Method for manufacturing micro channel by combining laser polarization selective ablation with acid etching

A selective, micro-channel technology, applied in the field of femtosecond laser applications, can solve the problems of low processing efficiency and other products, and achieve the effects of controllable processing degree, considerable processing shape and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

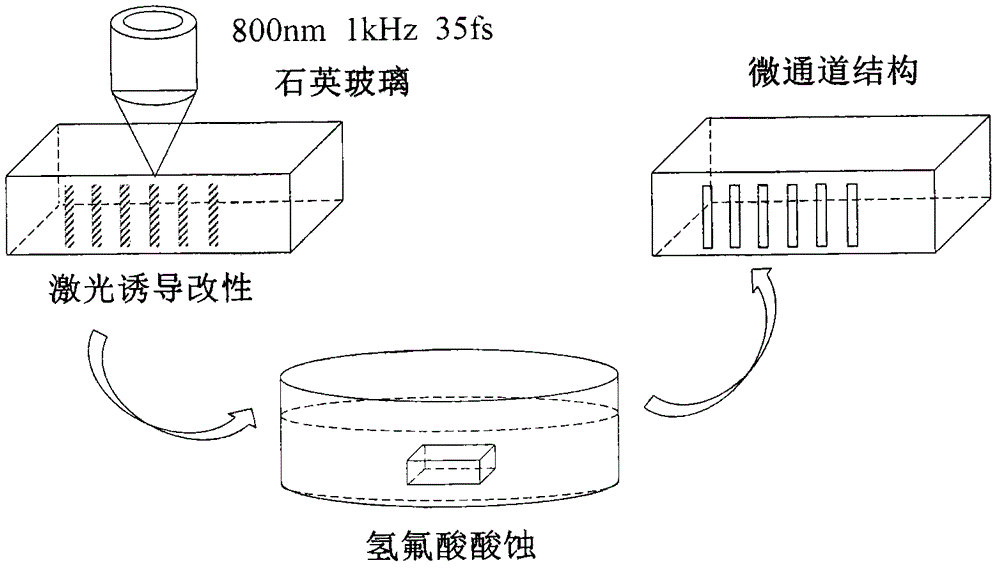

[0027] The method for preparing microchannels by using laser polarization selective ablation combined with acid etching, the specific steps are as follows:

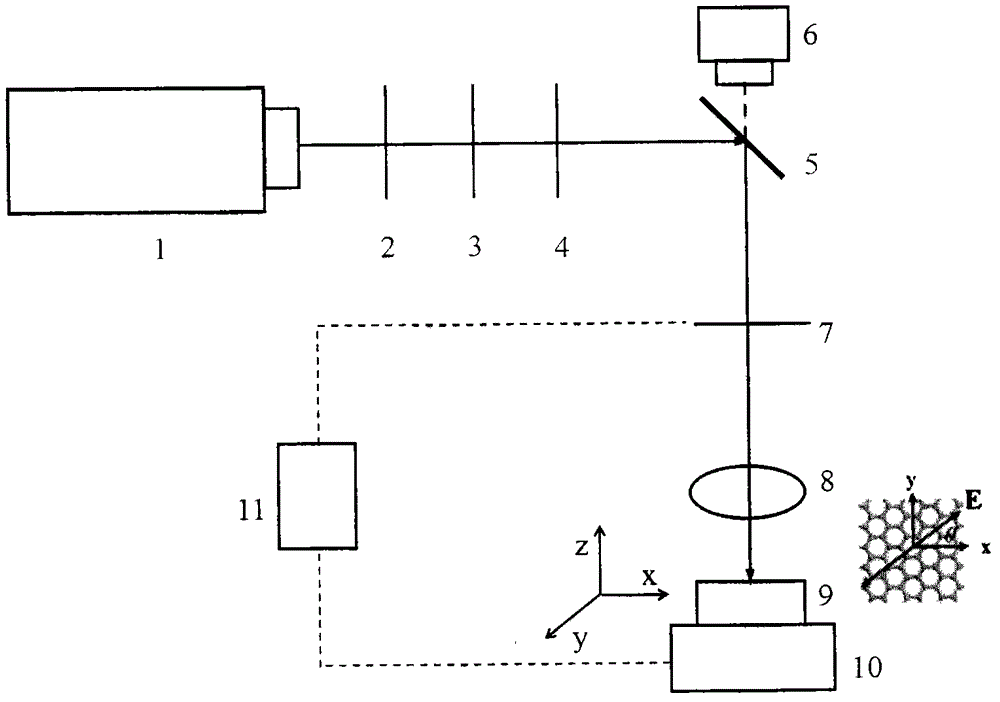

[0028] Step 1. Laser modification of quartz glass by adjusting the polarization angle at intervals of 5 degrees

[0029] Step 2: Etch with a hydrofluoric acid solution with a concentration of 8%, process a microchannel structure, and then obtain the corresponding polarization angle when the processing efficiency is the highest

[0030] Step 3: Modify the material with a laser at the polarization angle corresponding to the highest processing efficiency obtained in step 2

[0031] Step 4, acid etching with a hydrofluoric acid solution with a concentration of 8%, so as to obtain a material with microchannels

[0032] The processing flow of the embodiment of the present invention is as figure 1 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com