Patents

Literature

52results about How to "Quick drying effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

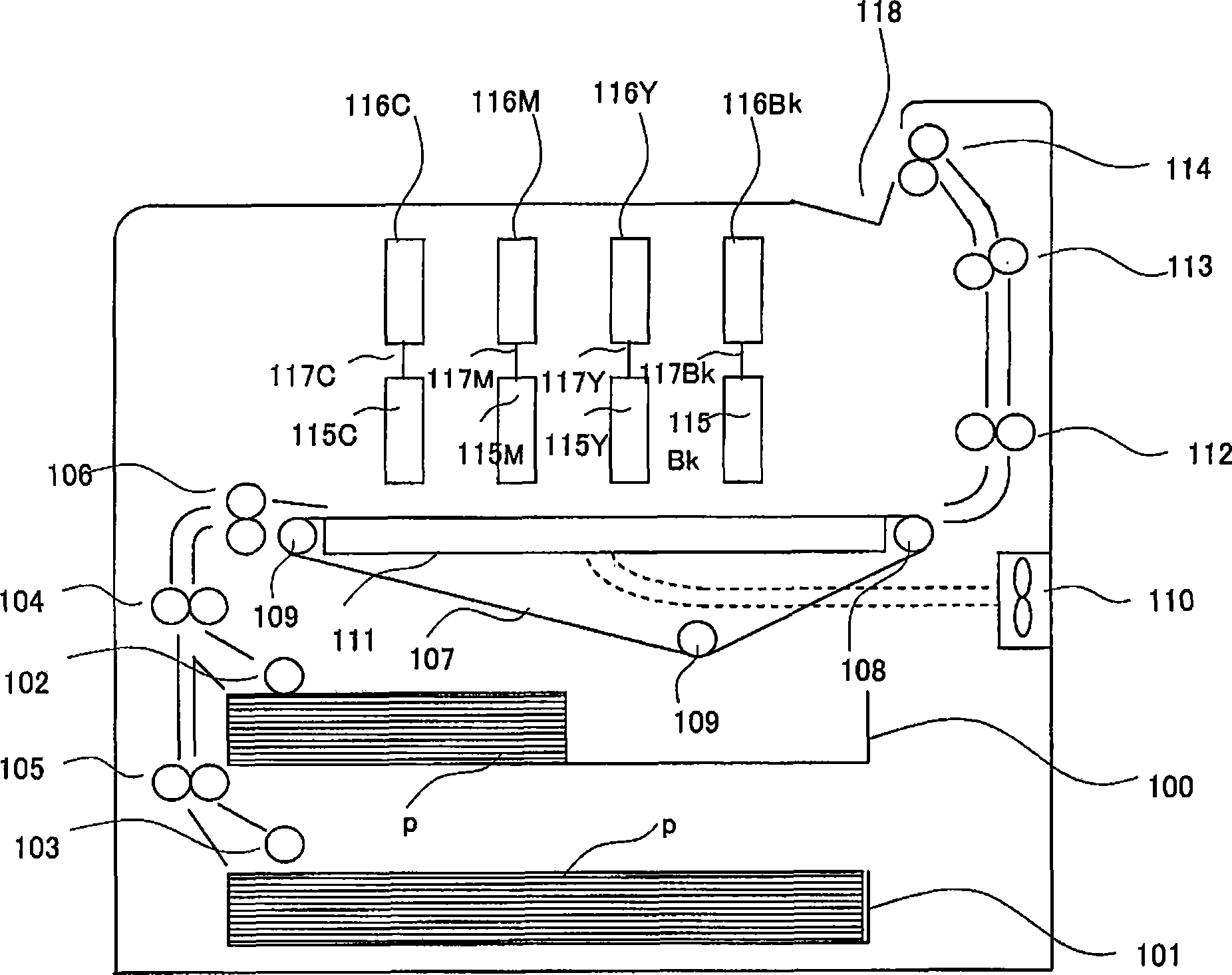

Ink jet recording process

ActiveUS20110234728A1Quick drying effect is goodHigh-quality and abrasion resistanceMeasurement apparatus componentsDuplicating/marking methods2-PyrrolidoneSolvent

Recording onto a non-ink-absorbing recording medium is performed using an aqueous ink composition containing a first solvent composed of at least one selected from 2-pyrrolidone, 1,3-dimethyl-imidazolidinone, and N,N′-dimethylpropylene urea, a second solvent composed of at least one selected from 1,2-hexanediol and 1,2-pentanediol, and a third solvent composed of at least one selected from glycol diethers and heating the non-ink-absorbing recording medium at 40 to 60° C.

Owner:SEIKO EPSON CORP

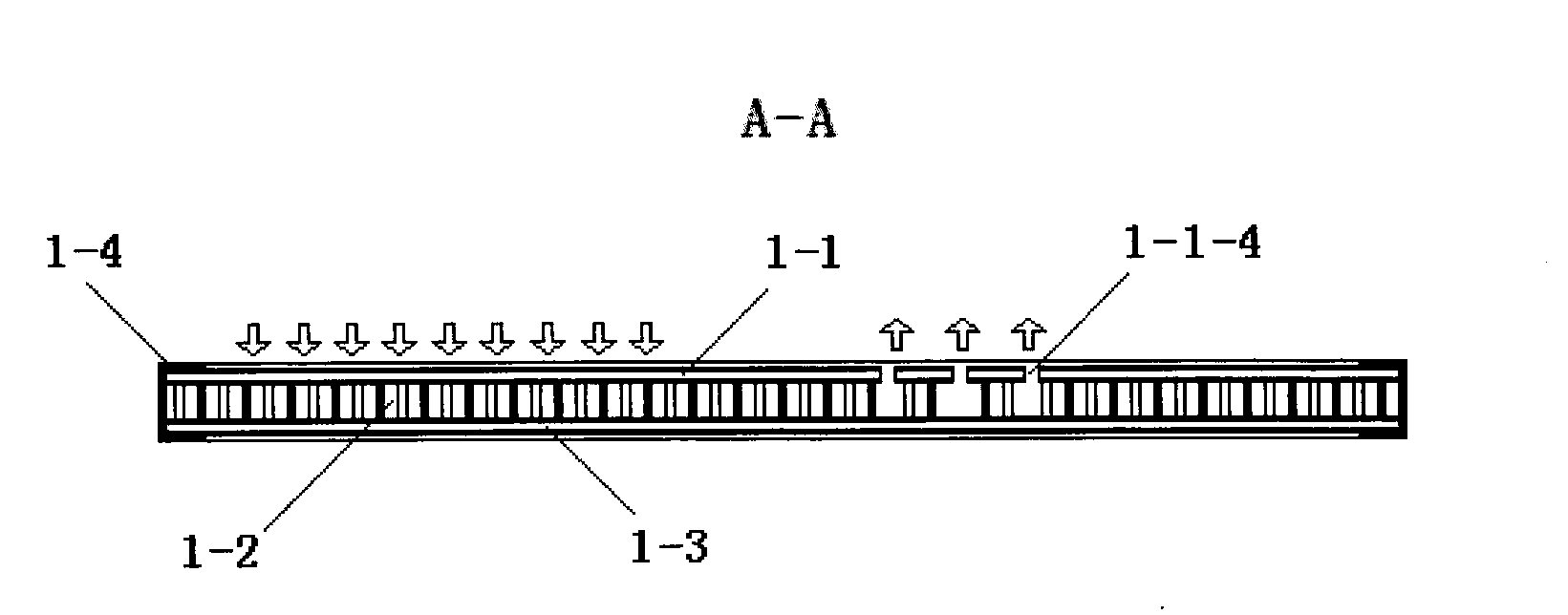

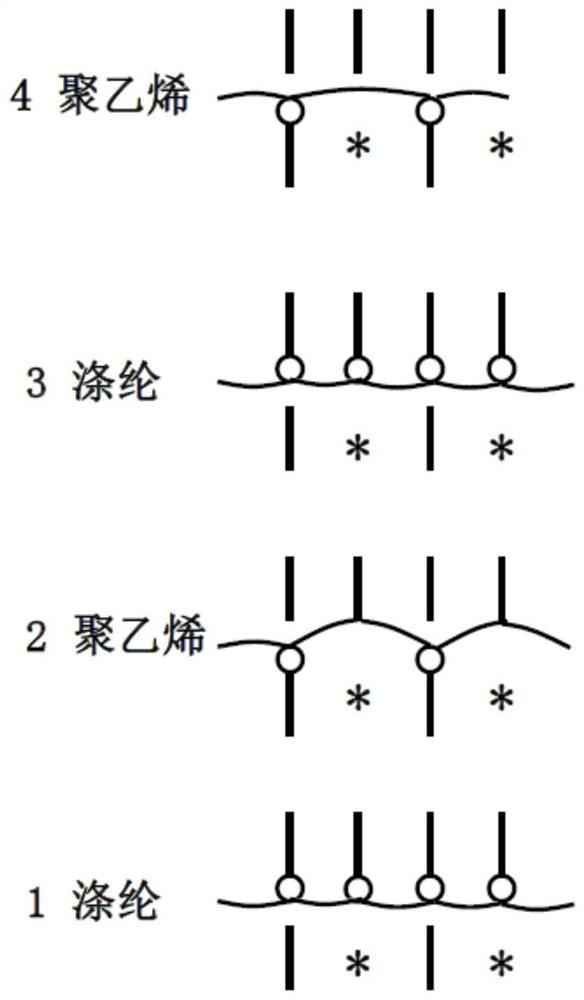

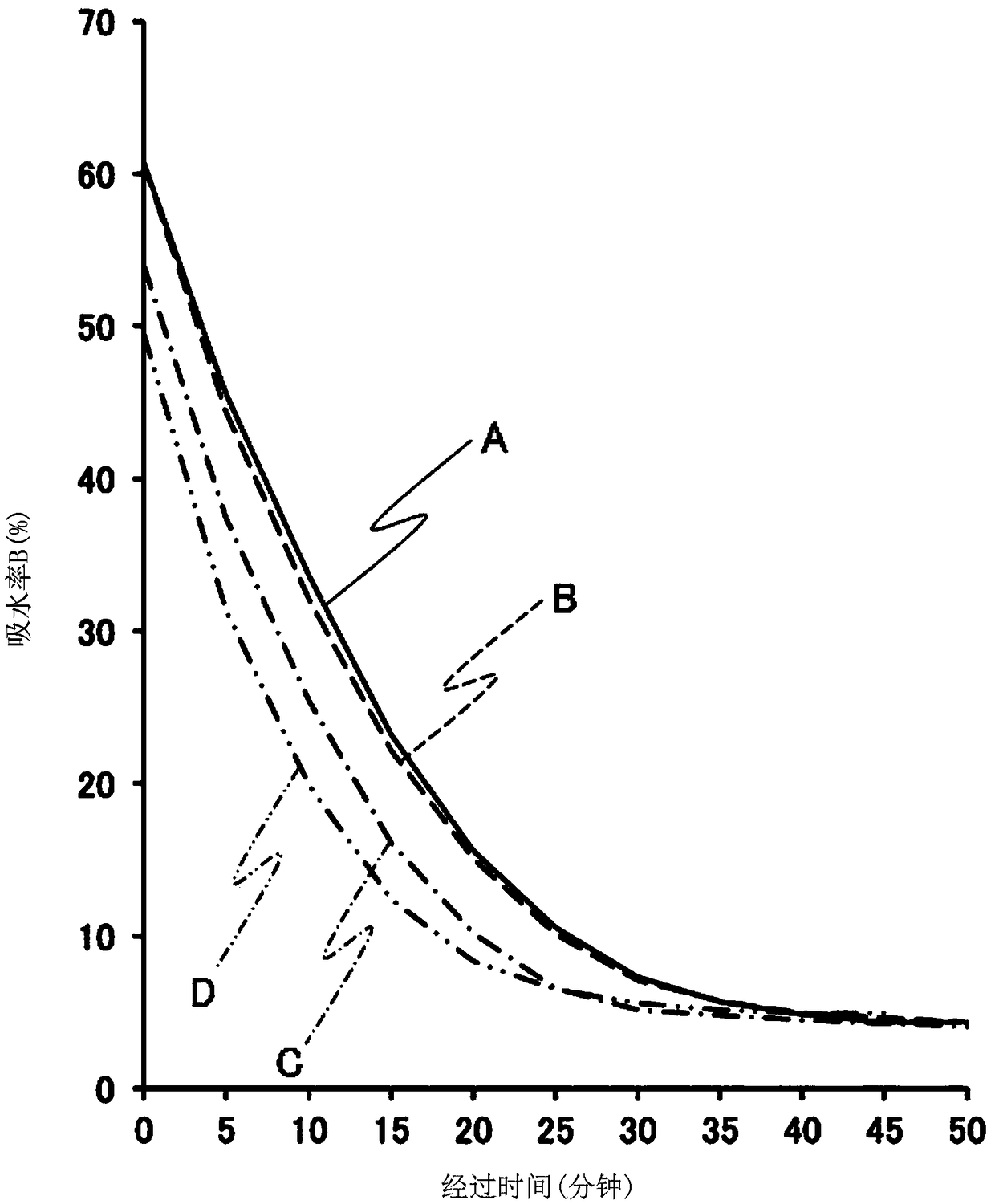

One-way moisture conduction fast-drying cotton/polyester composite knitted fabric

InactiveCN103668732AImprove wearing comfortFeel goodWeft knittingHeating/cooling textile fabricsPolymer scienceMoisture absorption

The invention relates to one-way moisture conduction fast-drying cotton / polyester composite knitted fabric. Cotton yarn serving as the material of an inner layer of the fabric and super-fine denier polyester filaments serving as the material of an outer layer of the fabric are woven to form gray cloth, and then the one-way moisture conduction fast-drying cotton / polyester composite knitted fabric is obtained through preshaping, splitting, dying, washing, hydrophilic soft finishing and shaping. According to the one-way moisture conduction fast-drying cotton / polyester composite knitted fabric, a plain weave single-sided tissue structure is adopted, the cotton yarn which is good in moisture absorption capacity and poor in moisture conduction capacity is woven into the inner surface of the fabric, the super-fine denier polyester filaments which have the Y-shaped cross section and are higher in moisture absorption and moisture conduction capacity are woven into the outer surface of the fabric, the super-fine denier polyester filaments are much larger than cotton in surface area, sweat on the body surface can be rapidly conducted to the outer layer and evaporated rapidly, and the inner layer of the fabric is kept dry and comfortable.

