Moisture-absorbing odor-eliminating modified cotton quilt and preparation method

A technology for moisture absorption and perspiration, cotton batting, applied in textiles, papermaking, non-woven fabrics, etc. The effect of improving elasticity and breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

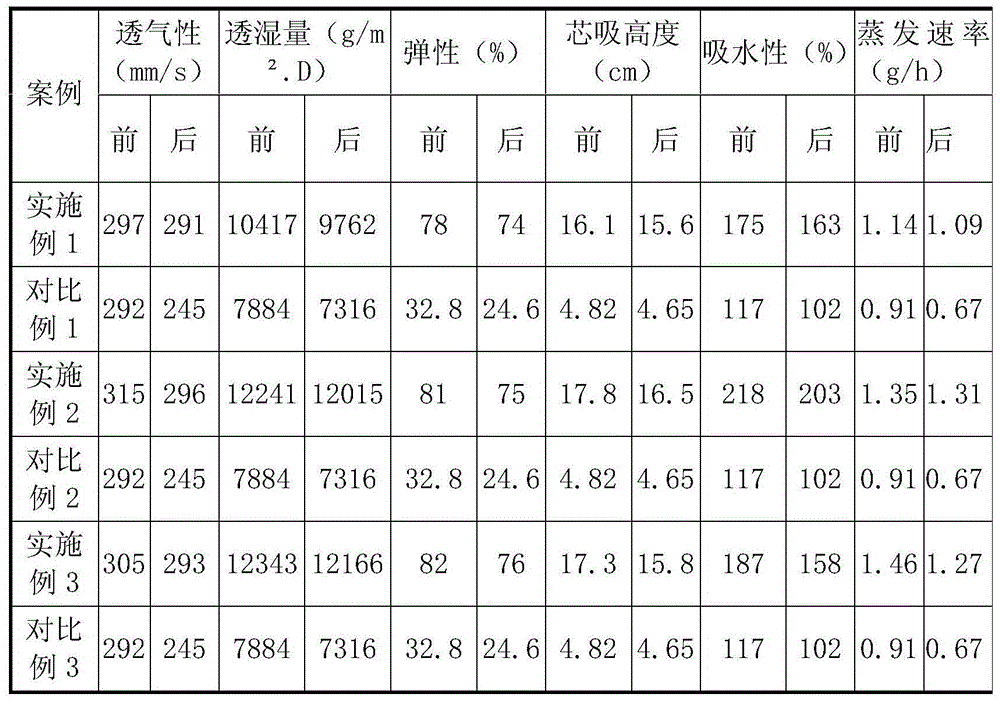

Examples

Embodiment 1

[0058] A moisture-absorbing and deodorizing modified cotton batting, the mass ratio of components is:

[0059] 10% moisture-absorbing and sweat-wicking Lucca fiber, 10% water-releasing COOLBST fiber, 10% Huvis low-melting point fiber, 70% cotton, produced by Jiangsu Lanpin Fiber Technology Development Co., Ltd.

[0060] The Luca fiber has a fineness of 6.7D and a length of 64mm;

[0061] The COOLBST fiber has a fineness of 6.7D and a length of 61 mm;

[0062] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51 mm;

[0063] Cotton is three-level national reserve lint.

[0064] A method for preparing a moisture-absorbing and deodorizing modified cotton batting, comprising the steps of:

[0065] Step 1: Weigh the moisture-absorbing and sweat-wicking Lucca fiber, the water-releasing COOLBST fiber, the low-melting point fiber, and cotton according to the mass ratio of the designed cotton batt components and mix them evenly to obtain the ...

Embodiment 2

[0080] A moisture-absorbing and deodorizing modified cotton batting, the mass ratio of components is:

[0081] Jiangsu Lanpin Fiber Technology Development Co., Ltd. produces 15% moisture-wicking Lucca fiber, 20% water-releasing COOLBST fiber, 10% Huvis low-melting fiber, and 55% cotton.

[0082] Lucca fiber is 3D in size and 38mm in length;

[0083] The COOLBST fiber has a fineness of 6.7D and a length of 61 mm;

[0084] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51 mm;

[0085] Cotton is three-level national reserve lint.

[0086] A method for preparing a moisture-absorbing and deodorizing modified cotton batting, comprising the steps of:

[0087] Step 1: Weigh the moisture-absorbing and sweat-wicking Lucca fiber, the water-releasing COOLBST fiber, the low-melting point fiber, and cotton according to the mass ratio of the designed cotton batt components and mix them evenly to obtain the mixed material;

[0088] Step 2: After...

Embodiment 3

[0102] A moisture-absorbing and deodorizing modified cotton batting, the mass ratio of components is:

[0103] 20% moisture-absorbing and sweat-wicking Lucca fiber produced by Jiangsu Lanpin Fiber Technology Development Co., Ltd., water-releasing type

[0104] COOLBST fiber 10%, Huvis low melting point fiber 15%, cotton 55%,

[0105] The Luca fiber has a fineness of 6.7D and a length of 64 mm;

[0106] The COOLBST fiber has a fineness of 3D and a length of 37.9mm;

[0107] The melting point of Huvis low-melting fiber is 135°C; the denier is 4D, and the length is 51mm;

[0108] Cotton is three-level national reserve lint.

[0109] A method for preparing a moisture-absorbing and deodorizing modified cotton batting, comprising the steps of:

[0110] Step 1: Weigh the moisture-absorbing and sweat-wicking Lucca fiber, the water-releasing COOLBST fiber, the low-melting point fiber, and cotton according to the mass ratio of the designed cotton batt components and mix them evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com