Analysis method of antimony trisulfide in mixed agent for firecracker

A technology of antimony trisulfide and mixed reagents is used in material analysis by observing the influence on chemical indicators, analysis by chemical reaction of materials, preparation of samples for testing, etc., to achieve high measurement accuracy and application. Extensive, simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]Disassemble the firecrackers in a dry environment, separate the mixed agent, and store it in a ground glass bottle. Use a small number of times to grind repeatedly with an agate mortar, and sieve with a 120-mesh sieve. A small amount of ingredients that cannot be ground are directly mixed into the sample, mixed evenly, put into an oven and baked at 50°C±2°C for 3 hours, then transferred to a desiccator to cool down at room temperature for testing.

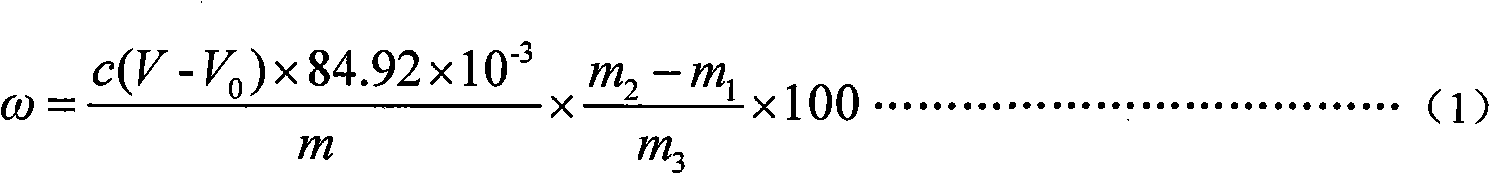

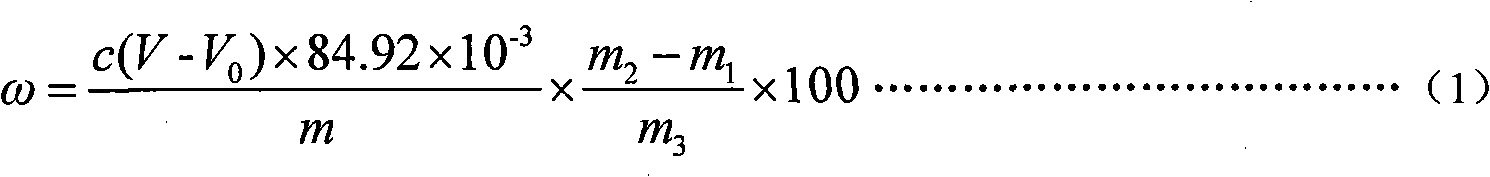

[0032] Weigh 0.6g of the sample to be tested (accurate to 0.0001g), put it in a 50mL beaker, add 3mL of hot water to dissolve it, filter it on a piece of medium-speed filter paper with constant weight by decanting method, and wash it repeatedly 20 times in this way. After volatilizing a large amount of water, place it in an oven to dry at 50°C±2°C for 1h. Wash the sulfur in the sample with 5mL of slightly hot carbon disulfide, shake the funnel gently to dissolve the sulfur in the residue completely and filter it down, wash i...

Embodiment 2

[0037] Disassemble the firecrackers in a dry environment, separate the mixed agent, and store it in a ground glass bottle. Use a small number of times to grind repeatedly with an agate mortar, and sieve with a 120-mesh sieve. A small amount of ingredients that cannot be ground are directly mixed into the sample, mixed evenly, put into an oven and baked at 50°C±2°C for 3 hours, then transferred to a desiccator to cool down at room temperature for testing.

[0038] Weigh 0.4g of the sample to be tested (accurate to 0.0001g), put it in a 50mL beaker, add 3mL of hot water to dissolve it, filter it on a piece of medium-speed filter paper with constant weight by decanting method, and wash it repeatedly 18 times in this way. After volatilizing a large amount of water, place it in an oven to dry at 50°C±2°C for 1h. Wash the sulfur in the sample with 4mL of slightly hot carbon disulfide, shake the funnel gently to dissolve the sulfur in the residue completely and filter it down, wash ...

Embodiment 3

[0043] Disassemble the firecrackers in a dry environment, separate the mixed agent, and store it in a ground glass bottle. Use a small number of times to grind repeatedly with an agate mortar, and sieve with a 120-mesh sieve. A small amount of ingredients that cannot be ground are directly mixed into the sample, mixed evenly, put into an oven and baked at 50°C±2°C for 3 hours, then transferred to a desiccator to cool down at room temperature for testing.

[0044] Weigh 0.3g of the sample to be tested (accurate to 0.0001g), put it in a 50mL beaker, add 3mL of hot water to dissolve it, filter it on a piece of medium-speed filter paper with constant weight by decanting method, and wash it repeatedly 15 times in this way. After volatilizing a large amount of water, place it in an oven to dry at 50°C±2°C for 1h. Wash the sulfur in the sample with 3mL of slightly hot carbon disulfide, shake the funnel gently to dissolve the sulfur in the residue completely and filter it down, wash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com