Owner:广东广纺检测技术股份有限公司

Aqueous inkjet ink and inkjet recording method

An embodiment of the invention is concerned with an aqueous inkjet ink containing an ink solvent containing water and a water-soluble organic solvent containing glycerin and triethylene glycol and a pigment dispersed in the ink solvent. The water-soluble organic solvent accounts for from 30 to 80% by weight of the ink solvent, a weight of the triethylene glycol is from 0.5 to 1.5 times the weight of the glycerin, and the pigment is blended in an amount of from 2 to 20% by weight of the total weight of the ink.

Owner:KK TOSHIBA +1

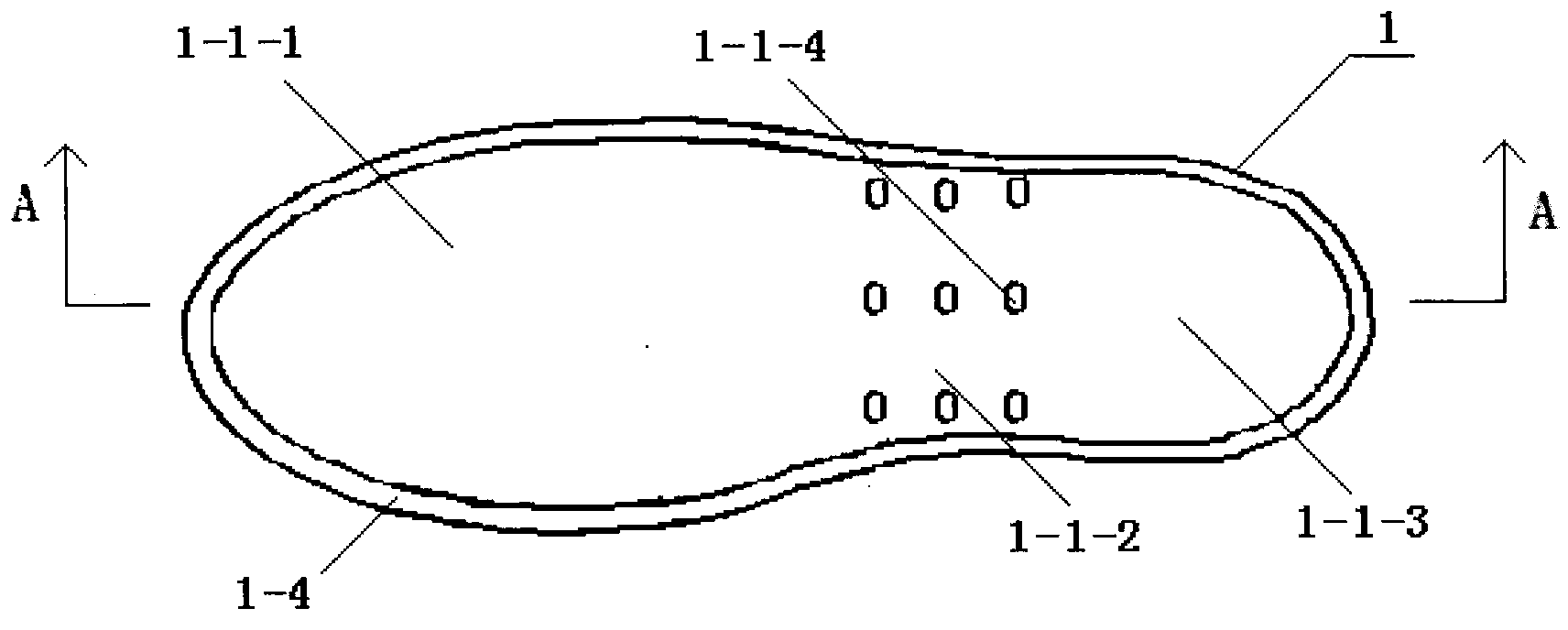

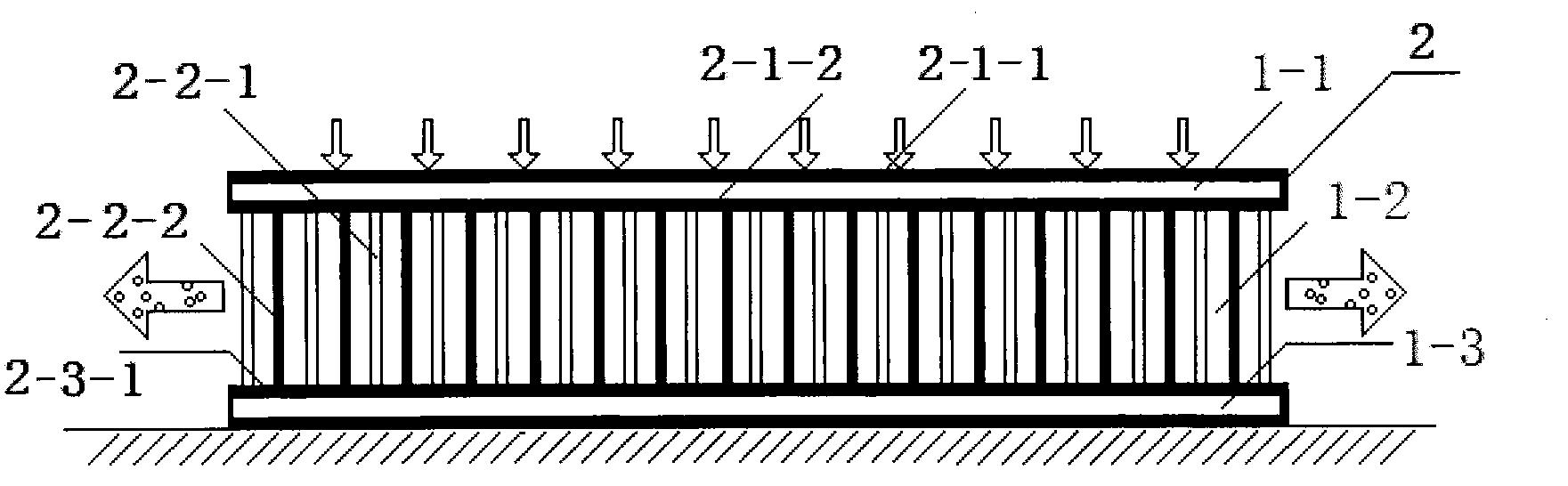

Moisture guide exhaust elastic insole and manufacturing method thereof

InactiveCN103266409AIncrease exhaustFacilitates one-way conductionLayered productsInsolesFiberMoisture storage

The invention provides a moisture guide exhaust elastic insole which is characterized by being manufactured through a moisture guide quick-drying elastic liner fabric. The moisture guide quick-drying elastic liner fabric comprises a moisture absorption layer, an elastic moisture guide layer and a moisture storage discharging layer, wherein the elastic moisture guide layer is arranged between the moisture absorption layer and the moisture storage discharging layer. The moisture absorption layer is composed of warp-knitting double-bar full-penetration texture or double-bar partial hollow-penetration texture which is woven by composite long yarns, the elastic moisture guide layer is composed of an air partition layer which is formed by elastic chemical fiber monofilaments and moisture guide core suction yarns in a supported mode, the upper end of each elastic chemical fiber monofilament is connected with the moisture absorption layer in a woven mode, and the lower end of each elastic chemical fiber monofilament is connected with the moisture storage discharging layer in a woven mode. The moisture storage discharging layer is composed of warp-knitting double-bar chaining weft insertion texture containing high moisture-absorption yarns. The moisture guide exhaust elastic insole can achieve the fact that moisture or water vapour is rapidly conveyed from inner layer space to outer layer space of a shoe in a wearing process of the insole. Meanwhile, the moisture guide exhaust elastic insole can guarantee that antibiosis deodorization type functional fibers can completely give play to the effect, and the sole of a user wearing the shoe is always in a dry, clean and comfortable state.

