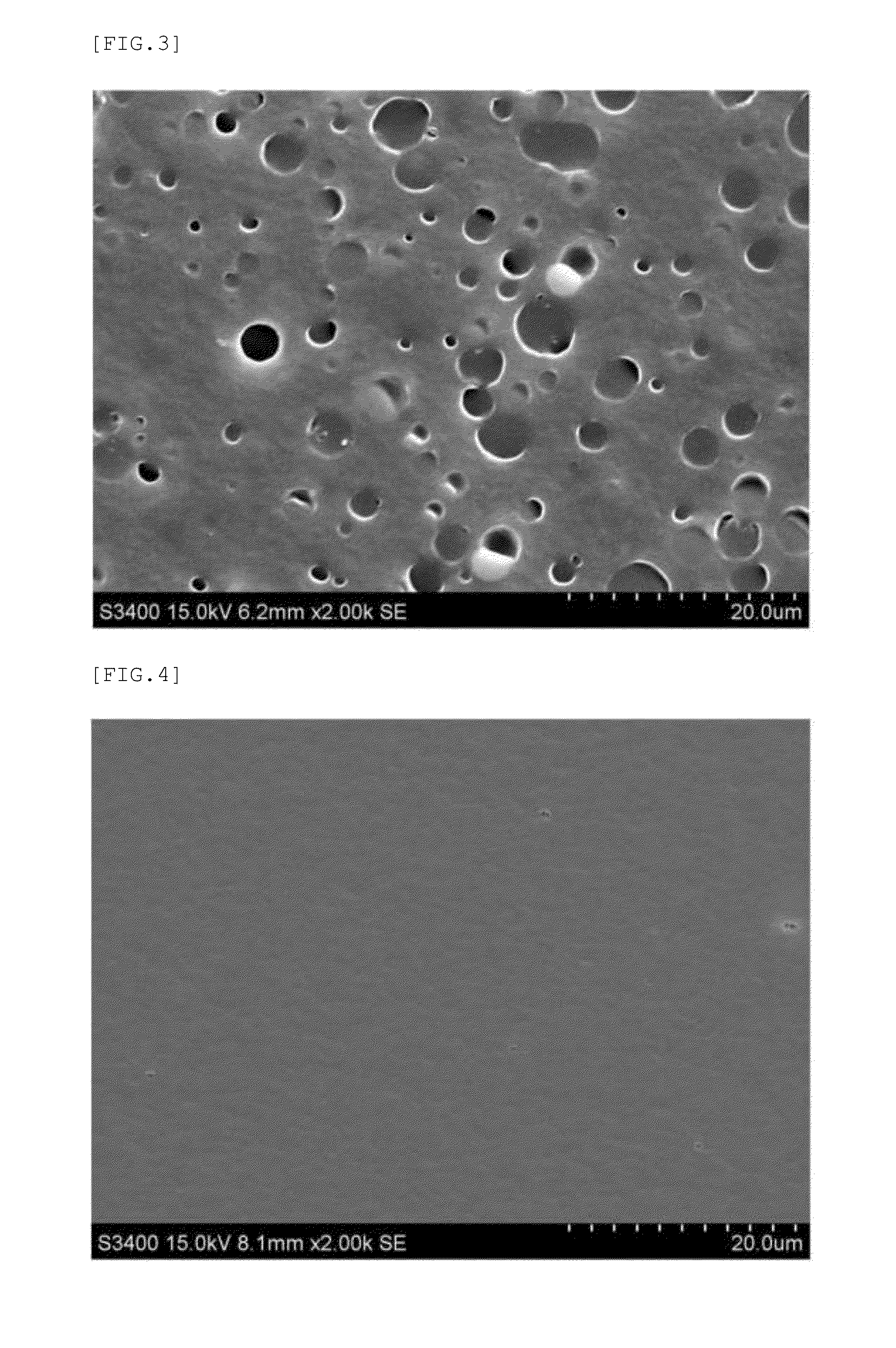

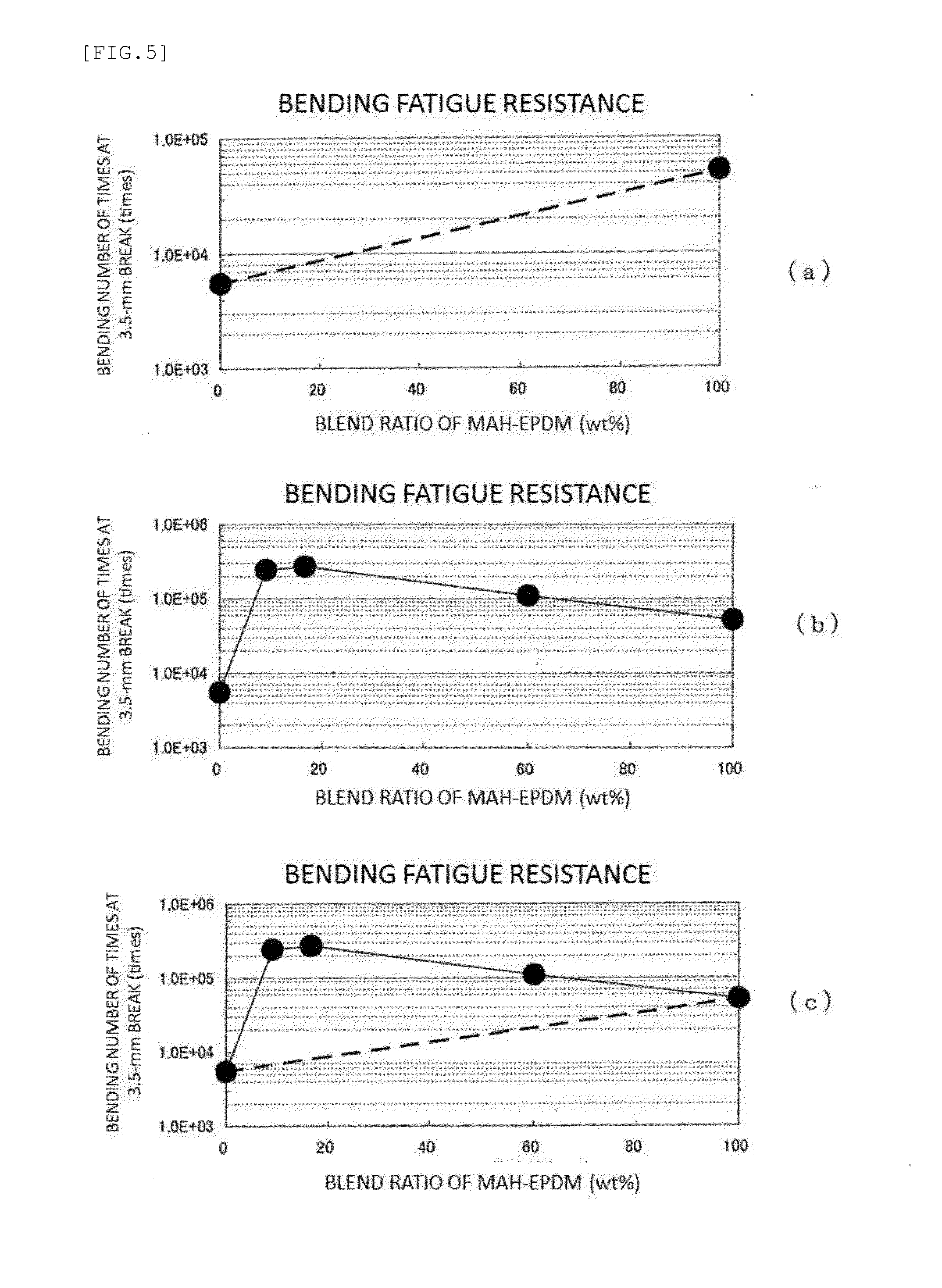

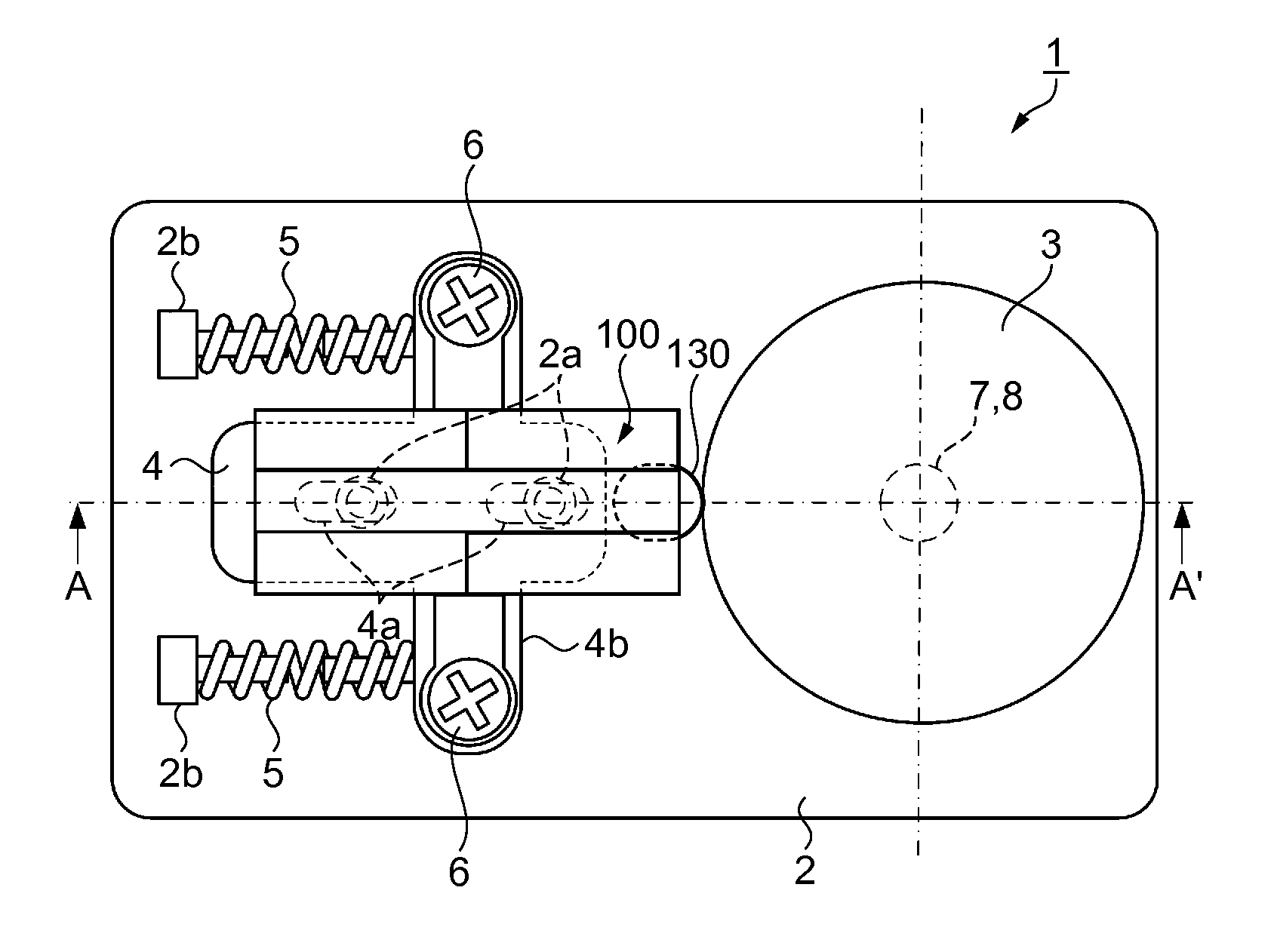

The thermoplastic resin composition according to the present invention includes a thermoplastic resin (A), and a modified ethylene copolymer (B) dispersed and contained therein, wherein the modified ethylene copolymer (B) in the thermoplastic resin composition has an average dispersed particle aspect ratio of 1 to 3.5, and an average dispersed particle diameter of not more than 3 μm. The modified ethylene copolymer (B) is preferably a copolymer, modified with an unsaturated carboxylic acid or a derivative thereof, of ethylene with at least one monomer component selected from the group consisting of (i) olefin components except for ethylene, (ii) diene components and (iii) ester components having an ethylenically unsaturated group.

