Silane modified acrylic resin, synthesis method and primer for silicone rubber

An acrylic resin, silane modification technology, applied in the direction of coating, can solve the problems of long curing time, poor bonding performance, high curing temperature, reduce the stability of bonding and curing, improve processing production efficiency and bonding effect strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

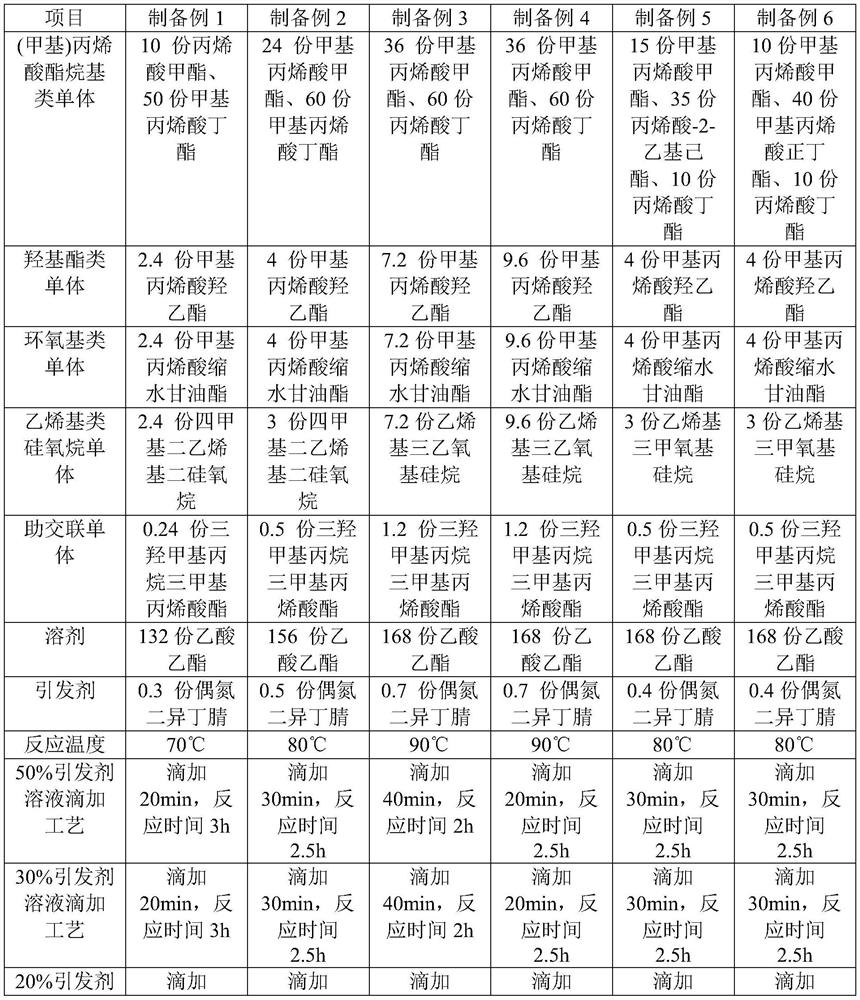

preparation example 1-6

[0064] A kind of synthetic method of silane modified acrylic resin, the steps are as follows:

[0065] S1. Weigh (meth)acrylic acid alkyl ester monomers, hydroxy ester monomers, epoxy monomers, vinyl siloxane monomers, and crosslinking monomers in parts by weight shown in Table 1. body, solvent; and sequentially added to a four-necked flask equipped with a stirrer, a thermometer and a reflux device, stirred evenly, and heated to the temperature shown in Table 1; where the solvent was first added in an amount of 80%.

[0066] S2. take the initiator shown in table 1 by weight and mix with the remaining 20% solvent in S1 to obtain an initiator solution;

[0067] S3. adopt multiple dropping method to add initiator solution, first drip 50% initiator solution, and drop time is as shown in table 1 in drop time and reaction time;

[0068] S4. continue to drip the 30% initiator solution, and the dropping time is as shown in table 1 at the dropping time and the reaction time;

[006...