Owner:DONGHUA UNIV

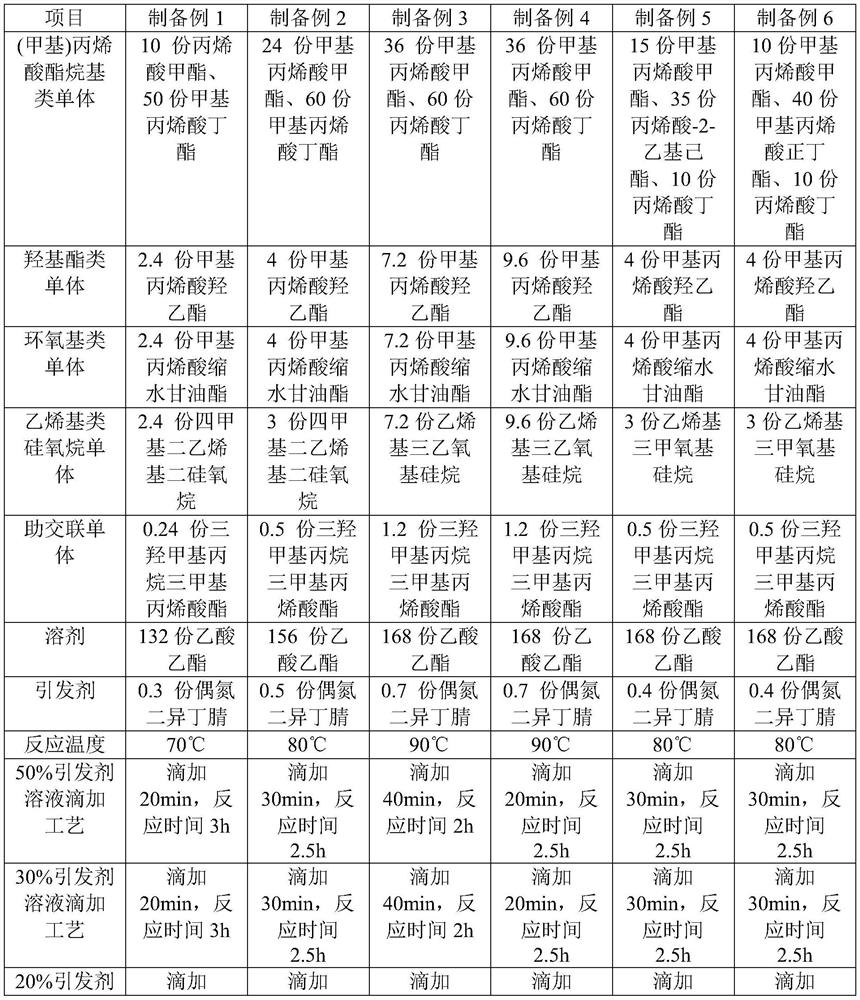

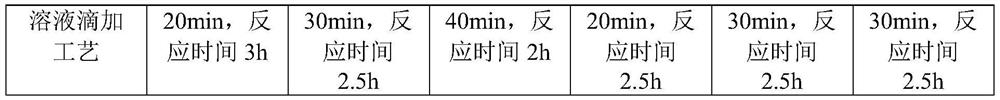

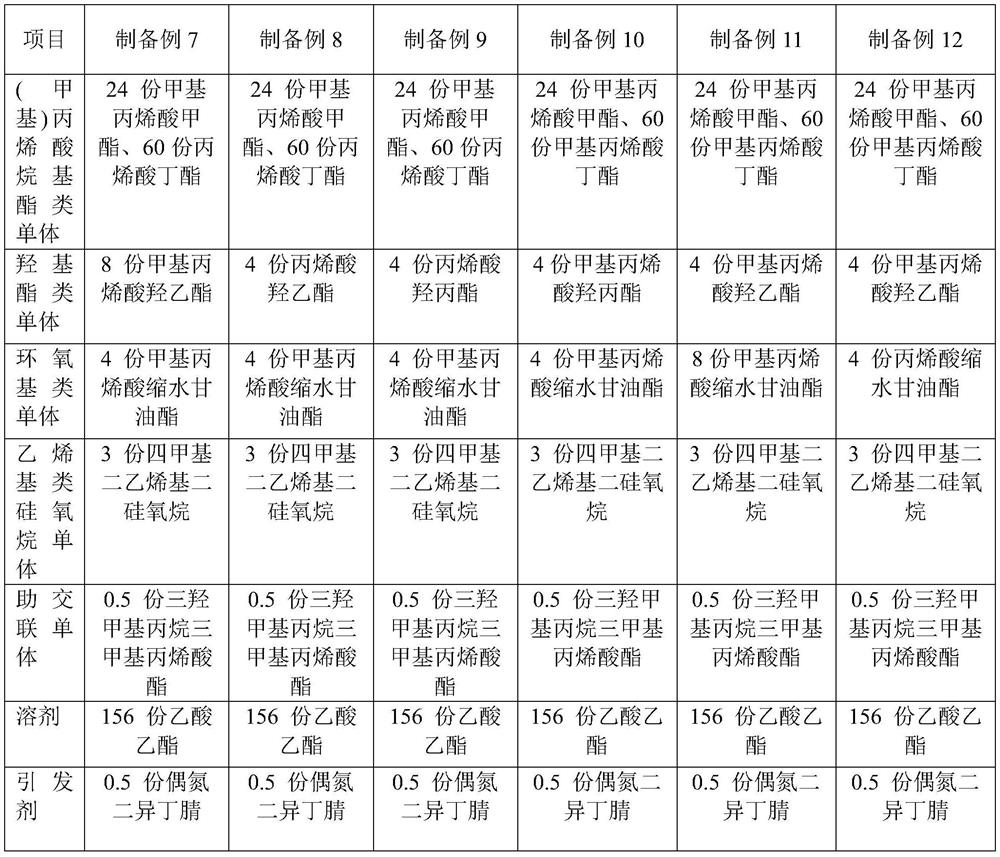

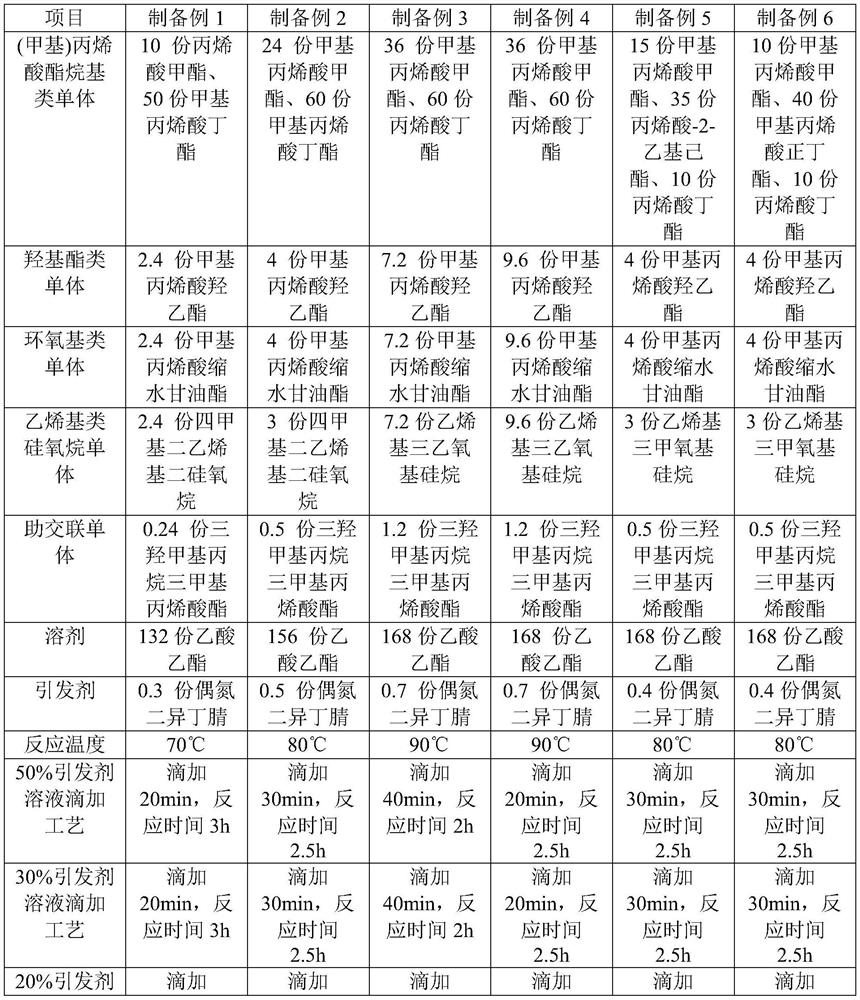

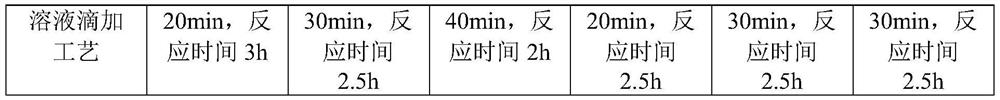

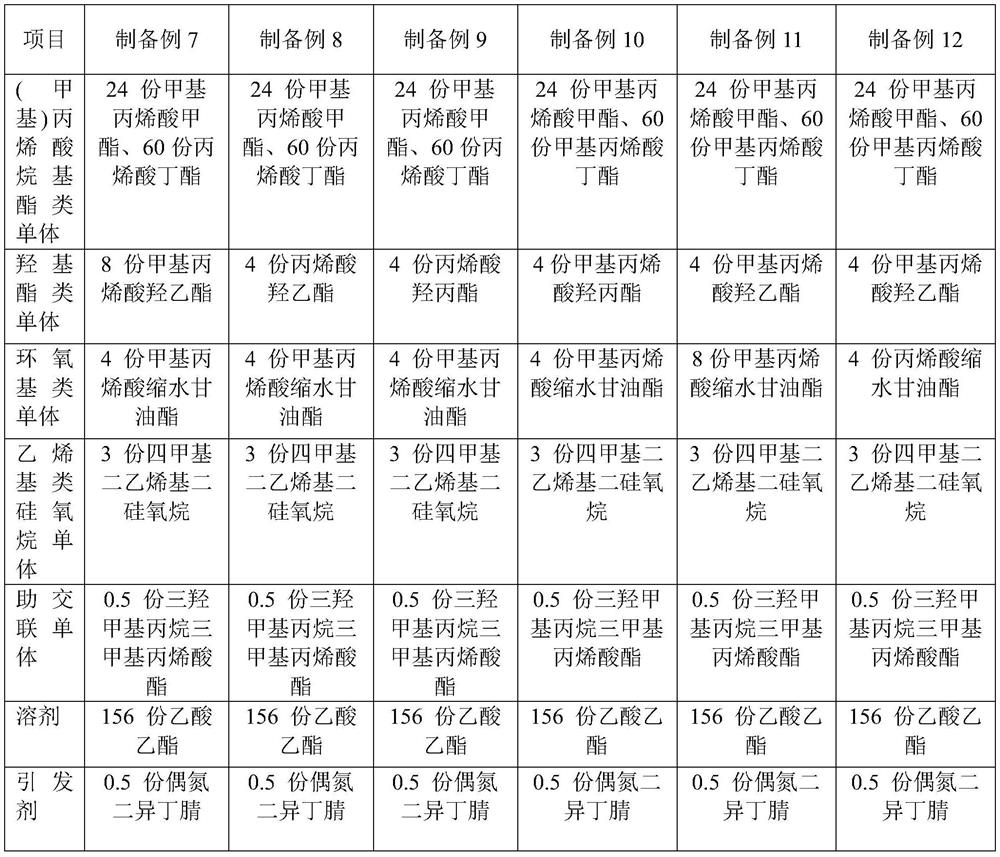

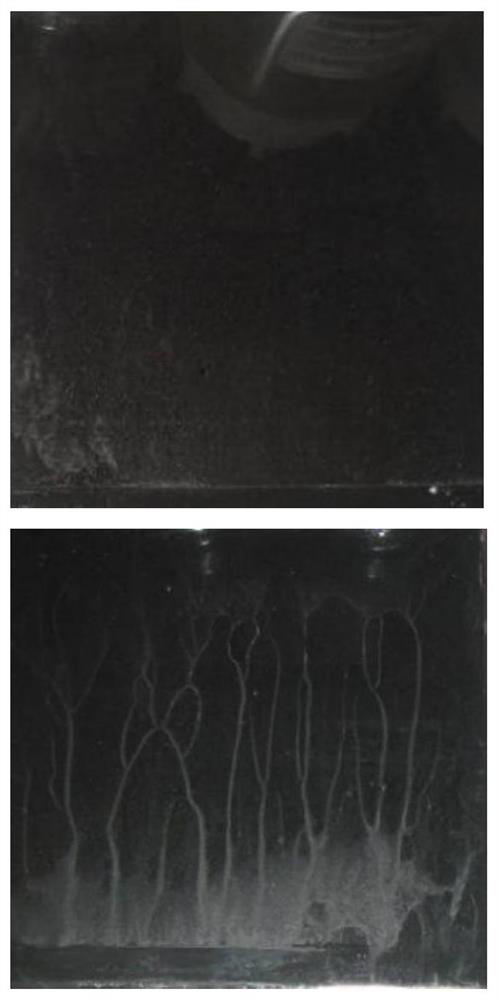

Silane modified acrylic resin, synthesis method and primer for silicone rubber

The invention relates to the technical field of resin synthesis and application thereof, and particularly discloses silane modified acrylic resin, a synthesis method and a primer for silicone rubber. The primer for the silicon rubber is prepared by dispersing the silane modified acrylic resin and the silane coupling agent titanate into a solvent for the primer and reacting through a catalyst. The silane modified acrylic resin provided by the invention can be used for preparing a primer for silicone rubber, and has the advantages of good adhesion, film-forming property, heat resistance, water resistance, low surface drying temperature, short time and the like; the invention relates to silane modified acrylic resin, which is prepared by dispersing (methyl) acrylic acid alkyl ester monomers, hydroxyl ester monomers, epoxy group monomers, vinyl siloxane monomers and assistant crosslinking monomers in a solvent for resin and carrying out free radical polymerization under the catalysis of an initiator, the silane modified acrylic resin obtained by the invention has excellent cohesion performance and film-forming performance, and is suitable for preparing a silicone rubber prime coat adhesive.