Owner:NITTA CORP

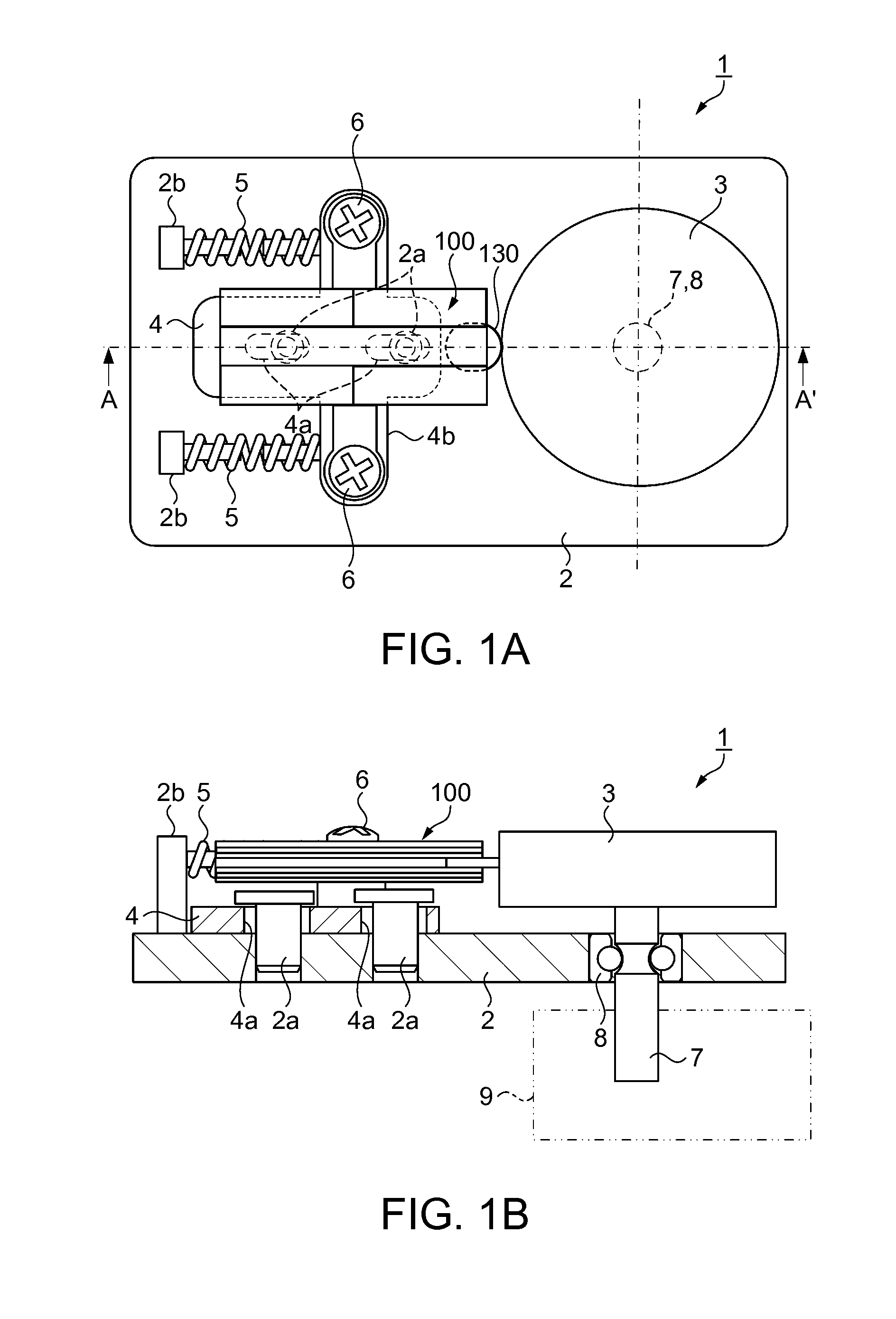

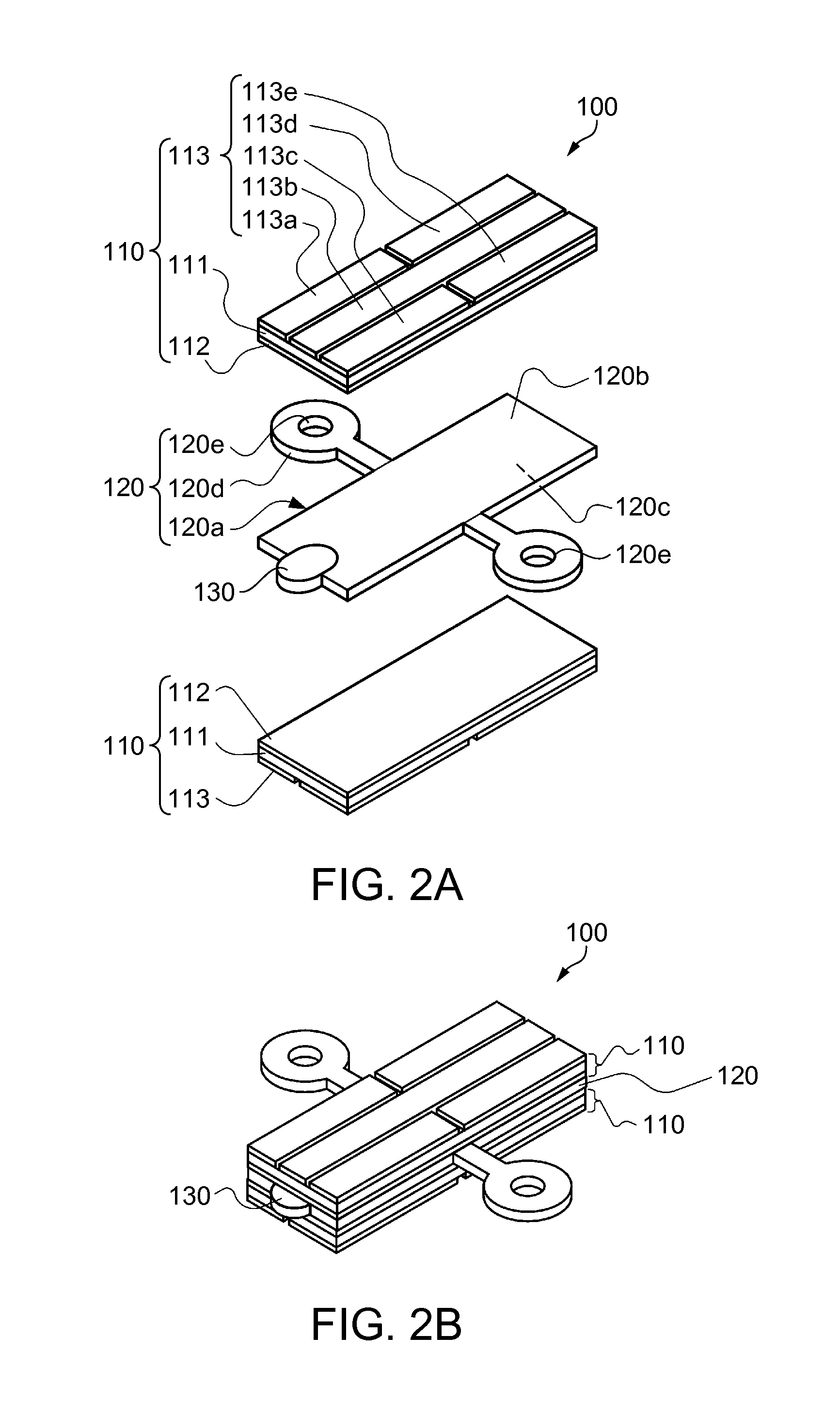

Piezoelectric motor, drive unit, electronic part transfer apparatus, electronic part inspection apparatus, robot, and printer

ActiveUS20130140952A1Avoid scratchesCut evenlyPiezoelectric/electrostriction/magnetostriction machinesGripping headsYoung's modulusAbutment

A piezoelectric motor includes a piezoelectric element, an oscillating plate including the piezoelectric element, a driving projection provided at an end of the oscillating plate, and a driven member driven by the driving projection coming into abutment therewith and is characterized in that Young's modulus E1 of the driving projection and Young's modulus E2 of the driven member are different.

Owner:SEIKO EPSON CORP

Slip resistant gloves and method for producing the same

InactiveUS20110265246A1Abrasion resistance is inferiorSlip resistant effect is improvedGlovesDomestic articlesFiberCoated surface

A slip resistant glove is disclosed which includes a fibrous glove and a rubber or a resin coating layer formed on the surface thereof, wherein recesses having a width of 0.1 to 425 μm, a depth of 0.1 to 200 μm and a number density of 1000 to 5000 per 1 square centimeter are provided at the surface of the coating layer. The glove of the present invention has well balanced slip resistance and abrasion resistance, and is excellent in slip resistance against oil, in particular, and has less amounts of anions and cations which cause rust.

Owner:SHOWA GLOVE

Tire with minimal-marking tread and skid steering, fixed axle, tire/wheel or vehicular track assembly where said tire or track has a minimal-marking tread

InactiveUS20020140288A1Great abrasionImprove featuresSpecial tyresDriving beltsTreadPhysical property

The present invention relates to tires and vehicular tracks having minimal-marking rubber treads and particularly to skid steering, fixed axle, tire / wheel or track assemblies where said tire or vehicular track has a minimal-marking tread. In particular, such rubber tread has a surface intended to be ground-contacting which is also intended to be minimal-marking and having suitable physical properties for a tire tread.

Owner:VEYANCE TECH

Surface material for ball and ball

ActiveUS7566488B2Improve wear resistanceGreat abrasionHollow inflatable ballsHollow non-inflatable ballsElastomerBall game

A skin material for balls which is a sheet-form material comprising a base layer and formed on one side there of a coating layer made of a polymeric elastomer, characterized in that (1) the coating layer is composed of three layers (C-1), (C-2), and (C-3) disposed in this order from the surface side, (2) the layer (C-3) on the base layer side is made of a porous polymeric elastomer, (3) the layer (C-1) on the surface side is made of a polymeric elastomer containing a pressure-sensitive adhesive, and (4) the coating layer comprises one or more polymeric elastomers which have or do not have fine through-holes extending from the surface side to the base layer; and a ball having the skin material bonded to the surface. The skin material for ball-game balls brings about excellent wet gripping and is excellent also in wearing resistance and impact absorption.

Owner:TEIJIN CORDLEY

Method for manufacturing dental mill blank

ActiveUS20150182315A1Improve mechanical propertiesIncrease resistanceArtificial teethDentistry preparationsShell moldingCam

A method for producing a dental mill blank, characterized in that the method includes contacting an inorganic filler molded article produced by subjecting an inorganic filler to press molding and a polymerizable monomer-containing composition, and allowing the polymerizable monomer to polymerize and cure. When the method of the present invention is used, a dental mill blank having a high inorganic powder content and excellent mechanical strength is obtained. In addition, the dental mill blank obtained is suitably used in the fabrication of a dental prosthesis having high mechanical strength and excellent gloss retention, by machining a mill blank using a CAD / CAM system.

Owner:KURARAY NORITAKE DENTAL

Electrophotographic photosensitive member, electrophotographic apparatus, and process cartridge

ActiveUS6998210B2Abrasion resistance be excellentExcellent resistanceElectrographic process apparatusCorona dischargeEngineeringHardness

The present invention relates to an electrophotographic photosensitive member comprising a surface layer excellent in adhesiveness and abrasion resistance, having a hardness and a toughness, and not degrading the charge transport property. One aspect of the present invention provides an electrophotographic photosensitive member comprising a photosensitive layer on a conductive support, wherein a surface layer of the photosensitive member contains a crosslinked epoxy-modified resol type phenolic resin, and at least one of a charge transport material and a conductive fine particle.