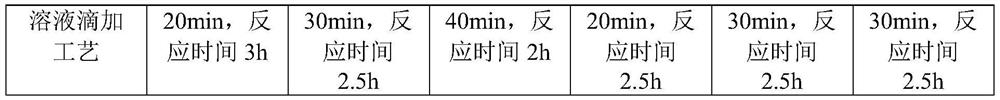

preparation example 7-12

[0075] The preparation method, reaction temperature and initiator solution dripping process of Preparation Examples 7-12 are the same as those of Preparation Example 2, the difference lies in the raw materials and contents of each component, as shown in Table 2.

[0076] Table 2 Preparation Example 7-12 each component composition and its dosage

[0077]

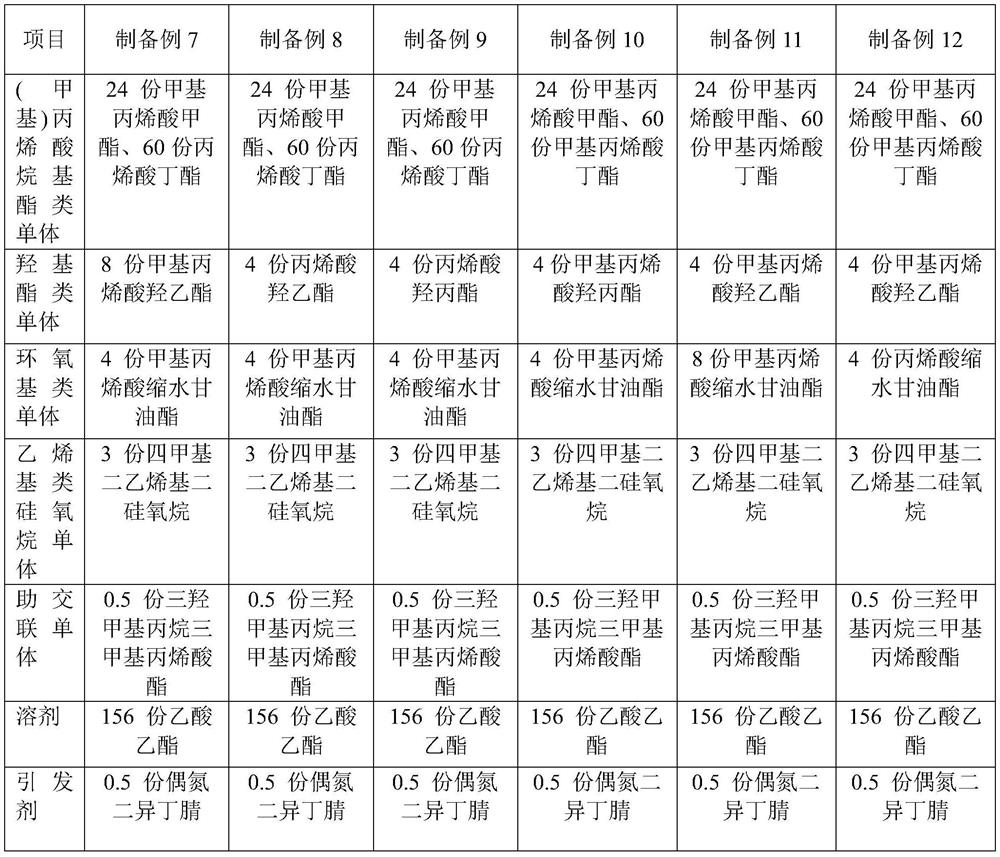

preparation example 13-18

[0079] The preparation method, reaction temperature and initiator solution dripping process of Preparation Examples 13-18 are the same as those of Preparation Example 2, the difference lies in the raw materials and contents of each component, as shown in Table 3.

[0080] Table 3 preparation example 13-18 each component composition and dosage thereof

[0081]

[0082]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com