Owner:SHENZHEN KANGLIBANG TECH

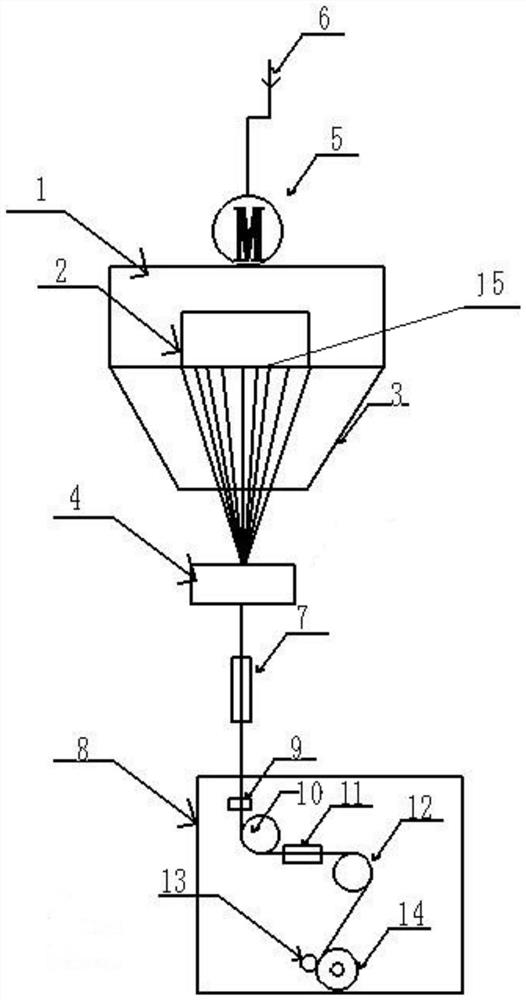

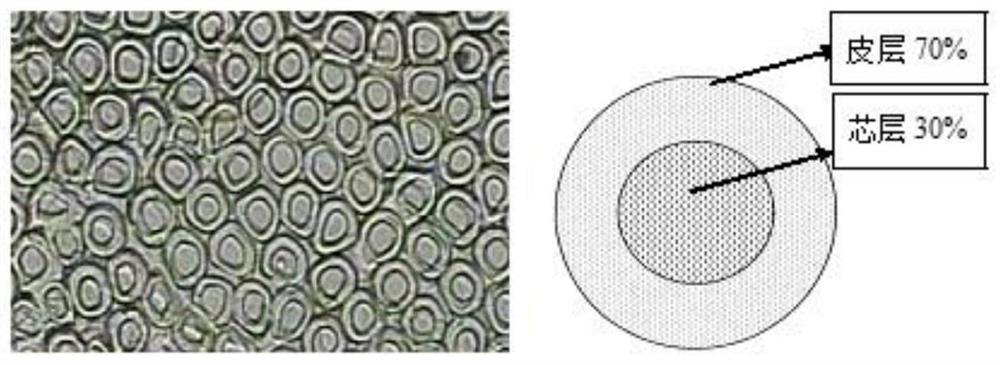

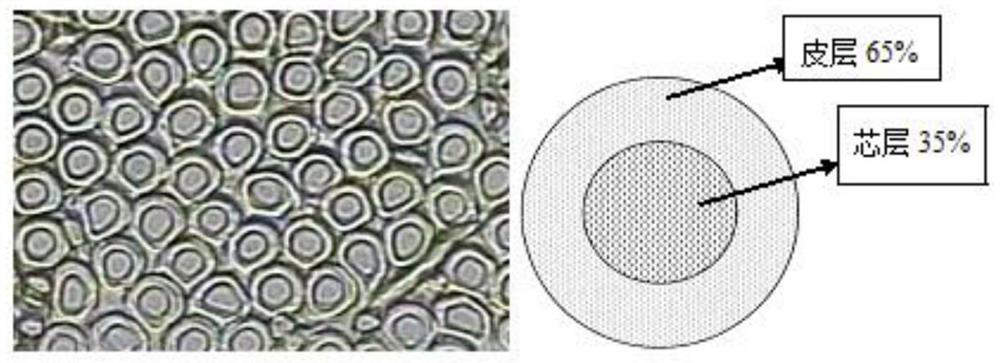

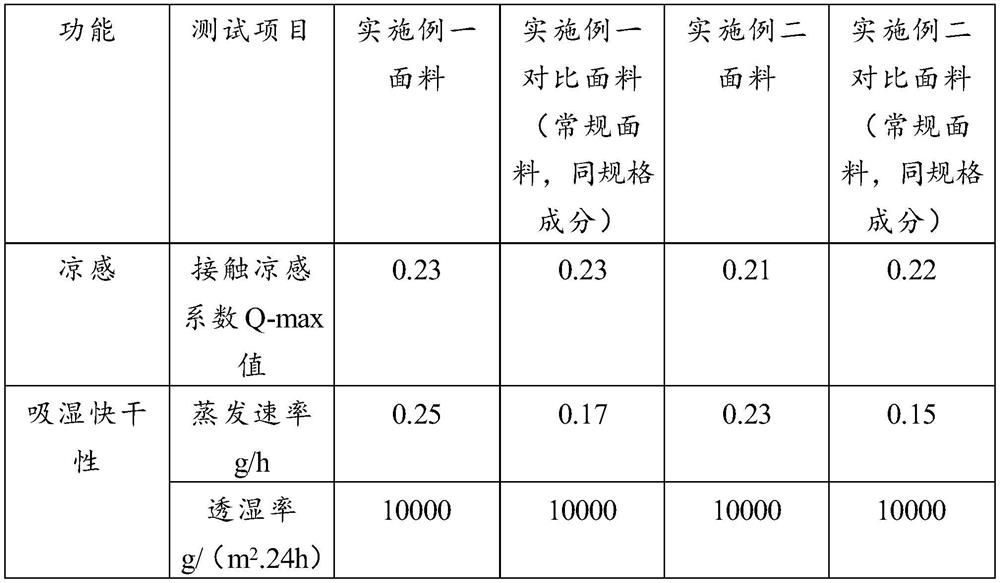

Preparation process of cool quick-drying composite fibers and fabric

ActiveCN112695396ACool and quick dryingLow water absorptionFilament forming substance formingFilament/thread formingFiberNylon material

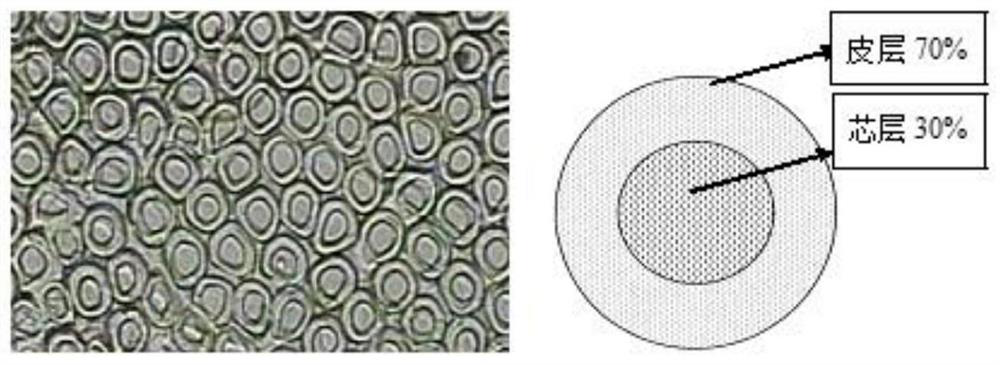

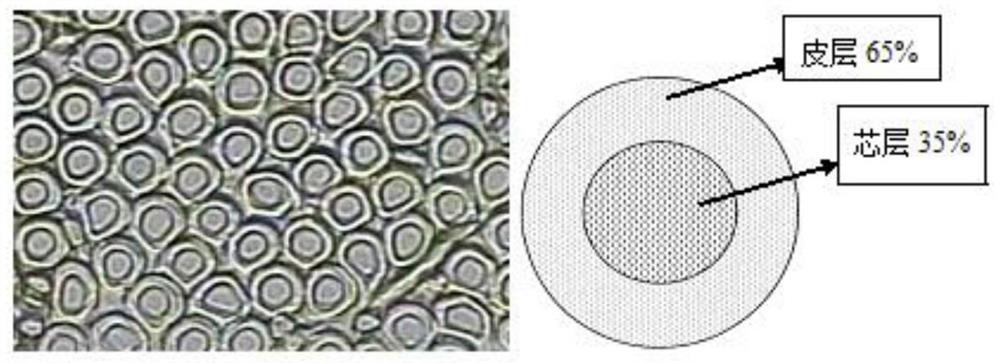

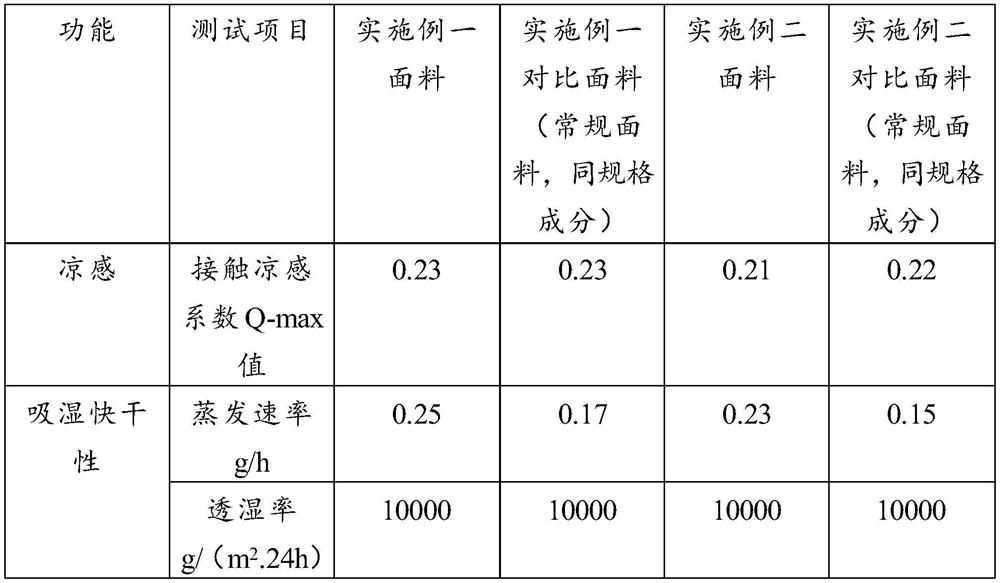

The invention provides a reparation process of cool quick-drying composite fibers and fabric. The preparation process of the cool quick-drying composite fibers comprises the following steps: melting and extruding a fiber skin layer material into first melt according to a high-temperature melting and low-temperature extrusion mode; melting and extruding a fiber core layer material into second melt according to a low-temperature melting and high-temperature extruding mode; wherein the fiber skin layer material comprises 84-89 parts by weight of PA6 and 10-13 parts by weight of jade powder; and the fiber core layer material is polypropylene; and carrying out extrusion molding on the first melt and the second melt through a skin-core composite spinning assembly, and drafting is conducted to obtain the cool quick-drying composite fibers. The skin-core composite fibers prepared by the invention not only maintain the cool feeling characteristic of a nylon material, but also improves the quick-drying performance of the nylon material, and improves the wearing comfort. The contact cooling coefficient Q-max value of the fabric woven by the fibers is 0.20 or above, and the fabric has good quick-drying performance and is comfortable to wear.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

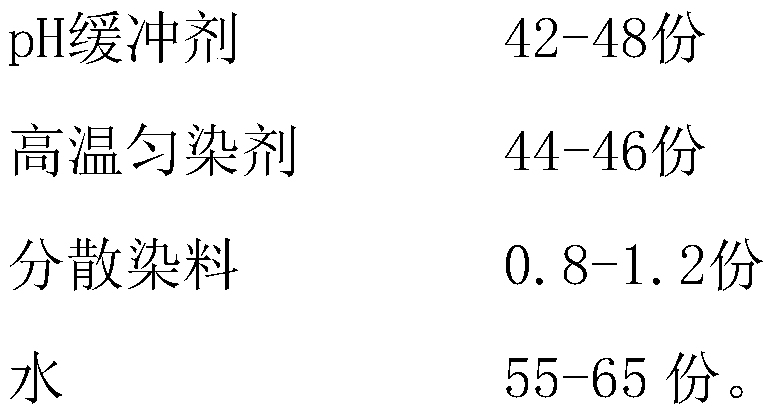

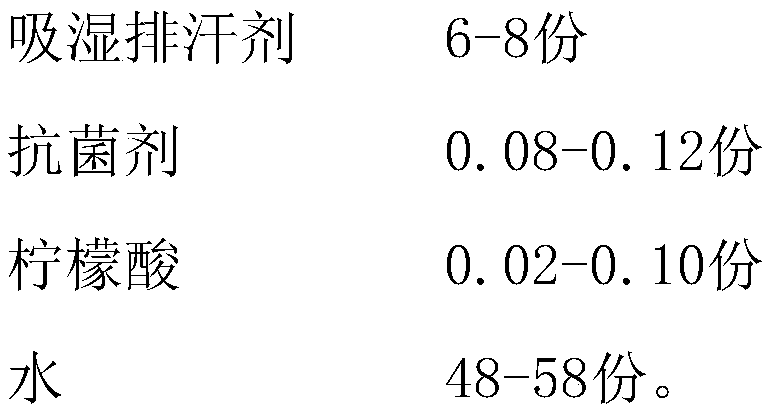

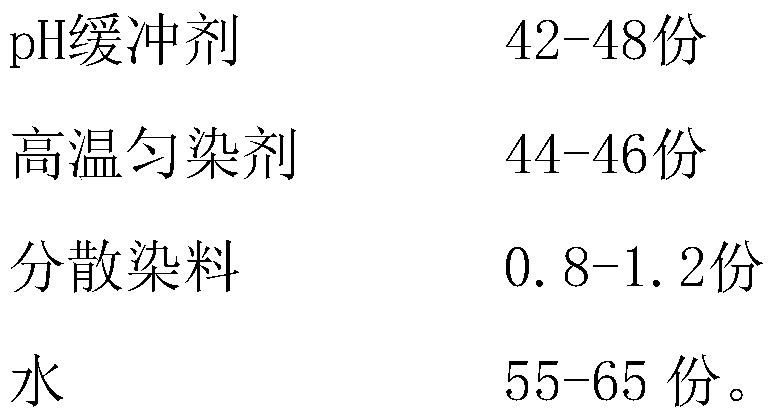

Dyeing and finishing processing process for moisture absorption and sweat releasing COOLPLUS fabric

InactiveCN102535143AGood hygroscopicityQuick drying effect is goodFabric breaking/softeningFibre typesColour fastnessEconomic benefits

The invention relates to a dyeing and finishing processing process for moisture absorption and sweat releasing COOLPLUS fabric. According to the process, a special processing method and process conditions are used so as to ensure the quality of products. The process has the advantages that: the fabric has better moisture absorption and quick drying performance after being processed by the dyeing and finishing process; and high color fastness, draping properties and soft hand feeling of the fabric can be ensured. The opening of the process is the development of an open width dyeing and finishing process. According to the special processing method of the processing process, the quality of the products is ensured, and the quality and the grade of the products are obviously improved. The research and development of the products and the breakthrough of the process provide reference for the development of high-grade and personalized textile fabric, provide guide for the expansion of market and create high economic benefit for enterprises.