Owner:CANON KK

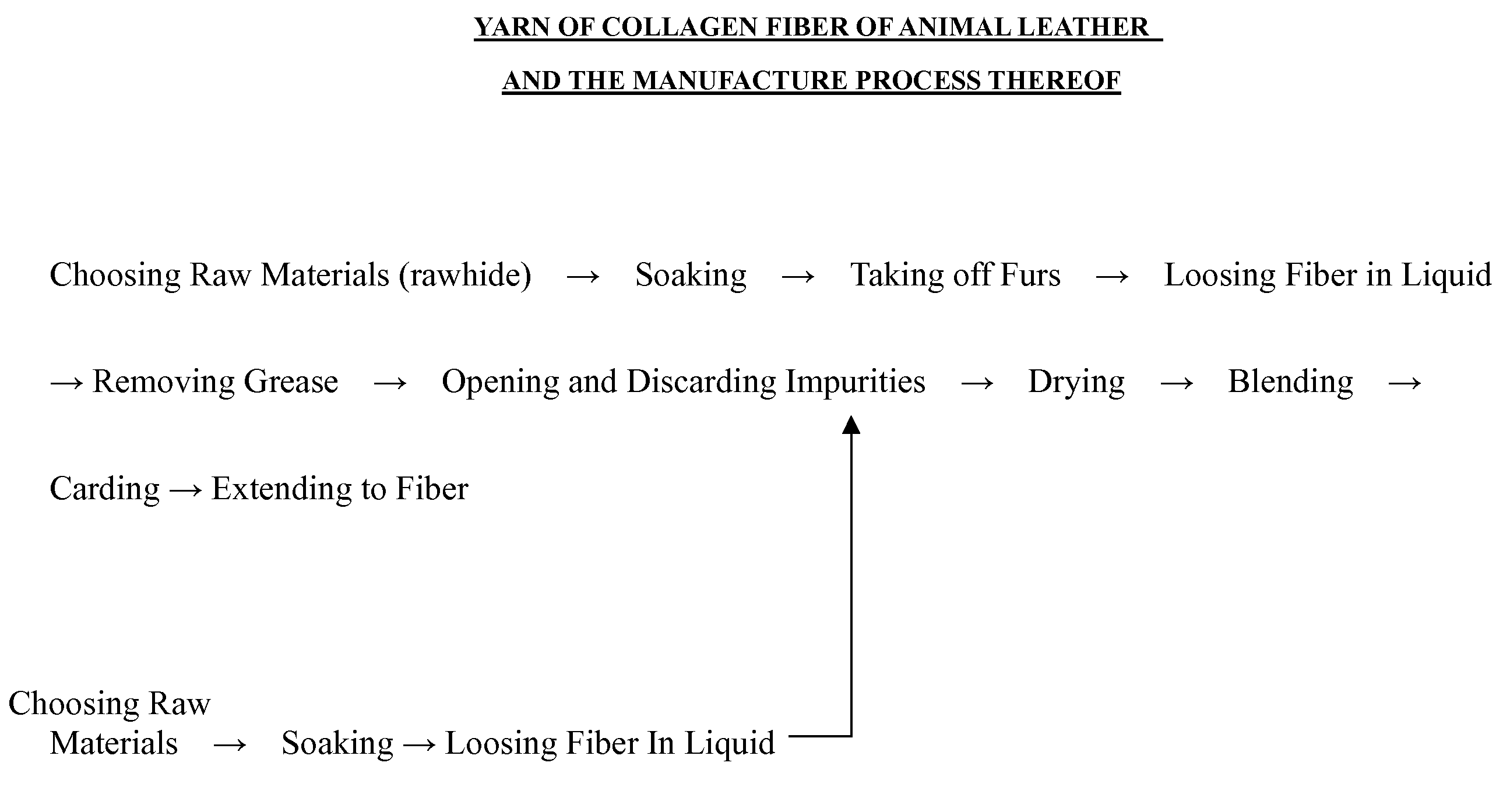

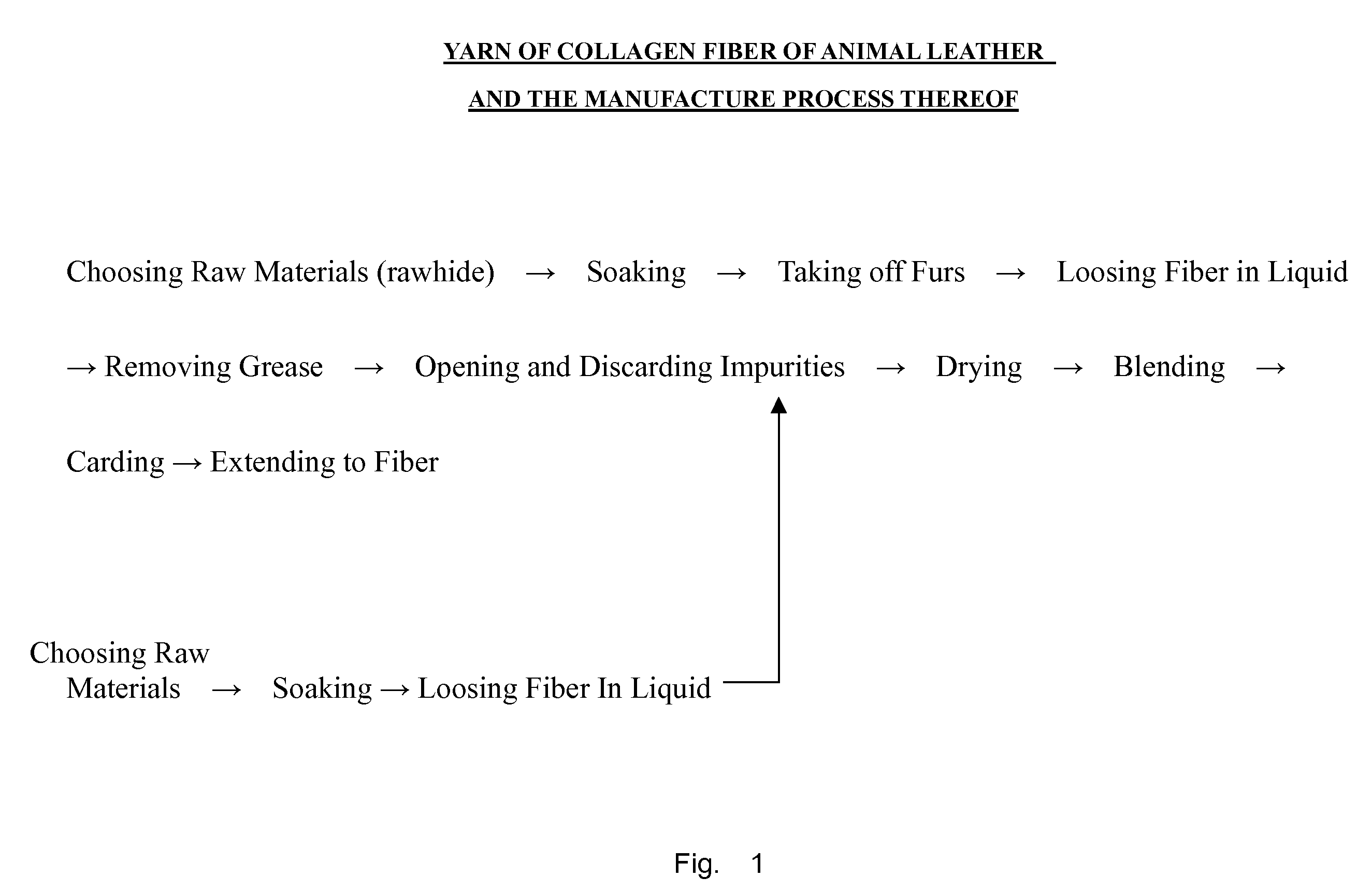

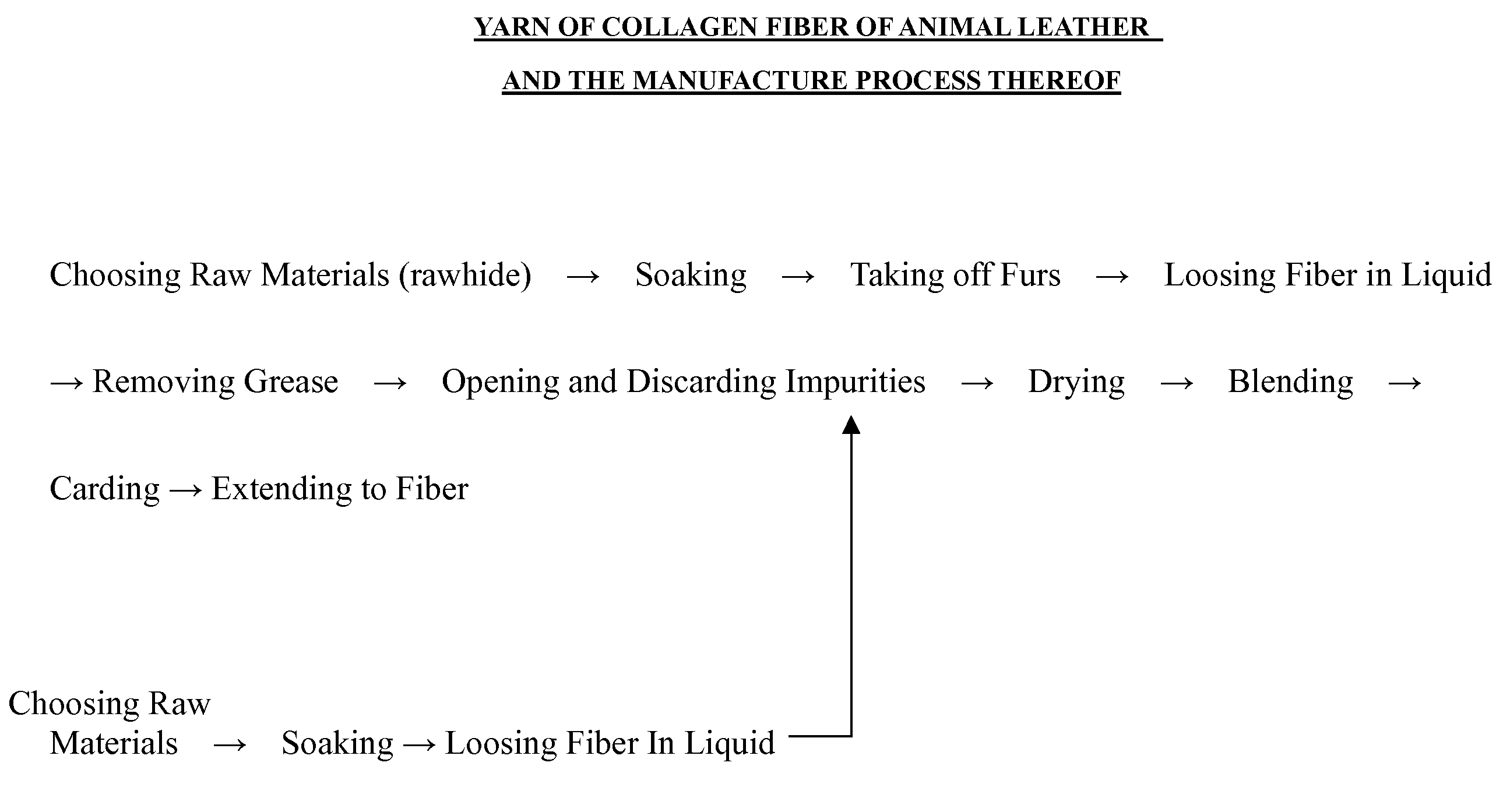

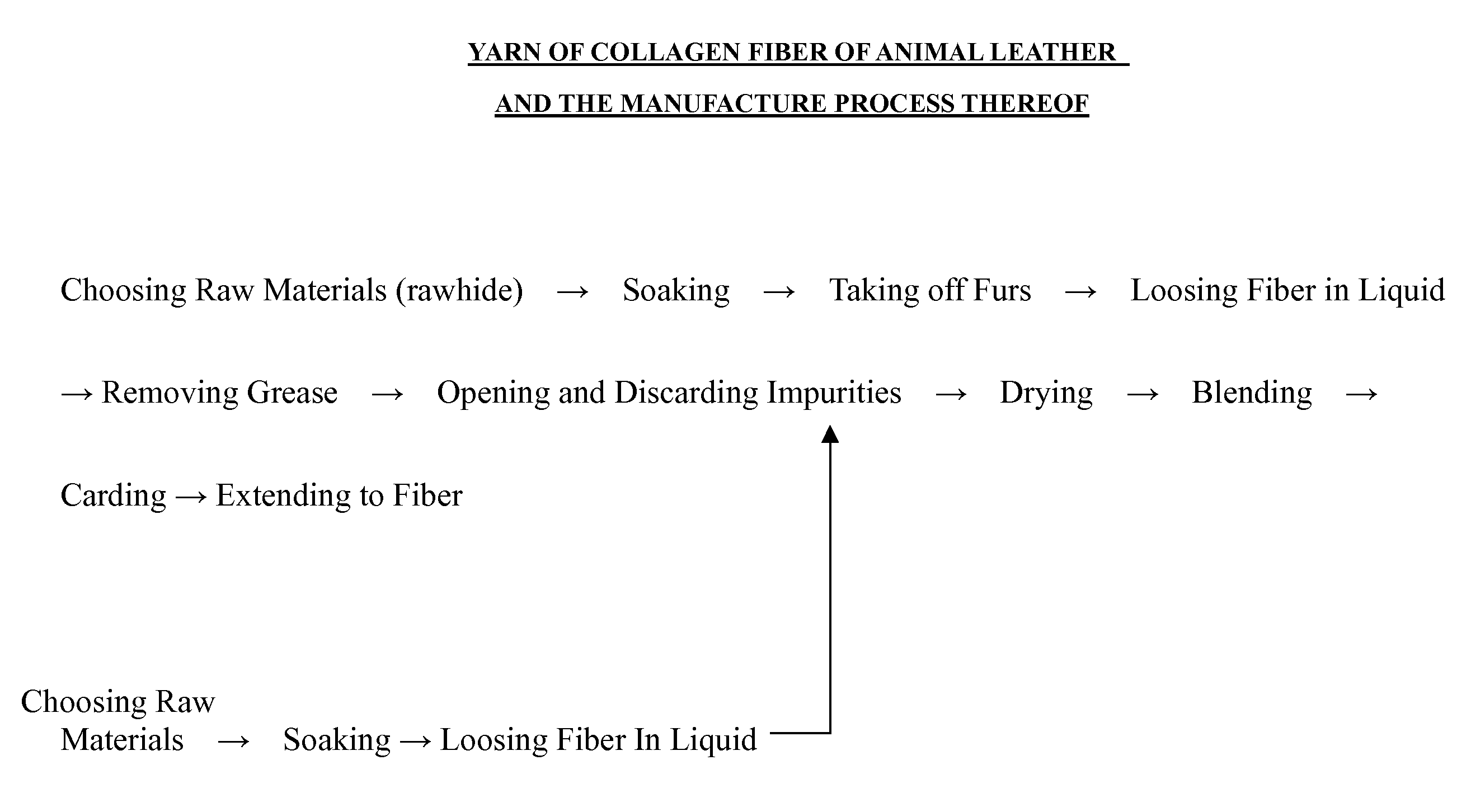

Yarn of animal collagen fiber and manufacture process thereof

InactiveUS20070186352A1Broaden the field of applicationIncrease profitSuture equipmentsAnimal materialYarnTextile fiber

A kind of yarn of animal collagen fiber and the manufacture process thereof, characterized in that the yarn is made of 1-100 WT % of collagen fiber of animal leather, and 0-99 WT % of textile fiber. The yarn of animal collagen fiber is made by the following procedure: choosing raw materials, loosing fiber, assorting, blending, carding, drawing, and twisting, if using the rawhide, the above procedure should add the steps of liming, washing, deliming, tanning and dehydrating. The raw material of the yarn can be the rawhide of any animal, as well as the leftover material or worn-out leather. The yarn has excellent properties, high tensile strength, abrasion resistance, softness, water adsorbent, oil adsorbent, flame-retardant, and can be woven, knitted and braided. The yarn can be used to weave high quality fabric with high count and high strength for four seasons, which greatly broadens the application fields of animal leather, improves the utilization of the leather and provides a kind of spinnable fiber for the textile industry. Therefore, the present invention can be widely used in textile industry.

Owner:ZHANG LIWEN

Yarn of animal collagen fiber and manufacture process thereof

InactiveUS8328878B2Improve usabilityHigh tensile strengthSuture equipmentsOther chemical processesYarnTextile fiber

A kind of yarn of animal collagen fiber and the manufacture process thereof, characterized in that the yarn is made of 1-100 WT % of collagen fiber of animal leather, and 0-99 WT % of textile fiber. The yarn of animal collagen fiber is made by the following procedure: choosing raw materials, loosing fiber, assorting, blending, carding, drawing, and twisting, if using the rawhide, the above procedure should add the steps of liming, washing, deliming, tanning and dehydrating. The raw material of the yarn can be the rawhide of any animal, as well as the leftover material or worn-out leather. The yarn has excellent properties, high tensile strength, abrasion resistance, softness, water adsorbent, oil adsorbent, flame-retardant, and can be woven, knitted and braided. The yarn can be used to weave high quality fabric with high count and high strength for four seasons, which greatly broadens the application fields of animal leather, improves the utilization of the leather and provides a kind of spinnable fiber for the textile industry. Therefore, the present invention can be widely used in textile industry.

Owner:ZHANG LIWEN

Abrasion resistant textile sleeve, improved multifilament yarn therefor and methods of construction thereof

PendingUS20170207005A1Excellent abrasion resistanceLow costProtective fabricsInsulated cablesYarnMelt temperature

A textile sleeve for routing and protecting an elongate member against abrasion and method of construction thereof are provided. The sleeve includes a flexible wall having a plurality of yarns interlaced with one another. At least some of the plurality of yarns are provided as improved multifilament yarns having low-melt filaments and non-low-melt filaments. The low-melt filaments have a first melt temperature and the non-low-melt filaments having a second melt temperature, with the second melt temperature being greater than the first melt temperature. The low-melt filaments are bonded with the non-low-melt filaments to prevent relative sliding movement therebetween.

