Preparation process of cool quick-drying composite fibers and fabric

A preparation process and composite fiber technology, applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of decreased contact coolness and no improvement in quick-drying performance, so as to reduce water absorption and keep cool Sensitive properties, the effect of increasing the coolness of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention first carries out the preparation of fiber cortex material:

[0029] In parts by mass, mix 84-89 parts of PA6 slices, 10-13 parts of jade powder, and preferably 1-3 parts of coupling agent, and add them into a twin-screw machine to melt at a temperature of 230-250°C. The rotating speed can be 100-130r / min. The above-mentioned nylon material in the molten state is extruded through the head of the wire drawing machine, and the extrusion temperature is preferably controlled at 210-220° C., and the head pressure of the wire drawing machine is 0.2-0.3 MPa. After the nylon filament is cooled by the cold water tank, it enters the granulator and cuts into granules. The speed of the granulator can be 140r / min, and the particle size is generally 3-6mm. The mass parts and process parameters within the scope of this application can meet the production requirements, and have little influence on the final fiber performance.

[0030] Among the...

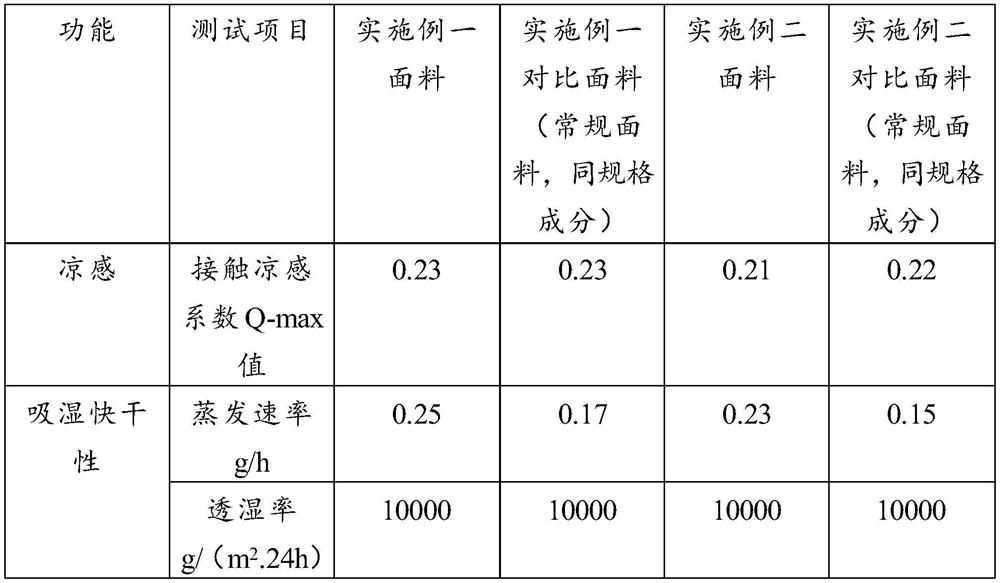

Embodiment 1

[0054] 1. Preparation of fiber cortex material:

[0055] In parts by mass, mix 84-89 parts of PA6 slices, 10-13 parts of jade powder, and 1-3 parts of coupling agent evenly and add them to a twin-screw machine, melt at a temperature of 230-250°C, and the screw speed is 100-130r / min. The nylon material in the molten state is extruded through the head of the wire drawing machine, the extrusion temperature is controlled at 210-220°C, and the pressure of the head of the wire drawing machine is 0.2-0.3MPa. After the nylon filament is cooled by the cold water tank, it enters the granulator and cuts into granules. The speed of the granulator is 140r / min, and the particle size is 3-6mm.

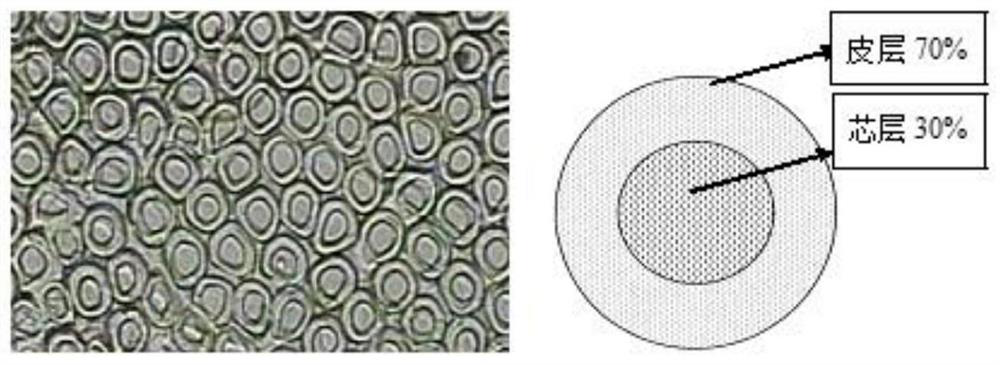

[0056] 2. Preparation of skin-core composite fiber:

[0057] 1) Add the fiber sheath material prepared above into the first screw extruder, melt and extrude it into a melt, then transport the melt to the spinning box, pass through the pre-filter, and evenly distribute it to the sheath core In com...

Embodiment 2

[0076] 1. Preparation of fiber cortex material:

[0077] In parts by mass, mix 84-89 parts of PA6 slices, 10-13 parts of jade powder, and 1-3 parts of coupling agent evenly and add them to a twin-screw machine, melt at a temperature of 230-250°C, and the screw speed is 100-130r / min. The nylon material in the molten state is extruded through the head of the wire drawing machine, the extrusion temperature is controlled at 210-220°C, and the pressure of the head of the wire drawing machine is 0.2-0.3MPa. After the nylon filament is cooled by the cold water tank, it enters the granulator and cuts into granules. The speed of the granulator is 140r / min, and the particle size is 3-6mm.

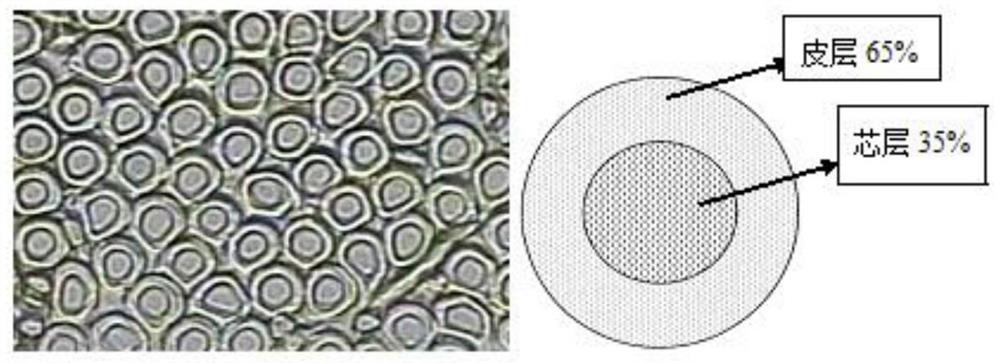

[0078] 2. Preparation of skin-core composite fiber:

[0079]1) Add the fiber sheath material prepared above into the first screw extruder, melt and extrude it into a melt, then transport the melt to the spinning box, pass through the pre-filter, and evenly distribute it to the sheath core In comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com