Owner:天津天纺投资控股有限公司国印分公司

Antibacterial comfortable fabric and preparation process thereof

ActiveCN110978710AImprove durable hydrophilicityImprove antistatic performanceBiochemical fibre treatmentFibre typesYarnFiber

The invention relates to the technical field of fabrics, in particular to an antibacterial comfortable fabric and a preparation process thereof. The antibacterial comfortable fabric is formed by weaving composite yarns, wherein the composite yarns are formed by stacking surface yarns, elastic fiber yarns and bottom yarns; after stacking forming, the surface yarns form a surface layer, the elasticfiber yarns form an elastic middle layer, and the bottom yarns form a bottom layer; the elastic fiber yarns are low-temperature spandex with a fineness of 30 to 60 D; and the bottom yarns are corn fibers with a fineness of 45-100D / 45-75F. The antibacterial comfortable fabric disclosed by the invention is formed by compositely weaving three kinds of yarn fibers, three yarn layers are sequentially formed on the prepared fabric, and the middle layer is elastic, so the fabric is improved in wearing comfort and skin friendliness, has environmental protection, warm keeping, machine washing, non-ironing functions and the like, and is good in air permeability, high in moisture volatilization rate, good in quick-drying property, comfortable to wear and free of stuffiness and skin sticking feeling;and meanwhile, the corn fibers are adopted as the bottom layer, so the contact comfort of the fabric and the skin is improved.

Owner:东莞信望纺织有限公司

Quick-drying durable luminescent material and preparation method thereof

The invention discloses a quick-drying durable luminescent material, which comprises the following raw materials in parts by weight: 50-70 parts of deionized water, 12-16 parts of ethyl acrylate, 8-12 parts of methyl cellulose, 3-6 parts of persulfuric acid, 1-4 parts of aluminum sulfate, 2-5 parts of vinyltrimethoxysilane, 6-10 parts of propylene carbonate, 55-60 parts of Sr2O3, 25-30 parts of Al2O3, 7-9 parts of Y203, 5-7 parts of Yb203, and 1-3 parts of Tm203. According to the luminescent material obtained by the method provided by the invention, under the same condition, the afterglow time is relatively long and can reach 600 minutes or above, and meanwhile, the drying time of the material is greatly reduced and can be shortened by 15 seconds or above, so that a very good quick-drying effect is achieved.

Owner:河北地质大学

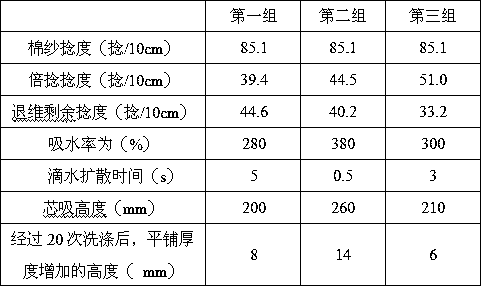

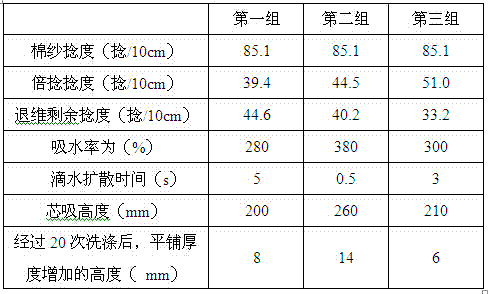

Method for producing yarn used for sponge towels

The invention provides a method for producing yarn used for sponge towels. The method for producing yarn used for sponge towels comprises steps of yarn production through cotton raw materials, yarn production through water soluble vinylon, and two-for-one twisting. With respect to the yarn used for sponge towels, the yarn quality indexes are that the evenness CV is 7.50%, the yarn contains zero thin place per km, zero thick place per km and one nep per km, the degree of twist is 44.5 twisting / 10 cm, the average strength is 1489 cN, the weight cv is 1.4 %, the yarn contains 12.03 hairs having the length of 3-9 mm per m, and the hairiness index H value is 2.28. The towel prepared by the yarn used for sponge towels is soft and comfortable, and the degree of twist is low and is 33.2-44.6 twisting / 10 cm; the towel is good in hygroscopicity, and the water absorption rate is 380%; drip diffusion time is 0.5 s, the wicking height is 260 mm, after the towel is washed every time, the degree of twist is reduced, the more the towel is washed, the fluffier the towel is, and the better the effect is.

Owner:BOFINE TEXTILE

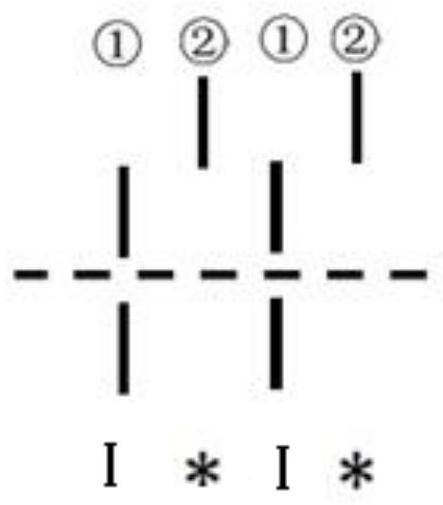

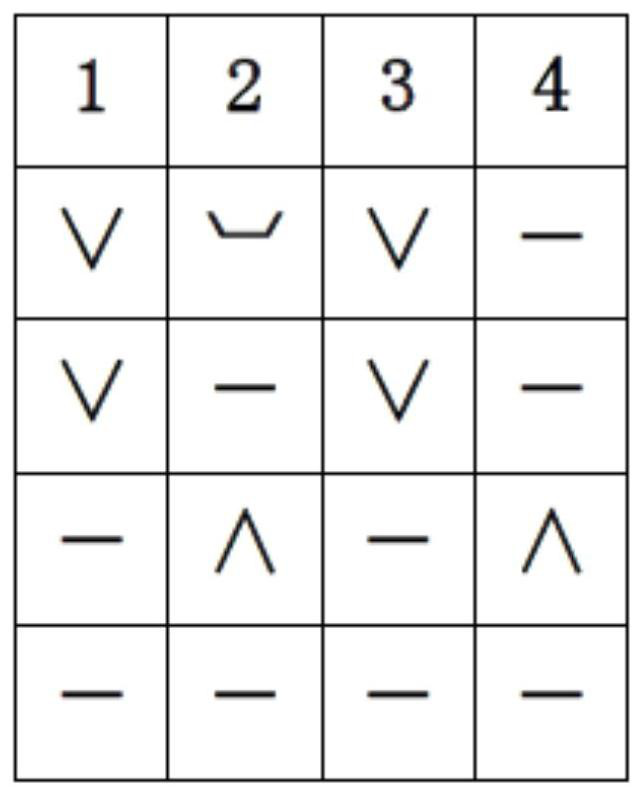

Light-weight quick-dry cool one-way moisture-conducting knitted fabric and production method thereof

InactiveCN112760793AAchieve one-way moisture transfer effectAchieve cool feelingWeft knittingYarnPolyester

The invention discloses a production method of a light-weight quick-dry cool one-way moisture-conducting knitted fabric. The production method comprises the steps that a double-sided machine is provided, and triangles and knitting needles are arranged according to the design requirements of the fabric; yarns are provided, and the yarns comprise superfine polyester fiber yarns and polyethylene yarns; the double-sided machine is utilized, one-interval one-needle drawing mode is adopted in a needle cylinder needle in the double-sided machine, and four paths are adopted as a cycle for knitting, specifically, the superfine polyester fiber yarns are adopted for knitting in a first path and a third path, the polyethylene yarns are adopted in a second path and a fourth path for knitting, wherein the first path and the third path are knitted into the outer layer of the fabric, the second path and the fourth path are knitted into the inner layer of the fabric, and the inner layer of the fabric is a skin contact surface, and the inner layer of the fabric is of a drawn needle breathable structure. According to the production method of the light-weight quick-dry cool one-way moisture-conducting knitted fabric, the obtained fabric has the advantages of coolness, breathability, moisture conductivity, portability and good quick-drying property, and can meet high requirements of functional fabrics.

Owner:JIANGSU JUJIE MICROFIBERS TEXTILE GRP

Strong quick-dry pure-cotton knitted fabric and production process thereof

ActiveCN106988112AImprove water absorptionSmall water absorptionWeft knittingHeating/cooling textile fabricsYarnPulp and paper industry

The invention provides a strong quick-dry pure-cotton knitted fabric and a production process thereof. The production process of the pure-cotton knitted fabric includes the steps: A, yarn treatment: dividing yarns into two parts, performing hydrophilic treatment on one part of yarns, and performing waterproof treatment on other part of yarns; B, weaving: weaving the treated yarns by the aid of a gross waterproof yarn and a gross hydrophilic yarn at intervals to obtain gray cloth; C, dyeing and finishing: performing gray cloth sizing, dyeing, soaping, drying and finished product sizing on the woven gray cloth to obtain the strong quick-dry pure-cotton knitted fabric. According to the production process, hydrophilic treatment and waterproof treatment of the yarns are performed, hole suction effects are formed by the aid of the weaving process of the gross waterproof yarn and the gross hydrophilic yarn at intervals, strong quick-dry effects are achieved by matching a dyeing and finishing process and additives, residual moisture is 10% 60 minutes before water washing, residual moisture is 10% after bearing washing for 10 times, and drip diffusion time is within 3 seconds before water washing and after water washing for 10 times.