Owner:FEDERAL MOGUL POWERTAIN LLC

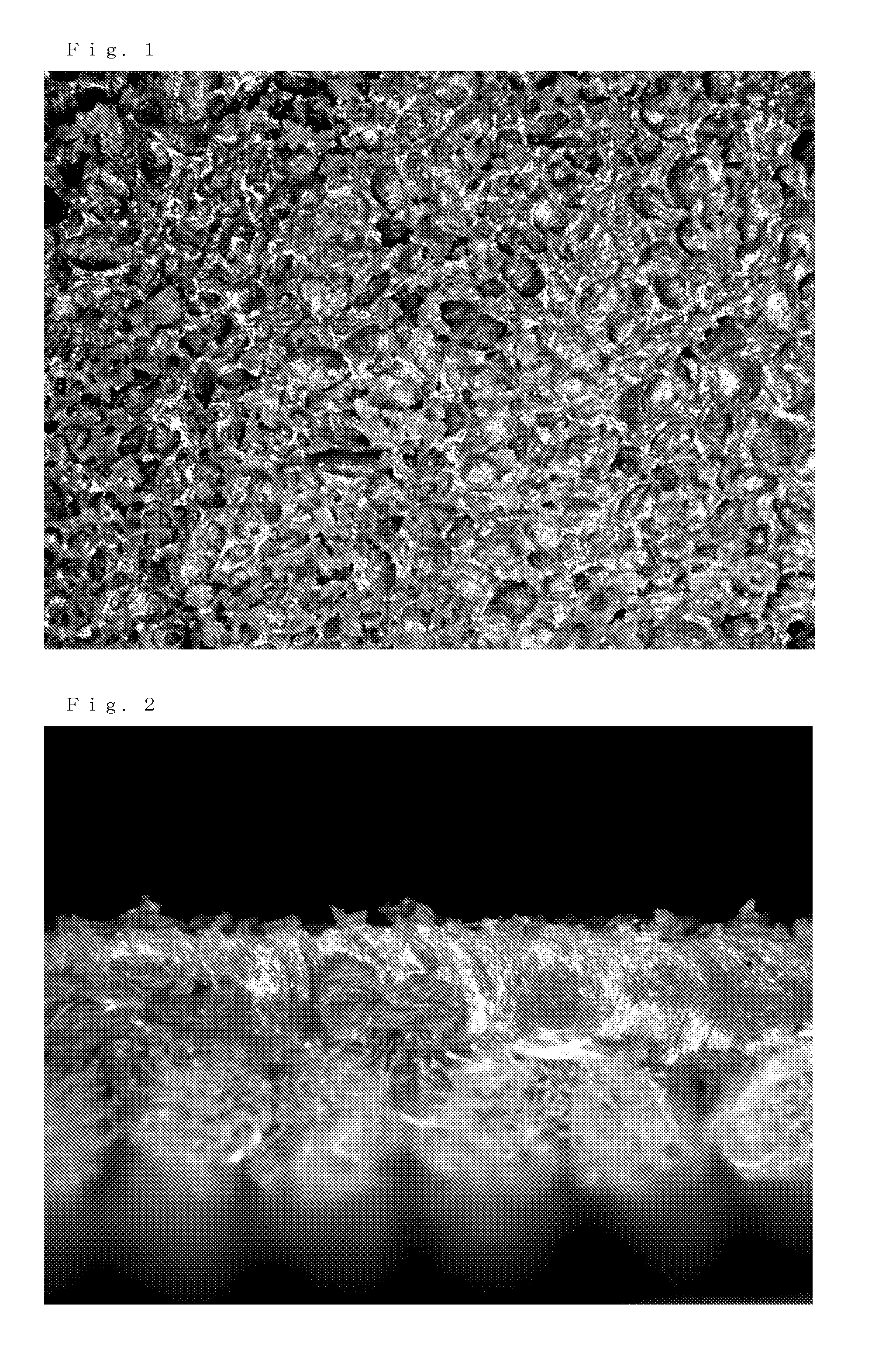

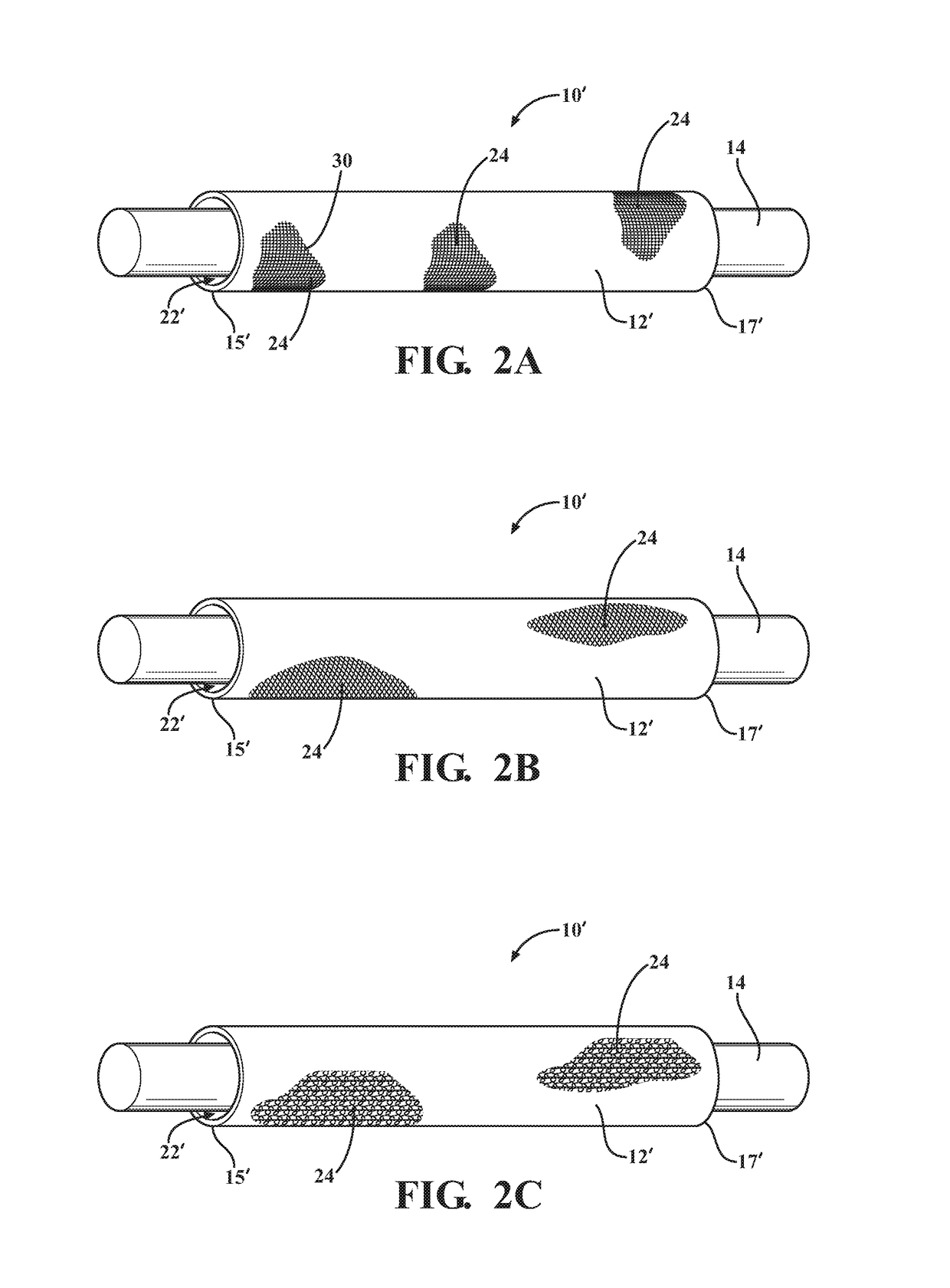

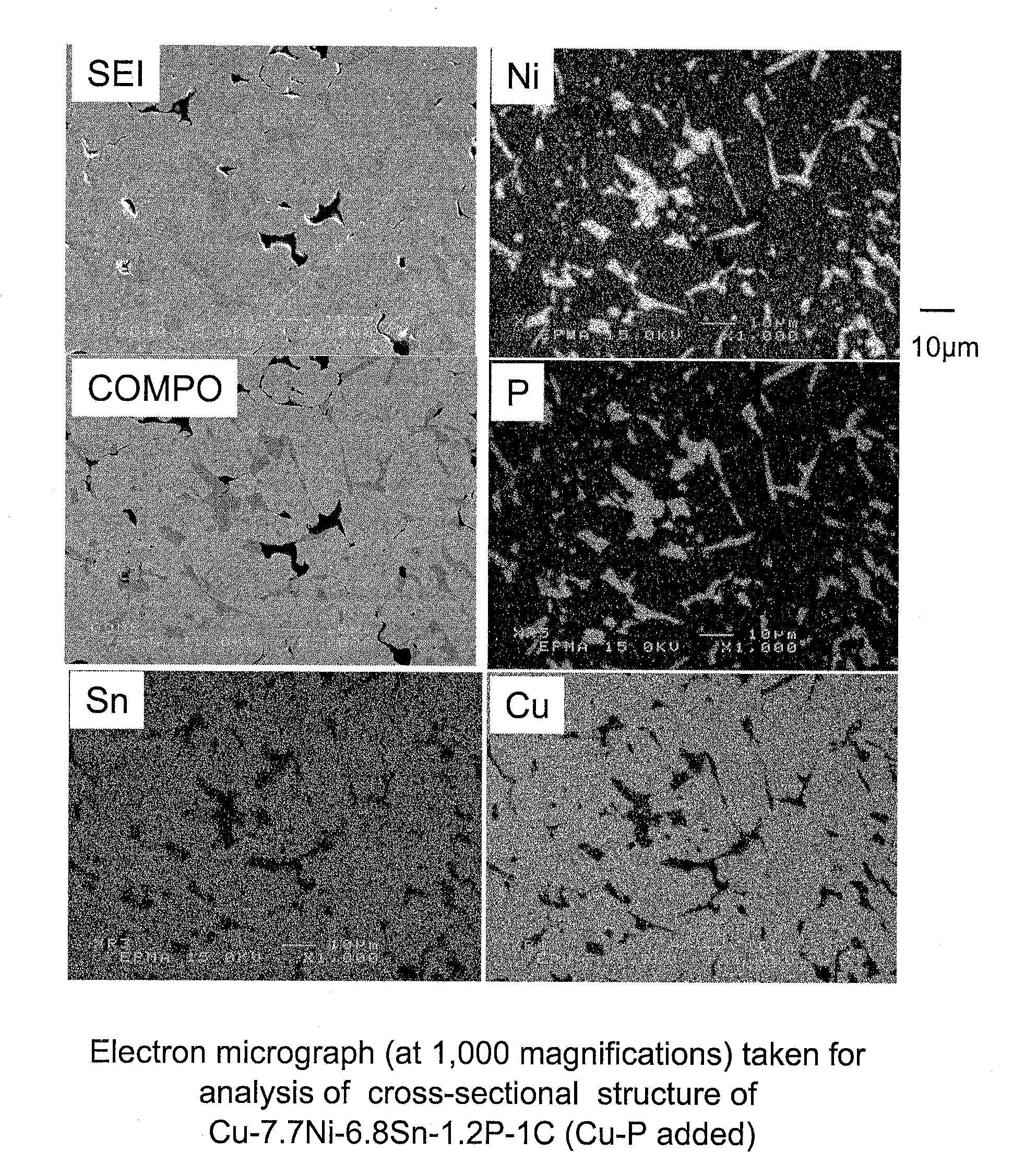

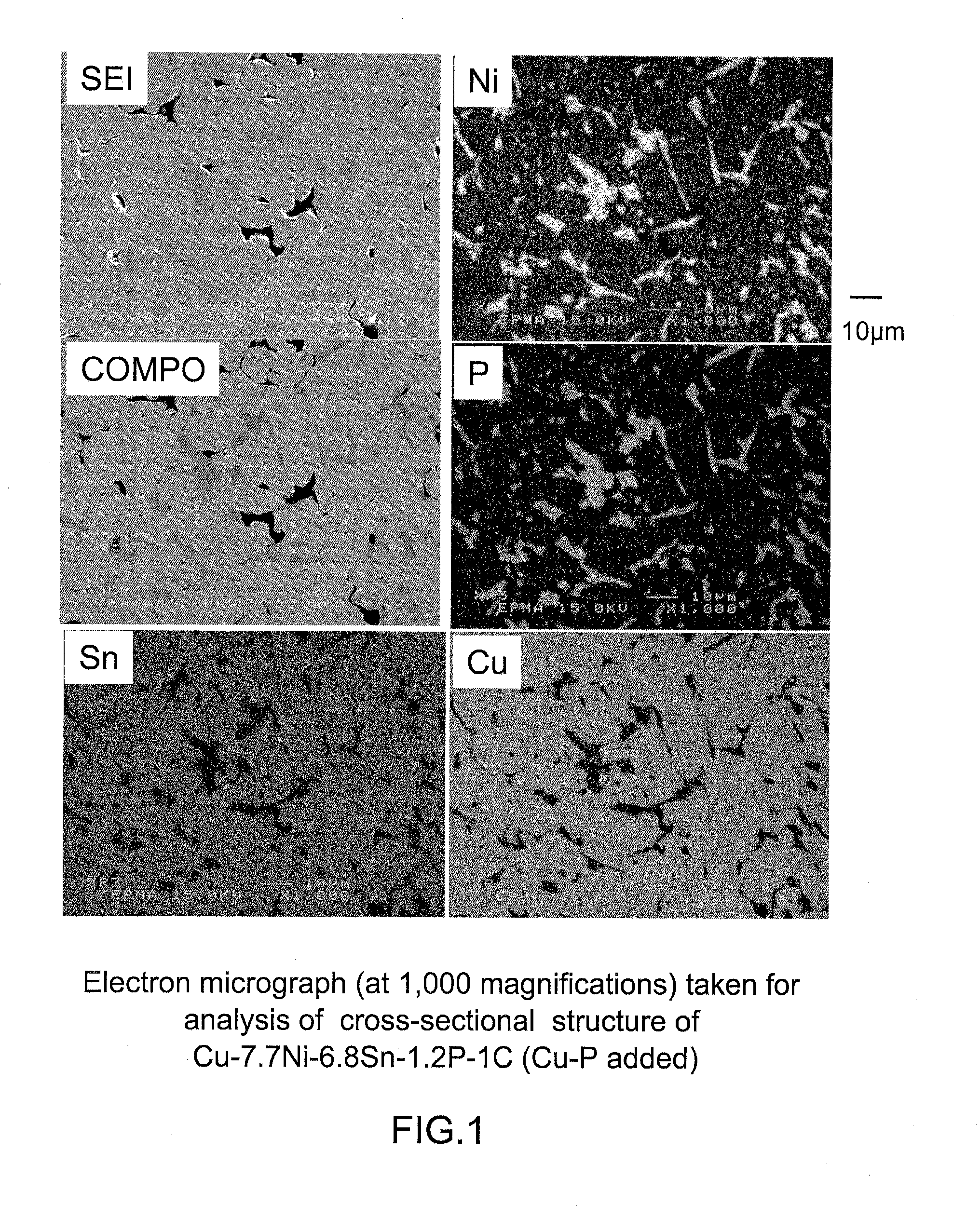

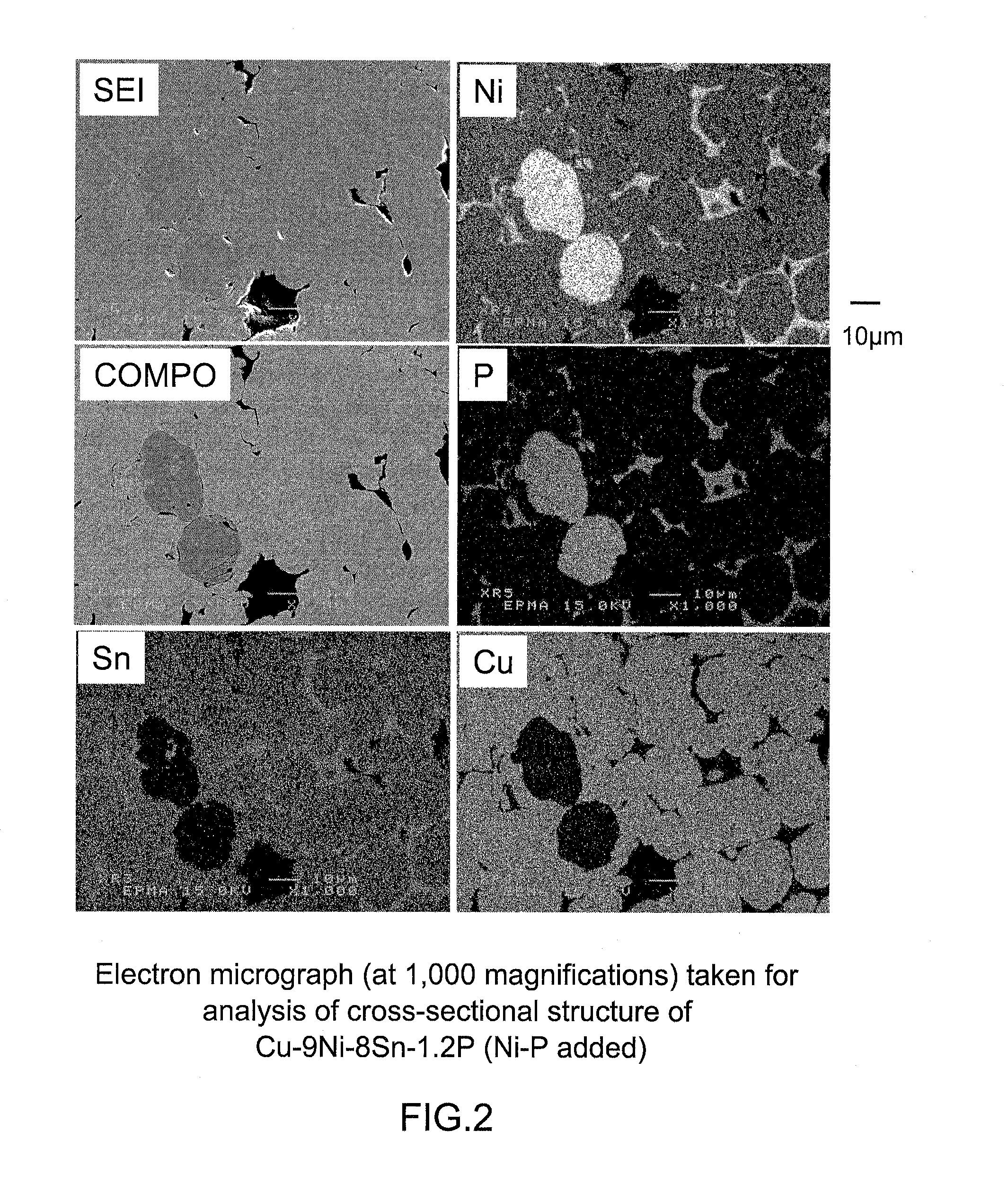

Cu-BASED OIL-IMPREGNATED SINTERED BEARING

There is provided a Cu-based oil-impregnated sintered bearing which can be used for high-load applications such as an ABS system and a wiper motor system in automobile, can be manufactured at low cost, and is excellent in abrasion resistance and seizure resistance. The bearing contains 5 to 40% by mass of Ni, 3 to 15% by mass of Sn, 0.5 to 4.0% by mass of P, or further 0.3 to 5.0% by mass of a solid lubricant, and a remainder comprising Cu and inevitable impurities, and has a metallic structure in which a phase mainly composed of Ni and P is dispersed in a matrix, and has a 5 to 25% porosity.

