Moisture guide exhaust elastic insole and manufacturing method thereof

An elastic, insole technology, applied in insoles, footwear, clothing, etc., to achieve high-humidity conduction gradients, accelerate the quick-drying process, and promote one-way conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

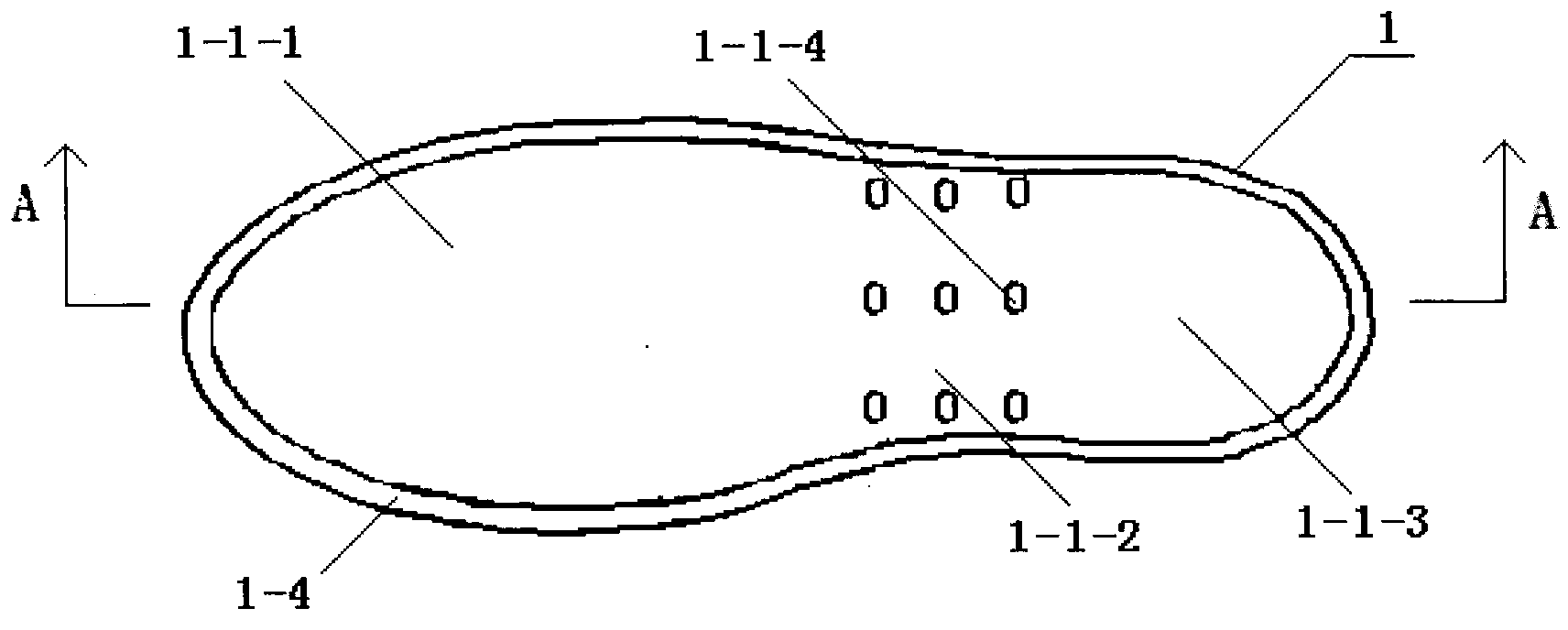

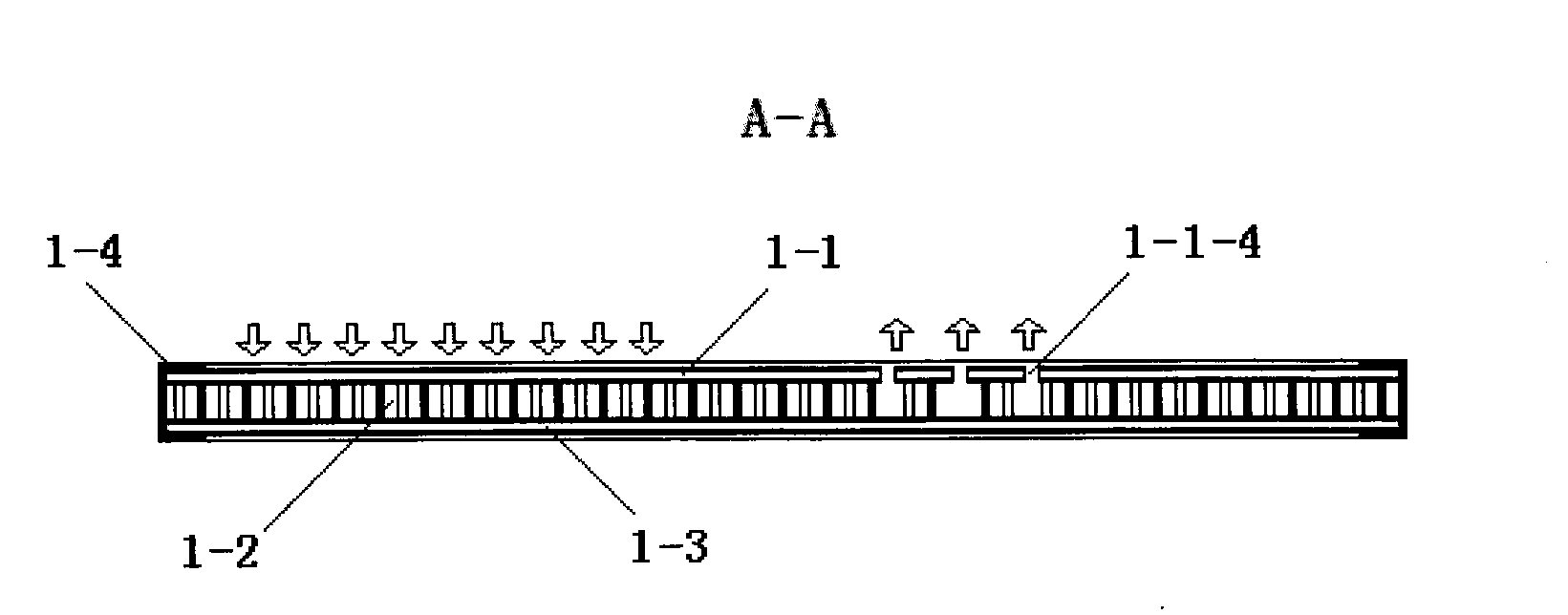

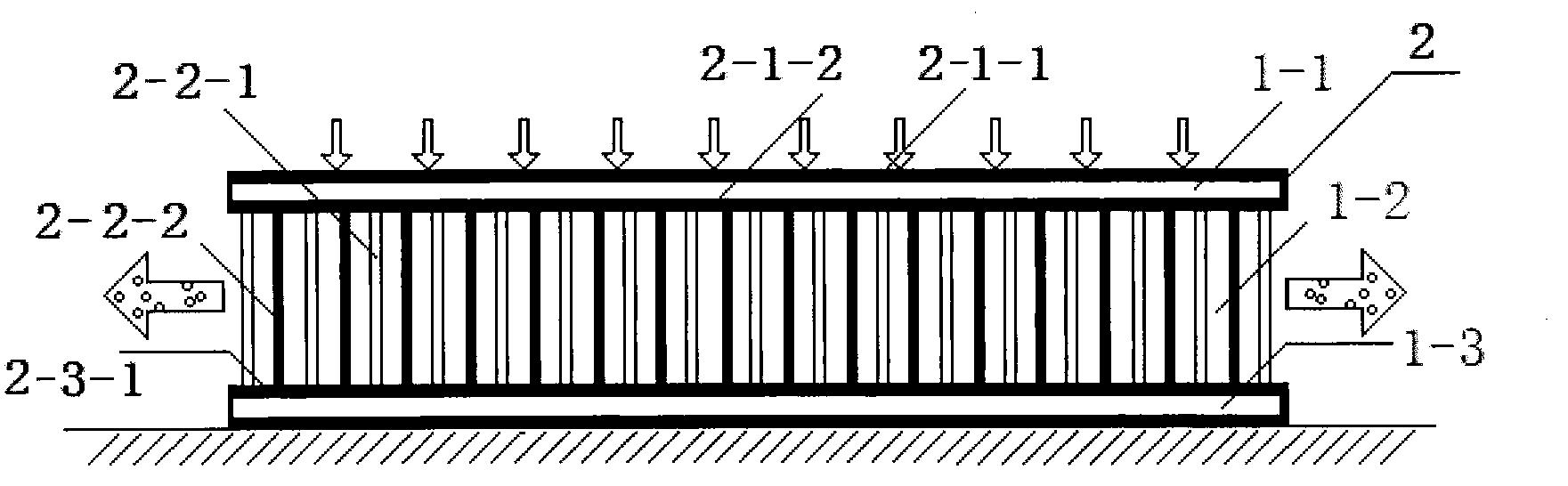

[0035] Such as figure 2 Shown is the A-A sectional view of the moisture-conducting and exhausting elastic insole. The moisture-conducting and exhausting elastic insole is made of moisture-conducting and quick-drying elastic liner fabric 2, such as image 3 As shown, the moisture-conducting and quick-drying elastic liner fabric 2 includes a moisture-absorbing layer 1-1, an elastic moisture-conducting layer 1-2 and a moisture storage and releasing layer 1-3, and the elastic moisture-conducting layer 1-2 is located on the moisture-absorbing layer 1-1 and the moisture storage and release layer 1-3; the moisture-absorbing layer 1-1 is composed of warp-knitted double-comb part air-through structure woven with composite filaments, and the air-through part of the comb bar is set on The arch of the insole is 1-1-2, such as figure 1 Shown, form exhaust hole 1-1-4. The elastic moisture-conducting layer 1-2 is composed of an elastic chemical fiber monofilament 2-2-1 and a moisture-cond...

Embodiment 2

[0056] Such as figure 2 Shown is the A-A sectional view of the moisture-conducting and exhausting elastic insole. The moisture-conducting and exhausting elastic insole is made of moisture-conducting and quick-drying elastic liner fabric 2, such as image 3 As shown, the moisture-conducting and quick-drying elastic liner fabric 2 includes a moisture-absorbing layer 1-1, an elastic moisture-conducting layer 1-2 and a moisture storage and releasing layer 1-3, and the elastic moisture-conducting layer 1-2 is located on the moisture-absorbing layer 1-1 and the moisture storage and release layer 1-3; the moisture-absorbing layer 1-1 is composed of warp-knitted double-comb part air-through structure woven with composite filaments, and the air-through part of the comb bar is set on The arch of the insole is 1-1-2, such as figure 1 Shown, form exhaust hole 1-1-4. The elastic moisture-conducting layer 1-2 is composed of an elastic chemical fiber monofilament 2-2-1 and a moisture-cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com