Owner:DONGGUAN TEXWINCA HLDG

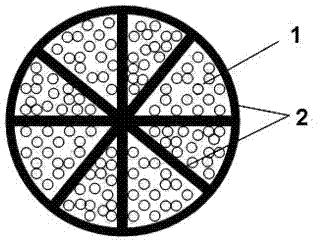

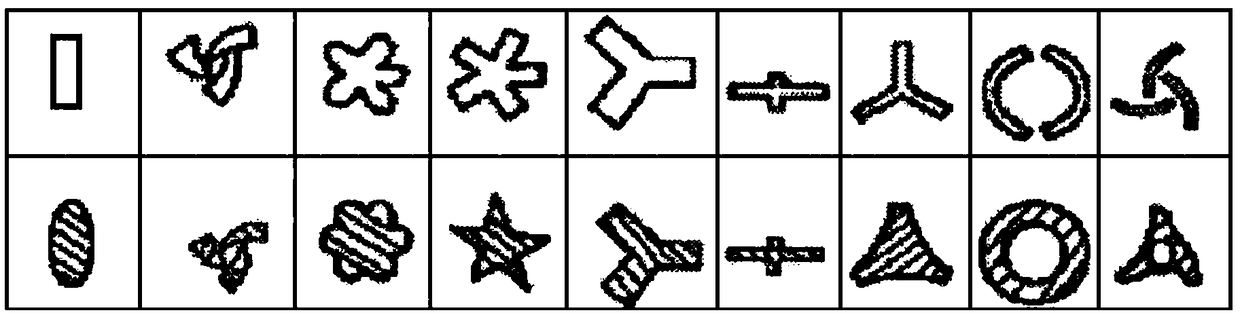

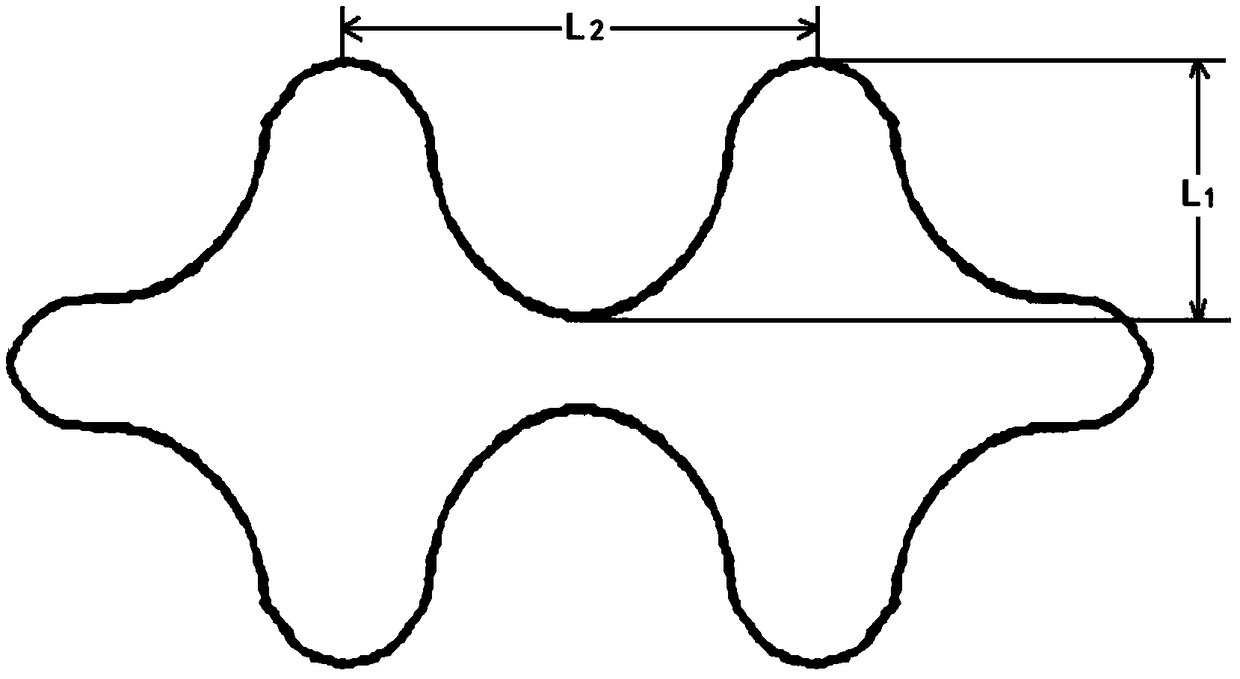

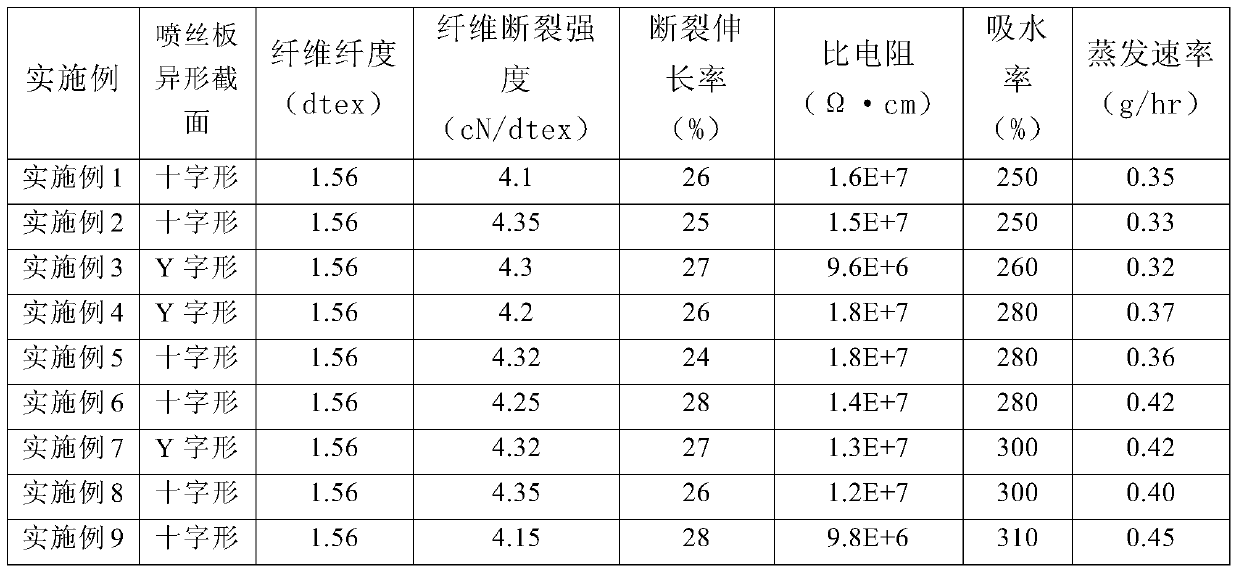

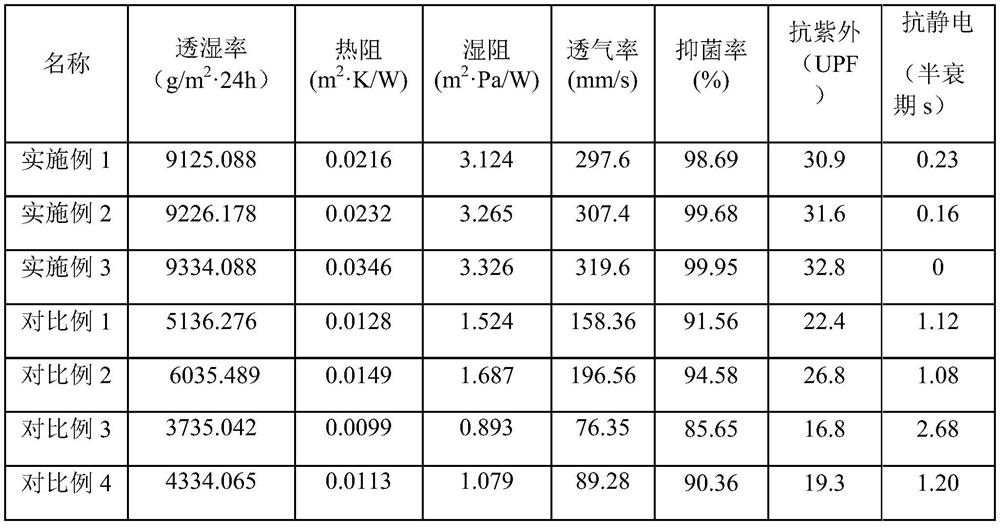

Modified cross-section fiber and moisture-absorbing and quick-drying fabric prepared from modified cross-section fiber

ActiveCN108642592AGood moisture absorptionGood moisture managementFilament/thread formingMonocomponent copolyesters artificial filamentTextile fiberPolyethylene terephthalate glycol

The invention relates to a modified cross-section fiber and a moisture-absorbing and quick-drying fabric prepared from the modified cross-section fiber, and relates to the technical field of textile fibers. The modified cross-section fiber is a non-circular modified cross-section fiber produced by spinning of a modified polyester chip, the modified cross-section fiber has at least two grooves, theratio of the height (L1) of the grooves to the width (L2) of the grooves is 0.5 or more, and the modified polyester chip is obtained by transesterification and polycondensation reaction of a reactionraw material containing terephthalic acid or polyethylene terephthalate and ethylene glycol. The moisture-absorbing and quick-drying fabric prepared from the modified cross-section fiber has good moisture absorption, moisture guiding and quick-drying effects, has good wearing comfort, no moisture-reducing phenomenon and can maintain a long-lasting antibacterial property.

Owner:JIAXING FUSHENGDA DYEING & FINISHING

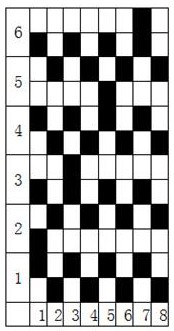

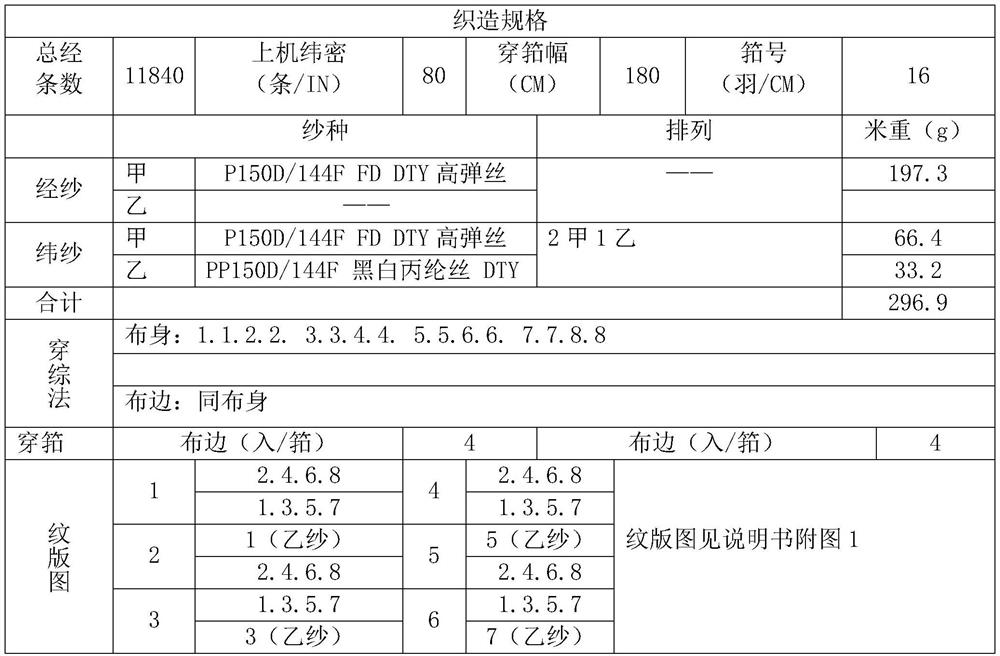

Single-sided moisture-conducting polyester-acrylic fabric and preparation process thereof

InactiveCN112095203AGood hygroscopicityQuick drying effect is goodDry-cleaning apparatus for textilesMulti-ply fabricsPolyesterPolymer science

The invention relates to a single-sided moisture-conducting polyester-acrylic fabric and a preparation process thereof. The preparation process comprises the following specific steps of weaving, coldbatch desizing, overflow dyeing, reduction cleaning, dewatering scotching and moisture absorption and sweat releasing and shaping. According to the weaving, polyester is used as a warp yarn and the polyester and polypropylene fiber are used as a weft yarn to weave weft backed weave, the front face is plain weave, the back face is jacquard weave, and the yarn use amount ratio of the polyester to the polypropylene fiber in the weft yarn is 2 to 1; and according to the moisture absorption and sweat releasing shaping, moisture absorption and sweat releasing agents TF-620 pass through a shaping groove, are fully extruded through a padder and then enter a drying oven, and the parameters of temperature*speed*air volume*overfeeding are set to be (125-135 DEG C)*(25-30 M / min)*(1400-1600 cfm)*(3%-5%). According to the single-sided moisture-conducting polyester-acrylic fabric and the preparation process thereof, the polyester-acrylic fabric is endowed with excellent hygroscopicity and quick-drying property, the high-level quick-drying property is still kept after multiple times of washing, dryness and breathability are kept, and meanwhile, the antibacterial effect further meets the national standard requirements.