Owner:DIAMET CORP

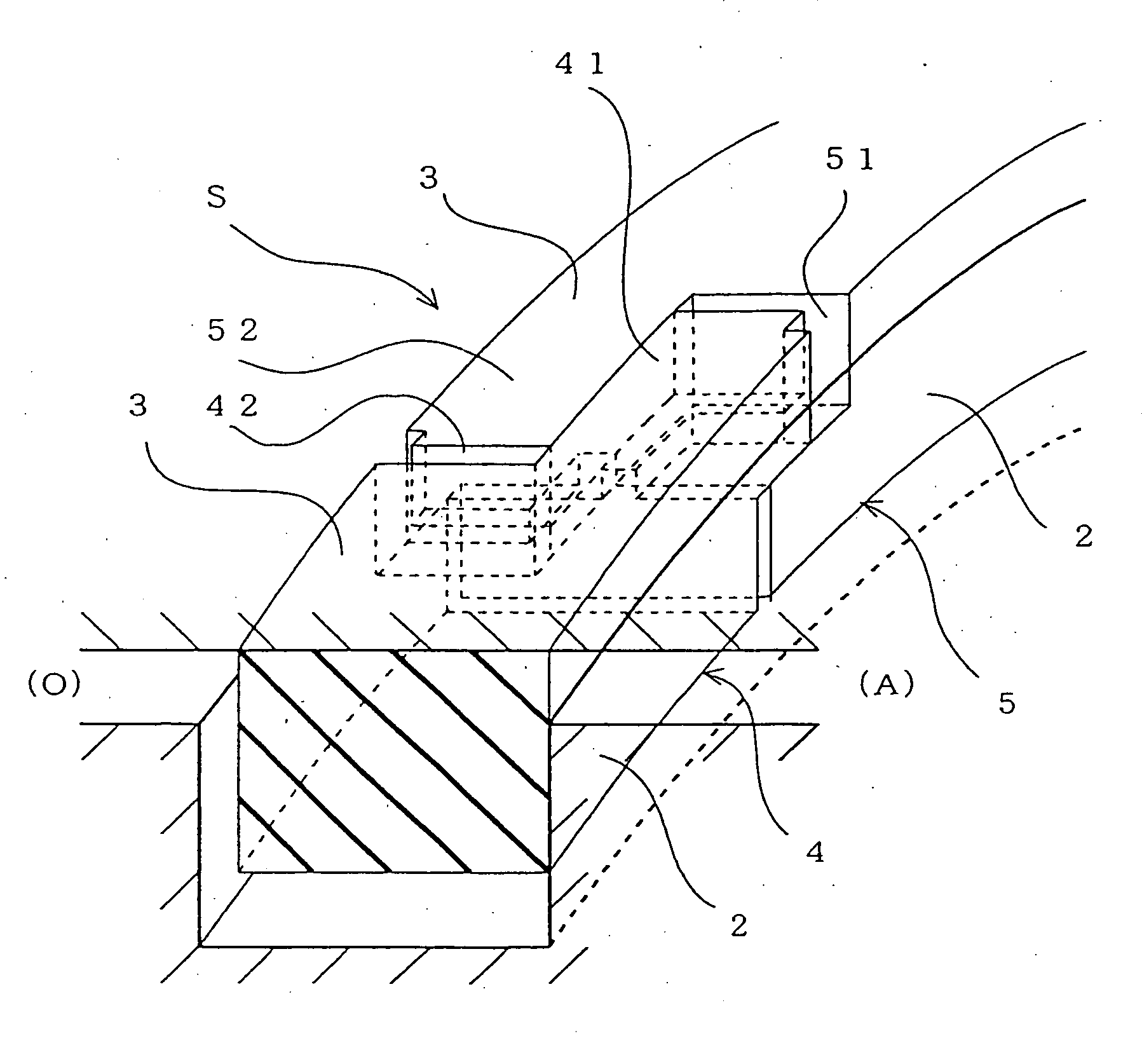

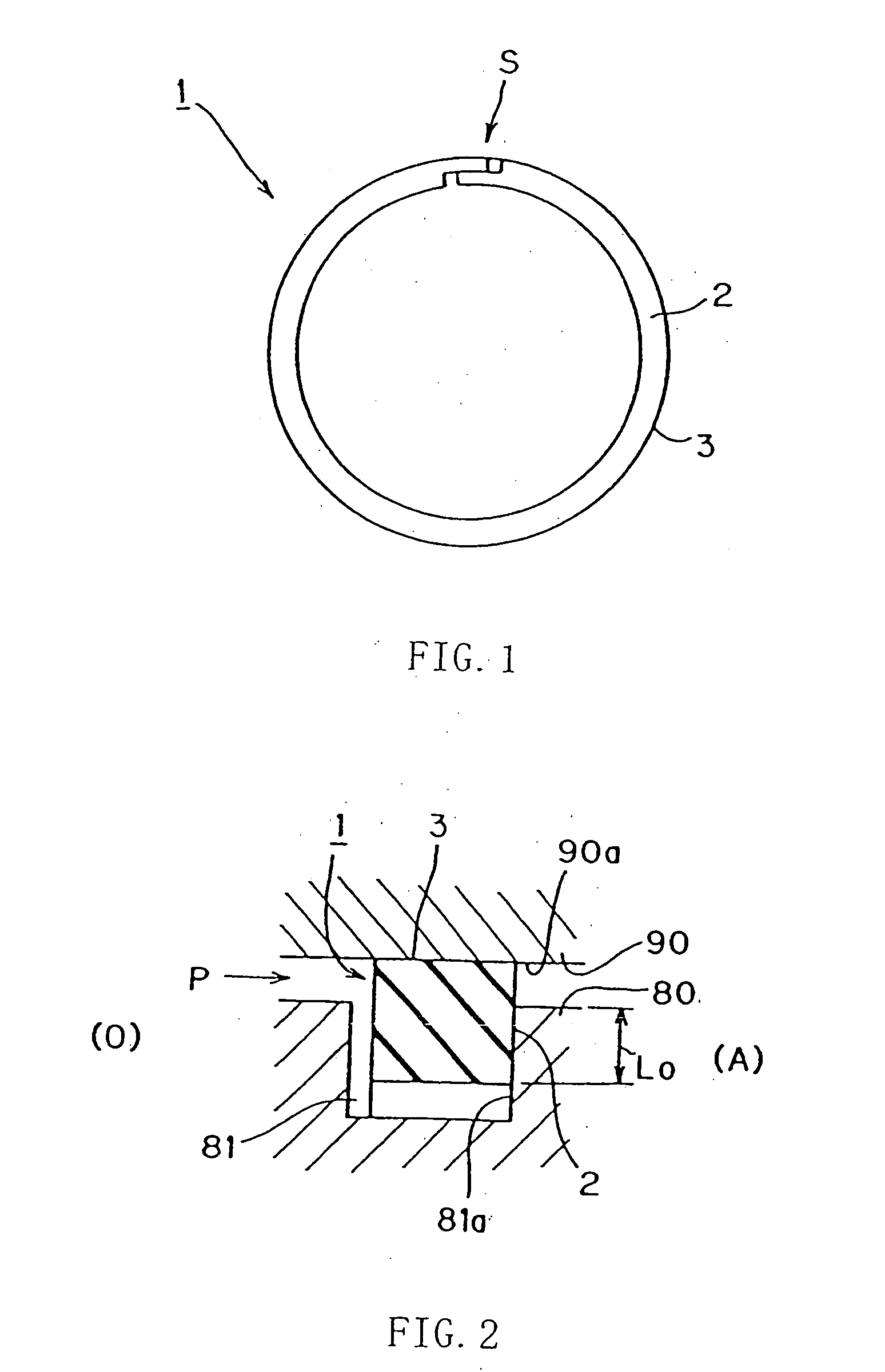

Seal ring

InactiveUS20050116426A1Improve wear resistanceImprove abilitiesEngine sealsPiston ringsFree rotationEngineering

A seal ring for sealing an annular clearance between two members which are disposed for free rotations relative to each other. At a cut portion which is cut at a portion of the seal ring, there is formed a passage for allowing leakage when the cut end portions engage with each other. This passage is given a sectional shape of square or the like. This passage improves an abrasion resistance.

Owner:NOK CORP

Surface material for ball and ball

ActiveUS20060199686A1Improve wear resistanceGreat abrasionHollow inflatable ballsLayered productsBall gameWear resistance

A surface material for balls, formed of a sheet-shaped material having a coating layer formed from an elastic polymer on one surface of a base material layer, (1) said coating layer being formed of three layers C-1, C-2 and C-3 which are arranged in the order of C-1, C-2 and C-3 from a front surface side, (2) the layer C-3 being present on the base material layer side and formed from a porous elastic polymer, (3) the layer C-1 being present on the front surface side and being formed from an elastic polymer containing a tackifier, and (4) the coating layer being formed from the elastic polymers having fine through holes reaching the base material layer from the front surface side or having no such fine through holes, and a ball having a surface to which the above surface material is bonded. The present invention provides a surface material for balls for ball games, which is excellent in gripping characteristic at a moistened time and is also excellent in abrasion resistance and impact absorption capability.

