One-way moisture conduction fast-drying cotton/polyester composite knitted fabric

A knitted fabric, one-way moisture transfer technology, applied in knitting, liquid/gas/steam textile material treatment, weft knitting and other directions, can solve the problems of affecting the wearing comfort of the fabric, low chemical stability, poor durability, etc., to achieve Improve the effect of poor hygroscopicity in contact with the skin, improve the feel and gloss, and improve the wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

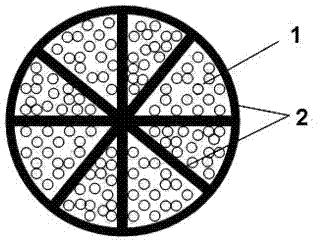

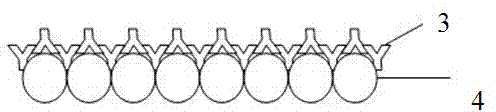

[0017] Through the weaving method of single-sided plain weaving, the cotton yarn with a specification of 40 counts is used as the inner layer material by a large circular machine; the ultra-fine denier polyester filament with a specification of 75D / 280f and a "Y" cross-sectional shape is used as an outer layer material to weave gray cloth .

[0018] The gray cloth is pre-set at 170°C, the speed is 30min, the time is 40s, the overfeed is 6%, and then at 98°C, it is opened with 1g / L degreasing agent and 6g / L NaOH solution for 60min. The fabric after fiber opening is dyed by the overdyeing dyeing method of conventional cotton / superfine denier nylon. Soak the dyed fabric with polyether-modified amino silicone oil 15g / L for 30min at room temperature, pass through a paddle car, and dry at 105°C. The fabric was shaped at 165°C to obtain a unidirectional moisture-guiding and quick-drying cotton / polyester composite knitted fabric. The mass content of cotton yarn in the composite knitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com