Owner:晋江万兴隆染织实业有限公司

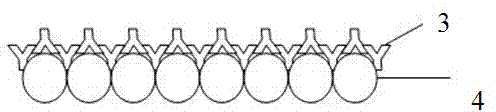

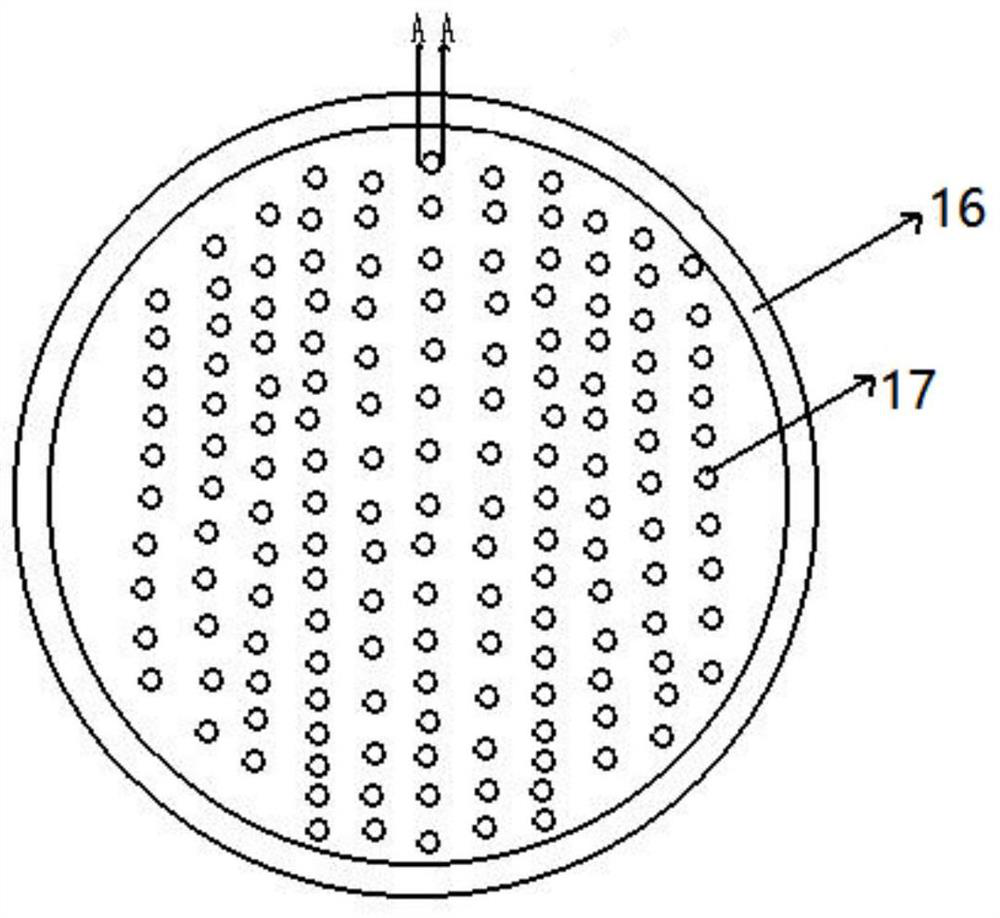

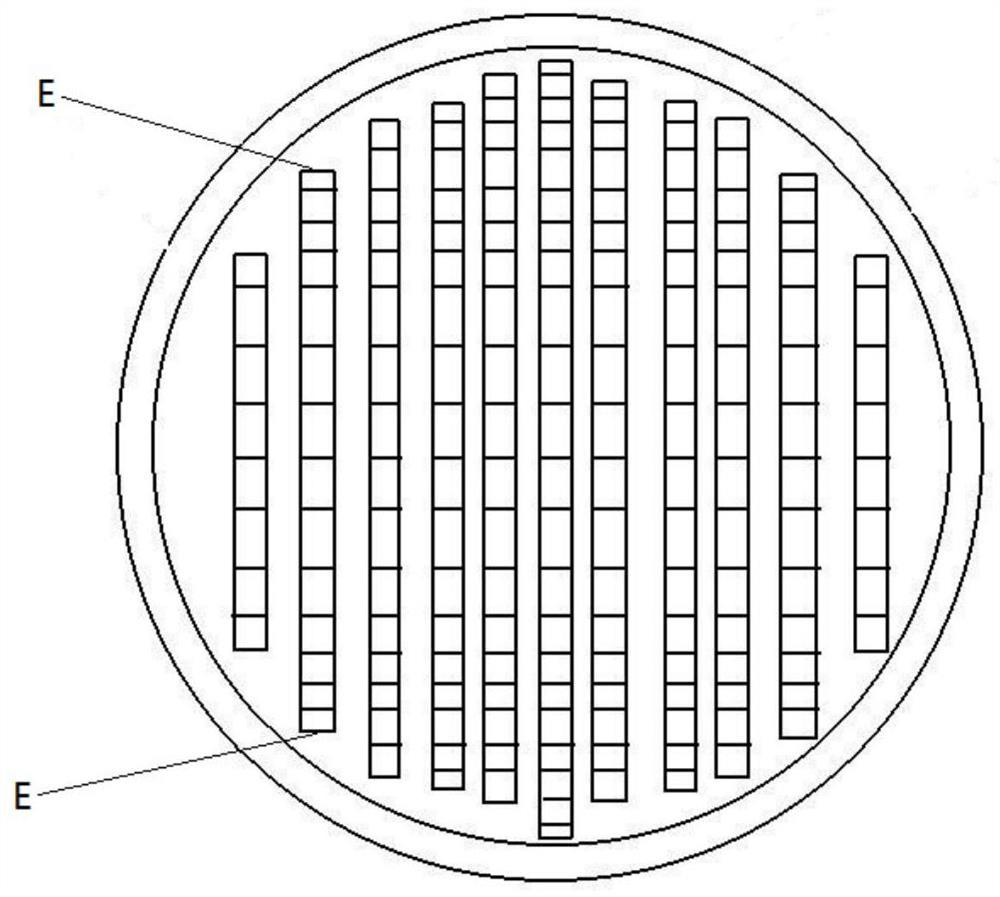

Manufacturing method of moisture-conducting and temperature-conducting wicking polyester fibers

InactiveCN112593299ABig spaceDry and moisture-conducting and temperature-conducting propertiesNew-spun product collectionFilament manufacturePolyesterFiber

The invention relates to a manufacturing method of moisture-conducting and temperature-conducting wicking polyester fibers. The manufacturing method comprises the following steps that multi-arc cross-shaped spinneret orifices are adopted; wherein the multi-arc cross shape comprises four leaves, namely a leaf I, a leaf II, a leaf III and a leaf IV; the leaf I is defined by two line segments and a major arc; the two line segments are parallel to each other, the two ends of each line segment are flush, one end of each line segment is an m end, the other end of each line segment is an n end, and the m ends of the two line segments are connected through the major arc; a straight line, which passes through the circle center of the circle corresponding to the major arc and is simultaneously arranged at equal intervals with the two line segments, is taken as a line L, wherein one point, which is positioned outside the leaf I and is close to the n end, on the line L is a point O; the leaf II, the leaf III and the leaf IV are correspondingly formed by rotating the leaf I around the point O by 90 degrees, 180 degrees and 270 degrees respectively; and the technological process comprises a winding procedure. A comb-shaped filament separator is arranged in a winding machine, and the comb-shaped filament separator porcelain piece is shaped like a formula as shown in the specification. The problems that in the prior art, a large number of broken filaments and filament burrs are generated in the spinning process, and tows are prone to jumping out when passing through a comb-shaped filamentseparator porcelain piece are effectively solved.

Owner:JIANGSU DELI CHEM FIBER CO LTD

Method for manufacturing functional yarn having deodorization property and quick sweat absorbency

ActiveCN107109710AGood sweat absorptionQuick drying effect is goodMelt spinning methodsAbrasion resistant fibresYarnFiber

The present invention relates to a method for manufacturing a functional yarn by using zirconium phosphate having a multilayer structure as a deodorizing material and spinning a molten polymerized material through a non-circular cross-sectional spinneret. According to the present invention, zirconium phosphate inorganic microparticles with low hardness and a layer structure are contained in the molten polymerized material, thereby minimizing the abrasion of the production process equipment, and achieving excellent deodorizing property and quick sweat absorbency, when fibers are manufactured.

Owner:HYOSUNG CORP

Preparation process and fabric of a cool-feeling and quick-drying composite fiber

ActiveCN112695396BCool and quick dryingLow water absorptionFilament forming substance formingFilament/thread formingFiberNylon material

The invention provides a preparation process and fabric of a cool-feeling and quick-drying composite fiber. The process includes the following steps: extruding a fiber skin material into a first melt by extruding a fiber skin layer at a high temperature and low temperature; extruding a fiber core layer into a first melt; The material is melted and extruded into the second melt according to the mode of low-temperature melting and high-temperature extrusion; the fiber skin layer material includes 84-89 mass parts of PA6 and 10-13 mass parts of jade powder; the fiber core layer material is a poly Propylene; the first melt and the second melt are extruded through a skin-core composite spinning assembly, and drawn to obtain a cool-feeling and quick-drying composite fiber. The skin-core composite fiber prepared by the invention not only maintains the cool feeling characteristic of the nylon material, but also improves the quick-drying performance of the nylon material and improves the wearing comfort. The contact cooling coefficient Q-max value of the fabric woven from this fiber is above 0.20, and has good quick-drying performance and is comfortable to wear.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

Water-based anticorrosive composite paint remover for ship having deodorizing function and preparation method thereof

InactiveCN106398379AImprove securityGood paint removal effectChemical paints/ink removersWater basedAdhesive

The invention discloses a water-based anticorrosive composite paint remover for a ship having a deodorizing function. The paint remover is prepared from the following raw materials in parts by weight: 34-36 parts of benzyl alcohol, 4-5 parts of N-methylpyrrolidone, 4-6 parts of anhydrous ethanol, 0.5-0.7 part of ethyl cellulose, 0.2-0.4 part of urotropine, 11-12 parts of etidronic acid, 3-5 parts of vanilla oil, 0.4-0.6 part of tea polyphenol, 12-14 parts of chestnut shell, 12-14 parts of peanut isolated protein powder, 2.3-2.5 parts of vinyltrimethoxysilane, 0.3-0.5 part of sodium tripolyphosphate, 1.6-1.8 parts of self-made emulsifier and 44-46 parts of water. By compounding the benzyl alcohol and the N-methylpyrrolidone to serve as main solvent, using the anhydrous ethanol as cosolvent, using the pregelatinized peanut isolated protein powder as a thickening adhesive, using the granular modified chestnut shell carbon powder as a filler to achieve high adsorptivity, and further adding the vanilla oil and other effective components, the prepared composite paint remover has an obvious deodorizing effect and a high paint removing efficiency.

Owner:丁文龙

Novel low-toxicity high-adsorption marine waterborne anticorrosion composite paint remover and production method thereof

InactiveCN106497214AGood compatibilityReduce dosageChemical paints/ink removersChemistryBENZYL ALCOHOL/WATER

The invention discloses a novel low-toxicity high-adsorption marine waterborne anticorrosion composite paint remover, produced from, by weight, 35-36 parts of benzyl alcohol, 4-5 parts of N-methyl-2-pyrrolidone, 5.8-6.8 parts of absolute ethyl alcohol, 6-8 parts of citric acid, 0.2-0.4 part of calcium sulfonate, 0.5-0.7 part of cellulose acetate, 2.1-2.4 parts of polyepoxysuccinic acid, 4-6 parts of papermaking waste residue, 7-9 parts of water hyacinth, 3-4 parts of cassia oil, 0.3-0.5 part of chitosan, 11-12 parts of wheat starch, 2.4-2.9 parts of phenyltriethoxysilane, 1.4-1.9 parts of a self-made emulsifier, and 47-50 parts of water. The composite paint remover produced herein has low volatility and low toxicity, is safe to a metal base, is harmless to operators or environments, is convenient and quick to construct, high in adsorption and good in paint removing performance.

Owner:丁文龙

Moisture-absorbing odor-eliminating modified cotton quilt and preparation method

InactiveCN104562433AFully evenly distributedEvenly distributedNon-woven fabricsFiberIndustrial scale

The invention discloses a moisture-absorbing odor-eliminating modified cotton quilt and a preparation method. The cotton quilt component comprises a functional fiber, a low-melting-point fiber and cotton, wherein the functional fiber is at least one selected from a moisture-absorbing sweat-releasing fiber and a moisture-absorbing draining fiber. The preparation method of the cotton quilt comprises the following steps of weighing raw materials and uniformly mixing and stirring; opening, removing impurities and carding into sheets; stacking and forming a raw cotton fiber sheet; increasing the temperature of the raw cotton fiber sheet to 130-180 DEG C and then keeping the temperature; pressing and sizing; grinding, thereby acquiring the moisture-absorbing odor-eliminating modified cotton quilt. The moisture-absorbing odor-eliminating modified cotton quilt is reasonable in component ratio, is easy in processing and manufacturing, is stable in heat insulation and is difficult to be dampened. The prepared cotton quilt has the long-lasting fluffy, moisture-absorbing and odor-eliminating functions while the use property of the cotton quilt is not influenced. The cotton quilt is fit for industrial scale production.

Owner:HUNAN PROVINCE CHANGSHA CITY AIWANTING HOME TEXTILES

Method for preparing wet-absorb and fast-dry multifunctional cloth

InactiveCN101818400BEasy selection of raw materialsProcess steps are easy to controlWoven fabricsPolyesterSoftening

The invention relates to a method for preparing wet-absorb and fast-dry multifunctional cloth in the technical field of textiles, which comprises the following steps of: (1) selecting materials, wherein raw materials of warp yarns comprise 25 to 35 percent of polyester yarn, 35 to 55 percent of bamboo fiber, and 25 to 35 percent of cotton fiber, and raw materials of weft yarns comprise 45 to 65 percent of natural cotton fiber and 35 to 55 percent of silk fiber; (2) adopting interactive weaving to prepare the raw materials into gray cloth; and (3) finishing the whole technology of the weaved cloth by turning cloth and sewing, refining, dehydrating, scotching, drying, presetting, alkali reduction, water washing, dyeing, water washing, dehydrating and scotching, and softening and setting. The prepared multifunctional cloth has the characteristics of obvious wet-absorb and fast-dry effect, antistatic performance, antibiosis and low elasticity.