Owner:TEIJIN CORDLEY

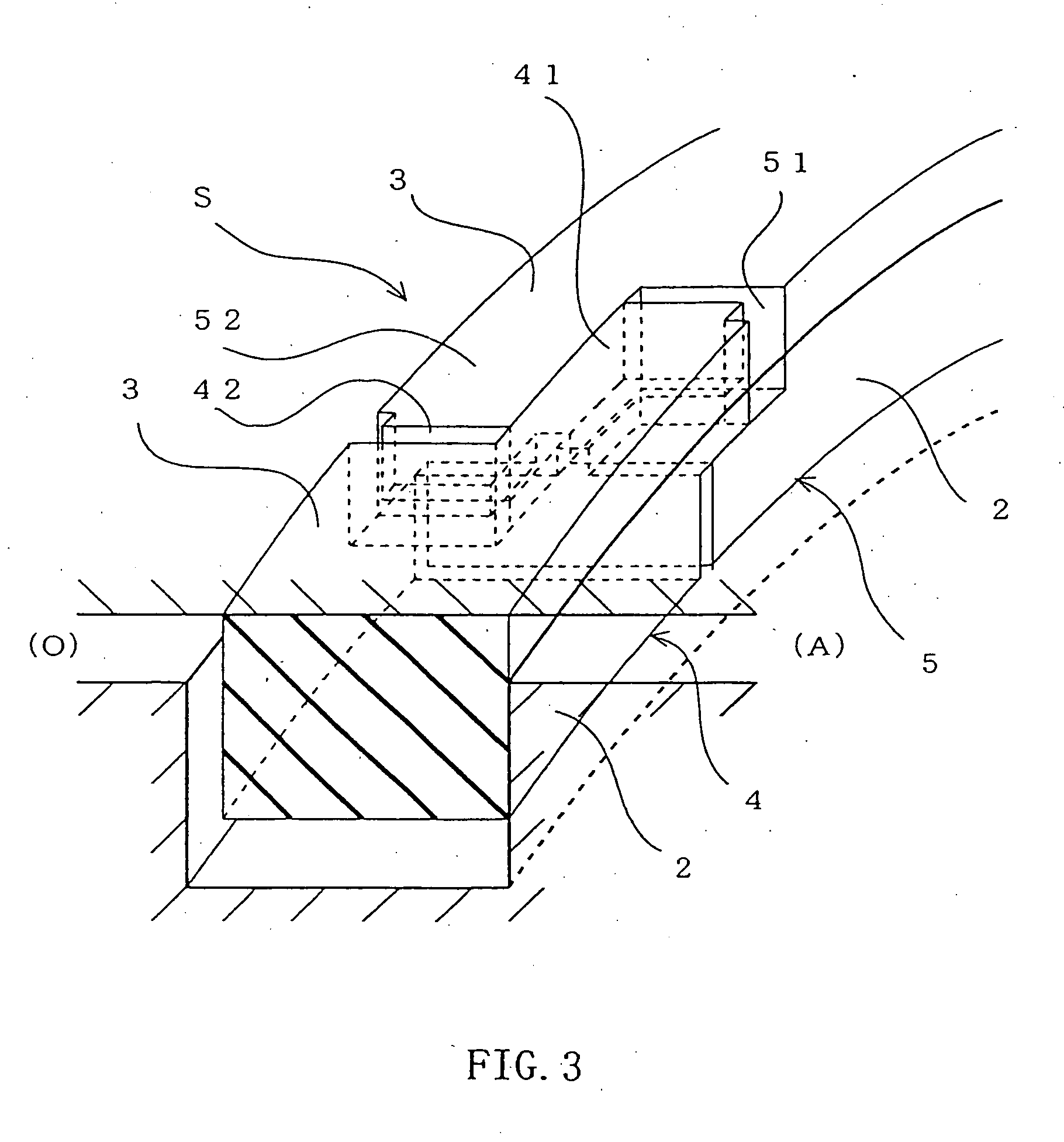

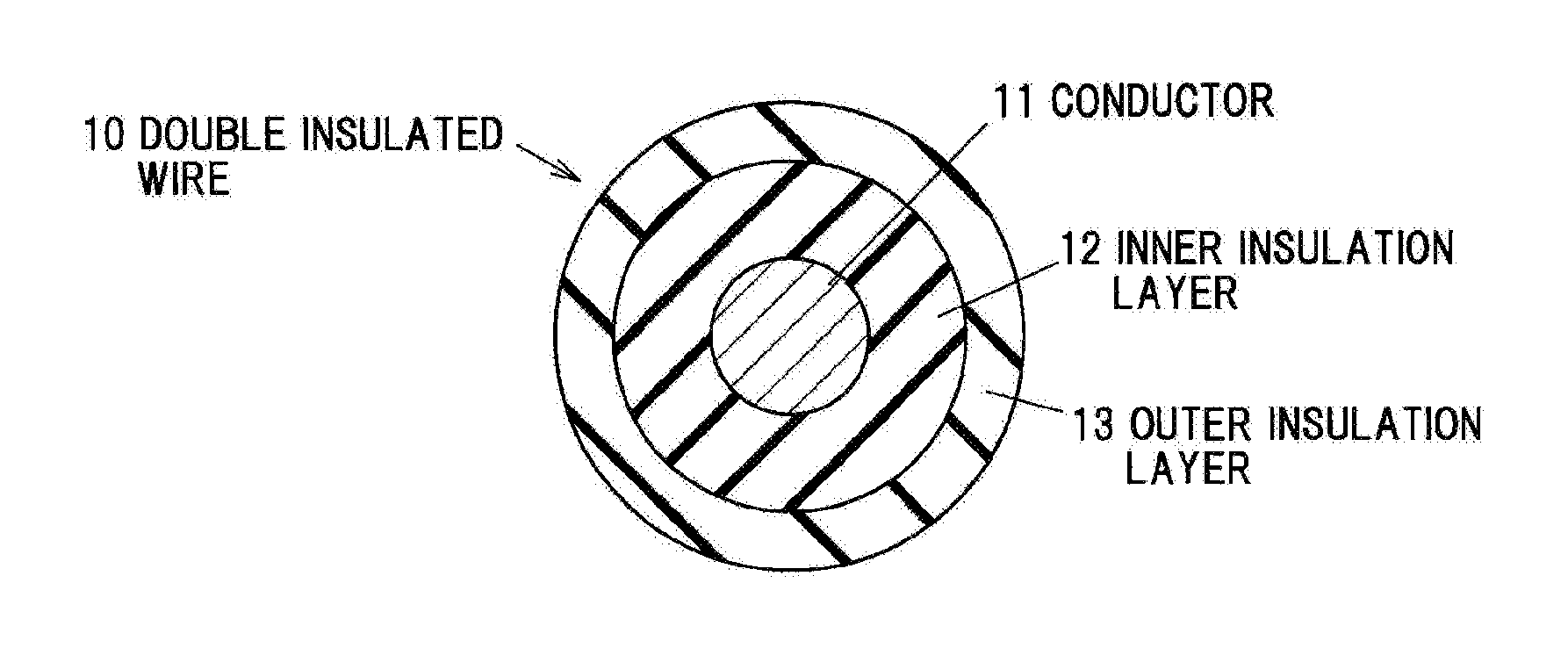

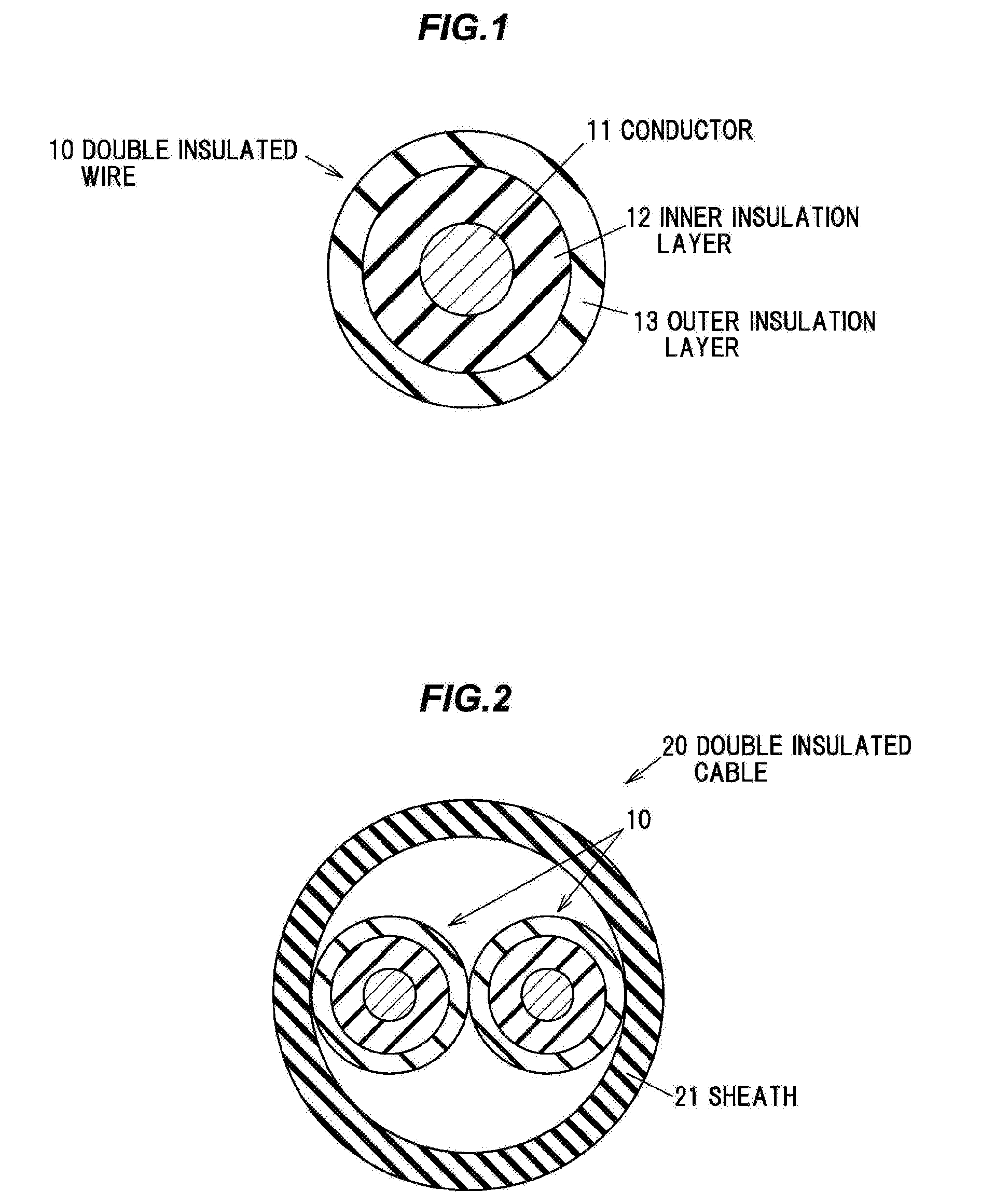

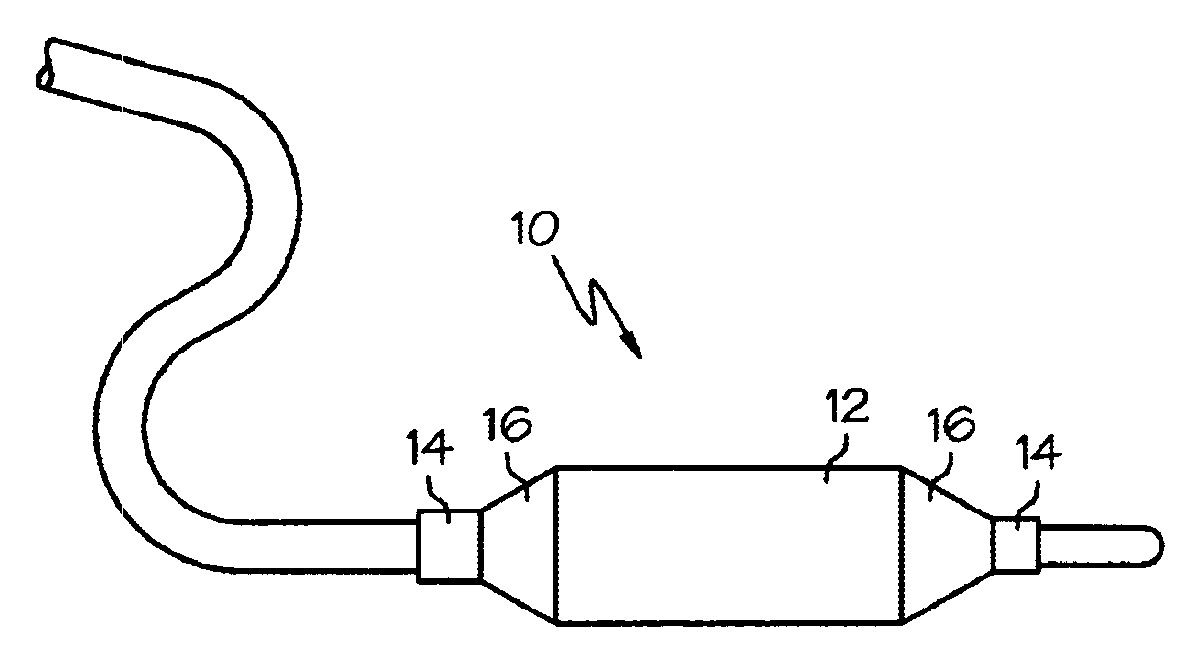

Multilayer insulated wire and multilayer insulated cable

ActiveUS20170032867A1Great abrasionImprove penetration resistancePlastic/resin/waxes insulatorsInsulated cablesCross-linkElectrical conductor

A multilayer insulated wire includes a conductor, an inner insulation layer, and an outer insulation layer. A gel fraction of the inner insulation layer defined below is not less than 80%. A gel fraction of the outer insulation layer defined below is less than the gel fraction of the inner insulation layer and not less than 75%. An insulation covering layer including the inner and outer insulation layers is cross-linked and has a tensile modulus of not less than 500 MPa in a tensile test conducted at a tensile rate of 200 mm / min. Gel fraction (%)=(mass of inner or outer insulation layer after being immersed in xylene at 110° C. for 24 hours, then left at 20° C. and atmospheric pressure for 3 hours and vacuum-dried at 80° C. for 4 hours / mass of inner or outer insulation layer before immersion in xylene)×100

