Photosensitive synthetic stone raw material composition and production method of photosensitive synthetic stone

A technology of raw material composition and production method, which is applied in the field of photosensitive synthetic stone raw material composition, can solve the problems of black surface, poor corrosion resistance, and easy oxidation of metal powder, etc., and achieve stable product performance, good economic benefits, and use The effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the implementation manners of the present invention will be further described in detail below.

[0029] A raw material composition of photosensitive synthetic stone, the raw material composition includes epoxy resin, tin dioxide, antimony trisulfide and nano filler, the composition of epoxy resin, tin dioxide, antimony trisulfide and nano filler The weight ratio is 10:1.25:1.25:1, and the nano-filler is a nano-filler made by mixing nano-silica and nano-calcium carbonate in a weight ratio of 1:1.

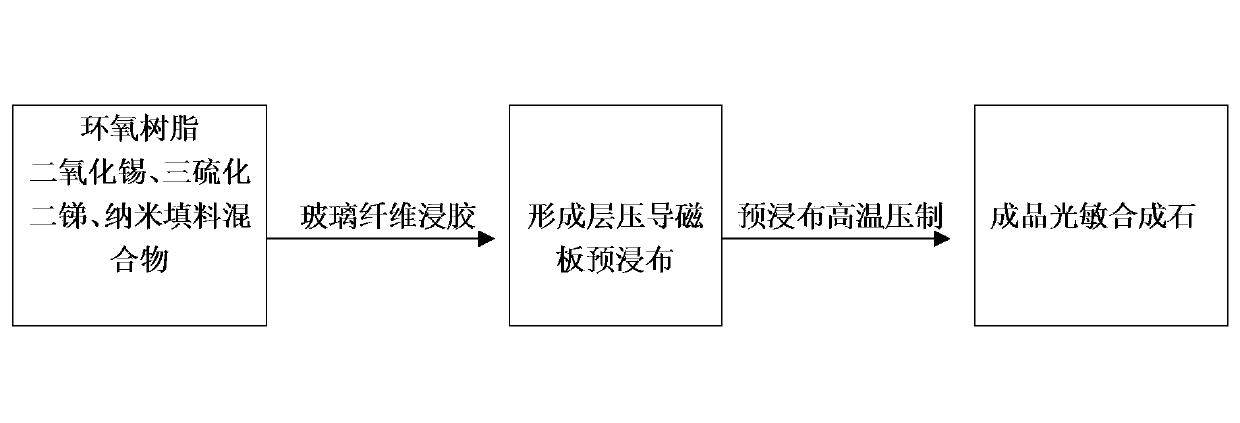

[0030] A production method for producing photosensitive synthetic stone by using the above raw material composition, the specific method comprises the following steps:

[0031] (1) Nano-silica and nano-calcium carbonate are mixed in a weight ratio of 1:1 to make nano-fillers;

[0032] (2) Pour epoxy resin, tin dioxide, antimony trisulfide and the nanofiller in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com