Owner:山东澳亚纺织有限公司

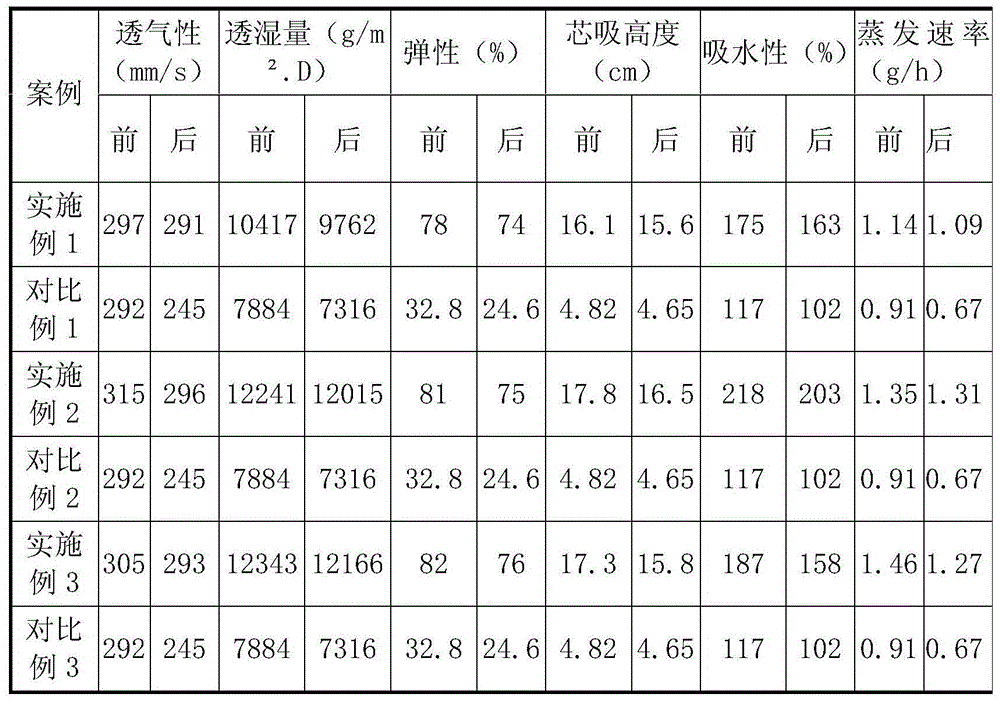

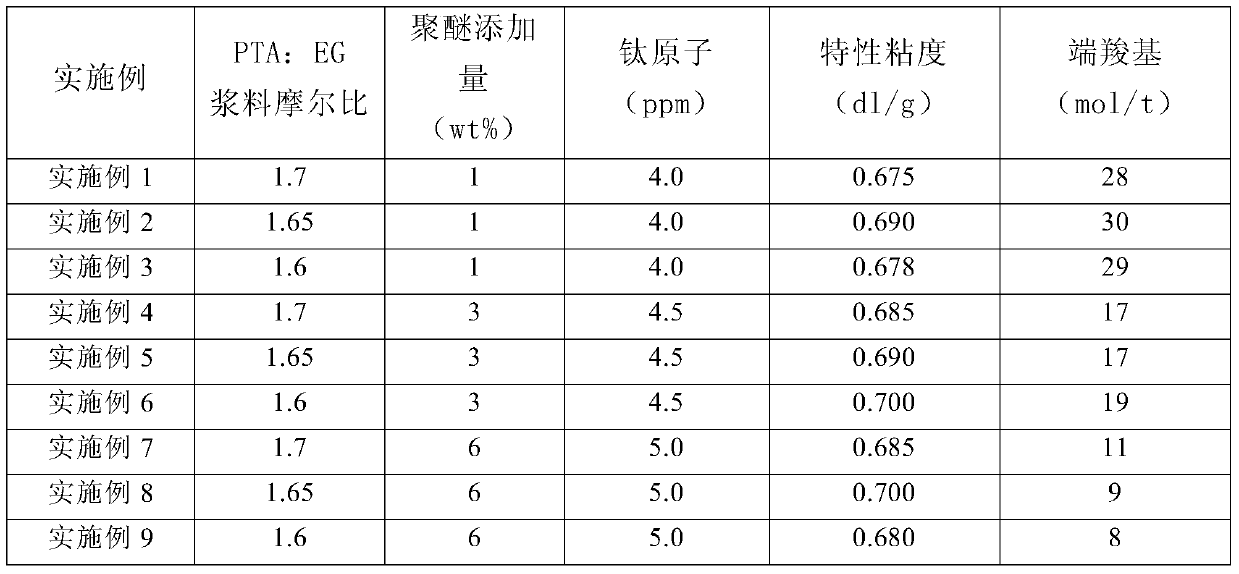

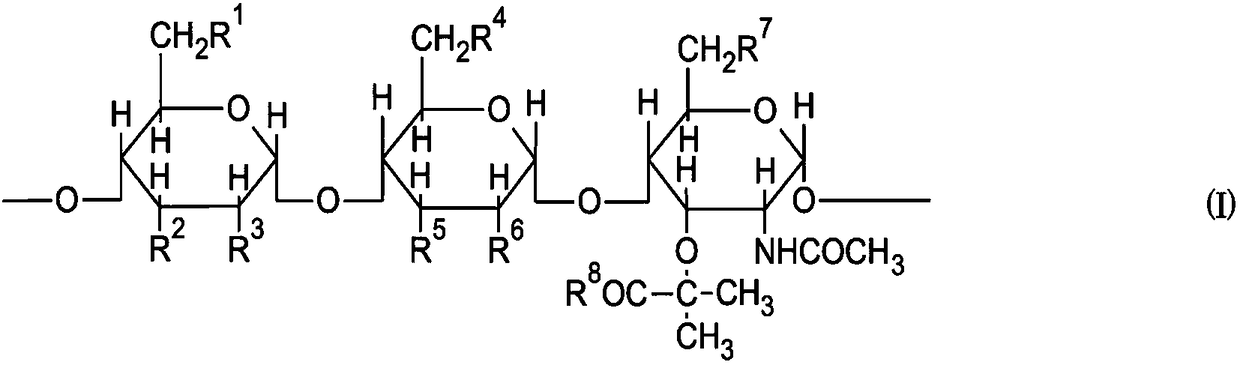

A kind of production method of special polyester staple fiber for vortex spinning with hydrophilic moisture conduction

ActiveCN105586660BImprove spinning efficiencyLow modulusSpinning head liquid feederTextile treatment by spraying/projectingFiberEnvironmental resistance

A production method for hydrophilic moisture-transmitting polyester staple fibers specially used for vortex spinning is disclosed. The method adopts a continuous polyester production device for production. The method includes subjecting a hydrophilic modifying agent, terephthalic acid (PTA for short) and ethylene glycol (EG for short) to ternary copolymerization under action of a titanium catalyst to obtain hydrophilic polyester melt, increasing pressure through a booster pump, delivering directly through a melt pipe to a spinning device, metering through a metering pump, feeding the melt into a spinning box, spinning through a special-shaped section, performing after-treatment, mixing with common terylene according to a ratio, and chopping to obtain the staple fibers. The method allows hydrophobic polyester melt to be turned into the hydrophilic polyester melt and makes the polyester melt more environmental friendly and stabler. The produced polyester staple fibers specially used for vortex spinning has hydrophilic and moisture-transmitting functions, and can be used for manufacturing fabrics with permanent moisture-absorbing and quick-dry properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyformaldehyde fiber finishing liquid, finishing method and polyformaldehyde blended fabric

PendingCN113846483AReduce interface thermal resistanceIncrease void structureLight resistant fibresProtective garmentWoven fabricAloe Extract

The invention relates to the technical field of polyformaldehyde textiles, and particularly provides polyformaldehyde fiber finishing liquid, a finishing method and a polyformaldehyde blended fabric. The polyformaldehyde fiber finishing liquid is prepared from 1 percent to 5 percent of natural factor, 1.0 percent to 1.5 percent of polyethylene glycol 1500, 0.5 percent to 1.5 percent of nano boron carbide, 1 percent to 2 percent of nano zinc oxide and the balance of water, wherein the natural factor is at least one of anthocyanin, tea saponin or an aloe extract. The finishing method comprises the steps of adding polyformaldehyde fibers into the polyformaldehyde fiber finishing liquid, heating, dipping and drying to obtain finished polyformaldehyde fibers. A polyformaldehyde fiber blended fabric obtained by blending the finished polyformaldehyde fibers and cotton type fibers has excellent heat conduction and moisture conduction performances, quick drying capacity, high comfort and high ultraviolet resistance, and is particularly suitable for being used as fabric of summer clothes and sportswear.

Owner:KAILUAN GRP +1

Rayon fiber

ActiveCN109208105AGood hygroscopicityImprove water absorptionWeft knittingMonocomponent cellulose artificial filamentPhylum CyanobacteriaMoisture absorption

The present invention provides a rayon fiber having excellent moisture absorption, water absorption, and quick-drying properties and being used for clothes such as gloves, clothes, socks, shirts and suits, materials of masks, diapers and the like, makeup wipes, and the like. The invention also provides a woven fabric containing the rayon fiber, and a nonwoven fabric containing the rayon fiber. Therayon fiber has a moisturizing property, and the polysaccharide derived from Suizenji cyanobacteria is contained in a ratio of 0.01 to 0.5 parts by mass per 100 parts by mass of the rayon fiber.

Owner:OMIKENSHI +2

A kind of silane-modified acrylic resin, synthesis method and primer for silicone rubber

The application relates to the technical field of resin synthesis and its application, and specifically discloses a silane-modified acrylic resin, a synthesis method and a primer for silicone rubber. A primer for silicone rubber is prepared by dispersing the above-mentioned silane-modified acrylic resin and silane coupling agent titanate in a solvent for the primer and reacting with a catalyst. The silane-modified acrylic resin of the present application can be used to prepare a primer for silicone rubber, which has the advantages of good adhesion, film-forming property, heat resistance, water resistance, low surface-drying temperature and short time; a silane-modified Acrylic resin, the silane-modified acrylic resin is composed of (meth)acrylic acid alkyl ester monomers, hydroxyl ester monomers, epoxy monomers, vinyl siloxane monomers, cross-linking monomers The silane-modified acrylic resin obtained in this application has excellent cohesive properties and film-forming properties, and is suitable for the preparation of silicone rubber primers. adhesive.

Owner:SHENZHEN KANGLIBANG TECH

Ceramic grinding aid for ceramics grinding aluminate cement and manufacturing method thereof

The invention discloses a ceramic grinding aid for ceramics grinding aluminate cement and a manufacturing method thereof. The ceramic grinding aid comprises three components, wherein a component A ispre-fermentation product obtained by mixing the following raw materials in parts by weight: 15-18 parts of wheat bran powder, 0.2-0.3 part of collagen activating enzyme water agent, 15-18 parts of drystraw powder and 0.2-0.3 part of Cytophaga agent and fermenting for 18-20 hours; a component B is soaking product by soaking the following raw materials in parts by weight: 150-180 parts of a sodiumsilicate aqueous solution containing sodium silicate solute with the concentration of 10%, 2-3 parts of pine bark and 2.2-2.4 parts of calcium oxide for 3 day; a component C is 8-10 parts of hard abrasive aid silica. The invention has modified magnesium cement to obtain the technical effects of acid-alkali resistance, good internal bonding force, anti-expansion, cushioning function, improvement incutting uniformity and cutting efficiency.

Owner:山东天汇科技有限公司

A kind of anti-fouling and dust-proof quick-drying cleaning agent composition

ActiveCN111778112BDoes not cause uneven dispersionGood dispersionOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentEngineering

The invention relates to an antifouling and dustproof quick-drying cleaning agent composition, which comprises the following components in mass parts: 1-3 parts of AEO9; 1-4 parts of APG; 5-15 parts of modified polysiloxane; 2.5-6 parts of surfactant; 1.5-3 parts of 2-tridecyloxyethanol, wherein the modified polysiloxane is a product obtained through the condensation reaction of hydrogen-containing silicone oil and polyol monomethyl ether. The above composition is a low-toxicity, green and environment-friendly composition that does not contain any insoluble solid particulate matter; it can quickly form a film on the hard surface of kitchen facilities, and has excellent quick-drying effect, decontamination effect and long-lasting anti-fouling effect and other effects.

Owner:江西凡可科技有限公司

Biodegradable water-based anti-corrosion composite paint remover for ships and preparation method of paint remover

The invention discloses a biodegradable water-based anti-corrosion composite paint remover for ships. The paint remover is prepared from raw materials in parts by weight as follows: 37-38 parts of benzyl alcohol, 2-3 parts of N-methyl pyrrolidone, 6.7-7.3 parts of absolute ethyl alcohol, 0.2-0.5 parts of sodium malate, 2-4 parts of alkyl glycoside, 5-7 parts of polylactic acid, 1-2 parts of maltodextrin powder, 12-13 parts of corn gluten meal, 11-14 parts of pomegranate rind, 6-8 parts of a styrene-acrylic emulsion, 2.8-3.2 parts of phenyl trimethoxy silane, 1.8-2.2 parts of a self-made emulsifier and 46-49 parts of water. The prepared composite paint remover has high dissolution capacity for common paint layers, has the high paint removal speed, is low in cost and can be reused, waste residues produced by paint removal can be biodegraded, raw materials are easy to obtain, and the production technology is simple.

Owner:丁文龙

A kind of production method of yarn for sponge towel

The invention provides a method for producing yarn used for sponge towels. The method for producing yarn used for sponge towels comprises steps of yarn production through cotton raw materials, yarn production through water soluble vinylon, and two-for-one twisting. With respect to the yarn used for sponge towels, the yarn quality indexes are that the evenness CV is 7.50%, the yarn contains zero thin place per km, zero thick place per km and one nep per km, the degree of twist is 44.5 twisting / 10 cm, the average strength is 1489 cN, the weight cv is 1.4 %, the yarn contains 12.03 hairs having the length of 3-9 mm per m, and the hairiness index H value is 2.28. The towel prepared by the yarn used for sponge towels is soft and comfortable, and the degree of twist is low and is 33.2-44.6 twisting / 10 cm; the towel is good in hygroscopicity, and the water absorption rate is 380%; drip diffusion time is 0.5 s, the wicking height is 260 mm, after the towel is washed every time, the degree of twist is reduced, the more the towel is washed, the fluffier the towel is, and the better the effect is.

Owner:BOFINE TEXTILE

Method for preparing antibacterial quick-drying cotton fiber

InactiveCN108978208AImprove hydrophilicityLower surface energyBiochemical fibre treatmentMicroballoon preparationAcetic acidFiber

The invention provides a method for preparing an antibacterial quick-drying cotton fiber. The method comprises the following steps: (1) crushing corn straws, mixing with deionized water, performing microwave extraction, filtering and concentrating an extracting solution, diluting with ethanol, adjusting pH, after separating out a flocculent precipitate, standing for 2 hours, performing suction filtration, drying, and crushing to obtain vegetable gum, and then mixing with deionized water to form a vegetable gum solution for standby use; (2) dissolving the cotton fiber in a sodium carbonate solution, soaking at a temperature of 35 DEG C for 15 to 35 minutes, taking out and washing with deionized water; (3) dissolving antibacterial microcapsules and a penetrant NR in the vegetable gum solution, stirring evenly, and then adding glacial acetic acid to mix evenly; (4) impregnating the cotton fiber treated in step (2) in a mixed solution in step (3) to be subjected to soaking treatment, taking out and washing with ethanol and drying, and then baking to obtain the antibacterial quick-drying cotton fiber. The method for preparing the antibacterial quick-drying cotton fiber provided by the invention can make the cotton fiber have good hygroscopicity, quick-drying property and long-lasting antibacterial property.

Owner:SUZHOU TIANAO SPECIAL EMBROIDERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com