Owner:HITACHI METALS LTD

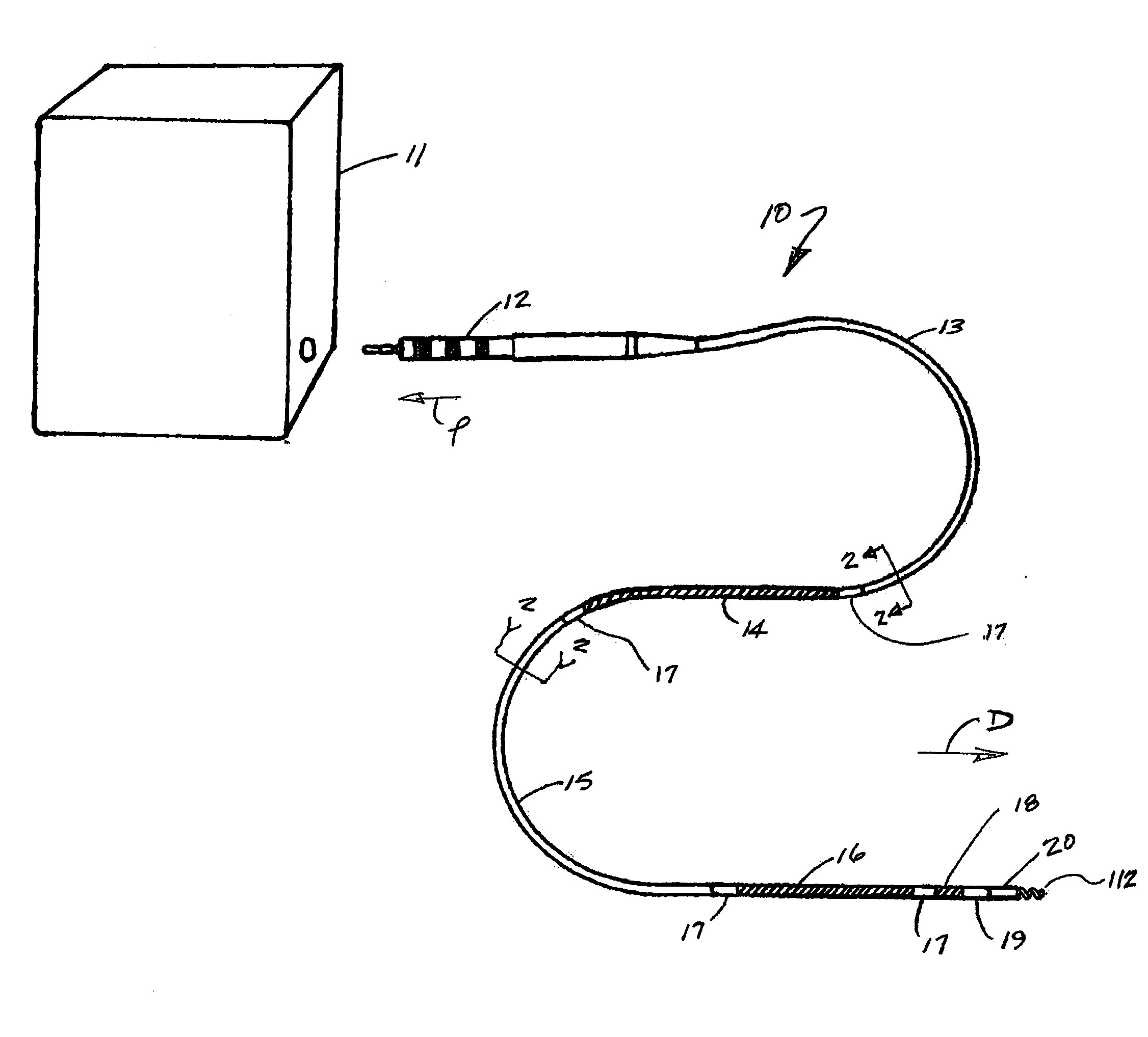

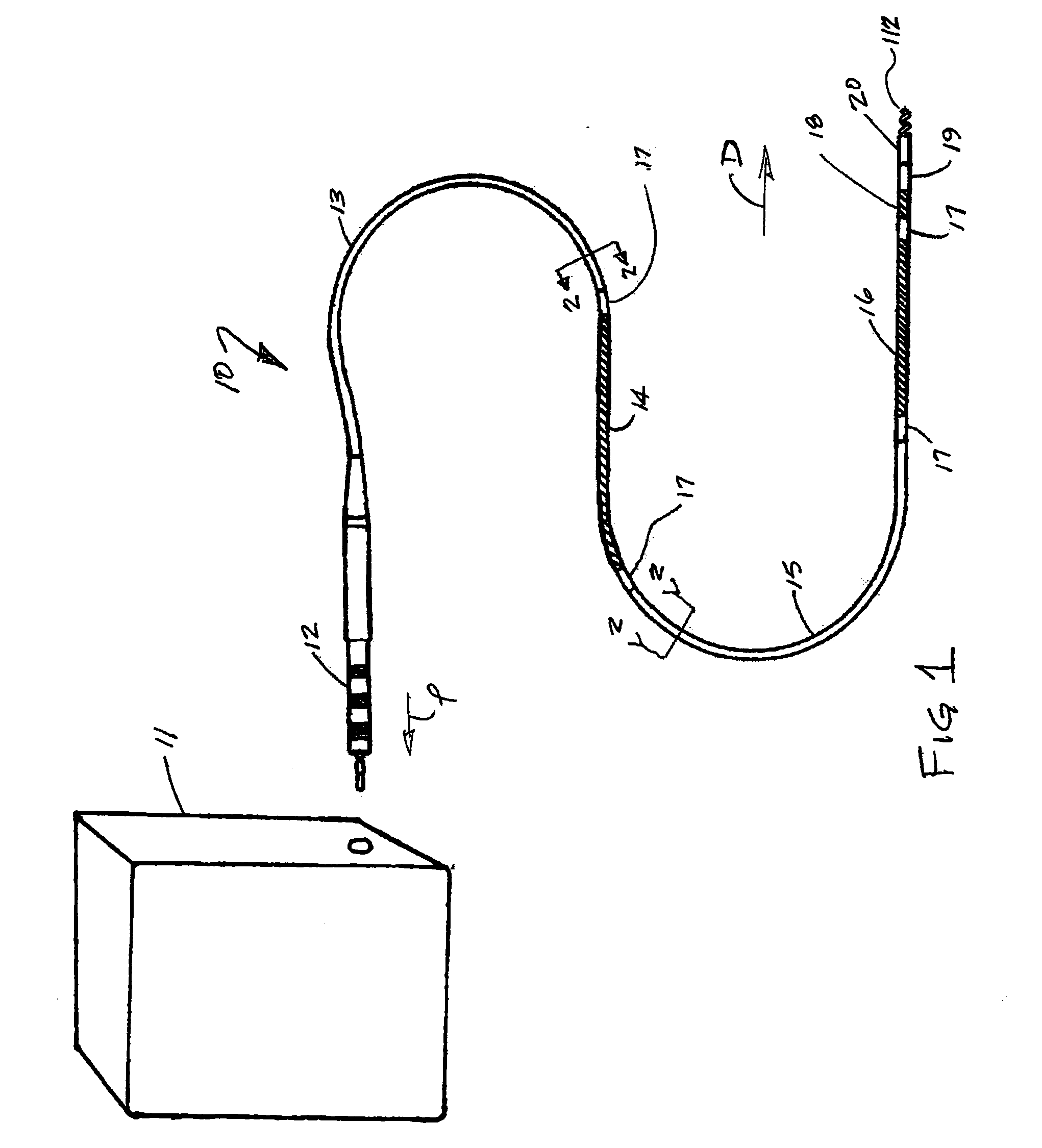

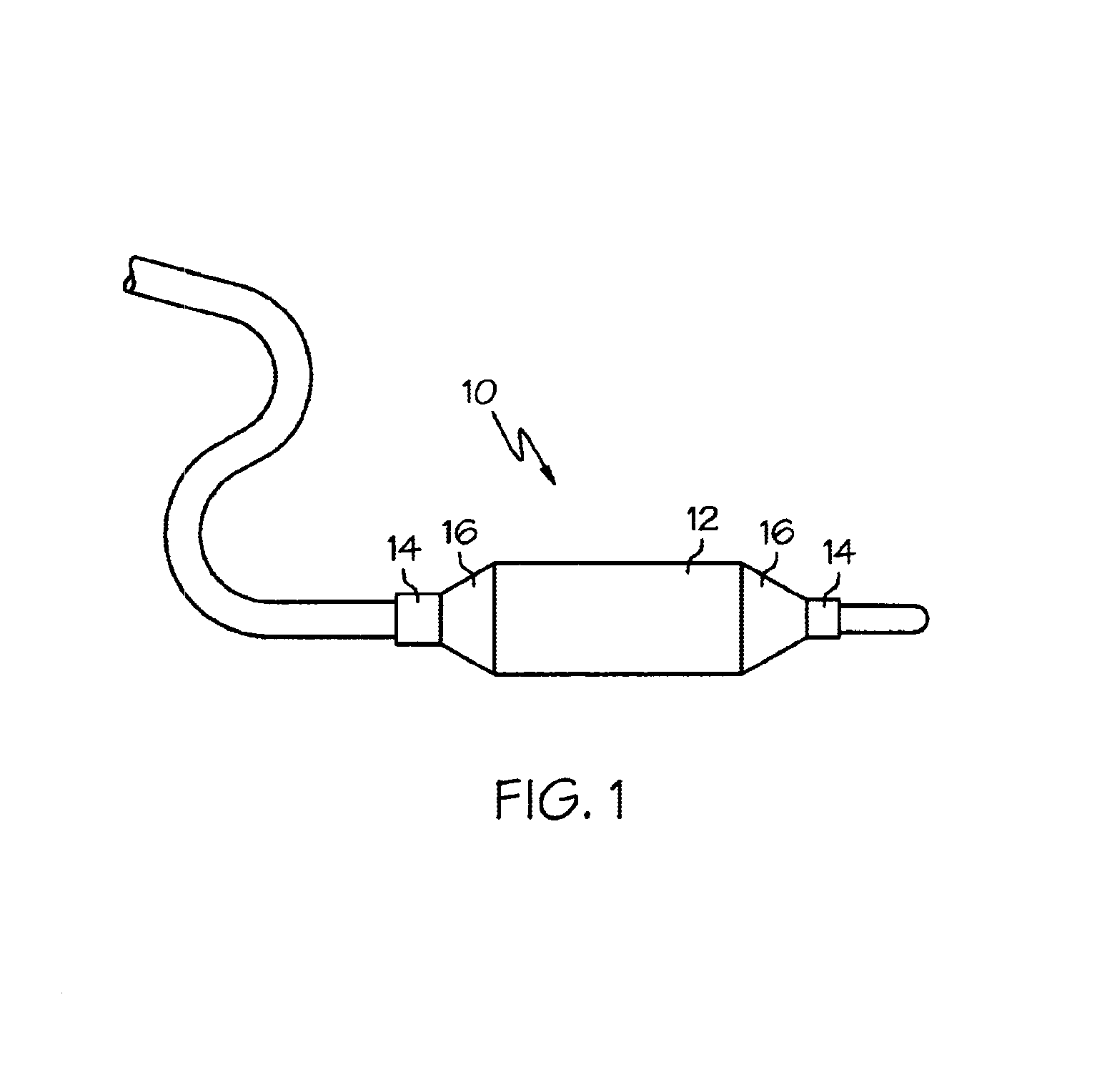

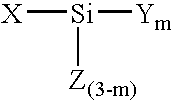

Moisture curable balloon materials

InactiveUS6946174B1High strengthGreat abrasionBalloon catheterSynthetic resin layered productsMedicineSilanes

The present invention relates to a catheter device having a dilatation balloon formed from a polymeric material crosslinked by moisture through —Si—O—Si—linkages, and to a method of making the same. The polymeric material is formed by reacting at least one organofunctional hydrolyzable silane with at least one polymer. The crosslinked polymeric structure is ideal for forming more resilient and durable catheter balloons. In particular, the catheter balloons have excellent abrasion resistance.

Owner:BOSTON SCI SCIMED INC

Abrasion-Resistant Adhesive Tape

InactiveUS20100291820A1Improve wear resistanceExcellent abrasion resistanceFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyesterAutomotive industry

This invention relates to adhesive tapes comprising a polyester support, a polymer coating, and an adhesive layer. The polymer coating may be on the side opposite the adhesive layer or between the support and the adhesive layer. The adhesive tape of the present invention is particularly suited for wire harnessing in the automotive industry.

Owner:GROUPE SCAPA FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com